Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Troubleshooting

Subscribe to Our Youtube Channel

Summary of Contents for Lincoln Electric 12251

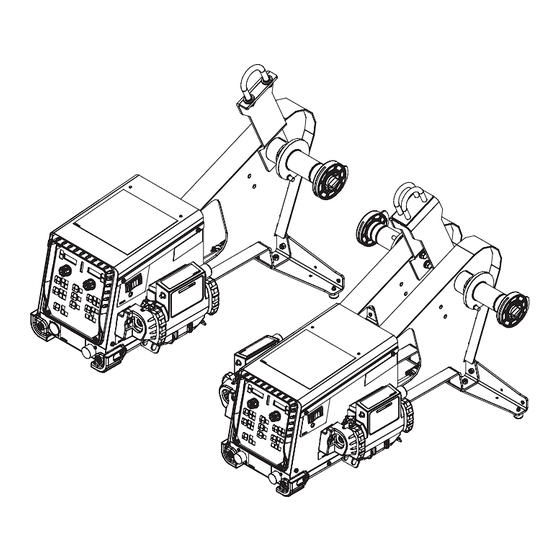

- Page 1 FLEX FEED ™ 84, FLEX FEED ™ 84 DUAL For use with machines having Code Numbers: Flex Feed 84: 12251, 12252, 12253, 12544 Flex Feed 84 Dual: 12259, 12262, 12545 Flex Feed 84 Control Box: 12271 SERVICE MANUAL SVM270 | Issue D ate 16-Oct...

- Page 2 THANK YOU FOR SELECTING A QUALITY PRODUCT BY KEEP YOUR HEAD OUT OF THE FUMES. DON’T get too close to the arc. LINCOLN ELEC TRIC. Use corrective lenses if necessary to stay a reasonable distance away from the arc. READ and obey the Safety Data PLEASE EXAMINE CARTON AND EQUIPMENT FOR Sheet (SDS) and the warning label DAMAGE IMMEDIATELY...

-

Page 3: Section A: Warnings

MAGNETIC FIELDS MAY W117.2-1974. A Free copy of “Arc Welding Safety” booklet BE DANGEROUS E205 is available from the Lincoln Electric Company, 22801 St. Clair Avenue, Cleveland, Ohio 44117-1199. 2.a. Electric current flowing through any conductor BE SURE THAT ALL INSTALLATION, OPERATION, causes localized Electric and Magnetic Fields (EMF). -

Page 4: Electric Shock Can Kill

S FETY ELECTRIC SHOCK ARC RAYS CAN BURN. CAN KILL. 3.a. The electrode and work (or ground) circuits are 4.a. Use a shield with the proper filter and cover plates to protect your electrically “hot” when the welder is on. Do eyes from sparks and the rays of the arc when welding or not touch these “hot”... - Page 5 S FETY WELDING AND CUTTING CYLINDER MAY EXPLODE IF SPARKS CAN CAUSE DAMAGED. FIRE OR EXPLOSION. 7.a. Use only compressed gas cylinders containing the correct shielding gas for the process used 6.a. Remove fire hazards from the welding area. If and properly operating regulators designed for this is not possible, cover them to prevent the welding sparks the gas and pressure used.

-

Page 6: Table Of Contents

LINCOLN ELECTRIC Flex Feed™ 84, Flex Feed™ 84 Dual Service Manual Flex Feed™ 84, Flex Feed™ 84 Dual Service Manual Last update: 2016/10/01 FLEX FEED™ 84, FLEX FEED™ 84 DUAL ...................... 1 Service Manual................................1 Theory of Operation ..............................3 INPUT RECEPTACLE, INPUT RECTIFIER AND USER INTERFACE BOARD ............ - Page 7 LINCOLN ELECTRIC Flex Feed™ 84, Flex Feed™ 84 Dual Service Manual COLD INCH/FEED GAS PURGE SWITCH REMOVAL AND REPLACEMENT PROCEDURE ........ 41 GAS SOLENOID(S) REMOVAL AND REPLACEMENT PROCEDURE .............. 43 WIRE DRIVE MOTOR(S) REMOVAL AND REPLACEMENT PROCEDURE ............45 OPTIONAL OUTPUT CONTACTOR(S) REMOVAL AND REPLACEMENT PROCEDURE ........50 USER INTERFACE BOARD REMOVAL AND REPLACEMENT PROCEDURE ............

-

Page 8: Theory Of Operation

LINCOLN ELECTRIC Flex Feed™ 84, Flex Feed™ 84 Dual Service Manual Theory of Operation Figure E.1 – Input receptacle, input rectifier and user interface board Input Receptacle, Input Rectifier and User Interface Board When a 14-pin Amphenol cable is connected, from a compatible welding power source, to the input receptacle the input receptacle receives (24 –... -

Page 9: Wire Drive Board

LINCOLN ELECTRIC Flex Feed™ 84, Flex Feed™ 84 Dual Service Manual Figure E.2 – Wire drive board Wire Drive Board When the wire drive board receives the procedure and process information from the user interface board the wire drive board sends the appropriate armature voltage to the wire drive motor and energizes the gas solenoid that is being activated by the welding gun (either left or right). -

Page 10: Troubleshooting & Repair

Troubleshooting & Repair HOW TO USE TROUBLESHOOTING GUIDE Service and repair should be performed by only Lincoln Electric Factory Trained Personnel. Unauthorized repairs performed on this equipment may result in danger to the technician and machine operator and will invalidate your factory warranty. For your safety and to avoid Electrical Shock, please observe all safety notes and precautions detailed throughout this manual. -

Page 11: Pc Board Troubleshooting Procedures

ELECTRIC SHOCK can kill. • If you return a PC board to The Lincoln Electric Company for credit, it must be in the static-shielding bag. This will • Have an electrician install and service this prevent further damage and allow proper failure analysis. -

Page 12: Troubleshooting Guide

4. Check the welding gun for loose or broken connections. If for any reason you do not understand the test procedures or are unable to perform the test/repairs safely, contact the Lincoln Electric Service Department for electrical troubleshooting assistance before you proceed. Call 1-888-935-3877. - Page 13 5. Check the pressure on the drive rolls. If for any reason you do not understand the test procedures or are unable to perform the test/repairs safely, contact the Lincoln Electric Service Department for electrical troubleshooting assistance before you proceed. Call 1-888-935-3877.

- Page 14 If for any reason you do not understand the test procedures or are unable to perform the test/repairs safely, contact the Lincoln Electric Service Department for electrical troubleshooting assistance before you proceed. Call 1-888-935-3877.

- Page 15 If for any reason you do not understand the test procedures or are unable to perform the test/repairs safely, contact the Lincoln Electric Service Department for electrical troubleshooting assistance before you proceed. Call 1-888-935-3877.

- Page 16 LINCOLN ELECTRIC Flex Feed™ 84, Flex Feed™ 84 Dual Service Manual PROBLEMS POSSIBLE AREAS OF RECOMMENDED COURSE OF (SYMPTOMS) MISADJUSTMENT(S) ACTION ERROR CODES PASS Clr PASS CODE RESET DIP SWITCH #4 OF WIRE DRIVE 1 1. TURN POWER OFF, SET DIP...

-

Page 17: Motor Overload

LINCOLN ELECTRIC Flex Feed™ 84, Flex Feed™ 84 Dual Service Manual 2. IF TWO SINGLE WIRE DRIVES 2. PLACE BOTH SWITCHES IN THE ARE CONNECTED TO ONE USER “WIRE FEED” AND THEN SELECT INTERFACE AND BOTH HAVE A ONE SWITCH FOR GOUGING. -

Page 18: Test Procedures

If for any reason you do not understand the test procedures or are unable to perform the test/repairs safely, contact the Lincoln Electric Service Department for electrical troubleshooting assistance before you proceed. Call 1-888-935-3877. - Page 19 LINCOLN ELECTRIC Flex Feed™ 84, Flex Feed™ 84 Dual Service Manual Connect plugs J81, J82, J83, J84, J85, J86 and J87 to the wire drive board. See Wiring Diagram. Repeat for each wire drive PC board. Using a 5/16” nutdriver, attach the four screws securing the roof panel to the machine.

- Page 20 LINCOLN ELECTRIC Flex Feed™ 84, Flex Feed™ 84 Dual Service Manual Figure F.2 – Wire drive board plug locations Figure F.3 – Case side panel mounting screw locations...

-

Page 21: Cold Inch/Feed Gas Purge Switch Test Procedure

If for any reason you do not understand the test procedures or are unable to perform the test/repairs safely, contact the Lincoln Electric Service Department for electrical troubleshooting assistance before you proceed. Call 1-888-935-3877. - Page 22 LINCOLN ELECTRIC Flex Feed™ 84, Flex Feed™ 84 Dual Service Manual Figure F.4 – Cold inch/feed gas purge switch locations Figure F.5 – Cold inch/feed gas purge switch lead location...

- Page 23 LINCOLN ELECTRIC Flex Feed™ 84, Flex Feed™ 84 Dual Service Manual Figure F.6 – Cold inch/feed gas purge switch terminal location...

-

Page 24: Gas Solenoid(S) Test Procedure

If for any reason you do not understand the test procedures or are unable to perform the test/repairs safely, contact the Lincoln Electric Service Department for electrical troubleshooting assistance before you proceed. Call 1-888-935-3877. - Page 25 LINCOLN ELECTRIC Flex Feed™ 84, Flex Feed™ 84 Dual Service Manual Figure F.7 – Gas solenoid locations Figure F.8 – Gas solenoid lead locations...

-

Page 26: Wire Drive Motor(S) And Tach Feedback Test Procedure

If for any reason you do not understand the test procedures or are unable to perform the test/repairs safely, contact the Lincoln Electric Service Department for electrical troubleshooting assistance before you proceed. Call 1-888-935-3877. - Page 27 LINCOLN ELECTRIC Flex Feed™ 84, Flex Feed™ 84 Dual Service Manual 10. If the armature voltage is not present (step 5) and the motor operates normally when an isolated power source is applied, the wire drive board may be faulty.

- Page 28 LINCOLN ELECTRIC Flex Feed™ 84, Flex Feed™ 84 Dual Service Manual Figure F.10 – 14-pin connection cable pin locations Figure F.11 – Tach lead locations...

-

Page 29: Optional Output Contactor(S) Test Procedure

If for any reason you do not understand the test procedures or are unable to perform the test/repairs safely, contact the Lincoln Electric Service Department for electrical troubleshooting assistance before you proceed. Call 1-888-935-3877. - Page 30 LINCOLN ELECTRIC Flex Feed™ 84, Flex Feed™ 84 Dual Service Manual 15. Perform the Case Cover Replacement Procedure. Figure F.12 – Contactor location Figure F.13 – Red and black contactor lead locations...

-

Page 31: User Interface Board Test Procedure

If for any reason you do not understand the test procedures or are unable to perform the test/repairs safely, contact the Lincoln Electric Service Department for electrical troubleshooting assistance before you proceed. Call 1-888-935-3877. - Page 32 LINCOLN ELECTRIC Flex Feed™ 84, Flex Feed™ 84 Dual Service Manual Figure F.14 – Front panel mounting screws and user interface board location Figure F.15 – User interface board plug and lead locations...

-

Page 33: Wire Drive Board Test Procedure

If for any reason you do not understand the test procedures or are unable to perform the test/repairs safely, contact the Lincoln Electric Service Department for electrical troubleshooting assistance before you proceed. Call 1-888-935-3877. - Page 34 LINCOLN ELECTRIC Flex Feed™ 84, Flex Feed™ 84 Dual Service Manual Table F.1 – Wire drive board voltage tests LEAD EXPECTED DESCRIPTION TEST POINTS CONDITIONS NUMBERS READING J82 PIN 4 (+) TO CORRECT INPUT VOLTAGE INPUT POWER 34 – 69 VDC J82 PIN 3 (-) APPLIED TO MACHINE.

-

Page 35: Motor Power

LINCOLN ELECTRIC Flex Feed™ 84, Flex Feed™ 84 Dual Service Manual TRANSDUCER POWER J85 PIN 14 (-) APPLIED TO MACHINE. RIGHT SIDE TACH J83 PIN 9 (+) TO CORRECT INPUT VOLTAGE +5 VDC INPUT POWER J83 PIN 12 (-) APPLIED TO MACHINE. - Page 36 LINCOLN ELECTRIC Flex Feed™ 84, Flex Feed™ 84 Dual Service Manual Figure F.16 – Wire drive board location Figure F.17 – Wire drive board plug and LED locations...

- Page 37 LINCOLN ELECTRIC Flex Feed™ 84, Flex Feed™ 84 Dual Service Manual Figure F.18 – Wire drive board lead locations...

-

Page 38: Fan Motor Test Procedure

If for any reason you do not understand the test procedures or are unable to perform the test/repairs safely, contact the Lincoln Electric Service Department for electrical troubleshooting assistance before you proceed. Call 1-888-935-3877. - Page 39 LINCOLN ELECTRIC Flex Feed™ 84, Flex Feed™ 84 Dual Service Manual Figure F.19 – Front panel mounting screws location...

-

Page 40: Current Transducer(S) Test Procedure

If for any reason you do not understand the test procedures or are unable to perform the test/repairs safely, contact the Lincoln Electric Service Department for electrical troubleshooting assistance before you proceed. Call 1-888-935-3877. - Page 41 LINCOLN ELECTRIC Flex Feed™ 84, Flex Feed™ 84 Dual Service Manual Table F.2 – DC supply voltages from wire drive board (right side) EXPECTED DESCRIPTION TEST POINT (POS) TEST POINT (NEG) READING POSITIVE VOLTAGE SUPPLY PLUG J85 PIN 4 (LEAD 805)

- Page 42 LINCOLN ELECTRIC Flex Feed™ 84, Flex Feed™ 84 Dual Service Manual Figure F.20 – Current transducer location Figure F.21 – Wire drive board plug and lead locations...

-

Page 43: Input Rectifier Test Procedure

If for any reason you do not understand the test procedures or are unable to perform the test/repairs safely, contact the Lincoln Electric Service Department for electrical troubleshooting assistance before you proceed. Call 1-888-935-3877. - Page 44 LINCOLN ELECTRIC Flex Feed™ 84, Flex Feed™ 84 Dual Service Manual Table F.6 - Input rectifier forward voltage drop tests TEST POINT (POS) TEST POINT (NEG) EXPECTED READING TOP AC TERMINAL POSITIVE TERMINAL 0.2 VDC – 0.7 VDC BOTTOM AC TERMINAL POSITIVE TERMINAL 0.2 VDC –...

- Page 45 LINCOLN ELECTRIC Flex Feed™ 84, Flex Feed™ 84 Dual Service Manual Figure F.23 – Input rectifier location Figure F.24 – Input rectifier lead and terminal locations...

-

Page 46: Removal And Replacement Procedures

If for any reason you do not understand the test procedures or are unable to perform the test/repairs safely, contact the Lincoln Electric Service Department for electrical troubleshooting assistance before you proceed. Call 1-888-935-3877. - Page 47 LINCOLN ELECTRIC Flex Feed™ 84, Flex Feed™ 84 Dual Service Manual Figure F.25 – Cold inch/feed gas purge switch lead locations Figure F.26 – Cold inch/feed gas purge side tab locations...

-

Page 48: Gas Solenoid(S) Removal And Replacement Procedure

If for any reason you do not understand the test procedures or are unable to perform the test/repairs safely, contact the Lincoln Electric Service Department for electrical troubleshooting assistance before you proceed. Call 1-888-935-3877. - Page 49 LINCOLN ELECTRIC Flex Feed™ 84, Flex Feed™ 84 Dual Service Manual Figure F.27 – Gas solenoid(s) lead locations Figure F.28 – Gas solenoid flat washer and mounting nut locations...

-

Page 50: Wire Drive Motor(S) Removal And Replacement Procedure

If for any reason you do not understand the test procedures or are unable to perform the test/repairs safely, contact the Lincoln Electric Service Department for electrical troubleshooting assistance before you proceed. Call 1-888-935-3877. - Page 51 LINCOLN ELECTRIC Flex Feed™ 84, Flex Feed™ 84 Dual Service Manual Using a 5/16” nutdriver, remove the two screws securing the motor top support to the machine. Figure F.33. Carefully maneuver the motor top support to allow access to the wire drive motors.

- Page 52 LINCOLN ELECTRIC Flex Feed™ 84, Flex Feed™ 84 Dual Service Manual Figure F.29 – Gun adaptor mounting screw location Figure F.30 – Electrode lead and gas hose mounting hardware locations...

- Page 53 LINCOLN ELECTRIC Flex Feed™ 84, Flex Feed™ 84 Dual Service Manual Figure F.31 – Sense lead mounting screw location Figure F.32 – Feedplate and drive gear mounting screw locations...

- Page 54 LINCOLN ELECTRIC Flex Feed™ 84, Flex Feed™ 84 Dual Service Manual Figure F.33 – Motor top and bottom support mounting screw locations...

-

Page 55: Optional Output Contactor(S) Removal And Replacement Procedure

If for any reason you do not understand the test procedures or are unable to perform the test/repairs safely, contact the Lincoln Electric Service Department for electrical troubleshooting assistance before you proceed. Call 1-888-935-3877. - Page 56 LINCOLN ELECTRIC Flex Feed™ 84, Flex Feed™ 84 Dual Service Manual 14. Using a 5/16” nutdriver, remove the two bolts and washers securing each contactor to the rear panel while holding the square nut in place. See Figure F.37. 15. Using a 5/16” nutdriver, remove the four screws securing the motor bottom support to the machine.

- Page 57 LINCOLN ELECTRIC Flex Feed™ 84, Flex Feed™ 84 Dual Service Manual Figure F.34 – Motor top and bottom support mounting screw locations Figure F.35 – Bus bar and contactor mounting bolt and nut locations...

- Page 58 LINCOLN ELECTRIC Flex Feed™ 84, Flex Feed™ 84 Dual Service Manual Figure F.36 – Contactor red and black lead locations Figure F.37 – Contactor mounting screw locations...

-

Page 59: User Interface Board Removal And Replacement Procedure

If for any reason you do not understand the test procedures or are unable to perform the test/repairs safely, contact the Lincoln Electric Service Department for electrical troubleshooting assistance before you proceed. Call 1-888-935-3877. - Page 60 LINCOLN ELECTRIC Flex Feed™ 84, Flex Feed™ 84 Dual Service Manual Figure F.38 – Front panel mounting screw locations Figure F.39 – User interface board plug locations...

- Page 61 LINCOLN ELECTRIC Flex Feed™ 84, Flex Feed™ 84 Dual Service Manual Figure F.40 – Front panel, knob, felt washer and mounting screw locations...

-

Page 62: Wire Drive Board Removal And Replacement Procedure

If for any reason you do not understand the test procedures or are unable to perform the test/repairs safely, contact the Lincoln Electric Service Department for electrical troubleshooting assistance before you proceed. Call 1-888-935-3877. - Page 63 LINCOLN ELECTRIC Flex Feed™ 84, Flex Feed™ 84 Dual Service Manual Figure F.41 – Wire drive board plug locations Figure F.42 – Wire drive board mounting nut locations...

-

Page 64: Fan Assembly Removal And Replacement Procedure

If for any reason you do not understand the test procedures or are unable to perform the test/repairs safely, contact the Lincoln Electric Service Department for electrical troubleshooting assistance before you proceed. Call 1-888-935-3877. - Page 65 LINCOLN ELECTRIC Flex Feed™ 84, Flex Feed™ 84 Dual Service Manual Figure F.43 – Front panel mounting screw locations Figure F.44 – Fan mounting screw and panel hole locations...

-

Page 66: Current Transducer(S) Removal And Replacement Procedure

If for any reason you do not understand the test procedures or are unable to perform the test/repairs safely, contact the Lincoln Electric Service Department for electrical troubleshooting assistance before you proceed. Call 1-888-935-3877. - Page 67 LINCOLN ELECTRIC Flex Feed™ 84, Flex Feed™ 84 Dual Service Manual REPLACEMENT PROCEDURE 1. Carefully slide the new current transducer(s) onto the bus bar. 2. Using a 1/4” nutdriver, attach the screw, lock washer and flat washer securing each current transducer to the bus bar.

- Page 68 LINCOLN ELECTRIC Flex Feed™ 84, Flex Feed™ 84 Dual Service Manual Figure F.46 – Bus bar mounting nut locations Figure F.47 – Current transducer mounting screw locations...

-

Page 69: Input Rectifier Removal And Replacement Procedure

If for any reason you do not understand the test procedures or are unable to perform the test/repairs safely, contact the Lincoln Electric Service Department for electrical troubleshooting assistance before you proceed. Call 1-888-935-3877. - Page 70 LINCOLN ELECTRIC Flex Feed™ 84, Flex Feed™ 84 Dual Service Manual Figure F.48 – Front panel mounting screw locations Figure F.49 – Input rectifier lead locations...

- Page 71 LINCOLN ELECTRIC Flex Feed™ 84, Flex Feed™ 84 Dual Service Manual Figure F.50 – Input rectifier mounting nut and washer location...

-

Page 72: Retest After Repair

LINCOLN ELECTRIC Flex Feed™ 84, Flex Feed™ 84 Dual Service Manual RETEST AFTER REPAIR Retest a machine: • If it is rejected under test for any reason that requires you to remove any part which could affect the machine’s electrical characteristics.

Need help?

Do you have a question about the 12251 and is the answer not in the manual?

Questions and answers