Table of Contents

Advertisement

Quick Links

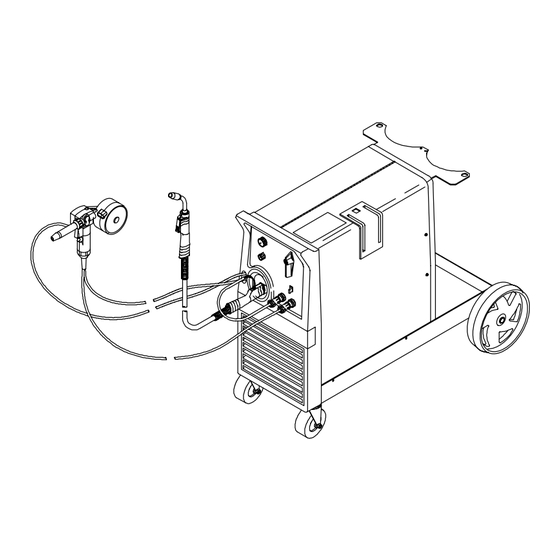

Micro-Pulse 2000

M-15 Gun And Spoolmate

185 Spool Gun

For Warranty Claims And Technical Support, Contact:

Milweld Inc., National Distributor

P.O. Box 338, Hortonville, WI 54944-0338

Tel 920-779-0916 Fax 920-779-0924

Auto Arc

OM-202 487

November 2000

Processes

MIG (GMAW) Welding

Pulsed MIG (GMAW-P)

Flux Cored (FCAW) Welding

Description

Arc Welding Power Source

and Wire Feeder

R

Advertisement

Table of Contents

Troubleshooting

Need help?

Do you have a question about the Auto Arc Micro-Pulse 2000 and is the answer not in the manual?

Questions and answers