Table of Contents

Advertisement

Quick Links

Table of Contents

with Individual Row Control

Read the operator manual entirely. When you see this symbol, the

subsequent instructions and warnings are serious - follow without

exception. Your life and the lives of others depend on it!

Illustrations may show optional equipment not supplied with standard unit or

may depict similar models where a topic is identical.

ORIGINAL INSTRUCTIONS

© Copyright 2019

Table of Contents

Index

Operator Manual

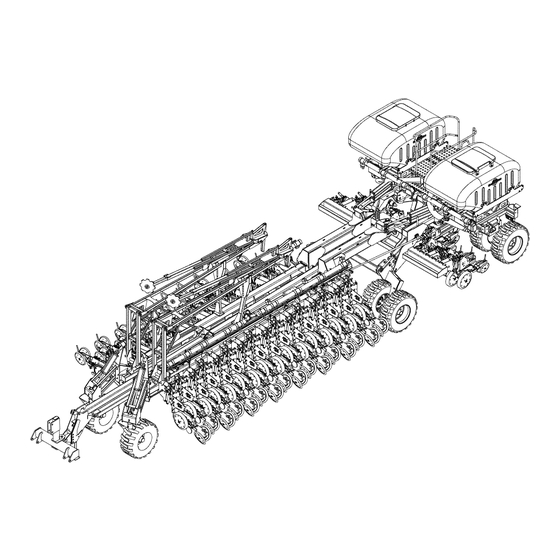

60 Foot Yield-Pro

Manufacturing, Inc.

www.greatplainsmfg.com

Printed 2019-03-19

Index

YP2425IR

®

Planter

®

Meters

29711

EN

411-241M

Advertisement

Table of Contents

Troubleshooting

Summary of Contents for GREAT PLAINS Yield-Pro YP2425IR

- Page 1 Table of Contents Index Operator Manual YP2425IR ® 60 Foot Yield-Pro Planter ® with Individual Row Control Meters Manufacturing, Inc. www.greatplainsmfg.com Read the operator manual entirely. When you see this symbol, the subsequent instructions and warnings are serious - follow without exception.

-

Page 2: Machine Identification

Machine Identification Record your machine details in the log below. If you replace this manual, be sure to transfer this information to the new manual. If you or the dealer have added options not originally ordered with the machine, or removed options that were originally ordered, the weights and measurements are no longer accurate for your machine. - Page 3 Great Plains Manufacturing, Inc. assumes no responsibility for errors or omissions. Neither is any liability assumed for damages resulting from the use of the information contained herein. Great Plains Manufacturing, Inc. reserves the right to revise and improve its products as it sees fit.

- Page 4 YP2425IR Cover Index Marker Extension .............58 Seed Pool Recovery ..........87 Marker Gauge Wheel Adjustment ......59 Population Troubleshooting Charts .........88 Marker Chain Length Adjustment......59 Maintenance and Lubrication..........96 Dual Marker Speed Adjustment .......60 Maintenance..............96 Height Switch Adjustment..........61 Material Clean-Out ............97 Fan and Meter Pressurization Adjustment ......61 Air Box Clean-Out ............97 Furrow Check: ............62 Air System Clean-Out ..........97...

-

Page 5: Important Safety Information

YP2425IR Table of Contents Index Important Safety Information Look for Safety Symbol The SAFETY ALERT SYMBOL indicates there is a potential hazard to personal safety involved and extra safety precaution must be taken. When you see this symbol, be alert and carefully read the message that follows it. -

Page 6: Avoid High Pressure Fluids

YP2425IR Table of Contents Index Important Safety Information PTO-Specific Hazards Applies only to optional PTO pump. Even if you are experienced in PTO operations, review the “Using PTO Safely” topic on page 2 of the PTO manual (411-015M). Topics in that manual dealing with PTO hazards include this PTO alert symbol. -

Page 7: Wear Protective Equipment

YP2425IR Table of Contents Index Important Safety Information Wear Protective Equipment Great Plains advises all users of chemical pesticides or herbicides to following personal safety equipment. Waterproof, wide-brimmed hat Waterproof apron. Face shield, goggles or full face respirator. -

Page 8: Use Safety Lights And Devices

YP2425IR Table of Contents Index Important Safety Information Use Safety Lights and Devices Slow-moving tractors and towed implements can create a hazard when driven on public roads. They are difficult to see, especially at night. Use flashing warning lights and turn signals whenever driving on public roads. -

Page 9: Tire Safety

YP2425IR Table of Contents Index Important Safety Information Tire Safety Tire changing can be dangerous and should be performed by trained personnel using correct tools and equipment. When inflating tires, use a clip-on chuck and extension hose long enough for you to stand to one side–not in front of or over tire assembly. -

Page 10: Safety Reflectors And Decals

Keep all safety decals clean and legible. Replace all damaged or missing decals. Order new decals from your Great Plains dealer. Refer to this section for proper decal placement. When ordering new parts or components, also request corresponding safety decals. -

Page 11: Daytime Reflectors

YP2425IR Table of Contents Index Important Safety Information Daytime Reflectors 29710 838-267C On the back of seed box support structure each end (above wheels, inside of red reflectors); two total Amber Reflectors 838-265C On the front of the center section front lower tool bars, on the rear of the wing tool bars, and on the sides of the seed box frame;... - Page 12 YP2425IR Table of Contents Index Important Safety Information Danger (in Spanish) 818-557C 29710 Advising non-English readers to seek translation On side of tongue; one total Danger: Electrocution Hazard 838-599C One each side or marker upright arm, each side; 29710 four total Danger: Rotating Driveline (Option) 34843 858-030C...

- Page 13 YP2425IR Table of Contents Index Important Safety Information Warning: Pinch/Crush 818-045C On forward transport wheel arms, each side On rear axle by seed hopper, each side; five total 29710 Warning: Speed 818-188C WARNING EXCESSIVE SPEED HAZARD To Prevent Serious Injury or Death: Do Not exceed 20 mph maximum transport speed.

- Page 14 YP2425IR Table of Contents Index Important Safety Information Warning: Markers: Pinch/Crush 818-682C One each side or marker upright arm, each side; 29710 four total Warning: Hot Fluid (Option) 34843 858-004C WARNING I N G r’s ve nt r at al BE ID LIN ve nt G SP...

- Page 15 YP2425IR Table of Contents Index Important Safety Information Caution: Transport Locks 818-351C Hitch tongue, Rockshaft face, forward center transport wheels, front of wing casters; five total 29796 Caution: Tires Not A Step 818-398C One front face each wing gauge wheel, One each side front center axle;...

-

Page 16: Description Of Unit

YP2425IR Table of Contents Index Introduction Great Plains welcomes you to its growing family of new ® product owners. The 60 Foot Yield-Pro Planter ® with Air-Pro Meters (YP2425IR) has been designed with care and built by skilled workers using quality materials. -

Page 17: Owner Assistance

Refer to Figure 2 Your machine’s parts were specially designed and should only be replaced with Great Plains parts. Always use the serial and model number when ordering parts from your Great Plains dealer. The serial-number plate is located on the left end of the seed cart tool bar, as shown. -

Page 18: Preparation And Setup

YP2425IR Table of Contents Index Preparation and Setup This section helps you prepare your tractor and YP2425IR Planter for use, and covers tasks that need to be done seasonally, or when the tractor/planter configuration changes. Before using the YP2425IR Planter in the field, you must hitch the planter to a suitable tractor, inspect systems, level the planter. -

Page 19: Hitching Tractor To Planter

YP2425IR Table of Contents Index Preparation and Setup Hitching Tractor to Planter Crushing Hazard: Do not stand or place any part of your body between planter and moving tractor. You may be severely injured or killed by being crushed between the tractor and planter. Stop tractor engine and set park brake before attaching cables and hoses. -

Page 20: Protecting Fan Hydraulic Motor Seals

Preparation and Setup Color Coded Hydraulic Hoses Refer to Figure 4 Great Plains hydraulic hoses have color coded handle grips to help you hookup hoses to your tractor outlets. Hoses that go to the same remote valve are marked with the same color. -

Page 21: Electrical Hookup

YP2425IR Table of Contents Index Preparation and Setup Electrical Hookup Refer to Figure 5 (which depicts the North American lighting connector , seed monitor connector a DC power connector for Row PRO). Your YP2425IR Planter is equipped with standard and optional devices that... - Page 22 YP2425IR Table of Contents Index Preparation and Setup Hitching with Hydraulic Tongue (Option) Refer to Figure 7 10. Move the tractor to near hitching position. OPEN 11. Connect the hydraulic hoses for the tongue circuit. This needs to be done before hitching in order to raise and lower the tongue.

- Page 23 YP2425IR Table of Contents Index Preparation and Setup Store Main Parking Stand Refer to Figure 9 and Figure 10 1. Remove the lower pin and the upper pin holding the parking stand 2. Move the stand from under the tongue to an inverted position in the bracket on the left side on the tongue.

-

Page 24: Tank Cart Hitching

YP2425IR Table of Contents Index Preparation and Setup Tank Cart Hitching If using a fertilizer cart, consult the cart manual for: • hitching cart tongue to planter • connecting pump control electronics to planter • connecting fertilizer feed hoses to planter Complete the tractor-planter hookup before making any tank cart connections. -

Page 25: Heights And Leveling

YP2425IR Table of Contents Index Preparation and Setup Heights and Leveling Level frame in planting conditions. Failure to do so may result in implement not All frame sections must be at the correct height and level producing desired results. to maintain even planting depth. -

Page 26: Wing Leveling

YP2425IR Table of Contents Index Preparation and Setup Center Section Level Check Vertical height and side-to-side level of the center section is set at the factory and cannot be field-adjusted. It does Any unevenness in ground that tilts the wings or center need to be verified before checking/adjusting the wings. -

Page 27: Lock Up Fertilizer Drive

YP2425IR Table of Contents Index Preparation and Setup Lock Up Fertilizer Drive YP242A Loss of Control and Sharp Object/Crushing Hazards: Do not lift or lower wheel by spoke or rim; use handle only. Keep feet out from under wheel. 90 pounds (41 kg) force is required to lift wheel. -

Page 28: Pre-Start Checklist

YP2425IR Table of Contents Index Operating Instructions This section covers general operating procedures. Experience, machine familiarity, and the following information will lead to efficient operation and good working habits. Always operate farm machinery with safety in mind. Pre-Start Checklist Perform the following steps before transporting the YP2425IR Planter to the field. - Page 29 YP2425IR Table of Contents Index Operating Instructions Unfolding the YP2425IR Planter The distance between the tractor and the seed structure decreases by 12 feet (3.7 m) during unfolding. Planter, tractor, or both will move during this operation. Crushing, Pinch-Point and Overhead Hazards: To prevent serious injury or death: ...

- Page 30 YP2425IR Table of Contents Index Operating Instructions Unfolding, Continued … 7. Raise tractor 3-point hitch or extend planter hydraulic tongue until tongue wing locks rise disengage. Machine Damage Risk: Raise hitch before unfolding. If hitch is not raised, wing locks remain in transport hooks.

-

Page 31: Raising/Lowering Planter

YP2425IR Table of Contents Index Operating Instructions Raising/Lowering Planter Refer to Figure 23 Planter raising/lowering relies on the four lift cylinders at the mainframe and wing end gauge wheels. The planter must be raised for folding and unfolding. The planter will not fully lower if transport locks are installed. - Page 32 YP2425IR Table of Contents Index Operating Instructions Raising Planter Refer to Figure 27 Pinch/Crush Risk: 1. If the planter has hydraulic hitch, set the Lift/Hitch Keep all personnel clear of center section and seed cart while switch to LIFT. raising tool bar. The wheels move inward. ...

- Page 33 YP2425IR Table of Contents Index Operating Instructions Folding the YP2425IR Planter Fold the YP2425IR Planter for moves between fields and over public roads, and for storage. The distance between the tractor and the seed structure increases by 12 feet (3.7 m) during unfolding. Planter, tractor, or both will move during this operation.

- Page 34 YP2425IR Table of Contents Index Operating Instructions Folding, Continued … Refer to Figure 31 If caster locks are engaged (wire handle indicator in FIELD position), they must be released before folding. 5. At each wing caster, move the lock control handle to the ROAD position.

-

Page 35: Rephasing Lift System

YP2425IR Table of Contents Index Operating Instructions Rephasing Fold System In typical use during a single planting operation, it is normal for the fold cylinders to get slightly out of phase, resulting in uneven folding and unfolding of the YP2425IR Planter. Every few planting days, rephase the cylinders with this procedure: 1. -

Page 36: Transporting The Planter

YP2425IR Table of Contents Index Operating Instructions Transporting the Planter Loss of Control Hazard: Ensure that the towing vehicle is adequate for the task. Using an inadequate tow vehicle is extremely unsafe, and can result 26142 in loss of control, serious injury and death. The planter can weigh up to 50,000 pounds (22 780kg), depending on configuration and seed load. -

Page 37: Transport Checklist

YP2425IR Table of Contents Index Operating Instructions Transport Checklist If heading to the field, before departing, ensure that opener depth, seed rate and fertilizer rate have been determined, or that the necessary data is with you. Plan the route. If towing a cart hitched to the planter, plan the route so that no reverse movements will be necessary. -

Page 38: Loading Materials

YP2425IR Table of Contents Index Operating Instructions Loading Materials For trailing tank cart, see the Operator manual for the cart. 82 Bushel Hopper Operation Tipping Hazard: Load an 82 bu. hopper only when mounted on the cart. A full Approximate capacity of bulk seed hopper, hopper can weigh over 5000 lbs (2268 kg), which is above the in bushels, at 10 inch increments. -

Page 39: Changing The Seed Box Or 82 Bu. Hopper

YP2425IR Table of Contents Index Operating Instructions Changing the Seed Box or 82 bu. Hopper ® The Planter 60ft Yield-Pro Planter accepts Great Plains 82 bu. hoppers or bulk seed boxes that meet ® the Pioneer PROBOX specification. Hoppers for the YP2425IR Planter are provisioned as a pair. - Page 40 YP2425IR Table of Contents Index Operating Instructions 12. If mounting a seed box for the first time in a season, open the new seed box and measure out approximately 3 gallons (11 liters) of seed into a pail. cup (80 ml) of Ezee Glide Plus. Mix and pour into air box before mounting new seed box.

-

Page 41: Auxiliary Hydraulics

YP2425IR Table of Contents Index Operating Instructions Auxiliary Hydraulics Refer to Figure 39, Figure 40 and Figure 41 The planter includes, as standard equipment, an auxiliary hydraulic circuit, intended to power a seed auger for loading bulk hoppers. The Aux quick-disconnect ports are on the frame. -

Page 42: Marker Operation

YP2425IR Table of Contents Index Operating Instructions Marker Operation Figure 42 26042 Marker Unfolding Overhead Hazard: To prevent serious injury or death, do not allow anyone to stand near or beyond the end of the wings during marker operations. Marker arms are heavy and marker discs may be sharp. -

Page 43: Marker Unfold (One Side)

YP2425IR Table of Contents Index Operating Instructions Marker Unfold (one side) Refer to Figure 42 and Figure 44 1. If the Auxiliary Hydraulic circuit has been used recently, confirm that the manual Marker/Aux valve on the left wing is set to “Marker”. ®... - Page 44 YP2425IR Table of Contents Index Operating Instructions Air System Operation Figure 45 29595 ® ® Yield-Pro Air System for Air-Pro Seed Metering Meter Pressurization System Elements ( shows air direction) ® Hydraulic Fan Pressure Sensor Lines Air-Pro Seed Meter Split-Air Manifold Pressure Sensor Chamber Row Pressurizing Tubes Servo-Controlled Vane...

- Page 45 YP2425IR Table of Contents Index Operating Instructions Air System Overview The hydraulic fan supplies air for both seed delivery and meter operation. Fan rpm is operator-adjusted (page 43) via the tractor’s hydraulic flow control, and reported by the seed monitor system. The rest of the system is fully automatic.

- Page 46 YP2425IR Table of Contents Index Operating Instructions Fan Circuit Operation See also “Fan and Meter Pressurization Adjustment” on page 61. Refer to Figure 46 Three hydraulic hoses serve the fan, and must be properly connected for the fan to operate in the correct direction , at recommended speeds, and without damage.

- Page 47 65 - 88 lpm • seed suspension in a bulk seed box * This assumes a 2007+ Great Plains hopper, or older hopper with the vent line update. For an older unvented hopper, use the • unstable split air control rpms recommended for ProBox.

-

Page 48: Weight Transfer Operation (Option)

YP2425IR Table of Contents Index Operating Instructions Y-Tubes Refer to Figure 47 Y-tube gates can be shut off to feed only one row for single-row planting on a twin-row machine. In the photograph, the left meter tube is open and the right closed. -

Page 49: Monitor Operation

• a Type 3 three-section boom, typically used with a CFM: Tank Pump Control Great Plains PFC cart user-provisioned trailing cart, Refer to Figure 50 above. The “Fert.Pump” switch supplied by a pump and manifold on the cart. on the Clutch Folding Module is used only with Great Use only pre-mixed liquid fertilizer. - Page 50 YP2425IR Table of Contents Index Operating Instructions SML Cart Pump System Diagram Figure 51 36414 Cart Pump Fertilizer System 2019-03-19 Table of Contents Index 411-241M...

- Page 51 YP2425IR Table of Contents Index Operating Instructions SML Cart Tank Fertilizer System Elements Liquid fertilizer system callouts are consistent across Boom Supply Strainer A filter element in the canister traps large particles that this entire manual. No single system includes all might clog boom orifice plates.

-

Page 52: Trailer Operations

Trailer direction is extremely difficult to control. Fertilizer Systems Operation Hydraulic Fertilizer Pump This information applies to planters with Great Plains hydraulic fertilizer pumps. For systems using customer provisioned components (pump, tanks or controllers), consult the documentation for those components. - Page 53 YP2425IR Table of Contents Index Operating Instructions The hydraulic fertilizer system may be enabled or disabled entirely using the Channel On/Off softkey , or by disabling the Channel in the main Channel Setup screen (circled). Figure 54 36438 Fertilizer Rate on Work Screen Ground Drive Pump Operation PFC1600 PFC2000...

-

Page 54: Field Set-Up Checklist

YP2425IR Table of Contents Index Operating Instructions Field Set-Up Checklist Use the following tables to develop a final checklist for To complete checklists, you may need to refer to the: your tractor/planter configuration. Additional or fewer SRM: Seed Rate Manual (SRM), steps may be necessary depending on tractor features, ®... - Page 55 YP2425IR Table of Contents Index Operating Instructions Row Units Checklist Page Hydraulic System Checklist Page Preset depth handles to 7 holes showing Check tractor hydraulic reservoir full above “T” Inspect connections for leaks Preset down force springs to first notch (lightest) setting for most conditions, 2nd Perform a raise and lower operation notch otherwise)

-

Page 56: Field Operation

YP2425IR Table of Contents Index Operating Instructions Field Operation Perform all steps in “Pre-Start Checklist” on page 24 Use Depth Control mode. If tractor 3-point hitch and “Field Set-Up Checklist” on page 50. control is set for Load Control, hitch movement may cause changes in row unit depth resulting in uneven depth control. -

Page 57: Short-Term Parking

YP2425IR Table of Contents Index Operating Instructions Short-Term Parking 1. Fold markers. See “Folding the Markers” on page 39. Roll-Away Hazard: 2. Choose a location with level firm ground. Do not DO NOT unhitch planter while on a slope. Always block tires unhitch on a slope. -

Page 58: Long Term Storage

YP2425IR Table of Contents Index Operating Instructions Long-Term Storage Complete Parking steps (page 53) first. Store the YP2425IR Planter indoors if possible. Great Plains recommends parking/storing in the raised configuration, folded, on the parking stands and with all lift cylinder locks installed. 1. - Page 59 YP2425IR Table of Contents Index Adjustments To get full performance from your YP2425IR Planter, you Even if your planting conditions rarely change, some of need an understanding of all component operations. these items need periodic adjustment due to normal Many provide adjustments for optimal field results. Some wear.

-

Page 60: Setting Material Rates

YP2425IR Table of Contents Index Adjustments Setting Material Rates Planting Rate Adjusting the planting rate requires the following: 1. Monitor configuration: The seed monitor must be set up with the correct row count, row spacing and disk cell count. See the ®... -

Page 61: Gauge/Transport Wheel Adjustments

YP2425IR Table of Contents Index Adjustments Gauge/Transport Wheel Adjustments The gauge/transport wheels serve two functions: Refer to Figure 63 1. When the planter is lowered, the wheels establish the heights of their respective sections, nominally a tool bar height of 26 inches (66 cm) above the planting surface. -

Page 62: Marker Disk Adjustment

YP2425IR Table of Contents Index Adjustments Marker Disk Adjustment Sharp Object Hazard: Use caution when making adjustments in this area. Marker disks may be sharp. Refer to Figure 64 1. To change angle of cut, and the width of the mark, loosen inch bolts holding the disk assembly. - Page 63 Figure 67 29516 Marker Gauge Wheel Marker Chain Length Adjustment Great Plains suggests checking marker chain slack every few years. If any maintenance or repairs cause the chain to be disconnected, correct slack needs to be set on re-installation. Perform any checks and adjustments with the marker folded and tilted down into its cradle.

-

Page 64: Dual Marker Speed Adjustment

YP2425IR Table of Contents Index Adjustments Dual Marker Speed Adjustment Crushing and Sharp Object Hazards: Never allow anyone near the planter when folding or unfolding the markers. You may be injured if hit by a folding or unfolding marker. Markers may fall quickly and unexpectedly if the hydraulics fail. -

Page 65: Height Switch Adjustment

The switch is located at the rear cross tube on the planter’s left side. Although factory-preset for typical planting conditions, Great Plains recommends adjusting this switch for your exact field conditions and planting depth. 1. Lower the planter to the height at which seed delivery is to begin. - Page 66 YP2425IR Table of Contents Index Adjustments 8. Check for meter fill: If a meter runs completely out of seed (“starved”), With fan running, put the tractor in Park and set the back-pressure to the air box manifold may prevent prompt refill.

-

Page 67: Fine-Tuning Meter Pressurization

YP2425IR Table of Contents Index Adjustments 15. Doubles: If all else is correct, and the overall average Excess meter pressurization can increase the incidence population is running high (or there are double seeds of doubles. Be sure to rule out other causes (such as upon furrow check), the cause may be two seeds in incorrect meter... - Page 68 YP2425IR Table of Contents Index Adjustments Seed Delivery Fan Adjustments Refer to Figure 72 The primary control for seed delivery air is fan rpm. The servo vane (not shown), under the control of the split air system, takes whatever is needed to maintain meter pressurization (the bottom three manifold outlets Remaining air is sent to the top outlets for seed delivery.

- Page 69 YP2425IR Table of Contents Index Adjustments Frame-Mounted Row Accessories Terra-Tine™ Adjustments Refer to Figure 73 through Figure 75 All adjustments must be made with the planter in the fully raised position. Equipment Damage Risk: Be sure to check that the Terra-Tine Row Cleaner tines DO NOT touch the coulter blade or any other attachments.

-

Page 70: Frame-Mounted Coulter Adjustments

YP2425IR Table of Contents Index Adjustments Frame-Mounted Coulter Adjustments Refer to Figure 75 Frame-mounted coulters may be run on-row or between rows. On-Row If run on-row, or within 2 in. (5.1 cm) of the furrow, adjust the shaft to set the coulter depth to be the planting depth or inch (6 mm) shallower. -

Page 71: Series Row Unit Adjustments

(which depicts a row unit populated with most optional accessories supported for use with the YP2425IR planter) From front to back, a Great Plains 25 Series row unit can include the following capabilities (some optional): 1. Lock-Up Pin Storage Hole (Hole Standard) See “Row Unit Shut-Off”... -

Page 72: Row Unit Down Pressure

YP2425IR Table of Contents Index Adjustments Row Unit Down Pressure Refer to Figure 78 The ideal amount of down-force causes the side gauge wheels to compress any loose surface soil, but not press a trench into subsoil. To assess down-force, operate the planter for a short distance on typical ground (with or without seeding), and stop. - Page 73 YP2425IR Table of Contents Index Adjustments An adjuster cam sets down pressure individually for each row unit. This is useful for penetrating hard soil and planting in tire tracks. For best results always adjust tractor tires so they are not ahead of 30 inch or 70 cm rows.

- Page 74 YP2425IR Table of Contents Index Adjustments Unit-Mount Cleaner Adjustments Refer to Figure 84 and Figure 85 Optional Martin row cleaners are unit-mounted, using: UMRC: Unit-Mount Row Cleaner (stand-alone), or UMC-RC: Unit-Mount Coulter RC (on coulter bracket, with or without a coulter disk present). There are two adjustments: 1.

-

Page 75: Coulter Adjustments

YP2425IR Table of Contents Index Adjustments Coulter Adjustments Coulters are not factory-installed. Check alignment and depth prior to first use. Coulter Depth Adjustment The ideal operating depth for coulters is inch (6 mm) above opener depth. Although they may have originally been set to this depth, coulter (and opener) blades wear with time, and may need adjusting. - Page 76 YP2425IR Table of Contents Index Adjustments Coulter Row Alignment Refer to Figure 88 For unit-mounted coulters, the ideal alignment is for the blade to open a furrow directly ahead of the opener discs. As a check on coarse alignment, sight along the coulter blade center-line , the gap between the opener blades...

-

Page 77: Row-Unit Opener Disk Adjustments

YP2425IR Table of Contents Index Adjustments Row-Unit Opener Disk Adjustments 25 Series openers have three adjustments: 1. planting/seed depth 2. opener disc to disc clearance 3. gauge wheel/opener disk clearance Setting Planting Depth Refer to Figure 90 The “T” handle sets planting depth by limiting the how high the side depth gauge wheels ride relative to the opener disks. -

Page 78: Side Gauge Wheel Adjustment

YP2425IR Table of Contents Index Adjustments Side Gauge Wheel Adjustment Side Gauge Side Gauge Refer to Figure 93 and Figure 95 Wheel Wheel Disc-to-wheel angle and clearance ideally has the wheel Opener just touching the disk when the wheel is raised to Disks planting depth (is up against the stop set by the “T”... - Page 79 YP2425IR Table of Contents Index Adjustments • If wheel does not fall freely, loosen hex-head bolt and slide wheel arm out just until wheel and arm move freely. Tighten hex-head bolt according to grade: inch Grade 5 bolt on 25 series: torque: 75 foot-pounds (102 N•m).

- Page 80 YP2425IR Table of Contents Index Adjustments Seed Meter Setup and Adjustment There are adjustments for seed inlet, and choice of disks. There are no other adjustments, in particular no brush adjustments, at the meter. Meter Rain Cover The rain cover keeps side winds from unseating seed in disk pockets.

- Page 81 YP2425IR Table of Contents Index Adjustments Optimal Seed Pool Slopes The optimal seed slope is one that results in the most consistent seeding, with minimal skips and doubles. The column at right has photographs of pool slopes found to 8:00 be optimal for representative seeds.

-

Page 82: Air-Pro ® Meter Disk Installation

YP2425IR Table of Contents Index Adjustments ® Air-Pro Meter Disk Installation 1. Cross-check Seed Rate Chart data against part number/description molded into disks to be used. Population Risk: Use the same disk in all active rows. 2. Inspect disks to be installed. Do not install damaged or excessively worn disks. -

Page 83: Row Unit Shut-Off

YP2425IR Table of Contents Index Adjustments Removing a Seed Disk Refer to Figure 106 1. Remove rain cover. If seed is present, close shutter to prevent more seed from entering meter. Attach funnel (page 98). 2. Hold seed disk in meter. Rotate disk clamp counterclockwise 45... - Page 84 YP2425IR Table of Contents Index Adjustments 1. Identify Rows to Shut Off On twin-row planters, openers are installed with short and long opener mounts. If locking up unused rows of a twin-row planter, shut off the rear (long mount) rows. On single-row planters with mid-length mounts, any rows may be locked up.

- Page 85 YP2425IR Table of Contents Index Adjustments 5. Lock-Up Row Alternate twin-row units (the rear units) can be pinned in the up position to accommodate single-row spacing. Refer to Figure 110 The lock-up pins for each front row unit are located in a storage hole in the row unit mount.

-

Page 86: Seed Firmer Adjustments

YP2425IR Table of Contents Index Adjustments Seed Firmer Adjustments Series 25 row units include a standard seed flap, and accept one of two optional seed firmers (which may be included in your selected opener bundle). Sharp Object Hazard: Row unit disk blades may be sharp. Use caution when making ®... -

Page 87: Press Wheel Adjustment

YP2425IR Table of Contents Index Adjustments Press Wheel Adjustment The press wheels close the furrow which gently presses the soil over the seed to ensure good seed-to-soil contact for even emergence. To provide consistent seed firming, the press wheels are free to move downward from their normal operating position. - Page 88 5. Tighten both hex head bolts (View from beneath opener) If press wheel adjustments do not provide satisfactory furrow closing, your conditions may require alternate press wheels. A variety of wheel assemblies are available. Consult your Great Plains dealer. 2019-03-19 Table of Contents Index 411-241M...

-

Page 89: Troubleshooting

YP2425IR Table of Contents Index Troubleshooting See also “Row-Pro™ Troubleshooting” on page 155. Planting Rate Problems When starting up with a new planter, a new crop or a new ® For seed monitor issues, see also the DICKEY-john population it is important to physically double check what Planter/Drill Control User Manuals, the monitor is reporting in the cab by digging seeds. -

Page 90: Seed Pool Troubleshooting

YP2425IR Table of Contents Index Troubleshooting Seed Pool Troubleshooting Figure 117 29743 ® Rear Cross-Section of Air-Pro Meter in Normal and Row-Failed Conditions Normal: Normal: Delivery Blockage or Bridging: Bridging: Filling Filled Back-flow Starvation Screen Shutter Seed pool at shutter Once inlet is filled to No seed arriving from Oversize... -

Page 91: Seed Pool Recovery

YP2425IR Table of Contents Index Troubleshooting Seed Pool Recovery When a meter has been starved of seed, back-flow of air through the open shutter reduces delivery air flow. This causes seed delivery to be slow. If you start or resume planting with an empty seed pool, the delivery flow may be too low to keep the meter supplied. -

Page 92: Population Troubleshooting Charts

YP2425IR Table of Contents Index Troubleshooting Population Troubleshooting Charts Population Too Low Problem Cause Solution Incorrect seed rate Check seed rate charts Overall Low Population Empty pockets on disk (skips) due to insufficient Methodically increase the controlled air to the meter. See air pressure. - Page 93 YP2425IR Table of Contents Index Troubleshooting Population Too Low Problem Cause Solution Shutter opening too wide - interfering with meter Adjust shutter to lower setting. pressurization Population, Single Row Shutter opening too narrow - starving meter of Adjust shutter to higher setting. seed (low seed pool) Y-tube partially or completely closed, reducing Open Y-tube for row...

- Page 94 YP2425IR Table of Contents Index Troubleshooting Population Too High Problem Cause Solution Incorrect seed rate Check seed rate charts Overall High Population Two seeds per pocket on the disk Methodically decrease the controlled air to the meter. See “Fan and (doubles), due to excess meter Meter Pressurization Adjustment”...

- Page 95 YP2425IR Table of Contents Index Troubleshooting Population Related Problem Cause Solution Run with rain covers in place to minimize ambient light intrusion. Use Mismatch ® the population adjustment factor in the DICKEY-john monitor Between Small seeds (example Milo) are not system to compensate for missed seeds.

-

Page 96: General Troubleshooting

YP2425IR Table of Contents Index Troubleshooting Seed Delivery Troubleshooting Problem Cause Solution Loosen pipe and spin so the bend is straight down and Single row doesn’t fill Y tube is bent/angled off feed pipe. Y-tube is not pointing to front or rear of air pipe. or keep up with other rows. - Page 97 YP2425IR Table of Contents Index Troubleshooting General Troubleshooting Problem Cause Solution See “Population Troubleshooting Charts” on page 88. Uneven seed spacing Excessive field speed. Reduce field speed. Unclean seed. Use clean seed. Damaged seed tube Inspect; repair or replace. ® ®...

- Page 98 YP2425IR Table of Contents Index Troubleshooting General Troubleshooting Problem Cause Solution Incorrect spring handle setting See “Press Wheel Adjustment” on page 83. Press wheels Insufficient row unit down-force See “Row Unit Down Pressure” on page 68. compacting Wedge shaped wheels work best on narrow spacings and in wet the soil as Use of incorrectly shaped tire for your conditions.

- Page 99 YP2425IR Table of Contents Index Troubleshooting General Troubleshooting Problem Cause Solution Speed If speeds don’t agree during planting (with planter lowered), Reading Monitor speed reading will only match re-calibrate radar speed sensor with planter lowered. See Doesn’t tractor with planter lowered page 145.

-

Page 100: Maintenance And Lubrication

YP2425IR Table of Contents Index Maintenance and Lubrication Maintenance Proper servicing and maintenance is the key to long implement life. With careful and systematic inspection, you can avoid costly maintenance, downtime, and repair. Always turn off and remove the tractor key before making any adjustments or performing any maintenance. -

Page 101: Material Clean-Out

YP2425IR Table of Contents Index Maintenance and Lubrication Material Clean-Out When planting is completed, it is commonly the case that some seed remains. There may be seed in the hopper or bulk box, seed in the airbox, a small amount of seed in Entrapment and Rapid Suffocation Hazard: the hose lines, and seed in the meters. -

Page 102: Meter Clean-Out

YP2425IR Table of Contents Index Maintenance and Lubrication Refer to Figure 121 8. If the planter has Y-tubes, shut off the gates at all of the Y-tubes. 9. Turn on the air fan and let it run. Use the “SPLIT AIR -” softkey to reduce the regulated air pressure to a low value, 1in water or less - this diverts most of the air to the bulk seed delivery... - Page 103 This can cause false low population alarms. The planter includes a seed tube brush (Great Plains part number 891-259C). If the seed meter is empty, remove the seed disc and insert the brush into the seed tube from above.

-

Page 104: Meter Brush Maintenance

YP2425IR Table of Contents Index Maintenance and Lubrication Meter Brush Maintenance Possible Chemical Hazard: Wear a respirator for brush cleaning. Brushes will have talc and graphite residue, and may have residues of hazardous seed treatments. Refer to Figure 125 A HEPA vacuum cleaner is recommended for brush cleaning. - Page 105 YP2425IR Table of Contents Index Maintenance and Lubrication Meter Brush Replacement Consult the Parts manual (401-626P) for current replacement part numbers. Refer to Figure 126 Tufted Brush Replacement 1. Remove and save both 10-24 hex head cap screws and nylon insert nuts (not shown). 2.

-

Page 106: Seed Disk Maintenance

YP2425IR Table of Contents Index Maintenance and Lubrication Seed Disk Maintenance Refer to Figure 128 When removing seed disks, inspect them for wear and damage. If there is any seed dust or treatment build-up in the cell pockets , or along the raised wiper ridges clean the disks and reinspect. -

Page 107: Air Box Residue Clean-Out

YP2425IR Table of Contents Index Maintenance and Lubrication Air Box Residue Clean-Out Planting in extremely dusty conditions, particularly dusty and humid conditions, or otherwise sticky soils, can lead to air residue build-up inside the airbox. This residue can cause seed delivery blockages. Refer to Figure 129 and Figure 130 (Figure 129 depicts a partially and a completely plugged agitation port, and build-up in the RH plenum chamber) -

Page 108: Bleeding Hydraulics

YP2425IR Table of Contents Index Maintenance and Lubrication Bleeding Hydraulics High Pressure Fluid Hazard: Relieve pressure before disconnecting hydraulic lines. Wear protective gloves and safety glasses or goggles when working with hydraulic systems. Escaping fluid under pressure can JIC Torque Chart have sufficient pressure to penetrate the skin causing serious injury. - Page 109 YP2425IR Table of Contents Index Maintenance and Lubrication Fold Cylinder Bleeding Refer to Figure 132 1. Begin with planter raised and lift cylinder locks installed. 2. Unpin cylinder rod ends. Orient cylinders so that rod ends may extend without striking planter parts. 3.

-

Page 110: Marker Shear Bolt Replacement

The shear bolt is a hex head cap screw, -13 x 2 inch Grade 5, Great Plains part number 802-130C, plus a -13 lock nut, Great Plains part number 803-019C. Figure 134 29516 Marker Shear Bolt Install a replacement shear bolt on the vertical faces on the side opposite from the pivot bolt. -

Page 111: Wing Alignment

YP2425IR Table of Contents Index Maintenance and Lubrication Wing Alignment To check and adjust wing alignment: 1. Unfold planter. See “Unfolding the YP2425IR Planter” on page 25. Lower planter. Pull forward. Refer to Figure 135 and Figure 136 2. Select a common reference point that is easy to access at the wing-end and center section end row units, such as the back of the press wheel assembly... -

Page 112: Disc Spreaders And Scrapers

YP2425IR Table of Contents Index Maintenance and Lubrication Disc Spreaders and Scrapers Refer to Figure 137 1. Remove side gauge wheels from arms to access row-unit discs and scrapers. 2. With the unit raised, check blade spreader wear. Replace spreader if it is inch (13 mm) wide or narrower. -

Page 113: Fertilizer System Maintenance

YP2425IR Table of Contents Index Maintenance and Lubrication Fertilizer System Maintenance With proper attention to maintenance, end of day clean-out, end of season clean-out and winterization, you can substantially increase the life and reliability of Possible Chemical Hazard: your fertilizer system. Protect the pump, clean the tanks, Wear proper protective equipment as required by chemical strainers, lines and nozzles, and you can avoid costly manufacturer. -

Page 114: Seed Flap Replacement

YP2425IR Table of Contents Index Maintenance and Lubrication Seed Flap Replacement Refer to Figure 140 To replace an 816-302C seed flap use a needle nose pliers or similar tool to grasp “T” top of flap. Pull upward to pull flap up out of metal bracket Push new seed flap down through metal bracket until flap snaps into place with “T”... - Page 115 YP2425IR Table of Contents Index Maintenance and Lubrication Lubrication Intervals (operating hours) Multi-purpose Multi-purpose Multi-pupose Inspection at which service oil lubricant spray lubricant grease lubricant is required Wing Casters: Parallel Arms 8 grease fittings; 1 each end of each arm, each wing Type of Lubrication: Grease Quantity: Until Grease emerges 26065...

- Page 116 YP2425IR Table of Contents Index Maintenance and Lubrication Marker Joints 26068 6 grease fittings; 3 each marker, each wing Type of Lubrication: Grease Quantity: Until Grease emerges Wing Frames 2 grease fittings; one each wing at wing-frame to tool bar joint Type of Lubrication: Grease Quantity: Until grease emerges...

- Page 117 YP2425IR Table of Contents Index Maintenance and Lubrication Rockshaft to Link Arm 26072 2 grease fittings; pin outside end, each link Type of Lubrication: Grease Quantity: Until grease emerges Lift Cylinders: Rod End 26073 2 grease fittings, one each inside end of pins, each side Type of Lubrication: Grease Quantity: Until grease emerges Center Links: Aft End...

- Page 118 YP2425IR Table of Contents Index Maintenance and Lubrication Caster Pivots 27383 2 grease fittings, one each inside end of tool bar, each side Type of Lubrication: Grease Quantity: Until grease emerges 25 Series Side Wheel Bushing On both sides of each row-unit Type of Lubrication: Grease Quantity: Until grease emerges 21960...

- Page 119 YP2425IR Table of Contents Index Maintenance and Lubrication Frame-Mounted Coulter (optional) Hub 13245 Type of Lubrication: Grease Quantity = Until grease emerges Unit-mount coulter bearings are sealed, and require no lubrication or repack. Frame-Mounted Coulter (option) Pivot 13246 1 grease fitting each swivel mount casting Type of Lubrication: Grease Quantity = Until grease emerges Wing Casters: Pivot...

- Page 120 YP2425IR Table of Contents Index Maintenance and Lubrication Hitch Parallel Arms (Hydraulic Tongue only) 4 grease fittings, 1 each end of each arm Type of Lubrication: Grease Quantity: Until grease emerges 26152 Tongue Latch 21924 Type of Lubrication: Spray lube Quantity: Coat working surfaces Tongue Slide Roller 26041...

- Page 121 YP2425IR Table of Contents Index Maintenance and Lubrication Row Cleaner Bearings 1 grease fitting each wheel, 1 or 2 wheels per row Type of lubrication: Grease Quantity = Until resistance is felt To avoid damaging the seal, do not add grease at high pressure.

- Page 122 YP2425IR Table of Contents Index Maintenance and Lubrication Transport Wheels: Wheel Hubs 26070 Seasonal 8 bearings; 2 each of 4 wheels Type of Lubrication: Grease Quantity: Repack Gauge Wheel Bearings Seasonal 4 bearings, 2 each side Type of Lubrication: Grease Quantity = Repack 26071 2019-03-19...

-

Page 123: Seed Lubricants

YP2425IR Table of Contents Index Maintenance and Lubrication Seed Lubricants To maximize performance of Great Plains metering systems, it is imperative to use “Ezee Glide Plus” or Bayer Seed Fluency Agent. Ezee Glide Plus Talc+Graphite Mix 821-069C bucket, 5 gallon (19 liter) Ezee Glide Plus Lubricant “Ezee Glide Plus”is suitable for all seeds, especially... -

Page 124: Seed Lubricant

YP2425IR Table of Contents Index Options 82 Bushel Seed Hoppers 82 bu. (2890 liter) hoppers may be purchased with the YP2425IR Planter or added later. Only the 82 bu. size is supported on the YP2425IR Planter. Left and right refer to the side of the planter and the side hopper with the lid hinge, allowing convenient access from the walkboard. - Page 125 YP2425IR Table of Contents Index Options Weight Transfer System This option provides two cylinders and a control valve that transfer up to 1000 pounds (450 kg) of mainframe weight to each wing. Option Package Part Number YP24 WEIGHT TRANSFER 411-174A This option is factory-installed if ordered with the planter (feature code 70).

-

Page 126: Trailer Hitch Weldment

YP2425IR Table of Contents Index Options Trailer Hitch Weldment This a accessory provides a 20 ton pintle hook intended for use with either the PFC1600 or PFC2000 tank carts. Description Order Number Trailer Hitch Weldment 401-467A When installed, the lower swing-down section of the walkboard ladder is replaced by steps integrated into the hitch weldment. - Page 127 YP2425IR Table of Contents Index Options Ground Drive Fertilizer Pump One or two pump kits integrate with the Type 2 fertilizer manifold system. They are mounted on the wing tool bars. Typical starter fertilizer applications require only one pump. A second pump is necessary at and above 20 gallons per acre.

- Page 128 Great Plains offers two models of VeriFlow nozzles: Description Part Number NOZZLE HI-VERIFLOW1 829-143C (0.25 to 2.8 gpm at 15 to 60 psi) NOZZLE VERIFLOW1 829-144C (0.15 to 1.5 gpm at 15 to 60 psi)

-

Page 129: High-Rate Dribblers

YP2425IR Table of Contents Index Options High-Rate Dribblers For use only with 25 Series openers. Dribblers apply liquid fertilizer slightly to the side of the closed furrow behind the press wheel. Dribblers are available in left and right hand offsets, for use on twin rows. - Page 130 YP2425IR Table of Contents Index Options Frame-Mounted (Zone) Coulters Vantage I Coulters These frame-mounted coulters may be used with or without the Vantage I fertilizer applicator. Use with Vantage I requires one or both Fertilizer Manifolds. Each part number outfits an entire planter. Frame-Mounted Coulter Only 15in Fluted Blade Packages Part No.

- Page 131 YP2425IR Table of Contents Index Options Unit-Mounted Row Options Row-Pro™ Row-Pro™ adds a pneumatic cylinder to each row unit, supplement the down-pressure springs. Under control of ® ® the DICKEY-john IntelliAg seed monitor, the included air system make real-time adjustments to row down force.

- Page 132 YP2425IR Table of Contents Index Options Unit-Mounted Disk Coulters Optional unit-mount disk coulters are available with 15 inch (38.1 cm) fluted blades, 15 inch turbo blades or 14 inch (35.6 cm) straight blades. If you need complete coulters, with unit mount and blade, the selection includes: 15in Fluted Packages Part Number...

-

Page 133: Row Cleaners

YP2425IR Table of Contents Index Options Row Cleaners Optional Martin row cleaners are unit-mounted, using either a coulter disk mounting bracket ( , with or without disk), “stand-alone”, using unit-mount assembly ( ). Twin-Row planters support only single-wheel unit-mounted row cleaners, in alternating left/right cleaner hub orientations. -

Page 134: Seed Meter Disks

YP2425IR Table of Contents Index Options Seed Meter Disks ® Air-Pro meters accept a variety of seed disks, each optimized for specific seeds, plus a special blank disk for row shut-off. Disks are simple to change. Choices include: Part Number Meter Disks Blank, 000 Cell 817-841C... -

Page 135: Seed-Lok ® Seed Firmer

Additional wheels are available, and all may be field-installed. This manual does not list kit part numbers as the available wheels are often region-specific. Consult your Great Plains dealer. For operations, see: 25155 “Press Wheel Adjustment” on page 83. -

Page 136: Appendix A - Reference Information

YP2425IR Table of Contents Index Appendix A - Reference Information CoverSpecifications and Capacities Specifications/Capacities, North America Model YP2425A-48TR Row Count 48 (24 Twin) Row Spacing 30 inch Working Width 60 feet Span (Width Between End Rows) 698 inches Swath (Channel Width) 720 inches Seed Capacity 82 Bu. -

Page 137: Hydraulic Diagrams

YP2425IR Table of Contents Index Appendix A - Reference Information Hydraulic Diagrams Hydraulic Alternator 36908 2019-03-19 Table of Contents Index 411-241M... - Page 138 YP2425IR Table of Contents Index Appendix A - Reference Information Auxiliary Hydraulics (standard) 26135 2019-03-19 Table of Contents Index 411-241M...

- Page 139 YP2425IR Table of Contents Index Appendix A - Reference Information 29778 2019-03-19 Table of Contents Index 411-241M...

- Page 140 YP2425IR Table of Contents Index Appendix A - Reference Information Hydraulic Tongue (Optional) i c s a u l y d r i f t h T o L b a s i c s a u l y d r i f t h e n d T o L...

- Page 141 YP2425IR Table of Contents Index Appendix A - Reference Information Lift 25227 2019-03-19 Table of Contents Index 411-241M...

- Page 142 YP2425IR Table of Contents Index Appendix A - Reference Information Markers 26131 2019-03-19 Table of Contents Index 411-241M...

- Page 143 YP2425IR Table of Contents Index Appendix A - Reference Information Wing Fold, Markers and Auxiliary 29577 2019-03-19 Table of Contents Index 411-241M...

-

Page 144: Chain Routing

YP2425IR Table of Contents Index Appendix A - Reference Information Chain Routing Fertilizer Pump Ground Drive Chain Routing (optional) 28417 28416 ® ® CDS-John Blue Pump Ground Drive CDS-John Blue Pump Ground Drive Lower Drive Chain Upper Drive Chain 2019-03-19 Table of Contents Index 411-241M... -

Page 145: Seed Hose Routing

YP2425IR Table of Contents Index Appendix A - Reference Information Seed Hose Routing Mechanical Routing, Left Side 26167 2019-03-19 Table of Contents Index 411-241M... - Page 146 YP2425IR Table of Contents Index Appendix A - Reference Information Facing forward with planter folded. GUIDES YP2425IR Machine Left Side RACK AIR BOX X X X X Ports L07-L10 Unused and Capped RACK 26173 YP2425IR-48TR, 30 inch Twin-Row, 48 Row Units Section Left Center Left Wing...

- Page 147 YP2425IR Table of Contents Index Appendix A - Reference Information Facing forward with planter folded. YP2425IR Machine Right Side GUIDES Seed Hose Routing RACK AIR BOX X X X X Ports R07-R10 Unused and Capped RACK 26173 YP2425IR-48TR, 30in Twin-Row, 48 Row Units Section Right Center Right Wing...

-

Page 148: Torque Values Chart

YP2425IR Table of Contents Index Appendix A - Reference Information Torque Values Chart Bolt Head Identification Bolt Head Identification Bolt Bolt 10.9 Size Size Grade 2 Grade 5 Grade 8 Class 5.8 Class 8.8 Class 10.9 ft-lb ft-lb ft-lb ft-lb ft-lb in-tpi ft-lb... -

Page 149: Appendix B - Initial Setup

YP2425IR Table of Contents Index Appendix B - Initial Setup Seed Monitor Console Installation The planter’s standard seed monitor system includes a virtual terminal and switch panel that must be mounted in ® the tractor cab. As supplied by DICKEY-john , the kit includes a flat bracket for the modules, and a ball swivel for mounting the bracket in the tractor. - Page 150 YP2425IR Table of Contents Index Appendix B - Initial Setup Weight Transfer Shipping Links NOTICE When a planter is on customer premises, and further DO NOT MOVE PLANTER FOLDED movements will only be done with a tractor or towing OR UNFOLDED WITHOUT CONNECTING FAN CASE DRAIN AND LOW PRESSURE vehicle having hydraulic motor return and case drain RETURN TO THE TRACTOR OR...

-

Page 151: Appendix C - Option Installation

YP2425IR Table of Contents Index Appendix C - Option Installation 122-278S Scraper Installation Optional carbide disc scrapers are not factory installed. Start with row 1 (left-most row unit). ® If a Keeton seed firmer is also installed, see the Parts Manual for assembly details. - Page 152 YP2425IR Table of Contents Index Appendix R - Row-Pro™ Preparation and Setup Row-Pro™ Setup (Option) The factory default setting for down-force is likely to differ from that required by your next field conditions. Before modifying the monitor setting for down-force, determine what actual down force is ideal for the initial use of the planter.

- Page 153 YP2425IR Table of Contents Index Appendix R - Row-Pro™ Operating Instructions Refer to Figure 145 Row-Pro™ is a factory installed option for implements with 25-series openers that equipped with ® ® DICKEY-john IntelliAg . It helps the spring down force system to maintain a user-determined, ideal weight for the side depth gauge wheels.

- Page 154 YP2425IR Table of Contents Index Appendix R - Row-Pro™ Row-Pro™ Components Refer to Figure 147 and Figure 148 The main systems of Row-Pro™ consist of: 1. An air compressor system: one 12VDC air compressor with air tank , two extension cables , and one fuse assembly 2.

- Page 155 YP2425IR Table of Contents Index Appendix R - Row-Pro™ Row-Pro™ Air Compressor System Row-Pro™ Air Compressor Refer to Figure 149 The 12VDC compressor requires both an electrical connection and a mounting location. It should be mounted in a location on the tractor or planter where most convenient.

- Page 156 YP2425IR Table of Contents Index Appendix R - Row-Pro™ Row-Pro™ Air Pressure Gauge Refer to Figure 152 Row-Pro™ is designed to run at 150 psi. When the psi drops to 135 the compressor engages and builds back up to 150 psi. Duty cycle varies based on air usage. Check for Air Leaks Before going to the field check for air leaks.

- Page 157 YP2425IR Table of Contents Index Appendix R - Row-Pro™ Row-Pro™ Adjustments Refer to Figure 153 Load Cell Reading These readings are displayed and adjusted from the ® IntelliAg seed monitor console. Control Mode: Auto is the normal running mode. Manual is used to control the valves only when the operator touches the increase or decrease icon on the work screen.

- Page 158 YP2425IR Table of Contents Index Appendix R - Row-Pro™ Sensitivity Adjust: Determines how responsive the decreases the reaction time. Going above 0 increases Controller is to input from the DPLCM. The range is from the reaction time. -10 to +10. Zero (0) is the average setting. Going below 0 Disable Down Pressure Modules: Modules interfacing with feedback sensors can be independently disabled so that down pressure to rear and/or front row units are not...

-

Page 159: Row-Pro™ Troubleshooting

YP2425IR Table of Contents Index Appendix R - Row-Pro™ Row-Pro™ Troubleshooting Problem Cause Solution Switch turned “off”. Turn switch “on”. Compressor won’t turn on Poor electrical connection. Clean connections and reassemble. Fuse blown. Replace fuse (60A). Section opener valves are installed in Install opener valves correctly. - Page 160 Great Plains (a division of Great Plains Manufacturing, Inc.) warrants to the original purchaser that this Great Plains unit will be free from defects in material and workmanship for a period of one year from the first use date when used as intended and under normal service and conditions for personal use;...

- Page 161 YP2425IR Cover Table of Contents Index caster lock .......... 30 coulter, frame-mounted ......66 CAUTION, defined ....... 1 coulter, unit-mounted ....67 ABS ............98 center section level ......22 covered models ........12 adding seed ........34 centering, press wheel ....... 83 crusts ..........97 agitation ..........45 CFM ..18 customer service ........13...

- Page 162 YP2425IR Cover Table of Contents gauge wheel scraper ....75 leaks ..........2 gloves ........... 3 leak, air ..........92 electric clutch operation ......40 goggles ..........3 LED, CFM ........25 electric clutch, tank ......49 GPS ........... 45 left vs. right hopper ......36 electrical hookup ........17 ground drive pumps ......

- Page 163 YP2425IR Cover Table of Contents milo ........76 seed meter setup ........76 model number ........13 seed monitor ........122 radar calibration ....... 145 models covered ........12 seed monitor console .......145 rain cover ........... 76 monitor active row pattern ....79 seed pool ..........77 raising a row unit ........

- Page 164 YP2425IR Cover Table of Contents sump return ........42 troubleshooting YP2425A-48TR ........12 sunflower ..........130 Row-Pro ........155 YP2425-2430..126 Swath Command ........17 turbo ..........128 YP2425-3620..126 sway blocks ........17 twin-row ..........81 YP2425-4715..126 switch panel ........145 Type 2 ..........20 YP2425-48TR 126 symbol, safety ........1 Type 3 ..........

- Page 165 YP2425IR Cover Table of Contents 207-199A, Terra-Tine™ ....126 60, option ......... 127 82 bu........34 207-200A, row cleaners ....129 802-024C, bolt ......... 147 820-259C, blade .......128 207-202A, row cleaners ....129 802-130C, shear bolt ....... 106 820-327C, blade .......128 22 kph ..........4 802-172C, bolt .........

- Page 166 Great Plains, Mfg. 1525 E. North St. P.O. Box 5060 Salina, KS 67402...

Need help?

Do you have a question about the Yield-Pro YP2425IR and is the answer not in the manual?

Questions and answers