Table of Contents

Advertisement

Quick Links

L4474

Rev. D

Table of content

1.0 INTRODUCTION ..............................................................1

2.0 SAFETY ............................................................................1

3.0 SPECIFICATIONS ...........................................................3

4.0 INSTALLATION ................................................................5

5.0 SCREENS DESCRIPTION...............................................6

6.0 OPERATION ...................................................................14

7.0 MAINTENANCE .............................................................16

8.0 ALARM GUIDE ...............................................................17

9.0 ATTACHED DOCUMENTS .............................................18

1.0 INTRODUCTION

1.1 Overview

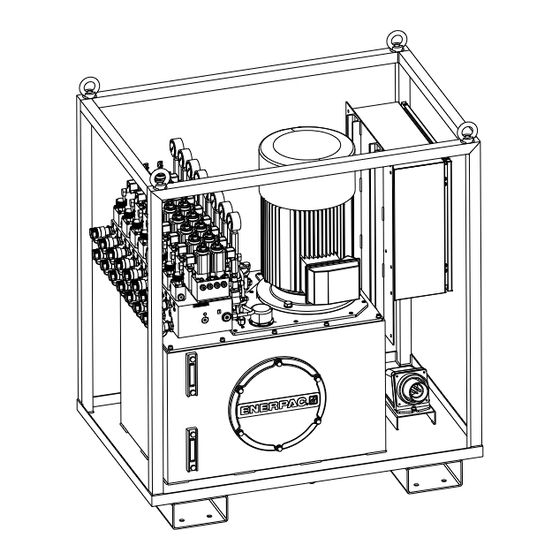

The Single Synchro Control (SFPSSC) & Sensor Synchro KIts

(SFPKSS4 & -8) together with SFP pumps are Enerpac's new

solution for multi-point lifting and lowering applications where

uneven loads need to be positioned equal and synchronously.

They are a far better alternative to using separately operated

pumps or manifolds with needle valves. Split Flow Pumps

are a safe and economical solution which can achieve lifting

accuracy of 4% across lifting points.

The Split Flow Pump with solenoid valves with the SFPSSC

connected enables control movement of the load remotely and

automatically. The load can be lifted/lowered simultaneously

using single or double-acting cylinders. Depending on the

application, the lifting points can be operated individually or

simultaneously in a synchronously mode.

1.2 Application

With the SFPSSC & SFPSS 4 or - 8 kits, the user can convert

a simple SFP pump into a synchronous lifting system. With

this system the user can make synchronous movement up to 8

cylinders. Built in warning and stop alarms for optimum safety,

it has a great accuracy of the cylinder position due to each

cylinder has a pressure line dedicated.

The application possibilities are infinite with the SFPSSC &

SFPSS 4 or - 8 kits, and the SFP pump, such as powering

interlinked hydraulic cylinders (single or double-acting), push

cylinders, stage lift, hollow plunger or lock nut cylinders. The

SFPSSC has 6 work modes. The operator can navigate to any

of these menus: Manual, Pre-Load, Automatic, Depressurize,

Tilting and Stage Lift.

1.3 Delivery Instructions

Upon delivery all components must be inspected for damage

incurred during shipping. If damage is found the carrier should

be notified at once. Shipping damage is not covered by the

Enerpac warranty. The carrier is responsible for all repair and

replacement costs resulting from damage in shipment.

1.4 Warranty

• Enerpac guarantees the product only for the purpose for

which is intended.

EN

10/21

Instruction Sheet

SINGLE SYNCHRO CONTROL KIT &

SENSOR JUNCTION BOXES

SFPSSC - SFPKSS4 - SFPKSS8

• Refer to the Enerpac Global Warranty document for terms and

conditions of the product warranty.

Any misuse or alteration invalidates the warranty.

• Observe all instructions as communicated in this manual.

• When replacement parts are needed, use only genuine

Enerpac replacement parts.

Modification to any part of the equipment outlined in this manual

should not be attempted, nor any component part be replaced

without first consulting Enerpac. Modifications may render the

equipment dangerous. Component parts are each rated to suit

the demands of the overall equipment design and replacement

with similar items without provenance may lead to unexpected

and dangerous accidental features.

If any equipment abuse is evident, the warranty will be

invalidated and Enerpac will not be made responsible for an

injury due to misuse or failure to comply with the above safety

notes.

1.5 EU Declaration of Conformity

Enerpac declares that this product has been tested

and conforms to applicable standards and is

compatible to all CE requirements.

A copy of an EU Declaration of Conformity is enclosed with

each shipment of this product.

2.0 SAFETY

Read all introductions carefully. Follow all recommended safety

precautions to avoid personal injury as well as damage to the

product and / or damage to other property. Enerpac cannot

be responsible for any damage or injury from unsafe use,

lack of maintenance, or incorrect operation. Do not remove

warning labels, tags, or decals. In the event of any questions or

concerns arising, contact Enerpac or a local Enerpac distributor

for clarification.

If you have never been trained on high-pressure hydraulic

safety, consult your distributor or authorised service center for

information about Enerpac Hydraulic Safety Courses.

This manual follows a system of safety alert symbols, signals,

words, and safety messages to warn the user of specific

1

SIMATIC HMI

SIEMENS

SYSTEM

RESET

OK

ALARMS

START

CYCLE

PAUSE

START

CYCLE

MOTOR

STOP

STOP

CYCLE

MOTOR

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for Enerpac SFPSSC

-

Page 1: Table Of Contents

1.2 Application notes. With the SFPSSC & SFPSS 4 or - 8 kits, the user can convert a simple SFP pump into a synchronous lifting system. With 1.5 EU Declaration of Conformity... -

Page 2: Safety

• Enerpac does not recommend the use of the SFP Series Protect hoses from crush risks, such as heavy objects or pump with multiple telescopic cylinders (such as the Enerpac vehicles;... -

Page 3: Specifications

Enerpac recommends the kit SFPKPT (pressure transducer removable kit) is acquired with SFPSSC. It is needed to connect 3. Pause Cycle button: In automatic movements, use this pressure transducers to the SFP to have an optimal performance button to temporarily stop the movement. - Page 4 5. Start/Stop motor push-button. use with Enerpac EVO-WSS series stroke sensors 6. Decompress push-button. 4. CSFP cable plug to connect communication to the standard SFP pump control panel 5. CSSC connector, to connect the SFPKSS with SFPSSC master throuhg the cable SFPCOMM-25.

-

Page 5: Installation

This cable is used to make the communication connection 3. Pull the socket between the SFPSSC master and SFPKSS4 or SFPKSS8 kits. 4. Insert the card into the holder. The entry of the card slot is chamfered on its bottom right. The edge of the cards is chamfered accordingly 5. - Page 6 Connect the SFPCOMM-25 cable to the SFPKSS4 or SFPKSS8 communication plug. Use the connector number 5 according to the Figure 3. Automatically the SFPSSC monitor will be switched on and the initial screen will be shown. Note that SFPKSS4 and SFPKSS8 can also be used to as part of a multiple SFP network utilizing CLNC12 network controller.

-

Page 7: Screens Description

The system is submitted with the standard user profile which Tapping in each button the user can access to the screens of is recorded with the user name: enerpac and password: 100. movements section. The background color of this section is gray. -

Page 8: Parameters Screen

5.3 Parameters Screen WORK DATA PARAMETERS RECORDING SYSTEM STOP 0:00:00 AM NUMBER OF CYLINDERS SYNCHRO PARAMETERS SPANS LANGUAGE HPU 1 AUTO SCAN 0.00 2 Cylinders. WORK TOLERANCE (mm) 0.00 STOP TOLERANCE (mm) A = 0 MAXIMUM CYLINDER LOAD UNIT SELECTION (Ton) (Ton) Ton. - Page 9 Figure 17 to see the advises that come up when using the 2. Cylinder calibration selection: The user must set if the scanning tool). calibration is going to be carried out or not, depending on the type of cylinder used. Refer to Figure 20 for details. 8.

-

Page 10: Offset Screen

2. Cylinder stroke: The user must type the maximum stroke of 3. Offset button: Push and hold this button during 3 seconds the cylinder. to convert the value A into 0 and Z will keep the current value of A. 3. -

Page 11: Manual Screen

1. Calibration: If the calibration is allowed, based on the place and retract to get the plunger into the cylinder. The user of the stroke sensor (refer to paragraph 5.4 for further must set what direction of the movement is going to be details), this button allows calibrating (equalize the cylinder executed. - Page 12 Figure 28, Tilting Screen Details Enerpac recommends setting the final load value less than 10% of the expected load at each cylinder. This movement allows making movements with load inclination purposes.

-

Page 13: Data Recording

In this screen the user can check the details of the current tilting 4. Retract Delta value: The user must type the final position of movement. the cylinder in this step. The cylinder will retract the plunger to place the outer blocks to have a support to make a lifting In this screen there are the following elements: or lowering to a new level. -

Page 14: Language Screen

3. Check the green light in the SFPKSS4 or SFPKSS8 is correct. If so, the connection with the SFP is correct. 4. Check for alarms in the SFPSSC control. If any alarm has came up, check and solve the root cause and push the reset alarm button in the keypad. -

Page 15: Manual Mode

WARNING Enerpac recommends carrying out this step prior to lifting Enerpac recomends always to set the layout of the cylinders a structure in the Automatic mode because in this way the in such a way that the calibration is allowed. If cylinders are... - Page 16 for cylinders calibrated case, refer to the notice in the paragraph 5.5). DANGER! This operation is intended to release residual pressure from the system. Visually confirm that cylinders are not supporting the load prior to performing 5. Select the cylinders which are going to be involved in the this operation.

-

Page 17: Maintenance

Logo device, a factory recall IP must be performed. In order to reset the IP follow the following steps (The SFPSSC monitor must be desconnected from the SFPKSS4 or SFPKSS8): 1. Disconnect the SFPCOMM-25 cable from the SFPKSS4 or SFPKSS8. -

Page 18: Alarm Guide

“Work Tolerance” • Reset alarm. parameter. HPU Communication • The SFP does not communicate • Check the connected cables between SFPSSC and Failure correctly with the SFPSSC. the electric cabinet of SFP. • Reset alarm. Maximum Total Load •... -

Page 19: Attached Documents

Safety Stop: Single Control • Safety Stop is activated pressing on • Deactivate Safety Stop button. emergency stop button at SFPSSC • Reset alarm pressing on reset alarms button at key (figure 1, item 5). pad (figure 2, item 5).

Need help?

Do you have a question about the SFPSSC and is the answer not in the manual?

Questions and answers