ABB PGC5007 Operating Instruction

Total sulfur analyzer

Hide thumbs

Also See for PGC5007:

- Service instructions manual (88 pages) ,

- Operating instruction (124 pages) ,

- Service instruction (88 pages)

Table of Contents

Advertisement

Quick Links

—

A B B M E A S U R E M E N T & A N A LY T I C S | O p E R AT I N g I N S T R U C T I O N

PGC5007 Total sulfur analyzer

Process gas chromatograph

Measurement made easy

Further information

Additional documentation on the pgC5007 total

sulfur analyzer is available for download at

www.abb.com/analytical.

Alternatively simply scan this code.

Advertisement

Chapters

Table of Contents

Summary of Contents for ABB PGC5007

- Page 1 A B B M E A S U R E M E N T & A N A LY T I C S | O p E R AT I N g I N S T R U C T I O N PGC5007 Total sulfur analyzer Process gas chromatograph Measurement made easy Further information Additional documentation on the pgC5007 total sulfur analyzer is available for download at www.abb.com/analytical. Alternatively simply scan this code.

- Page 2 ABB Inc. and its affiliates are not liable for damages and/or losses related to such security breaches, any unauthorized access, interference, intrusion, leakage and/or theft of data or information.

-

Page 3: Table Of Contents

Maintenance information ......... 11 Detector repair ..........35 Preventive maintenance ........11 Replacing the photomultiplier assembly ....35 PGC5007 troubleshooting guide ......12 Replacing the burner block ........35 Replacing the burner block wiring ......37 Furnace repair ........... 23 Replacing the burner block o-rings ....... -

Page 4: Safety And Symbols

Alerts the user to pertinent facts and conditions. Indicates a potential hazard which could cause serious injury and/or death, or indicates the presence of a hazard which could result in corruption of software or damage to equipment or property. 4 OI/PGC5007-EN, rev C... -

Page 5: Description

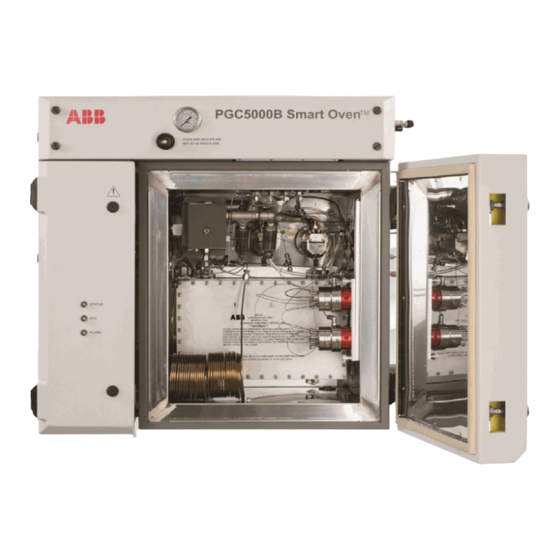

2 Description 2.1 General The Process Gas Chromatograph, Total Fuel Sulfur PGC5007 (Fuel Sulfur Analyzer), performs total sulfur measurements for various hydrocarbon blends. It operates the same as the standard Process Gas Chromatograph PGC5000 described in Operations Guide 9AKK104295F4814 and Technical Service Guide 9AKK104295D4816. It differs from the PGC5000 in having a furnace contained within the isothermal Smart Oven™... -

Page 6: Vapor Version

Using air as the carrier, the furnace oxidizes the sample into carbon dioxide, sulfur dioxide and water, and passes them through the column to the detector for measurement of the total sulfur, as sulfur dioxide (SO 6 OI/PGC5007-EN, Rev C... -

Page 7: Operation

Analytical valves are controlled using the valve button under the Setup Tab (see Figure 3.1). Refer to the Data Package for flow rates and pressures applicable to your analyzer. Fig. 3.1. Analytical Valve Control Screen Select applicable valves from the list on the left side of the folder display. Adjust as necessary for the application. 7 OI/PGC5007-EN, Rev C... - Page 8 PGC5007 Operating Instructions 3 Operation When you are matching column flows, refer to the Data Package for flow rates and valve configurations. Figure 3.2 illustrates a typical flow diagram for the liquid version of the PGC5007. SUPPLY HEATER AIR ADJ...

-

Page 9: Power Distribution

The Fuel Sulfur Analyzer utilizes the same power distribution circuits as the standard PGC5000 analyzer. In addition, the PGC5007 has an autoformer to provide 40 VAC power to the furnace located within the furnace Exd enclosure in the oven section of the analyzer (see Figure 3.5). -

Page 10: Detector

The FPD Electrometer PCB, located inside the Electronics compartment of the isothermal oven, digitizes the detector output signal for processing. This assembly also provides energy for FPD flame sensing and ignition. 10 OI/PGC5007-EN, Rev C... -

Page 11: Maintenance Information

900 deg C. 1 year Separation Columns minutes This permeation 3 years Sulfur wafer is located in Addition minutes the Flame Module Photometric Detector’s Burner Block. 11 OI/PGC5007-EN, Rev C... -

Page 12: Pgc5007 Troubleshooting Guide

PGC5007 PGC5007 Operating Instructions 4 Maintenance information 4.2 PGC5007 troubleshooting guide This subsection provides troubleshooting information by category. Use the listing below to determine the desired troubleshooting category and its location in the manual. Description Page Cyclic Short Term Drift... -

Page 13: Cyclic Short Term Drift

Gas/Fuel Contamination Electrical Noise Contaminated Contaminated Faulty Faulty FPD Makeup Gas Regulator Coaxial Cable Amplifier Replace FPD Replace Amplifier Assembly Coaxial Cable Contaminated Contaminated Carrier Tubing Loose Noisy Power Connections Supply Tighten cable Replace Power connections Supply 13 OI/PGC5007-EN, Rev C... -

Page 14: Signal Offset (Fpd)

Electrical Noise Hydrocarbon Contaminated Faulty Faulty FPD Contaminates Regulator Coaxial Cable Amplifier Replace FPD Replace Amplifier Assembly Coaxial Cable Water in Contaminated FPD Vent Tubing Noisy Power Loose Connections Supply Tighten cable Replace Power connections Supply 14 OI/PGC5007-EN, Rev C... -

Page 15: No Peaks

Chromatograph displays extra peaks or a noted difference in composite chromatograph MYSTERY PEAKS appearance from that of the calibration. Calibration Sample All Process and Only Calibration Samples Verify that the correct calibration sample is being used 15 OI/PGC5007-EN, Rev C... -

Page 16: Variable Sample Size

REPORT peak to be nonexistent or unknown. Gating in the method needs to be modified to ensure gating of the missing peak in the report Modify the gate ON/OFF time in the method table 16 OI/PGC5007-EN, Rev C... -

Page 17: Chromatogram Oversize Or Off Scale

Discrimination is the non-linear PEAK unequal dilution of hydrocarbons DISCRIMINATION in the column train. Discrimination is usually the result of a leak or incorrectly adjusted sample splitter. 17 OI/PGC5007-EN, Rev C... -

Page 18: Temperature Probe Open

No heat to a specific PROBE SHORTED temperature zone. Sensor to the Zone input has shorted ISOTHERMAL OVEN HEATER THERMOCOUPLE FAULTY Isothermal oven overtemperature sensor open LOSS OF OVEN AIR No Oven Air to Air Bath Ovens 18 OI/PGC5007-EN, Rev C... -

Page 19: Open Or Shorted Heater

TEMPERATURE Defective Runaway temperature probe Heater There is not trend output at TREND OUTPUT input device, or the trend NOT FUNCTIONING output value is not correct. CORRECTLY Incorrect Trend No Trend Output Output 19 OI/PGC5007-EN, Rev C... -

Page 20: No Analyzer Keypad Response

FLAME WILL NOT attempts to light the flame have failed. IGNITE Plugged Vent Incorrect Flame Insufficient Insufficient Defective Broken Burner Fuel Line Out Indication Ignitor Splitter Flow Port Detector Empty Permeation Failure Electronics Not Set Module 20 OI/PGC5007-EN, Rev C... -

Page 21: Low Carrier Pressure Hardware Alarm

Stream Not Stream Not Defective No Activation Air Stream Step Inactive Assigned to Included in Wiring to Actuator Instruction Correct Random Missing from Method Table Stream Method Table Stepping Check wiring Table and repair as necessary 21 OI/PGC5007-EN, Rev C... -

Page 22: Analyzer Will Not Power Up (X-Purge)

SHORT QUARTZ Furnace is running too hot. TUBE LIFE Furnace Too Hot Reduce furnace Thermocouple not operating temperature In position Columns have broadened REPEATED COLUMN out and lowered peaks. FAILURES Excessive Column Failures Replace columns 22 OI/PGC5007-EN, Rev C... -

Page 23: Furnace Repair

If the diaphragm valves are on a slider (see Figure 5.1), you will have to move them up to allow removal of the furnace housing cover. Thumbscrew Thumbscrew Locking Pin (behind thumbscrew) Fig. 7.1. Valves on Slider 23 OI/PGC5007-EN, Rev C... - Page 24 11. Remove the 40 M3 hex socket screws that hold the furnace housing cover (see Figure 5.3). The cover temperature must be below 40° C before you remove the screws. Fig. 5.3. Furnace Housing 24 OI/PGC5007-EN, Rev C...

-

Page 25: Removing The Furnace

Wrench Here Fig. 5.5. Left-Side Carrier Connections If this is the vapor version of the PGC5007, the right-side carrier line is a mirror image of the left-side carrier line. Remove the right-side carrier line as follows: Use the ABB Tee Wrench to hold the elbow. -

Page 26: Installing The Furnace (Liquid Version)

If this is the liquid version, remove the right-side carrier line as follows (see Figure 5.6): Use the ABB Tee Wrench to hold the nut as shown in Figure 5.5. Using a 9/16-inch wrench, disconnect the line just outside the furnace on the quartz tube. -

Page 27: Installing The Furnace (Vapor Version)

Position the furnace so that the furnace tube is centered in the furnace end cap. Tighten the screws holding the furnace. On the right-side carrier line: Use the ABB Tee Wrench to hold the elbow in place. Tighten the 1/4-inch fitting. Tighten the 5/16-inch fitting. -

Page 28: Installing A New Sulfur Furnace Tube

Assemble the tube nut, graphite ferrule and new thermocouple. Insert the new thermocouple assembly into the furnace until the tip touches the furnace tube. Tighten the tube nut slightly but still allowing the thermocouple to be moved. 28 OI/PGC5007-EN, Rev C... -

Page 29: Installing The Furnace Cover

5.9 Installing the furnace cover Verify that the internal heat shield is in place. Apply low-sodium lubricant ABB P/N 3617948-1 to all 40 cover bolts. Place the cover onto the housing. Install the 40 cover bolts and torque all cover bolts to 16 in-lbs. -

Page 30: Liquid Sample Valve Repair

This responsibility includes ensuring adequate ventilation in analyzer shelter and obtaining proper work permits, etc. To ensure the integrity of the components within the Liquid Sample Valve (LSV), use the tools in LSV Tool Kit 791K009-1 when assembling or disassembling the LSV. 30 OI/PGC5007-EN, Rev C... -

Page 31: Liquid Sample Valve Disassembly On Analyzer

20. Inspect the piston rod O-ring for visible imperfections. If imperfections are found, remove the piston rod O-ring from the piston rod. 21. Unscrew the tensioning nut from the body. 22. Inspect the tensioning nut O-ring for visible imperfections. If imperfections are found, remove the O-ring from the tensioning nut. 31 OI/PGC5007-EN, Rev C... -

Page 32: Liquid Sample Valve Reassembly On Analyzer

6 Liquid sample valve repair 6.3 LSV reassembly on the analyzer In all steps the lubricant used is High Vacuum Grease, ABB part number 006904-1. Clean the seals with acetone and air dry them. Clean the sample chamber with acetone and air dry it. -

Page 33: Removing The Lsv From The Analyzer

Remove the furnace cover as described in “Removing the Furnace Cover.” At the right side of the furnace, remove the carrier line as follows (reference Figures 5.3 and 5.4): Use the ABB Tee wrench to hold the nut. Using a 9/16-inch wrench, disconnect the line just outside the furnace tube. - Page 34 Install the four screws holding the flange to the side of the analyzer and tighten the screws. At the right side of the furnace reconnect the carrier line as follows (reference Figures 5.3 and 5.4): Use the ABB Tee wrench to hold the nut. Connect he 9/16-inch line just outside the furnace tube.

-

Page 35: Detector Repair

Remove power from the analyzer. Allow all temperature zones to cool, maintaining flow while the columns are cooling. Turn off carrier, sample, and air to the analyzer. Open the Electronics Enclosure side door. Locate the DTC PCB (see Figure 7.1). 35 OI/PGC5007-EN, rev C... - Page 36 16. Reconnect the Ground/Retaining Strap. 17. Reconnect all lines removed when you removed the Burner Bock. 18. Route the cabling through the Electronics Enclosure and reconnect the wires to the appropriate terminals on the DTC PCB. 36 OI/PGC5007-EN, rev C...

-

Page 37: Replacing The Burner Block Wiring

Insert the new Jet and O-Ring into the nut until it seats fully. 10. Carefully install and tighten the nut for the Jet assembly. 11. Reconnect carrier, gas and air lines. 12. Close the isothermal oven door. 37 OI/PGC5007-EN, rev C... -

Page 38: Replacement Parts

8 Replacement parts 8.1 Ordering information The replacement parts listed in this section are specific to the PGC5007. For all other replacement parts in the analyzer, you must refer to the Recommended Spare Parts Lists in the Data Package. Since the component parts specific to any given system are defined by the particular application, you should refer to the “Recommended Spare Parts Lists”... - Page 39 NOTES 39 OI/PGC5007-EN, rev C...

- Page 40 We reserve the right to make technical changes or modify the contents of this document without prior notice. With regard to purchase orders, the agreed particulars shall prevail. ABB does not accept any responsibility whatsoever for potential errors or possible lack of information in this document.

Need help?

Do you have a question about the PGC5007 and is the answer not in the manual?

Questions and answers