Table of Contents

Advertisement

Quick Links

CALL TOLL FREE 877-742-2878 FOR SALES AND SUPPORT

SERVICE & OPERATING MANUAL

Original Instructions

Certified Quality

ISO 9001 Certified

ISO 14001 Certified

Warren Rupp, Inc.

A Unit of IDEX Corporation

800 N. Main St.,

Mansfield, Ohio 44902 USA

Telephone 419.524.8388

Fax 419.522.7867

SANDPIPERPUMP.COM

© Copyright 2022 Warren Rupp, Inc.

All rights reserved

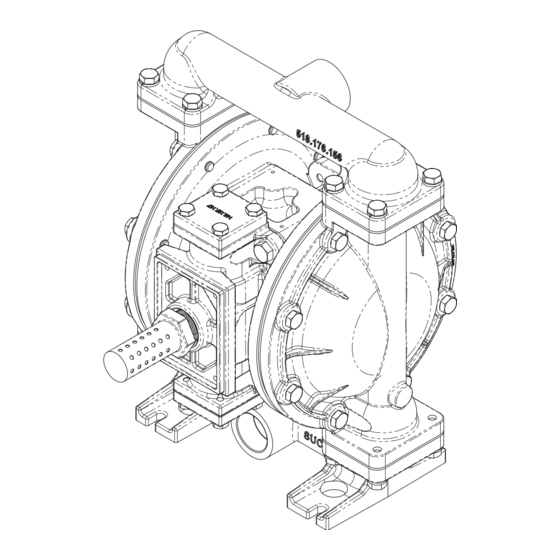

Model U1F

Metallic

Design Level 1

Return to BurtProcess.com

s a n d p i p e r p u m p. c o m

Advertisement

Table of Contents

Summary of Contents for Idex Warren Rupp Sandpiper U1F Metallic

- Page 1 Certified Quality Model U1F Metallic Design Level 1 ISO 9001 Certified ISO 14001 Certified Warren Rupp, Inc. A Unit of IDEX Corporation 800 N. Main St., Mansfield, Ohio 44902 USA Telephone 419.524.8388 Fax 419.522.7867 SANDPIPERPUMP.COM © Copyright 2022 Warren Rupp, Inc.

-

Page 2: Safety Information

Safety Information IMPORTANT WARNING When used for toxic or aggressive fluids, the pump should Read the safety warnings and instructions in this manual always be flushed clean prior to disassembly. before pump installation and start-up. Failure to comply with the recommendations stated in this manual could damage the pump and void factory warranty. - Page 3 Temperature Tables Table 1. Category 1 & Category 2 ATEX Rated Pumps Ambient Temperature Process Temperature Temperature Maximum Surface Tem- Range [°C] Range [°C] Class perature [°C] -20°C to +80°C T100°C -20°C to +108°C T135°C -20°C to +60°C -20°C to + 160°C T200°C -20°C to +177°C (225°C) T2...

-

Page 4: Table Of Contents

Table of Contents SECTION 1: PUMP SPECIFICATIONS ....1 • Explanation of Nomenclature • Performance • Materials • Dimensional Drawings SECTION 2: INSTALLATION & OPERATION ...5 • Principle of Pump Operation • Recommended Installation Guide • Troubleshooting Guide SECTION 3: EXPLODED VIEW ......8 •... -

Page 5: Explanation Of Nomenclature

Explanation of Pump Nomenclature Your Model #: ____ ____ (fill in from pump nameplate) Pump Pump Check Design Wetted Diaphragm/ Check Valve Non-Wetted Porting Pump Pump Brand Size Valve Level Material Check Valve Seat Material Options Style Options Options Model #: Pump Brand Non-Wetted Material Options UL79 Listed... -

Page 6: Performance

Performance S1F METALLIC SUCTION/DISCHARGE PORT SIZE MODEL U1F Metallic Performance Curve • 1" NPT (internal) Performance based on the following: elastomer fitted pump, flooded suction, water at ambient conditions. The use of other materials and varying hydraulic conditions may result in deviations in excess of 5%. •... -

Page 7: Dimensional Drawings

Dimensional Drawings U1F UL79 Listed Metallic Design Level 1 Dimensions in inches (mm dimensions in brackets). Dimensional Tolerance:±1/8" (± 3mm) The dimensions on this drawing are for reference only. A certified drawing can be requested if physical dimensions are needed. DISCHARGE PORT 1”... - Page 8 Dimensional Drawings U1F UL79 Listed Metallic Design Level 1 Dimensions in inches (mm dimensions in brackets). Dimensional Tolerance:±1/8" (± 3mm) The dimensions on this drawing are for reference only. A certified drawing can be requested if physical dimensions are needed. DISCHARGE PORT 1”...

-

Page 9: Principle Of Pump Operation

Principle of Pump Operation Air-Operated Double Diaphragm (AODD) pumps are powered by compressed air or nitrogen. The main directional (air) control valve distributes ① compressed air to an air chamber, exerting uniform pressure over the inner surface of the diaphragm . -

Page 10: Recommended Installation Guide

Recommended Installation Guide Available Accessories: 1. Surge Suppressor Unregulated Air Supply to Surge 2. Filter/Regulator Suppressor 1 Surge Suppressor 3. Air Dryer 4. Lubricator Pressure Gauge Note: Surge Suppressor and Shut-Off Valve Piping, including air line, must be supported after the flexible connections. -

Page 11: Troubleshooting Guide

Troubleshooting Guide Symptom: Potential Cause(s): Recommendation(s): Pump Cycles Once Deadhead (system pressure meets or exceeds air Increase the inlet air pressure to the pump. Pump is designed for 1:1 pressure ratio at zero flow. supply pressure). (Does not apply to high pressure 2:1 units). Air valve or intermediate gaskets installed incorrectly. -

Page 12: Composite Repair Parts Drawing

Composite Repair Parts Drawing Service & Repair Kits Add Kits: AIR END KIT (Available Service Kits:) 476-230-000 Air End Kit Seals, O-Rings, Gaskets, Retaining Rings, Air Valve Assembly and Pilot Valve Assembly 476-213-760 Wetted End Kit Nitrile Diaphragms, Nitrile Check Balls and PTFE Check Valve Seats 476-213-635 Wetted End Kit... -

Page 13: Composite Repair Parts List

Composite Repair Parts List Item Part Number Description 031-183-000 Air Valve Assembly 050-028-760 Ball, Check 050-028-600 Ball, Check 070-012-170 Bushing 095-110-000 Pilot Valve Assembly 114-025-157 Intermediate 132-019-357 Bumper 135-036-506 Bushing 165-120-157 Cap, Air Inlet Assembly 170-044-330 Capscrew, Hex Hd 5/16-18 X 1.00 170-045-330 Capscrew, Hex Hd 5/16-18 X 1.25 170-069-330... -

Page 14: Material Codes

Material Codes - The Last 3 Digits of Part Number 000..Assembly, sub-assembly; 364..EPDM Rubber • Delrin and Hytrel are registered tradenames of E.I. DuPont. and some purchased items Color coded: BLUE 010..Cast Iron 365..Neoprene Rubber • Nylatron is a registered tradename 015..Ductile Iron Color coded: GREEN of Polymer Corp. -

Page 15: Air Distribution Valve Assembly

Air Distribution Valve Assembly ATEX Compliant Air Valve Assembly Parts List Item Part Number Description 031-183-000 Gas Valve Assembly 095-109-157 Valve Body 031-139-000 Sleeve and Spool Set 132-029-357 Bumper 560-020-360 O-Ring 165-127-157 Cap, End 170-032-330 Capscrew IMPORTANT AIR DISTRIBUTION VALVE SERVICING Read these instructions completely, before installation To service the air valve first shut off the compressed air, bleed and start-up. -

Page 16: Pilot Valve Assembly

Pilot Valve Assembly Pilot Valve Assembly Parts List Item Part Number Description 095-110-000 Pilot Valve Assembly 095-095-157 Valve Body 755-052-000 Sleeve (With O-rings) 560-033-360 O-ring (Sleeve) 775-055-000 Spool (With O-rings) 560-023-360 O-ring (Spool) 675-037-080 Retaining Ring For Pumps with Cast Iron Center Section Item Part Number Description... -

Page 17: Diaphragm Service Drawing, With Overlay

Diaphragm Service Drawing, with Overlay Diaphragm Service Drawing, Non-Overlay sandpiperpump Model U1F Metallic • u1fmdl1sm-rev1222... -

Page 18: Diaphragm Servicing

Diaphragm Servicing To service the diaphragms first shut Step #5: Installing the diaphragm off the suction, then shut off the dis- and rod assembly to the pump. charge lines to the pump. Shut off the Make sure the bumper (item 6) is compressed air supply, bleed the installed over the diaphragm rod. - Page 19 ACTUATOR PLUNGER SERVICING ACTUATOR PLUNGER SERVICING To service the actuator plunger first shut off the compressed air supply, bleed the pressure from the pump, and disconnect the air supply line from the pump. Step #1: See PUMP ASSEMBLY DRAWING. Using a 1/2" wrench or socket, remove the four capscrews (items 11).

-

Page 20: Check Valve Drawing

Check Valve Drawing with Metallic Seats with Non-Metallic Seats CHECK VALVE SERVICING Before servicing the check valve components, first shut off the suction line and then the discharge line to the pump. Next, shut off the compressed air supply, bleed air pressure from the pump, and disconnect the air supply line from the pump. - Page 21 CONVERTED EXHAUST ILLUSTRATION PUMP INSTALLATION AREA SAFE AIR EXHAUST DISPOSAL AREA 1" DIAMETER AIR EXHAUST PIPING MUFFLER Illustration #1 MUFFLER 1" DIAMETER AIR LIQUID EXHAUST PIPING LEVEL The pump comes equipped SUCTION with a standard metal muffler LINE Illustration #2 MUFFLER PUMPING HAZARDOUS LIQUIDS When a diaphragm fails, the pumped liquid or fumes...

-

Page 22: Ec Declaration Of Conformity

5 - YEAR Limited Product Warranty Warren Rupp, Inc. (“Warren Rupp”) warrants to the original end-use purchaser that no product sold by Warren Rupp that bears a Warren Rupp brand shall fail under normal use and service due to a defect in material or workmanship within five years from the date of shipment from Warren Rupp’s factory. - Page 23 EC Declaration of Conformity Manufacturer: Warren Rupp, Inc. 800 N. Main Street Mansfi eld, Ohio, 44902 USA Certifi es that Air-Operated Double Diaphragm Pump Models: DSB Series, DMF Series, G Series, HDB Series, HDF Series, HP Series, F Series, MS Series, S Series, SL Series, SP Series, SSB Series, T Series, U1F Series, WR Series; High Pressure Pump Models: EH Series, GH Series, SH Series;...

-

Page 24: Eu Declaration Of Conformity

EU Declaration of Conformity Manufacturer: Warren Rupp, Inc. A Unit of IDEX Corporation 800 North Main Street Mansfi eld, OH 44902 USA This declaration of conformity is issued under the sole responsibility of the manufacturer. Warren Rupp, Inc. declares that Air Oper- ated Double Diaphragm Pumps (AODD) and Surge Suppressors listed below comply with the requirements of Directive 2014/34/EU and applicable harmonized standards. - Page 25 UKEx EU Declaration of Conformity Manufacturer: Warren Rupp, Inc. A Unit of IDEX Corporation 800 North Main Street Mansfi eld, OH 44902 USA This declaration of conformity is issued under the sole responsibility of the manufacturer. Warren Rupp, Inc declares that Air Operated Double Diaphragm Pumps (AODD) and Surge Suppressors listed below comply with the requirements of United Kingdom Statutory Instruments 2016 No.

Need help?

Do you have a question about the Warren Rupp Sandpiper U1F Metallic and is the answer not in the manual?

Questions and answers