Table of Contents

Advertisement

Quick Links

Safety Precautions

[1] Product Outline

1. Features .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

2. S pecification .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

3. Names of Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

[2] Technology

1. Basic Configuratio . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

2. Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

[3] Maintenance

1. Maintenance List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

[4] Disassembly and assembly

1. Removing this Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

2. List of Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

3. Main Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-9

4. Periodic Parts Replacement, Consumable Parts, and Cleaning Parts . . . . . . . 4-11

5. Solenoids .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-16

6. Motors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-20

7. Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-24

8. PCBs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-27

[5] Actual wiring chart

1. Actual wiring chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Parts marked with "

" are important for maintaining the safety of the set. Be sure to replace these parts with

specified ones for maintaining the safety and performance of the set.

SERVICE MANUAL

DIGITAL FULL COLOR

MULTIFUNCTIONAL SYSTEM OPTION

INNER TRIMMER

MODEL

CONTENTS

SHARP CORPORATION

CODE: 00ZMXTM10/S2E

MX-TM10

This document has been published to be used

for after sales service only.

The contents are subject to change without notice.

Advertisement

Table of Contents

Summary of Contents for Sharp MX-TM10

- Page 1 SERVICE MANUAL CODE: 00ZMXTM10/S2E DIGITAL FULL COLOR MULTIFUNCTIONAL SYSTEM OPTION INNER TRIMMER MX-TM10 MODEL CONTENTS Safety Precautions [1] Product Outline 1. Features ............1-2 2.

- Page 2 Explanation of Symbols The following rules apply throughout this Service Manual: The following symbols are used throughout this Service Manual. Each chapter contains sections explaining the purpose of specific functions and the relationship between electrical and mechanical systems with reference to the timing of Symbols Explanation Symbols Explanation operation. In the diagrams, represents the path of mechanical drive; where a signal name Check.

- Page 3 Signal list Signal Name (Written in this Signal Name Parts Name Function / Operation manual) M101 FTM101 Motor Feed motor M102 FTM102 Motor Registration motor M103 FTM103 Motor Front estrangement motor M104 FTM104 Motor Rear estrangement motor M105 FTM105 Motor Press ...

-

Page 4: Table Of Contents

Contents Disassembly and assembly 4-1 Removing this Equipment - --------------------------------------------------4-2 List of Parts ---------------------------------------------------------------------4-7 Solenoids ---------------------------------------------------------------------------- 4-7 Safety Precautions Motors -------------------------------------------------------------------------------- 4-7 Sensors - ------------------------------------------------------------------------------ 4-8 Notes Before it Works Serving - --------------------------------------------0-2 PCBs ---------------------------------------------------------------------------------- 4-8 Main Units - ----------------------------------------------------------------------4-9 Product Outline Removing ... -

Page 5: Safety Precautions

Safety Precautions ■ Notes Before it Works Serving ... -

Page 6: Notes Before It Works Serving

Notes Before it Works Serving Caution: Caution: When servicing, be sure to follow the specified procedure. Before starting the service Never insert your finge into the cutter unit. work, be sure to turn off the host machine and finishe and unplug the finishe . Caution: Never turn off the host machine or finisher during downloading. If you do so, this equipment may become inoperative. Caution: When removing the cutter unit alone and putting it on a floo , be sure to put the cutter ... -

Page 7: Product Outline

Product Outline ■ Features ■ Specification ■ Names of Parts Product Outline... -

Page 8: High-Quality Trimming

Product Outline > Features > Compact Design Features High-quality Trimming Enables high-quality trimming of the fore edge of a booklet. Compact Design Installable in the finishe , requiring a small room. Product Outline > Features > Compact Design... -

Page 9: Specification

Product Outline > Specification : ‘17/Mar. Specification Paper size/type/weight for inserter and Trimming module Trimming Name MX-TM10 Trimming method Fore-edge trimming by reciprocating the upper blade Paper weight (Min) 60g/m Trimming mode Fore-edge trimming (only in one direction) Paper weight (Max) 300g/m Trim ... - Page 10 Product Outline > Specification Trimming Paper Size A4R Z-fold 210 x 148 A4R Booklet 210 x 148 A4R 3-fold/4-fold 210 x 99/74 257 x 182 182 x 257 210 x 148 148 x 210 SRA3 320 x 450 SRA4 320 x 225 Kiku ...

-

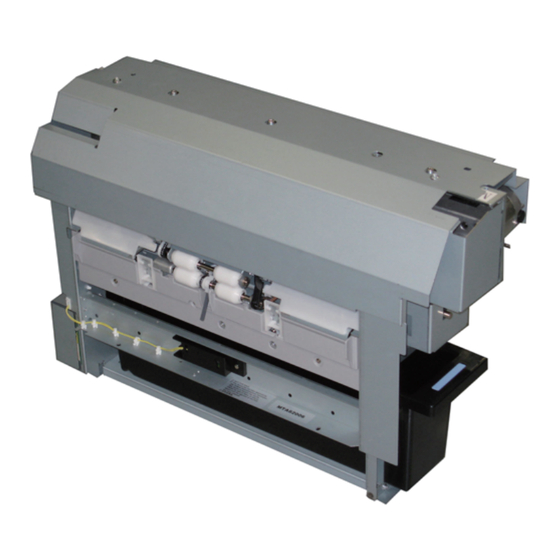

Page 11: Names Of Parts

Product Outline > Names of Parts > External View (Cutter Unit) Names of Parts External View (Cutter Unit) External View (Trimmer Unit Frame and Cutter Unit) Cutter unit Inlet guide Trimming blade Cutter motor Waste paper full sensor (light-emitting) Cutter motor clock sensor Handle Lower blade Paper delivery roller... -

Page 12: Cross Section

Product Outline > Names of Parts > Cross Section Cross Section Trimming blade Inlet roller (upper) Press roller (upper) Inlet sensor flag Paper delivery roller (upper) Paper delivery roller (lower) Inlet roller (lower) Lower blade Paddle Press roller (lower) Waste paper full sensor Waste paper full sensor (light-emitting) (light- receiving) -

Page 13: Technology

Technology ■Basic Configuratio Technology... -

Page 14: Functional Configuratio

Technology > Basic Configuratio > Functional Configuratio Basic Configuratio 2. Trimming block Functional Configuratio This equipment is mainly consists of a feed block, trimming block, paper delivery block, and waste paper stack block. 1. Feed block Feed block Receives the booklet stitched by the saddle stitcher, and then delivers it to 3. Paper delivery block the next block. T r i m m i n g Trims ... -

Page 15: Overview Of Electrical Circuitry

Technology > Basic Configuratio > Component Configuratio > Roller Layout Overview of Electrical Circuitry Component Configuratio ■ Roller Layout The operation sequence of this machine is controlled by the trimmer controller PCB. Trimmer controller PCB Motors Saddle stitcher Solenoids controller PCB Sensors... -

Page 16: Drive Configuratio

Technology > Basic Configuratio > Drive Configuratio Drive Configuratio ■ Sensor Layout Only the optical sensors on the feed path are shown below. M101 M104 M105 M106 S101 S103 Inlet sensor Paper delivery sensor M103 SL102 SL101 M102 F-2-4 F-2-5 M101: ... -

Page 17: Basic Operation Outline

Technology > Basic Configuratio > Basic Operation Outline Basic Operation Outline This equipment trims the fore edge of the stitched booklet, and then delivers the booklet to the saddle delivery tray. This equipment is optionally available and installed in the feed path inside the saddle finishe . When the booklet stitched by the saddle stitcher is fed to this equipment, registration is performed to be prepared for trimming. After this, the booklet is trimmed with it held down by press rollers and then delivered to the saddle delivery tray. These operations are controlled by the trimmer controller PCB. F-2-6 Technology ... -

Page 18: Controls

Technology > Controls > Overview Controls Sensor Function Reference Waste paper full sensor (light- Detects when waste paper is full 4-24 emitting/S011(PCB2)) Overview IWaste paper full sensor 4-25 (light- receiving/S011(PCB3)) This unit is installed between the saddle unit and saddle delivery tray of the saddle finishe . It stops the center bound booklet for a moment to trim the fore edge. Cutter motor clock The booklet loaded from the saddle unit is fed by the inlet roller. When the leading edge of ... -

Page 19: Construction Of The Control System

Technology > Controls > Construction of the Control System Construction of the Control System The booklet is fed by the inlet roller, press roller, and paper delivery roller. Cutter unit Each roller is driven by the feed motor (M101). The feed block is equipped with inlet rollers and the lower inlet roller is separated by the front estrangement motor (M103) in order to prepare for feeding of the center bound booklet. The ... -

Page 20: Registration Operation

Technology > Controls > Registration operation Registration operation Registration motor (M102) The sequence of registration operation is described below. 1. Drive the front estrangement motor (M103) before the center bound booklet is fed from the saddle unit to separate the inlet roller (lower). 2. Drive the feed motor (M101) when the booklet passed from the saddle unit reaches the ... -

Page 21: Trimming Operation

Technology > Controls > Trimming operation Trimming operation The sequence of trimming operation is described below. 1. After registration completes, drive the press motor (M105) and press the booklet with the press roller. If the booklet is larger than A3, drive the rear estrangement motor and press the booklet with the paper delivery roller before pressing with the press roller because air must be released from the leading edge of the booklet (back of the booklet). 2. After pressing the booklet with the press roller, drive the registration motor (M102) and ... -

Page 22: Servicing Work

Technology > Controls > Servicing Work > Scheduled Servicing 2-10 : ‘17/Mar. Servicing Work ■ Scheduled Servicing When the endurance time of a part expires soon, replace and/or clean it as required. Item Part name Expected Operation Reference service life Periodically None replaced parts Consumable Scratch prevention sheet 120,000 1piece Replacement 4-11 parts (front ... -

Page 23: Maintenance

Maintenance ■Maintenance List Maintenance... - Page 24 Maintenance > Maintenance List : ‘17/Mar. Maintenance List 5: Check (Clean, replace, or adjust according to necessity.) ¡: Clean p: Replace r: Adjust I: Lubricate Part name When calling When maintenance of the machine Remarks Paddle solenoid Replace at 120K bundles. Discharge needle Replace at 120K bundles.

-

Page 25: Disassembly And Assembly

Disassembly and assembly ■ Removing this Equipment ■ List of Parts ■ Main Units F-4-1 ■ P e r i o d i c P a r t s R e p l a c e m e n t , Consumable Parts, and ... - Page 26 Disassembly and assembly > Removing this Equipment Removing this Equipment 1) Open the finishe front door. 2) Remove the resin ring. F-4-2 F-4-3 3) Remove the finishe front door in the direction of the arrow. 4) Remove the jam dial (top). Remove 1 screw and remove the jam dial (bottom). F-4-5 F-4-4 Disassembly ...

- Page 27 Disassembly and assembly > Removing this Equipment 6) Pull out the saddle unit. 7) Remove 5 screws and remove the top cover. 5) Remove 3 screws and remove the inner cover. F-4-7 F-4-8 F-4-6 8) Remove 1 screw and remove the steel plate. Remove 1 bearing and 2 resin rings. Remove the steel plate and remove the drive belt. ...

- Page 28 Disassembly and assembly > Removing this Equipment 9) Pull out the saddle unit fully while pushing the stopper on both sides of the accuride rail in the direction of the arrow. F-4-10 10) Remove 2 connectors and remove cable from 3 locations of the wire saddle. F-4-11 Disassembly ...

- Page 29 Disassembly and assembly > Removing this Equipment 11) Remove cable from 3 locations of the wire saddle and remove 1 connector. F-4-12 12) Remove 1 connector and secure the cable to the cable guide. 13) Remove the cutter unit from the trimmer unit frame. MEMO: Hold ...

- Page 30 Disassembly and assembly > Removing this Equipment 14) Remove 2 screws. 15) Remove the trimmer unit frame from the finishe . MEMO: Hold the trimmer unit frame at the locations shown below. F-4-15 F-4-16 F-4-17 Disassembly and assembly > Removing this Equipment...

-

Page 31: Solenoids

Disassembly and assembly > List of Parts > Motors List of Parts Motors Solenoids M101 M105 M103 M102 M104 SL102 M106 SL101 F-4-19 Part name Reference F-4-18 M101 Feed motor 4-21 M102 Registration motor 4-20 M103 Front estrangement motor 4-22 Part ... -

Page 32: Sensors

Disassembly and assembly > List of Parts > PCBs Sensors PCBs S108 S104 S103 S105 S106 S109 PCB3 S101 PCB2 PCB1 S102 F-4-20 F-4-21 Part name Reference Part name Reference S101 Inlet sensor PCB1 Trimmer controller PCB 4-27 S102 Front estrangement motor HP sensor S103 Paper ... -

Page 33: Main Units

Disassembly and assembly > Main Units > Removing the cutter unit Main Units Removing the cutter unit 3) Remove 3 screws and remove the inner cover. 1) Remove the finishe front door. 2) Remove the jam dial (top). Remove 1 screw and remove the jam dial (bottom). F-4-22 F-4-23 4) ... - Page 34 Disassembly and assembly > Main Units > Removing the cutter unit 4-10 6) Remove the cable from 3 locations of the wire saddle and remove 1 connector. F-4-26 7) Remove 1 connector and secure the cable to the cable guide. 8) ...

-

Page 35: Periodic Parts Replacement, Consumable Parts, And Cleaning Parts

Disassembly and assembly > Periodic Parts Replacement, Consumable Parts, and Cleaning Parts > Removing the scratch prevention sheet (front top) 4-11 Periodic Parts Replacement, Consumable Parts, and Cleaning Parts Removing the scratch prevention sheet (front top) 1) Remove the trimmer unit from the finishe . 2) ... -

Page 36: Removing The Scratch Prevention Sheet (Front Bottom)

Disassembly and assembly > Periodic Parts Replacement, Consumable Parts, and Cleaning Parts > Removing the scratch prevention sheet (rear bottom) 4-12 Removing the scratch prevention sheet (front bottom) 1) Remove the trimmer unit from the finishe . 2) Remove 1 screw and remove the scratch prevention sheet (front bottom). ... -

Page 37: Removing The Scratch Prevention Sheet (Rear)

Disassembly and assembly > Periodic Parts Replacement, Consumable Parts, and Cleaning Parts > Removing the scratch prevention sheet (rear) 4-13 Removing the scratch prevention sheet (rear) 1) Remove the trimmer unit from the finishe . 2) Remove 3 screws at the front side, and 3 screws at the rear side. F-4-32 3) ... - Page 38 Disassembly and assembly > Periodic Parts Replacement, Consumable Parts, and Cleaning Parts > Removing the scratch prevention sheet (rear) 4-14 5) Remove 2 E rings, 1 resin flange 2 pulleys, 2 parallel pins, 1 belt, and 1 bearing from the rear side. Remove 1 E ring and 1 bearing from the front side. 6) ...

- Page 39 Disassembly and assembly > Periodic Parts Replacement, Consumable Parts, and Cleaning Parts > Removing the scratch prevention sheet (rear) 4-15 8) Remove E ring, pulley, parallel pin, and bearing at the front side. 9) Remove E ring and bearing at the rear side. Remove the belt and roller unit, and remove the scratch prevention sheet (rear). F-4-38 Note: When installing the paper ...

-

Page 40: Solenoids

Disassembly and assembly > Solenoids > Removing the paddle solenoid (SL102) 4-16 Solenoids Removing the paddle solenoid (SL102) 1)Remove the trimmer unit from the 3) Remove 2 far side connectors and remove 2 screws. Remove 3 front side screws and pull out 3 pins. finishe . - Page 41 Disassembly and assembly > Solenoids > Removing the paddle solenoid (SL102) 4-17 6) Remove 2 screws and remove the paddle solenoid together with the mount. F-4-42 4-17 Disassembly and assembly > Solenoids > Removing the paddle solenoid (SL102)

-

Page 42: Removing The Stopper Solenoid (Sl101)

Disassembly and assembly > Solenoids > Removing the stopper solenoid (SL101) 4-18 Removing the stopper solenoid (SL101) 1)Remove the trimmer unit from the finishe . 3) Remove 2 far side connectors and remove 2 screws. Remove 3 front side screws and pull out 3 pins. 2)Remove ... - Page 43 Disassembly and assembly > Solenoids > Removing the stopper solenoid (SL101) 4-19 6) Remove the connector and 2 screws, and remove the stopper solenoid together with the mount. F-4-46 4-19 Disassembly and assembly > Solenoids > Removing the stopper solenoid (SL101)

-

Page 44: Motors

Disassembly and assembly > Motors > Removing the registration motor (M102) 4-20 Motors Removing the registration motor (M102) 3) Remove 2 far side connectors and remove 2 screws. Remove 3 front side screws and pull out 3 pins. 1) Remove the trimmer unit from the ... -

Page 45: Removing The Feed Motor (M101)

Disassembly and assembly > Motors > Removing the press motor (M105) 4-21 Removing the feed motor (M101) 1)Separate the finishe from the host machine. 3)Remove 1 connector, 2 screws, and remove the feed motor. 2)Remove the cutter unit. F-4-50 Removing ... -

Page 46: Removing The Rear Estrangement Motor (M104)

Disassembly and assembly > Motors > Removing the front estrangement motor (M103) 4-22 Removing the rear estrangement motor (M104) 1)Separate the finishe from the host machine. 3)Remove 1 connector, 2 screws, and remove the rear estrangement motor. 2)Remove the cutter unit. F-4-52 Removing ... - Page 47 Disassembly and assembly > Motors > Removing the front estrangement motor (M103) 4-23 3)Pull out the saddle unit fully while pushing the stopper on both sides of the accuride rail in the direction of the arrow. F-4-54 4)Remove 1 connector, 2 screws, and remove the front estrangement motor. F-4-55 4-23 Disassembly ...

-

Page 48: Sensors

Disassembly and assembly > Sensors > Removing the waste paper full sensor (light emitting/S011(PCB2)) 4-24 Sensors Removing the waste paper full sensor (light emitting/S011(PCB2)) 2) Remove 1 screw and pull out the connector. 1) Remove the trimmer unit from the finishe . -

Page 49: Removing The Waste Paper Full Sensor (Light Receiving/S011(Pcb3))

Disassembly and assembly > Sensors > Removing the waste paper full sensor (light receiving/S011(PCB3)) 4-25 Removing the waste paper full sensor (light receiving/S011(PCB3)) 1) Open the finishe front door. 2) Pull out the saddle unit. F-4-58 F-4-59 3)Remove 1 screw and pull out the connector. F-4-60 4-25 Disassembly ... - Page 50 Disassembly and assembly > Sensors > Removing the waste paper full sensor (light receiving/S011(PCB3)) 4-26 4)Remove 2 hooks and remove the waste paper full sensor. F-4-61 4-26 Disassembly and assembly > Sensors > Removing the waste paper full sensor (light receiving/S011(PCB3))

-

Page 51: Pcbs

Disassembly and assembly > PCBs > Removing the trimmer controller PCB (PCB1) 4-27 PCBs Removing the trimmer controller PCB (PCB1) 1) Remove the trimmer unit from the finishe . 2) Remove 3 screws and remove the PCB cover. F-4-62 3) Pull out all connectors on the trimmer controller PCB. 4) ... -

Page 52: Actual Wiring Chart

A c t u a l w i r i n g chart ■Actual wiring chart Actual wiring chart... - Page 53 Actual wiring chart > Actual wiring chart Actual wiring chart C N 1 2 + 2 4 V 2 C N 8 C N 0 0 8 1 N . C . S101 P - G N D Inlet sensor C N 2 C N 0 0 8 2 1 C N 0 0 8 2...

- Page 54 LEAD-FREE SOLDER The PWB’s of this model employs lead-free solder. The “LF” marks indicated on the PWB’s and the Service Manual mean “Lead-Free” solder. The alphabet following the LF mark shows the kind of lead-free solder. Example: <Solder composition code of lead-free solder> Solder composition Solder composition code Solder composition...

- Page 55 CAUTION FOR BATTERY REPLACEMENT (Danish) ADVARSEL ! Lithiumbatteri – Eksplosionsfare ved fejlagtig håndtering. Udskiftning må kun ske med batteri af samme fabrikat og type. Levér det brugte batteri tilbage til leverandoren. (English) Caution ! Danger of explosion if battery is incorrectly replaced. Replace only with the same or equivalent type recommended by the manufacturer.

- Page 56 Adobe, the Adobe logo, Acrobat, and the Acrobat logo are trademarks of Adobe Systems Incorporated. PCL is a registered trademark of the Hewlett-Packard Company. Sharpdesk is a trademark of Sharp Corporation. All other trademarks and copyrights are the property of their respective owners. SHARP CORPORATION...

Need help?

Do you have a question about the MX-TM10 and is the answer not in the manual?

Questions and answers