Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for Tennant Castex PX-1300HP

- Page 1 PX-1300HP Carpet And Upholstery Cleaner Model No.: Operator and Parts Manual 610699 – 13 gal HP Can. Extractor CASTEX 12875 RANSOM STREET HOLLAND MI 49424 U.S.A. 610199 FAX: 1-800-678-4240 Rev. 01 (07-00) CUSTOMER SERVICE: 1-800-964-9644 Home Find... Go To..

-

Page 2: Table Of Contents

© 2000 Tennant Company Printed in U.S.A. distributor or from any of the manufacturer’s Castex is a registered United States trademark of Tennant Company subsidiaries. This machine will provide excellent service. However, the best results will be obtained at minimum costs if: •... -

Page 3: Safety Precautions

OPERATION 4. Before leaving or servicing machine: SAFETY PRECAUTIONS Turn off machine. – Unplug cord from wall outlet. – 5. When servicing machine: This machine is intended for commercial use. It is designed to clean carpet and upholstery in a indoor Unplug cord from wall outlet. -

Page 4: Safety Labels

OPERATION SAFETY LABELS The safety labels appear on the machine in the locations indicated. Replace labels if they become damaged or illegible. FOR SAFETY LABEL- Located on rear panel. FOR SAFETY: Read manual before operating machine. FLAMMABLE MATERIALS/ SPILLS LABEL- Located on rear panel. -

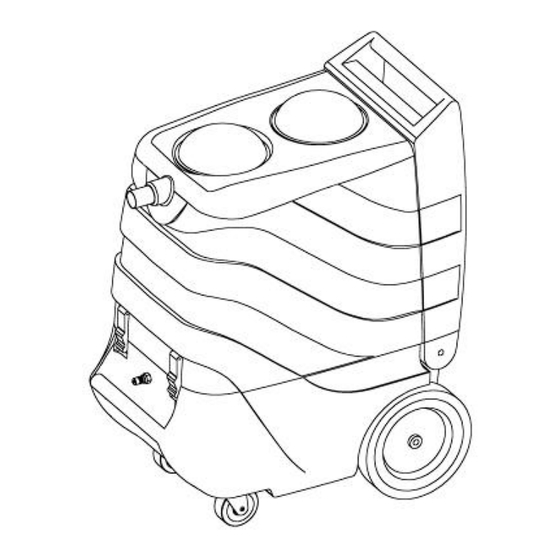

Page 5: Machine Components

OPERATION MACHINE COMPONENTS 1. Recovery Tank 8. Empty-Out Nozzle 2. Solution Tank (under lid) 9. Vacuum Hose Connector 10. Recovery Tank Drain 3. Recovery Tank Lid 4. Solution Tank Lid 11. Latches 5. Vacuum Switches 12. Push/Pull Handle 13. Solution Hose Connector 6. -

Page 6: Machine Operation

OPERATION ATTENTION: If using powdered cleaning 2. Take carpet cleaning wand in hand and squeeze chemicals, mix prior to adding. valve trigger while moving the tool in short forward and backward strokes over the carpet NOTE: If desired, water alone achieves excellent (Figure 5). -

Page 7: Draining Tanks

OPERATION 2. Operate accessory tool as normal (Figure 7). DRAINING SOLUTION TANK NOTE: Before cleaning upholstery, always check 1. Remove empty-out nozzle from its storage cleaning instructions sewn in furniture by bracket (Figure 9) and attach to end of solution manufacturer. -

Page 8: Machine Maintenance

OPERATION MACHINE MAINTENANCE MONTHLY MAINTENANCE (Every 80 Hours of Operation) 1. Lubricate wheels with water resistant oil. To keep machine in good working condition, simply 2. Inspect machine for water leaks and loose follow machine’s daily, weekly and monthly hardware. maintenance procedures. -

Page 9: Trouble Shooting

OPERATION TROUBLE SHOOTING PROBLEM CAUSE SOLUTION Machine does not operate. Faulty switches or wiring. Contact Service Center. Faulty power cord. Contact Service Center. Building circuit breaker tripped. Reset Breaker. Solution pump does not operate. Faulty switch or wiring. Contact Service Center. Faulty solution pump motor. -

Page 10: Specifications

OPERATION SPECIFICATIONS Model PX-1300HP LENGTH 711 mm (28 in) WIDTH 450 mm (17.7 in) HEIGHT 902 mm (35.5 in) WEIGHT 50 Kg (110lbs) SOLUTION TANK CAPACITY 49.2 L (13 gal) RECOVERY TANK CAPACITY 56.7L (15 gal) SOLUTION PUMP 120 V, 13.6 bar (200 psi), 1.6A VACUUM MOTOR 2- @120 V, 9A, 1026 W SEALED WATER LIFT... -

Page 11: Electrical Diagram

ELECTRICAL DIAGRAM 120 V WIRING DIAGRAM PX-1300HP (07-00) Home Find... Go To.. -

Page 12: Parts List

PARTS LIST TANK GROUP PX-1300HP (07-00) Home Find... Go To.. - Page 13 610610 HNDL CASTEX EDGE 3 SWITCH & 1 FUSE • 610534 HOSE VAC 1.5" FLEX 31" 610181 DECAL CASTEX PX-1300HP 610509 NECK VAC FLTR EDGE ROTO 610457 10-32 X 5/16 PHXSS 610464 NUT 10-32 NYLOK SS 610522 PLATE HANDLE SW COVR EDGE...

-

Page 14: Base Group

PARTS LIST BASE GROUP PX-1300HP (07-00) Home Find... Go To.. - Page 15 PARTS LIST BASE GROUP PART # DESCRIPTION QTY. PART # DESCRIPTION QTY. 610551 INSULATION BLOWERS 700 610580 NUT 1/4-20 HEX CP 610598 TIE WRAP 12" BLACK 610581 WASHER LOCK 1/4 610470 NUT 1/4-20 NYLOK ZINK 610583 DAMPENER VIB 1X1MXM 1/420 610471 WASHER 1/4 FLAT CP 610608 HOSE 2"...

-

Page 16: Pump 200 Psi Breakdown

PARTS LIST PUMP 200 PSI BREAKDOWN REF# PART # DESCRIPTION QTY. 610616 PUMP PUMPTEC 200 W/PLUG 120 610763 MOTOR, 200 PSI W/PLUG 120V • 610764 VALVE & O-RING KIT, PMPTC 200 • 610765 PLUNGER & SEAL KIT, PMPTC 200 • 610766 CAM &... -

Page 17: Options

OPTIONS FLOOR TOOL PART # DESCRIPTION QTY. PART # DESCRIPTION QTY. 610641 WAND & HOSE KIT HP-PX 610646 HOSE 1/4"SOL BLU X39.25DB 610709 WAND, FLOORTOOL HP-PX COMP 610629 "U"CLAMP,SUPP HOE HNDL EC 610624 GRIP, FLRTOOL 1 1/2 X 6 610645 WAND,"S"... - Page 18 OPTIONS HAND TOOL REF PART # DESCRIPTION QTY. REF PART # DESCRIPTION QTY. 610297 TOOL, UPHOLSTERY HP-PX 608898 TRIGGER, HAND TOOL 610670 TOOL, HAND HP BRASS JET W/VLV & TRIG 610658 4-40 X 7/8 PHXZINC 608891 TOOL, HAND W/O TRIGGER 610659 NUT, 4-40 HEX ZINC NYLOK 610654 6-32 X 1 PHXZINC 608892 SEAL, SOLUTION HOSE...

Need help?

Do you have a question about the Castex PX-1300HP and is the answer not in the manual?

Questions and answers