Advertisement

P77 Series Controls for Low Pressure Applications

Installation Guide

P77AAA, P77BCA

Applications

P77 Series Controls for Low Pressure Applications provide low pressure control of compressors on commercial

refrigeration and air-conditioning applications.

IMPORTANT:

Use this P77 Series Control only as an operating control. Where failure or malfunction of the control

could lead to personal injury or property damage to the controlled equipment or other property, additional precautions

must be designed into the control system. Incorporate and maintain other devices, such as supervisory or alarm

systems or safety or limit controls, intended to warn of or protect against failure or malfunction of the control.

IMPORTANT : Utiliser P77 Series Control uniquement en tant que dispositif de contrôle de fonctionnement.

Lorsqu'une défaillance ou un dysfonctionnement du contrôle risque de provoquer des blessures ou d'endommager

l'équipement contrôlé ou un autre équipement, la conception du système de contrôle doit intégrer des dispositifs de

protection supplémentaires. Veiller dans ce cas à intégrer de façon permanente d'autres dispositifs, tels que des

systèmes de supervision ou d'alarme, ou des dispositifs de sécurité ou de limitation, ayant une fonction

d'avertissement ou de protection en cas de défaillance ou de dysfonctionnement du contrôle.

P77 control models are typically used for low pressure Cut-out applications and pump-down control. Single-Pole,

Double-Throw (SPDT) switches allow you to install alarm devices or other control circuits. Automatic Reset

P77AAA Type models can also be wired for low-pressure Cut-in operation.

These controls are available in several pressure ranges and are compatible with most common refrigerants. They

may also be used on air, water, and other non-corrosive fluid applications.

Low-pressure P77BCA Type models with Manual Reset Lockout lock out when the Cut-out pressure is reached

and do not automatically reset when the pressure rises after Cut-out, providing shutdown capability for

unmonitored equipment. See Manual Reset Operation.

IP54 enclosures are standard on most models.

P77 Series Controls for Low Pressure Applications Installation Guide

Part No. 24-7664-3167, Rev. C

Release Issued September 2024

1

Advertisement

Table of Contents

Summary of Contents for Penn P77BCA

- Page 1 Low-pressure P77BCA Type models with Manual Reset Lockout lock out when the Cut-out pressure is reached and do not automatically reset when the pressure rises after Cut-out, providing shutdown capability for unmonitored equipment.

-

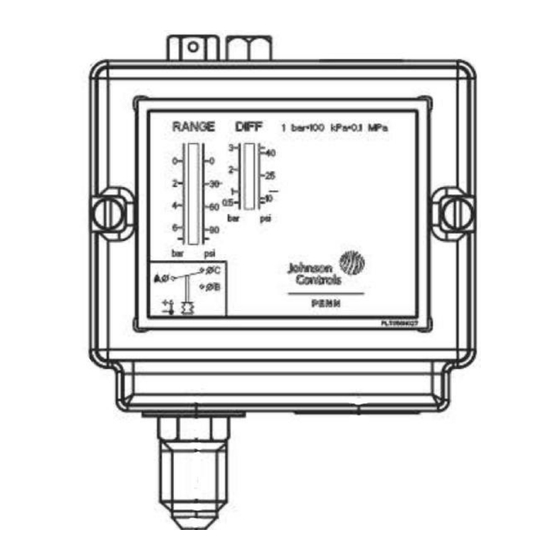

Page 2: Installation

Installation Dimensions See Figure 1 for control dimensions. These dimensions are nominal and subject to accepted manufacturing tolerances and application variables. Figure 1: Dimensions of P77 Low Pressure Control with IP54 Enclosure, in. (mm) Style 5 Connection Style 45 Connection Mounting Risk of Property Damage. - Page 3 Vertical Surface: Use four M4 x 6 mm + d screws (1) through the inner holes (2) on the back of the control case when mounting directly to a flat vertical surface (3). The screws cannot be longer than 6 mm + d (where d refers to thickness of mounting surface).

-

Page 4: Refrigerant Connections

IMPORTANT: Use terminal screws furnished in the switch block. Using other terminal screws will void the warranty and may damage the switch. P77 controls for low pressure applications are available with a Single-Pole, Double-Throw (SPDT) switch. Check the label inside the control cover for the model number, switch action, and electrical rating. Check the wiring terminal designations on the control switch block, and see the following wiring diagram when wiring the control. -

Page 5: Setup And Adjustments

Risk of Environmental and Property Damage. Coil and secure excess capillary tubing away from contact with sharp or abrasive objects or surfaces. Vibration or sharp or abrasive objects in contact with capillary tubes can cause damage that may result in refrigerant leaks, which may result in damage to the environment or property. - Page 6 IMPORTANT: Use the pressure control settings recommended by the manufacturer of the controlled equipment. Do not exceed the pressure ratings of the controlled equipment or any of its components when checking pressure control operation or operating the controlled equipment. IMPORTANT: After mounting, wiring, and evacuating the control, attach a reliable set of gauges to the controlled equipment, and operate the equipment (at least) three cycles at the pressures necessary to verify control setpoints and proper equipment operation.

-

Page 7: Technical Specifications

Table 3: Adjusting P77 Low Pressure Controls Callout Description Range and Differential Scales Range Screw Differential Screw Range Scale (only) Reset Button Pressure Connection Adjustment Lock Plate (if applied) Checkout Procedure for P77 Low Pressure Controls IMPORTANT: Use the pressure control settings recommended by the manufacturer of the controlled equipment. - Page 8 UNITED KINGDOM www.penncontrols.com ® Johnson Controls and Penn are registered trademarks of Johnson Controls in the United States of America and/or other countries. All other trademarks used herein are the property of their respective owners. © Copyright 2024 by Johnson Controls. All rights reserved.

Need help?

Do you have a question about the P77BCA and is the answer not in the manual?

Questions and answers