Table of Contents

Advertisement

Quick Links

( b o t h w i t h H i g h L e v e l C o n t r o l )

Room Sealed Radiant / Convector Gas Fires

THIS APPLIANCE IS FOR USE WITH NATURAL GAS (G20)

THIS APPLIANCE IS FOR USE IN THE UNITED KINGDOM (GB) AND THE

REPUBLIC OF IRELAND (IE) ONLY.

We trust that this Installer Guide gives sufficient details to enable the appliance to be installed

and maintained satisfactorily. However, if further information is required, the Valor

AdviceLine will be pleased to help.

Please telephone 0345 626341 (Local call rates apply).

INSTALLER: Please leave this guide with the owner

INSTALLER GUIDE

M O D E L

5 4 0 0

( w i t h L o w L e v e l C o n t r o l )

( G C 3 2 - 0 3 2 - 1 9 )

5 4 0 1

5 4 0 2

( G C 3 2 - 0 3 2 - 2 0 )

Valor Heating, Erdington, Birmingham B24 9QP

U l t i m a t e

C o l o u r w a y

&

Homestyle

www.valor.co.uk

600B726/01

Advertisement

Table of Contents

Summary of Contents for Valor 5400 Ultimate

- Page 1 REPUBLIC OF IRELAND (IE) ONLY. We trust that this Installer Guide gives sufficient details to enable the appliance to be installed and maintained satisfactorily. However, if further information is required, the Valor AdviceLine will be pleased to help. Please telephone 0345 626341 (Local call rates apply).

- Page 2 INSTALLER’S GUIDE Because our policy is one of constant development and improvement, details may vary slightly from those given in this publication. © Valor Heating Page 2...

-

Page 3: Table Of Contents

INSTALLER’S GUIDE CONTENTS APPLIANCE DATA ....................4 GENERAL INSTALLATION REQUIREMENTS ..........6 UNPACKING & PRELIMINARY CHECKS ............. 11 GAS SUPPLY INSTALLATION ................13 WALL PREPARATION ..................14 FLUE TERMINAL INSTALLATION ..............18 GAS CONNECTION, FUEL BED & WINDOW FITTING ......21 FULL OPERATIONAL CHECKS ............... 22 FITTING FRONT UNIT.................. -

Page 4: Appliance Data

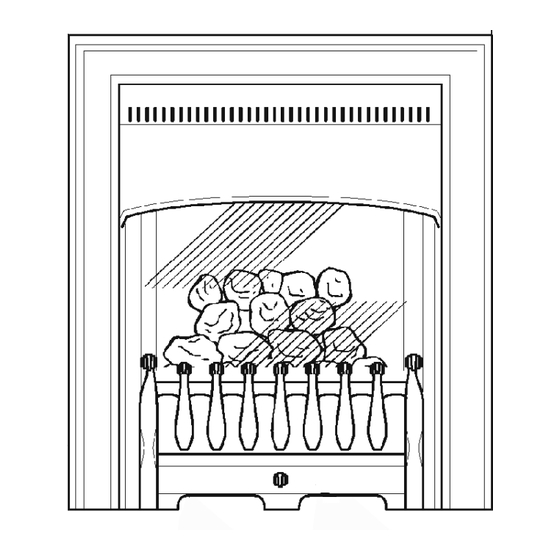

INSTALLER’S GUIDE 1 APPLIANCE DATA This product uses a burner compartment rear wall and gaskets containing Refractory Ceramic Fibres (RCF), which are man-made vitreous silicate fibres. Excessive exposure to these materials may cause temporary irritation to eyes, skin and respiratory tract. Consequently, it makes sense to take care when handling these articles to ensure that the release of dust is kept to a minimum. - Page 5 INSTALLER’S GUIDE Figure 1 Page 5...

-

Page 6: General Installation Requirements

2 GENERAL INSTALLATION REQUIREMENTS The appliance can be installed into the following :- A minimum 4.5in rebate surround or Valor 5in. spacer kit Part No 595129. Where either of these are mounted to a combustible wall make sure that there is no combustible material or combustible cladding in the area indicated on the wall fixing template. - Page 7 INSTALLER’S GUIDE All relevant codes of practice. The relevant parts of the current editions of the following British Standards:- BS 5440 Part 1 BS 5871 Part 1 BS 6891 In the republic of Ireland the installation must also conform to: The relevant parts of the current edition of IS 813 All applicable national and local rules in force.

- Page 8 INSTALLER’S GUIDE The appliance can be fitted to a purpose made proprietary class “O” 150° surround. 2.10 A hole 152mm (6in) dia. is required through the wall for the flue unit. The height of the hole centre is shown in figure 1 and on the wall-fixing template supplied with the appliance.

- Page 9 INSTALLER’S GUIDE Figure 2 Dimension Terminal Position Minimum (See fig.2) Distance Directly below an opening, air brick, opening window etc. 300mm Above an opening, air brick, opening window etc. 300mm Horizontally to an opening, air brick, opening window etc. 300mm Below gutters, soil pipes or drain pipes 300mm Below eaves...

- Page 10 INSTALLER’S GUIDE Figure 2A Page 10...

-

Page 11: Unpacking & Preliminary Checks

INSTALLER’S GUIDE 3 UNPACKING & PRELIMINARY CHECKS Unpacking The cartons contain the following :- 2 Fire retaining cables Model 5400 Ultimate 2 Eyebolts Supplied in one carton containing:- 2 Fibre wall plugs 1 Main fire assembly with front surround 2 No 6 tapping screws... - Page 12 INSTALLER’S GUIDE Appliance Disassembly 3.2.1 Front Surround Removal – Ultimate only See figure 3 Remove the two screws securing the bottom of the front ● surround to the sides of the convection box. Raise the front surround to allow the retaining lugs at the top ●...

-

Page 13: Gas Supply Installation

INSTALLER’S GUIDE 3.3.2 Check Flame Control Motor – Colourway & Homestyle Models Only See figure 6 Lift the plastic battery holder out of its ● metal support situated at the lower right corner. Fit the four 1.5V batteries and replace the ●... -

Page 14: Wall Preparation

INSTALLER’S GUIDE 5 WALL PREPARATION Select Appliance Position The flue must be installed so that it is at right angles to the back panel of the fire all round the flue circumference. For timber framed buildings make sure that the flue opening will be between studs. When being recessed into a non-combustible wall or builders opening the fire itself should be fitted vertically against a flat wall. - Page 15 (e.g. fibre cement board). As an option, a pre-cut insulating sheet is available from your appliance supplier or direct from Valor – Ask for Valor part no. 591229. The insulating sheet can be used to seal the annular gap between the flue unit...

- Page 16 INSTALLER’S GUIDE and the inner leaf sleeve – see section 5.5. Do not permanently fix the insulating sheet to the wall at this stage – see section 6.2. Cut the Flue Hole – Brick, Stone etc. Building Cut the hole for the flue unit. Make sure that it is straight and level. Though a hammer and chisel can be used, using a core drill is by far the quickest and simplest method for normal brickwork.

- Page 17 INSTALLER’S GUIDE Cut the Flue Hole –Timber Frame Buildings Figure 9a Timber frame wall preparation Drill the pilot hole and hole in outer wall as section 5.4. Since the flue will pass through combustible material in the inner leaf of the wall, a ●...

-

Page 18: Flue Terminal Installation

INSTALLER’S GUIDE Prepare appliance Fixing holes 5.6.1 Screwing case to wall Recheck the position of the screw fixing holes relative to ● the flue hole. Drill the four fixing holes to a minimum depth of 42mm ● using a 7mm diameter masonry drill. Insert four plastic wall plugs supplied. - Page 19 INSTALLER’S GUIDE Fig. 10 Flue Unit Installation – Brick etc. Building Fig. 10a Flue Unit Installation – Timber Framed Buildings Page 19...

- Page 20 INSTALLER’S GUIDE Fitting to Wall Fit the flue tubes firmly over the spigots ● at the rear of the fire. Make sure that the seam on the flue tube is not at the bottom. Push on until the outer (air) tube just covers the slots in the appliance outer spigot.

-

Page 21: Gas Connection, Fuel Bed & Window Fitting

INSTALLER’S GUIDE 7 GAS CONNECTION, FUEL BED & WINDOW FITTING Connect the Gas Supply Pipe Complete the supply pipe connection ● For concealed rear connection, the pipe run should have been extended as section • 4 of this guide. Connect the isolating elbow to the appliance inlet pipe. For Side Connection, the pipe should be routed to pass through the cut-out at the •... -

Page 22: Full Operational Checks

INSTALLER’S GUIDE 8 FULL OPERATIONAL CHECKS Check for Leaks Turn on the gas supply and check all joints up to the appliance gas tap for gas ● soundness using a soap solution or leak detection fluid. Check Control Operation If the fire is turned off or the flames go out, wait at least 3 minutes before attempting to relight. - Page 23 INSTALLER’S GUIDE 8.2.2 Colourway and Homestyle See figure 15. Depress the bottom half of the rocker switch ● located at the right side of the appliance case. This should cause the flame control knob (The left-hand control knob) to rotate clockwise until its bar is pointing vertically downwards A clicking sound will be heard while the flame control knob is rotating.

-

Page 24: Fitting Front Unit

INSTALLER’S GUIDE Check Reference Pressure The burner aeration is non-adjustable. The appliance is preset to give the correct heat input on Natural Gas at 20 mbar (8in w.g) inlet pressure and no further adjustment is necessary. The burner pressure should be checked at the pressure test point located on the pipe connecting the gas tap to the main burner (See figure 16). - Page 25 INSTALLER’S GUIDE Homestyle This pack weighs around 20kg (44lbs). To avoid any risk of injury, if you have any doubt about your ability to safely lift this pack and its contents, ask someone to assist you. Having assistance when installing this front will also reduce Figure 19 Bezel removal the risk of damaging the front or anything nearby.

-

Page 26: Final Review

INSTALLER’S GUIDE lift the cast front into position squarely with the convection box. Holding the cast front a little above the top surface of the convection box, locate the two lower location brackets into the lower case brackets and the upper location plate into the two slots in the upper case support. -

Page 27: Servicing & Parts Replacement

INSTALLER’S GUIDE 11 SERVICING & PARTS REPLACEMENT Always turn off the gas and make sure that the appliance is cool before commencing any servicing. (The inlet elbow on this appliance incorporates an isolating valve) Always test for gas soundness after refitting the appliance. This product uses a burner compartment wall and gaskets containing Refractory Ceramic Fibres (RCF), which are man-made vitreous silicate fibres. - Page 28 INSTALLER’S GUIDE Raise the front casting unit so that the bottom location ● brackets and the top location plate are released from the locations in the main fire case. See figure 25. 11.2 To Replace Tiles – Homestyle Model If the top is screwed to the sides, remove the top casting ●...

- Page 29 INSTALLER’S GUIDE 11.5 To Remove & Replace the Ceramic Burner plaques See figure 28 Remove the front ● unit. See section 11.1. Remove the ● window unit. See section 11.3 Lift out the ● ceramic fuel bed & rear wall. See section Figure 28 Plaque clamping screws 11.4 Remove the plaque clamping strips by detaching 6 screws.

- Page 30 INSTALLER’S GUIDE 11.7 To Remove the Complete Burner Module Remove the front unit. See ● section 11.1. Remove the window unit. ● See section 11.3 Lift out the ceramic fuel bed ● & rear wall. See section 11.4 Isolate the gas supply using ●...

- Page 31 INSTALLER’S GUIDE Replace in reverse order. When replacing the injector use a small amount of suitable ● thread sealant to prevent leakage of gas. Colourway & Homestyle only: When replacing, make sure that the wiring loom runs above and to the left of the battery box and behind the control valve. See figure 32. The motor lead connectors are two different sizes.

- Page 32 INSTALLER’S GUIDE Undo the inlet, outlet and pilot nuts on the gas valve. ● Remove the two mounting screws on the underside of the gas valve. See figure 34. ● Remove the valve by sliding it forward. ● Replace in reverse order. ●...

- Page 33 INSTALLER’S GUIDE 11.12 Short List of Spares Description No. Off Part No. Ceramic rear wall 571789 Injector-Main burner – Bray Cat.960 Size 270 571799 Pilot Unit SIT Ref. OP9706 571809 Pilot Gasket 571819 Control valve – Ultimate only 571829 Control valve – Colourway & Homestyle only 571859 Burner plaque &...

Need help?

Do you have a question about the 5400 Ultimate and is the answer not in the manual?

Questions and answers