Advertisement

Quick Links

Advertisement

Subscribe to Our Youtube Channel

Summary of Contents for Hyundai 10ES

- Page 1 10ES, 12ES Electric Stacker Operator’s Manual Service Manual...

- Page 2 We hope our electric stackers will bring great convenience to your work! Please read the manual carefully before operation This manual is a common manual. We reserve the right to modify technology of the electric stacker. If there is anything in the manual that is not consistent with the actual stacker, the actual stacker should be considered correct and the manual is only for reference.

- Page 3 1400kg 1200kg 1000kg 800kg 600kg 2500 mm 400kg 3000 mm 200kg 3300 mm 4000 mm 1000...

- Page 4 Table of Contents 1.Configuration diagram and main technical parameter…………………….2 2.Brief introduction of structure……………………………..………….…………..4 3.Safety specifications…………………………..…….……………….……………….4 4.Initial operation ………………………………………………………………………..10 5.Use and operation instruction……………………………………………………..12 6.Use, maintenanc and charging of storage battery………………………..13 7.Inspection before operation….……………………………….………..…………..16 8.Inspection after operation…………………………………….…….……………….17 9.Periodic maintenance and upkeep…………………………..……..…………….17 10. Storage, transportation, and loading & unloading of truck……………...22 11.Replacement of storage battery…………………………..………….....23 12.Common faults and troublshooting………........23 13.Common faults signal and trouble shooting………………………....26...

- Page 5 Brief introduction : Electric pallet stacker adopts storage batteries as the dynamic source and a AC motor as the driving force, traveling through gear transmission. The lifting of the fork relies on the DC motor and the hydraulic transmission system. The up-and-down movement of the oil cylinders lifts the fork and the goods. As the traveling and lifting of the stacker are electrically driven, it possesses the characteristics of energy saving, high efficiency, stable operation, easy operation, safety and reliability, low noise and no pollution, etc.This stacker adopts 24V storage battery, which greaty prolongs use time after one charging.

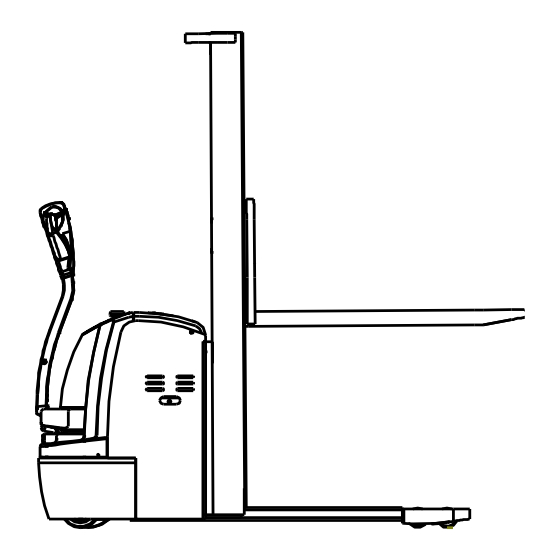

- Page 6 1. Configuration diagram Configuration diagram...

- Page 7 1.2 Main technical parameters(Electric Pallet Stacker) Manufacturer(abbreviated) HYUNDAI Model 10ES 12ES Driving model:Electric(Storage battery), Electric(storage battery) Driving model( Manual, Walking, Stand driving, diesel, gasoline, fuel gas walking Seat driving ,Order picking) Rated load Q(kg) 1000 1200 Load center distance (mm)

- Page 8 2.Brief introduction of structure (See also the structure diagram and the principle diagram of the major parts) The stacker mainly consists of frame, mast, fork, lifting oil cylinder, operation handle, steering device, driving wheel, storage battery pack, hydraulic power unit and control system for electrical equipment, etc 3.

- Page 9 Notice Please put on safety shoes and protective clothes. Do not wear clothes that are too loose for sake of being caught, which would result in danger. ⑶ Rules that must be observed: Notice Never drive the truck when you are tired or un-concentrated, with an injection of drug, or after a liquor drinking.

- Page 10 Only in the event that the truck manufacturer is no longer in business and there is no successor in the interest to the business, the user may arrange for a modification or alteration to a powered industrial truck, provided, however, that the user shall: a) Arrange for the modification or alteration to be designed, tested and implemented by an engineer(s) expert in industrial trucks and their safety;...

- Page 11 Notice If the driver’s view is shielded by the bulky goods carried, please drive backwards or drive under the guidance of other working personnel. Notice Ensure no people around the truck when driving backwards. Notice Driving through the narrow access shall be guided by working personnel. Notice At crossroad or other places impeditive for view, the driver shall not drive until there is no person at both sides.

- Page 12 Abrupt turning during traveling may cause the tilting of truck and result in serious accident. Do decelerate and take care to turn. Notice Observe all items of safety rules on working place. Decelerate and sound horn when travel by other truck or vehicles. Avoid driving in places with bad view. Notice Ensure to provide certain clearance between truck and entrance.

- Page 13 10)The operator shall master the traveling speed according to site condition.The truck shall slow down and move at a low speed when turning, at a narrow aisle, passing by swing doors or places where view impeded. And the truck shall keep enough distance with the forklift moving forward. Abrupt stop, sharp turn and overtaking are forbidden at dangerous places or where view is impeded except accidents.

- Page 14 4.Initial operation 4.1 Initial operation: 4.1.1 In case of dangerous conditions, the power can be cut off, and the battery plug must be connected to the emergency parking plug of the stacker itself. Warning It is strictly forbiddent to operate the stacker without emergency parking plug.

- Page 15 5.1.2 Check if there is any electric power in the batteries with the method indicated in Fig.I. Pull the general power switch out to turn on the general power supply, unlock the electric lock on the handle, check the electric energy meter on the instrument panel of the truck. If the zero end grid is bright, it indicates there is no electric power in the batteries and charging should be conducted at once.

- Page 16 division B as indicated in Fig. II, slowly start the truck and press the handle to the horizontal position to check that whether the truck can travel and brake normally. Move the control handle to division B as indicated in Fig.II, press the emergency reverse button on top of the control handle to ckeck that whether the truck can travel backward normally.

- Page 17 button and the fork rises to a proper height with the shelf (The bottom of the pallet is about 100mm higher than the goods shelf). Move the goods slowly to the accurate position of the shelf and press the lowering button to put the goods carefully on the shelf.

- Page 18 charging, first open the cover of battery case to take the charging plug out of the battery case, then insert the charging plug into the two phase AC power. And the charging will start after several seconds. Warning There is hydrogen gas accumulated in the battery case during charging.

- Page 19 6.1.8 After the initial charging is completed, the surface of the batteries should be cleaned. Close the cover of the open cover type liquid hole plug and then the batteries can be used. 6.2 Use and maintenance 6.2.1 In order to guarantee the service life of the batteries, the batteries in use should be fully charged. Insufficiently charged batteries must not be used.

- Page 20 6.4. Operation of electrolyte ⑴ Density check The suction type densimeter shall be used to check density. During operation, avoid spilling out the electrolyte, and do wear protection appliance. ⑵ Operation besides check Consult professional personnel, especially when complementing electrolyte (dilute sulfuric acid). ⑶...

- Page 21 Steering Operation handle Degree of tightness and rotary flexibility. system Oil pipe Leakage or not. Hydraulic oil Appropriate oil quantity. Lifting oil cylinder Whether there is any oil leakage. Pins, screws and all Check all the fasteners of the truck’s wheels, i.e. the fasteners pins or screws, loose or not.

- Page 22 Please contact the sales department of our company if you need to adjust or replace the components. 9.1 Precautions during maintenance: Notice The components for replacement shall be produced completely by our company. When replacing components of the truck, the components with the same safety requirement with the original design shall be used.

- Page 23 Inspection of hydraulic oil level: lower the fork to the lowest position, and oil charge is 12L. Recommendatory trademark for the hydraulic oil should be chosen. Check the capacity of storage battery: refer to the use and maintenance of storage battery. 9.4 The inspection according to the need Clean the truck Inspect and screw down each fastener...

- Page 24 Oil pipe Whether oil pipes leak or not. Hydraulic oil Proper quantity of oil. Lifting oil cylinder Whether there is any oil leakage or not. Electrolyte Liquid level,specific gravity and cleanness Plug Function, whether it is damaged or not Key switch Function Contactor Contact performance and function...

- Page 25 9.7 Maintenance for 600 hours(every three months) During the maintenance every three months, the monthly maintenance process shall be repeated. When the parts must be adjusted and replaced, please contact with maintenance personnel of our company. Burnish the coarse surface of contacts using sand paper. Contactor Replace according to the status when the function is not well.

- Page 26 All the working conditions mentioned above can use the hydraulic oil LHPISOVG46 in accordance with standard DIN51524T.2 for replacement. The viscidity of this lubricant is very high (mostly used hydraulic oil). If it is difficult to buy hydraulic oil, SAE20W/20 engine oil can be used to substitute HLP68 hydraulic oil. ⑵...

- Page 27 Check the status of storage battery and electrolyte, and imbrue the non-acid lubricating grease to the binding post of storage battery. All the electrical contacts should be sprayed using appropriate contacts spray. 10.2 Transportation of truck: If the truck needs to be transported for a long distance, support the side near to driver of truck with square timber to lift the driving wheels of truck from the ground.

- Page 28 connection storage ⑤The Tighten batteries is loose or has fallen off. ① The side-magnetic brake of the drive wheel does not suck and the Repair or replace stacker is in a braked condition. ②The walking motor carbon brush is worn or bad contact between the Repair or replace steering device...

- Page 29 quantity of filtered hydraulic oil ⑤ Insufficient voltage of the storage Charge the battery battery ⑥ The control handle is not horizontal or vertical, the oil pump motor has not Improper operation been turned on. ⑦ Damaged oil pump motor Repair or replace ⑧...

- Page 30 12. 1 Adjustment methods of safety valve pressure The pressure of safety valves has already been adjusted when the truck is ex-factory. Users shall not adjust the pressure at will. Otherwise it will bring danger to the truck’s hydraulic system and safety.

- Page 31 4 P,I setting improper 5 Failsafe delay too short Motor Overcurrent Motor overcurrent 1 Incorrect motor wiring 2 Controller defective. Motor Output Fault Controller output abnormal 1 Incorrect motor wiring 2 Controller defective. 1 Improper sequence of 1,4 Static Return To Off SRO sequencing error KSI,INTERLOCK,F/R 2 Wrong SRO type selected.

- Page 32 4,1 Service Total Disable Total KSI timer has expired. Expired total KSI timer. Total driving timer has Service Driver Disable Total driving timer has expired. expired. Setted (KSI) service timer Service Total Expired Setted (KSI) service timer has expired. has expired. Setted (driver) service Service Driver Expired Setted (driver) service timer has expired.

- Page 33 3.Governor is damaged. 4. Select error of governor type. 2,2 1. Open circuit of sharps line. BB WIRING CHECK Connection fault of urgency reverse. 2. Open circuit of sharps inspection line . 2,3 HPD Time sequence fault. 1. Time sequence of KSIimput, brake imput and governor imput default.

- Page 34 16.Packing list Packing List of Electric Pallet Stacker Consignee: Ex-work No.: Contract No.: Ex-work Date: Net weight Dimension Name Quantity Remarks (kg) (L× W× H) Electric pallet stacker A complete set. Technical documents, Accessory box accessories and spare parts. Note: 1. The following documents are in the file bag: ①...

- Page 35 Hydraulic Principle Diagram...

- Page 38 CURTIS 1232E CONTROLLER 10ES : #20128125~, 12ES : #20128136~...

- Page 39 Appendix 1 ISO3691 Powered industrial trucks—Safety code The Second Part Safety Code of motor industrial trucks in service, operation and maintenance Safety rules for the user and driver In order to use the motor industrial truck well, this part set up some rules. The 14.1 is applied to the user, the 14.2 is for the driver.

- Page 40 14.1.4.2 Stability The user should pay attention to section 6 of the code, which is about the stability of the truck in the working conditions. When operating correctly, the high lift truck accord with the section 6 is steady, but the incorrect operating or the wrong maintenance could let the truck working unsteadily.

- Page 41 All the work of changing the battery should carried out according to the description of user’s manual from the factory. When reinstall the battery, should adopt measures to make the battery connecting, orientation and fixation correctly. Do not put tools and other metal substance on the lidless battery. Without the special approval (for example the truck factory), the electrical motor truck should not change the battery with different voltage, weight or size.

- Page 42 On the gangplank or transition board should equipped handing or other available equipment to the effect of safety transport. On the conditions of possible, should set the fork hole or suspending ear for moving goods. The gangplank or transition board should have non-slip finishing. On the both sides of the gangplank or transition board, should mounted the facility to prevent the truck from going over it’s edge.

- Page 43 Only the personnel who have been trained and get the qualification of operation are permitted to drive the industrial truck. The motor industrial truck could not carry passengers, except for equipped with the facility for the passengers sitting. The driver should pay special attention to the operating circumstance, including the person nearby other staves and fixed or moving substances, and it is necessary to watch out for the passerby at any moment.

- Page 44 When stacking, the mast should tilt backward to ensure the stability of the load, approach the goods pile slowly. When the truck approach and face to the goods pile, it is necessary to adjust the mast to the vertical location, and lift the load a little higher than the height of the pile. Then running backward the truck Or if using reach truck, extense the fork and descend it to unload the goods.

- Page 45 In crossroads and the occasion that would obstruct the driver’s sight, the driver must reduce the speed of the truck, and issue sound signal. When the truck is operating with load, the driver must control turning equipment and brake system slowly and stably.

- Page 46 Before a semi- trailer that is not linked with a tractor runs on the road truck or railroad truck ,it must be ensured that the supporting part of the stilt of the semi- trailer is located at the supporting position. Before a motor-driven industry truck runs on the road vehicle or railroad vehicle, it must be ensured that the floor board can endure all the weight of the industry vehicle, load and the driver.

- Page 47 The truck which fuel oil system is leaking could not be uses without repair. 14.2.4.2 Refuel Before refuel, it is necessary to close the engine, brake the truck and the driver should leave the truck. The open flame and smoking is forbidden during refueling. 14.2.4.2.1 Liquid fuel (for example gasoline and diesel fuel) The truck using liquid fuel should add fuel in the appointed places.

- Page 48 In the battery charging area, should adopt measures to prevent open flame, spark or electric arc. Smoking is forbidden. The tools and other metal substance should put far away from the top of the battery without cover. The top of the battery should keep dry; the connection terminal should keep clean, wipe a little vaseline and screw down correctly.

- Page 49 working site in case of any leakage in fuel oil system. And the truck cannot be put into operation until all the leakages have been repaired. Inspection must be taken before reuse of all the dismountable liquefied petroleum gas containers or filling fuel into all the liquefied petroleum gas containers, to see whether there is the following defective or damage: A)...

- Page 50 Recording card of maintenance and upkeep process: Maintenance Maintenance Maintenance Items Material used Remarks time Part personnel Customer advisement feedback Occurrence Location of Items Faults causes Trouble-shooting Remarks time faults...

Need help?

Do you have a question about the 10ES and is the answer not in the manual?

Questions and answers