Summary of Contents for Pentair FLECK 2900

- Page 1 Operation & Maintenance Manual 2900 NXT2 Systems © Nelsen Corporation Part# 2900NXT2 OPERATION MANUAL...

-

Page 2: Table Of Contents

Table of Contents INTRODUCTION PRINCIPLES of ION EXCHANGE 2.1 Ion Exchange Softening Process 2.2 Quality of Effluent 2.3 Capacity of Ion Exchange 2.4 Regeneration Steps INSTALLATION, LOADING & START-UP PROCEDURES 3.1 Installation of Equipment 3.2 Loading of Gravel & Resin 3.3 Start-Up Procedures OPERATING &... - Page 3 Foreword The operating instructions contained herein are intended to serve as a guide for the operation of the water softener equipment. Since it is impossible to cover all operating contingencies and emergencies in a normal operating manual, the operator should read the manual and become familiar with it contents. They should also review the flow diagrams and vendor literature.

-

Page 4: Introduction

Section 1: Introduction Long term, successful operation of any softening system depends upon the care and attention it receives. Ordinarily, water treatment systems will provide uniform performance after the initial start-up period. Total gallons between regenerations and treated water purity usually do not vary appreciably over the life of the resin as long as the incoming water does not change. -

Page 5: Principles Of Ion Exchange

Section 2: Principles Of Ion Exchange Ion Exchange Softening Process In order to understand the softening process of ion exchange, it is first necessary to understand the meaning of the terms which are used in the explanation. Hard Water, Cation Exchanger, and Brine are defined below and used to show how the ion exchange process works. -

Page 6: Quality Of Effluent

Quality Of Effluent If the hard water contains less than 500 ppm (about 30 grains) of calcium, magnesium and sodium salts, all expressed as CaCO , it will be found that the effluent from a softener will contain an average of not more that 2 ppm actual total hardness (zero hardness by the soap test). -

Page 7: Regeneration Steps

Calculation Of Capacity - To determine the capacity of any cation exchanger, follow the procedure outlined below: From the analysis of the raw water, determine the actual total hardness as the sum of the calcium and magnesium concentrations expressed as CaCO . -

Page 8: Installation, Loading & Start-Up Procedures

Section 3: Installation, Loading & Start Up Procedures Installation of Equipment 1. Before beginning installation, review the following instructions to familiarize yourself with the general placement of the equipment. 2. The operating pressure is between 30 to 100 psi. If pressure is higher than 100 psi, then a pressure regulator must be installed. -

Page 9: Loading Of Gravel & Resin

Loading Gravel & Resin 1. Before loading the gravel, check the lower distributor for possible damage from shipping. Making sure all laterals are in proper location. Do NOT proceed with loading if any damage is evident. 2. Once the distributor is checked out ok, plug the end of the distributor tube with a PVC cap/ plug, clean rag or tape to keep the gravel and resin out of the center of the riser. -

Page 10: Start-Up Procedures

Start-Up Procedures 1. Once the piping and installation completed, and with the mineral in the tank, proceed with the following. 2. Open the manual by-pass valve. The manual inlet and outlet valves are to remain closed. 3. Plug electrical power of the main controller to a wall outlet (120v) 4. -

Page 11: Operating & Regeneration Procedures

Section 4: Operating & Regeneration Procedures 4.1 Normal System Operation The system is designed for fully automatic operation. Service runs will automatically terminate when an exhaustion end-point is reached. Although it should not be absolutely necessary to observe every regeneration, Operators should periodically witness a complete cycle to make sure that critical flow rates and steps have not gotten out of adjustment. -

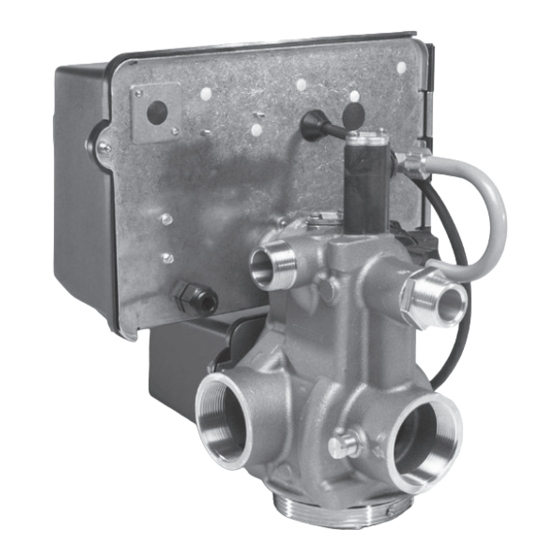

Page 12: Multi-Port Valve Operation

Multi-Port Valve Operation (See Section 8 – Fleck 2900s Control Manual) Multi-port valve consist of Fleck 2900s multi-port double piston operated valve. The valve operates with upper and lower piston that moves on a seals and spacer assembly. The upper piston is for regeneration and the lower piston is for service. - Page 13 Section 5: Operator Responsibilities Operator Maintenance Long term, reliable system performance depends upon how conscientiously the equipment is operated and maintained. Operator responsibilities should include the following recommended practices: 1. Maintain Operating Logs - Operators should maintain close control of the process by monitoring system performance daily.

-

Page 14: Trouble Shooting

Section 6: Trouble Shooting 6.1 General The most common system failures are either “poor water quality” or “short service” run. If the change in performance occurs suddenly i.e., within a couple of operating cycles, 9 times out of 10 these problems —... - Page 15 Inadequate Using a weak (less than Recharge at required times Regeneration 22 Be) brine solution Use salt which meets specification Use correct amount of dilution water Not using enough salt Check text for specified amount. Use correct saturated brine draw (or pumpage) Loss Of Ion Resin Surges during backwash...

-

Page 16: Increase Pressure Loss Or Decrease In Flow Rate

6.3 Increase Pressure Lose Or Decrease In Flow Rate Dirty Or Packed Bed - See above for possible causes and corrective actions. Restricted Flow – Obstruction in meter, piping or valves. Inspect and clean as required. -

Page 22: 7.6 Specifications

7.6 Specifications Specifications Model 120,000 150,000 210,000 300,000 450,000 600,000 Capacity (1) 120,000 150,000 210,000 300,000 450,000 600,000 Capacity (2) 96,000 120,000 168,000 240,000 360,000 480,000 Media Tank Size 16" x 65" 18" x 65" 21" x 62" 24" x 72" 30"... -

Page 23: Brine Float Setting

7.7 Brine Float Settings Salt Deck Brine valve set at Tank Size Cu. Ft. Brine Tank Brine Valve 9lb/cf. 15lb/cf. 6" 10" 18" 16 x 65 24 x 41 454-HF 16" 24" 6" 14" 24" 18 x 65 24 x 41 454-HF 20"... - Page 24 454 3⁄4" High Flow 454 3⁄4" High Flow Brine Valve Brine Valve 454 3/4" High Flow Brine Valve 454 3⁄4" HIGH FLOW BRINE VALVE — Today's 454 3⁄4" HIGH FLOW BRINE VALVE — Today's larger commercial brine valves demand higher larger commercial brine valves demand higher brine draw and refill rates.

- Page 25 time. 2. PVC brine pipe is recommended for use with these valves as it is non-corrosive and threads easily. 454 High Flow Brine Valve Installation Guide 1. Use Teflon tape only on threaded plastic pipe connections. Many liquid or paste pipe sealing 3.

- Page 26 Commercial/Industrial Rotationally Molded Brine Tanks Commercial and industrial water softeners require a 7.8 Commercial/Industrial Rotationally Molded Brine Tanks large volume of brine during each regeneration. Commercial and industrial water Commercial and industrial From a capacity of 95 water softeners require a softeners require a large volume of gallons to 500 gallons, our large volume of brine...

- Page 27 FLECK 2900S SERVICE MANUAL waterpurification.pentair.com...

- Page 28 JOB SPECIFICATION SHEET TABLE OF CONTENTS Job Number: ______________________________________________ JOB SPECIFICATION SHEET INSTALLATION Model Number: ____________________________________________ Water Hardness: __________________________________ppm or gpg START-UP INSTRUCTIONS Capacity Per Unit: __________________________________________ 3200 TIMER SETTING PROCEDURE Mineral Tank Size: ___________ Diameter: ________Height: ________ 3210 & 3220 TIMER SETTING PROCEDURE Salt Setting per Regeneration: _______________________________ 3200, 3210, 3220, 3230 REGENERATION CYCLE SETTING PROCEDURE...

-

Page 29: Installation

INSTALLATION a common line. 9. Make sure that the floor is clean beneath the salt storage Water Pressure tank and that it is level. A minimum of 20 pounds (1.4 bar) of water pressure is 10. Place approximately 1 inch (25 mm) of water above the grid required for regeneration valve to operate effectively. -

Page 30: Start-Up Instructions

INSTALLATION CONTINUED START-UP INSTRUCTIONS Meter Dome and Union Orientation The water softener should be installed with the inlet, outlet, and drain connections made in accordance with the Control valves outfitted with an electromechanical timer and manufacturer’s recommendations, and to meet applicable stainless steel water meter include a special male x female plumbing codes. -

Page 31: 3200 Timer Setting Procedure

3200 TIMER SETTING PROCEDURE How To Set Days On Which Water Conditioner Is To Regenerate (Figure 2) Rotate the skipper wheel until the number “1” is at the red pointer. Set the days that regeneration is to occur by sliding tabs on the skipper wheel outward to expose trip fingers. -

Page 32: Procedure

3210 & 3220 TIMER SETTING Timer Setting Procedure PROCEDURE CONTINUED How To Change The Length Of The Backwash Time The program wheel as shown in the drawing is in the service 3. The black center knob will make one revolution in the position. - Page 33 [ THIS PAGE LEFT INTENTIONALLY BLANK ] FLECK • 7 2900S Service Manual...

-

Page 34: 3200 Time Clock Timer Assembly

3200 TIME CLOCK TIMER ASSEMBLY 615023200 Rev A 8 • FLECK 2900S Service Manual... - Page 35 3200 TIME CLOCK TIMER ASSEMBLY CONTINUED Item No. Part No. Description Item No. Part No. Description 1 ....1 ..13870 ....Housing, Timer, 3200 27 ....1 ..14381 ....Skipper Wheel Assy, 12 Day 2 ....1 ..14265 ....Clip, Sping 1 ..14860 ....Skipper Wheel Assy, 7 Day 3 ....3 ..

-

Page 36: 3210 Meter Delayed Timer Assembly

3210 METER DELAYED TIMER ASSEMBLY 61502-3210 Rev A 10 • FLECK 2900S Service Manual... - Page 37 3210 METER DELAYED TIMER ASSEMBLY CONTINUED Item No. Part No. Description Item No. Part No. Description 30 ....1 ..14198 ....Label, Indicator 1 ....1 ..13870 ....Housing, Timer, 3200 31 ....1 ..15465 ....Label, Caution 2 ....1 ..13802 ....Gear, Cycle Actuator 32 ....1 ..

-

Page 38: 3220 Meter Immediate Timer Assembly

3220 METER IMMEDIATE TIMER ASSEMBLY 61502-3220 Rev B 12 • FLECK 2900S Service Manual... - Page 39 3220 METER IMMEDIATE TIMER ASSEMBLY CONTINUED Item No. Part No. Description Item No. Part No. Description 31 ....1 ..40617 ....Harness, 3220 1 ....1 ..13870 ....Housing, Timer 32 ....2 ..40422 ....Nut, Wire, Tan 2 ....1 ..15431 ....Gear, Cycle Actuator, System #5 33 ....1 ..

-

Page 40: 3230 Remote Start Timer Assembly

3230 REMOTE START TIMER ASSEMBLY 61502-3230R REV A 14 • FLECK 2900S Service Manual... - Page 41 3230 REMOTE START TIMER ASSEMBLY CONTINUED Item No. Part No. Description Item No. Part No. Description 18 ....1 ..19210-05 ..Program Wheel Assembly, 1 ....1 ..13870 ....Housing, Timer 3200 2 ....1 ..14265 ....Spring Clip 20 ....1 ..15055 ....Main Drive Gear 3 ....3 ..

-

Page 42: Upper Environmental Powerhead Assembly

UPPER ENVIRONMENTAL POWERHEAD ASSEMBLY 61501-2900 Rev G 16 • FLECK 2900S Service Manual... - Page 43 UPPER ENVIRONMENTAL POWERHEAD ASSEMBLY CONTINUED Item No. Part No. Description Item No. Part No. Description 25 ....1 ..19772 ....Bracket, Terminal Block 1 ....1 ..18697-15 ..Backplate, Hinged 26 ....1 ..40174 ....Terminal Block, Green/ 2 ....1 .......3200 Clock Timer Assembly Yellow Commercial, 809- ........3200 Meter Timer 260/141...

-

Page 44: Lower Environmental Powerhead Assembly

LOWER ENVIRONMENTAL POWERHEAD ASSEMBLY 19 9 61501-2900 Rev G 18 • FLECK 2900S Service Manual... - Page 45 LOWER ENVIRONMENTAL POWERHEAD ASSEMBLY CONTINUED Item No. Part No. Description Item No. Part No. Description ..40408 ....Harness, Lower Drive, Syst 7, 1 ....1 ..18709 ....Backplate, Lower Duplex, Lag, Enviromental 2 ....2 ..11224 ....Screw, Slotted Hex Head ..40398 ....Harness, Lower Drive, Syst 3 ....2 ..

-

Page 46: Control Valve Assembly

CONTROL VALVE ASSEMBLY 61500-2900 Rev F Downflow Upflow Item No. Part No. Description Item No. Part No. Description ..41428-09NP..Valve Body, 2900S, MCHD, 1 ....1 ..41428-01 ..Valve Body, 2900s, Machd, NPT, NP, U.S. Tap, Soft NPT U.S. Tap ADAPT, Top Coll .. - Page 47 CONTROL VALVE ASSEMBLY CONTINUED Item No. Part No. Description Item No. Part No. Description 4 ....6 ..11451 ....Spacer, 12 Hole ..61545 ....Piston Assy, 2900S, Upflow, Upper ..16589 ....Spacer, Hot Water ..61545-01 ..Piston Assy, 2900S, 5 ....1 ..14451 ....Piston, 2750 Upflow, Upper, Hot Water ..

- Page 48 CONTROL VALVE ASSEMBLY CONTINUED Item No. Part No. Description ..60721-30 ..DLFC, 1-inch F x 1-inch F, Item No. Part No. Description NPTF, 3.0 gpm ..60366-45 ..DLFC, 1-inch F x 3/4-inch ..60721-35 ..DLFC, 1-inch F x 1-inch F, F, NPT, 4.5 gpm NPTF, 3.5 gpm ..

-

Page 49: Control Valve Side Mount Adapter

CONTROL VALVE SIDE MOUNT ADAPTER 61415 Rev B Item No. Part No. Description 1 ....1 ..40316 ....Adapter, Sidemount 2 ....1 ..40372 ....O-ring - 142 3 ....1 ..40368 ....O-ring - 160, Sidemount, Flange 4 ....1 ..40310 ....Base, 2850/2900/3930, Rotating 5 ....7 .. -

Page 50: 1600 Series Brine System

1600 SERIES BRINE SYSTEM 60029 Rev C Item No. Part No. Description Item No. Part No. Description 17 ....1 ..11893 ....Cap, Injector, SS 1 ....2 ..10332 ....Fitting, Insert, 3/8 18 ....1 ..10229 ....Gasket, Injector Cap, 1600 2 ....1 ..12767 ....Screen, Brine 19 ....1 .. - Page 51 1600 SERIES BRINE SYSTEM CONTINUED Item No. Part No. Description 25 ..... 60480-01 ..Injector Assy, 1600, #1, Item No. Part No. Description Plastic 21 ....1 ..10914-000 ..Throat, Injector #000, ..60480-02 ..Injector Assy, 1600, #2, Brown Plastic ..10914-00 ..Throat, Injector #00, Violet ..

-

Page 52: 1650 Brine System Assembly

1650 BRINE SYSTEM ASSEMBLY 60011 Rev D Item No. Part No. Description Item No. Part No. Description Plastic 1 ....1 ..10329 ....Fitting, Tube, 3/8 Nut, Brass 1 ..60010-100 ..BLFC, 1650, 1.0 GPM, Plastic 2 ....1 ..10330 ....Fitting, Sleeve, 3/8 Celcon 15 ....1 .. - Page 53 1650 BRINE SYSTEM ASSEMBLY CONTINUED Item No. Part No. Description Item No. Part No. Description ..12973-3 ..Nozzle, Injector #3, PVC, 27 ....1 ..12550 ....Quad Ring -009 Grey 1 ..12550-01 ..Quad Ring -009 560CD ..12973-4 ..Nozzle, Injector #4, PVC, 28 ....1 ..

-

Page 54: 1700 Brine System Assembly

1700 BRINE SYSTEM ASSEMBLY 60034 Rev D 28 • FLECK 2900S Service Manual... - Page 55 1700 BRINE SYSTEM ASSEMBLY CONTINUED Item No. Part No. Description Item No. Part No. Description ..14801-05c ..Nozzle, Injector, #5c, White 1 ....1 ..14792 ....Plug, End, Brine Valve ..14801-06c ..Nozzle, Injector, #6c, Red 2 ....1 ..13201 ....Quad Ring, -020 25 ....1 ..

-

Page 56: 1710 Brine System Assembly

1710 BRINE SYSTEM ASSEMBLY 60604 Rev F Item No. Part No. Description Item No. Part No. Description 22 ..... 60605-00 ..Brine Valve, 1710, 2750, Blank 1 ....1 ..41202 ....Brine Valve, 1700, Plastic, ..60605-10 ..Brine Valve, 1710, 2750, 1.0 gpm 2 ....1 .. - Page 57 2-INCH BRASS METER ASSEMBLY Item No. Part No. Description Item No. Part No. Description 1 ....1 ..14456 ....Body, Meter, 2-inch 11 ....1 ..14680 ....Flow Straightener 12 ....1 ..14569 ....Nut, 2900 Meter ..14456-20 ..Body, Meter, 2-inch, BSP, Metric 13 ..........Meter Assy, 2-inch 2 ....1 ..

- Page 58 2-INCH STAINLESS STEEL METER ASSEMBLY IMPORTANT: For valves equipped with electromechanical timers and stainless steel meters, refer to the Meter Dome and Union Orientation section. Item No. Part No. Description Item No. Part No. Description Not Shown (optional) 1 ....1 ..62048-01 ..Service Kit, 2 inch Meter, Standard Range 1 ..

- Page 59 2-INCH PLASTIC METER ASSEMBLY 60621_REVB 60621 Rev D Item No. Part No. Description Item No. Part No. Description 12 ....1 ..14680 ....Flow Straightener 1 ....1 ..17689 ....Body, Meter, 2-inch Plastic w/Impeller Shaft Seat 13 ....2 ..17988 ....Nut, 2-inch Meter 2 ....1 ..

-

Page 60: 1600 Service Valve Operator (New Style)

1600 SERVICE VALVE OPERATOR (NEW STYLE) 60150 Rev A Item No. Part No. Description Item No. Part No. Description 1 ....1 ..11749 ....Guide, Brine Valve Stem 14 ....2 ..15415 ....Fitting, Insert, 1/2-inch Tube 2 ....1 ..10250 ....Ring, Retaining 15a ..1 .. -

Page 61: 2300 Safety Brine Valve

2300 SAFETY BRINE VALVE 60027 Rev D Item No. Part No. Description Item No. Part No. Description ..60002-36 ..Air Check, #500, 36 1 ....1 ..60027-00 ..Safety Brine Valve, 2300, inches Long Less Elbow ..60002-48 ..Air Check, #500, 48 2 ....1 .. -

Page 62: 2310 Safety Brine Valve

2310 SAFETY BRINE VALVE Item No. Part No. Description Item No. Part No. Description ..60068-30 ..Float Assy, 2310, w/30-inch 1 ....1 ..19645 ....Body, Safety Brine Valve, 2310 14 ....1 ..60002-10 ..Air Check, #500, American 2 ....1 ..19803 ....Safety Brine Valve Assy Hydro 3 ....1 .. -

Page 63: 2350 Safety Brine Valve

2350 SAFETY BRINE VALVE Item No. Part No. Description 1 ....1 ..60038 ....Safety Brine Valve, 2350 1A ....1 ..61024 ....Actuator Assy, 2350 Brine 2 ....1 ..60028-30 ..Float Assy, 2350, 30-inch Wht ....1 ..60026-30SAN .Float Assy, 2350, 30-inch Hot Water 3 ....1 .. -

Page 64: General Service Hints For Meter Control

GENERAL SERVICE HINTS FOR METER CONTROL Problem: Softener delivers hard water Reason: Reserve capacity has been exceeded. Correction: Check salt dosage requirements and reset program wheel to provide additional reserve. Reason: Program wheel is not rotating with meter output. Correction: Pull cable out of meter cover and rotate manually. Program wheel must move without binding and clutch must give positive clicks when program wheel strikes regeneration stop. -

Page 65: Troubleshooting

TROUBLESHOOTING Problem Cause Correction Water conditioner fails to Electrical service to unit has been Assure permanent electrical service (check fuse, regenerate. interrupted plug, pull chain, or switch) Timer is defective. Replace timer. Power failure. Reset time of day. Hard water. By-pass valve is open. -

Page 66: Water Conditioner Flow Diagrams - Downflow

WATER CONDITIONER FLOW DIAGRAMS - DOWNFLOW 1 Service Position 4 Slow Rinse Position 2 Backwash Position 5 Rapid Rinse 3 Brine Position 6 Brine Tank Refill Position 61500-2900 DOWNFLW Rev F 40 • FLECK 2900S Service Manual... -

Page 67: Water Conditioner Flow Diagrams - Upflow

WATER CONDITIONER FLOW DIAGRAMS - UPFLOW 1 Service Position 4 Back Wash Position 2 Brine Position 5 Rapid Rinse 3 Slow Rinse Position 6 Brine Tank Fill Position 61500-2900 UPFLW Rev F FLECK • 41 2900S Service Manual... -

Page 68: Flow Data & Injector Draw Rates - Downflow

FLOW DATA & INJECTOR DRAW RATES - DOWNFLOW TR22089-2900s Valve 1700 Series Injector Slow Rinse Rates TR22089-2900s Valve 1600 Series Injector Draw Rates 10.5 10.0 Inlet Pressure - psi # 3C # 4C # 5C # 6C 1700 series injectors Slow Rinse - gpm pressure # 3C... -

Page 69: Environmental Backplate Dimensions

ENVIRONMENTAL BACKPLATE DIMENSIONS 61500-2900LNE Rev B FLECK • 43 2900S Service Manual... -

Page 70: System #4

SYSTEM #4 Typical Single Tank Installation with Optional Meter SYSTEM #5 INTERLOCK Typical Twin Tank Installation with Optional Meter Interlock and No Hard Water Bypass 44 • FLECK 2900S Service Manual... -

Page 71: System #6 & #7

SYSTEM #6 & #7 Twin Series Regeneration Installation with a Remote Meter Twin Alternator Installation NOTE: On System 7, the power cord is on Unit 2. NOTE: System 7 can run with either one or two brine tanks. Two brine tanks should be used if regeneration is less than 4 hours. -

Page 72: System #4 Wiring

SYSTEM #4 WIRING Single Valve Regeneration Immediate and Delayed Valve Wiring 46 • FLECK 2900S Service Manual... - Page 73 SYSTEM #4 WIRING CONTINUED With Remote Starter Valve Wiring FLECK • 47 2900S Service Manual...

-

Page 74: System #5 Wiring

SYSTEM #5 WIRING Interlocked Regeneration Valve Wiring 18685-01 Rev D 18685-02 Rev D 48 • FLECK 2900S Service Manual... -

Page 75: System #6 Wiring

SYSTEM #6 WIRING Series Regeneration Valve Wiring 18686-01 Rev E 18686-02 Rev E FLECK • 49 2900S Service Manual... -

Page 76: System #7 Wiring

SYSTEM #7 WIRING Alternating Regeneration Valve Wiring 18687-01 Rev E 18687-02 Rev E 50 • FLECK 2900S Service Manual... - Page 77 SYSTEM #7 WIRING CONTINUED FLECK • 51 2900S Service Manual...

-

Page 78: 1600/1700 System Nozzle & Throat Chart

1600/1700 SYSTEM NOZZLE & THROAT CHART 1600 Brine System Standard Size Color Nozzle Throat #0 ..... Red ....10913-0 10914-0 #1 ..... White ....10913-1 10914-1 #2 ..... Blue ....10913-2 10914-2 #3 ..... Yellow .....10913-3 10914-3 #4 ..... Green ....10913-4 10914-4 Size Color Nozzle Throat... - Page 79 SERVICE ASSEMBLIES Adapters: 61525 ��������������������������� Softwater Adapter Kit, 2900s Cam Assemblies: 61415 ��������������������������� Adapter Assy, Sidemount 60160-00 ��������������������� Drive Cam Assy, RR, White 2850/2900/2930 60160-20 ��������������������� Drive Cam Assy, Std 61415NP ���������������������� Adapter Assy, Sidemount, NP 60160-22 ��������������������� Drive Cam Assy, Link, Environmental 2850/2900/2930 2900 Lower Drive 61415-20 ���������������������...

- Page 80 SERVICE ASSEMBLIES CONTINUED Safety Brine Valves: 60014 ��������������������������� Safety Brine Valve Assy, 2310 60038 ��������������������������� Safety Brine Valve , 2350 60027-FFA ������������������� Safety Brine Valve Body, 2300 Fitting Facing Arm 60027-FFS ������������������� Safety Brine Valve Body Fitting Facing Stud 60026-30SAN �������������� Float Assy, 400A/2350, 30-inch HW 60028-30 ���������������������...

- Page 81 FLECK • 55 2900S Service Manual...

- Page 82 For a detailed list of where Pentair trademarks are registered, please visit waterpurification.pentair.com/brands. § Pentair trademarks and logos are owned by Pentair plc or its affiliates. Third party registered and unregistered trademarks and logos are the property of their respective owners.

- Page 83 Section 8: 2900 Control Manual NXT2 Manual...

- Page 85 FLECK FLECK® NXT2 TIMER SERVICE MANUAL pentair.com...

- Page 86 24 VDC. Please make sure your voltage supply is compatible with your unit before installation. CALIFORNIA PROPOSITION 65 WARNING This product contains chemicals known to the WARNING: State of California to cause cancer or birth defects or other reproductive harm. 2 • Pentair Fleck NXT2 Timer ®...

-

Page 87: Operating Parameters

Regeneration Downflow - Total Number of Regenerations Flow Upflow - Regeneration Interval Filter - Last Settings Change - Error Log History Electrical 24V DC - Average Daily Usage (per weekday, 3 month history) Rating Pentair Fleck NXT2 Timer • 3... -

Page 88: Timer Display

Master Unit (auto-assigned) Remote Regeneration Network Indicator - Connected Master Programming Network Indicator - Disconnected User Programming Network Indicator - Unit Missing Diagnostics USB Connected (Field Programmer) Time of Day Programming Error Condition Present Remote Lock 4 • Pentair Fleck NXT2 Timer... -

Page 89: Timer Operation

Once all regeneration steps are complete, the timer returns to In Service and resumes normal operation. CYCLE 1/5 BACKWASH 00:10:00 CYCLE 2/5 DRAW 00:60:00 Pentair Fleck NXT2 Timer • 5... -

Page 90: Timer Features

Time Based - User must set clock to 12:01 pm to unlock Delayed - User must press and hold the Left and Down buttons While powering up the unit, when the Pentair logo appears, for 60 continuous seconds to unlock press and hold the Extra Cycle button to access the Reset menu then select Reset to Factory Defaults. - Page 91 Deactivates upon selected end time (Range: Start Time plus 1 minute) AUX.1:VOLUME BASED - VOLUME-G Activates when selected volume (gallon) 00100 is reached (Range: 0-99999) AUX.1:VOLUME BASED - DURATION-S Selected duration in seconds 0010 (Range: 0-9999 seconds) Pentair Fleck NXT2 Timer • 7...

- Page 92 Regeneration of a unit will begin after the other control has left Standby and returned to Service. When the Regeneration cycle is complete, the regenerated unit will enter Standby. Standby on each tank is controlled by the relay on the NXT2 circuit board. 8 • Pentair Fleck NXT2 Timer...

-

Page 93: Master Programming Mode Flow Chart

Range: 1-9999 seconds DAY OVERRIDE/TIME-DRIVEN Example: 10 D Range: Off - 99 Days REGEN. TIME Example: 02:OOHR Range: 0 - 23 Hours 59 Minutes. Pentair Fleck NXT2 Timer • 9 LOCK WINDOW #1 Example: Start Lock Window End Lock Window... -

Page 94: User Programming Mode Flow Chart

Example: Range: 1 - 999 grains per gallon SAVE AS NON-FACTORY VOLUME REMAINING - G Example: 09999 Range: 1 - 99999 gallons LOCK SETTINGS Example: TIME BASED Off, Delayed, Enter Code, Time Based DELAYED 10 • Pentair Fleck NXT2 Timer... -

Page 95: Diagnostic Programming Mode Flow Chart

REGEN INTERVAL Example: 3 D 21 H Duration between regenerations. LAST SETTINGS CHANGE Example: 14 H 0 M Last time programming settings were changed. Example: ERROR LOG Pentair Fleck NXT2 Timer • 11 ERROR LOG EMPTY Record of error events chronologically. -

Page 96: Time Of Day Programming Mode Flow Chart

NOTE: Press and hold the Left button to exit without saving. TIME Example: 11:00AM 12 or 24 hour formats available YEAR Example: 2018 Set current year MONTH Example: Set current month CALENDAR DAY Example: Set current day 12 • Pentair Fleck NXT2 Timer... - Page 97 Pentair Fleck NXT2 Timer • 13...

-

Page 98: Nxt2 Timer Assembly (2510, 2750, 2850, 2900, 3150, 3900 Valves)

(2510, 2750, 2850, 2900, 3150, 3900 VALVES) 62115 Rev A Item No. Part No. Description 1....1 ..62115 ....Timer Assy, NXT2 Service Assemblies 2....1 ..62120 ....Control Panel Assy, NXT2, Programmed 3....1 ..40941 ....Wire Harness, Upper Drive 14 • Pentair Fleck NXT2 Timer... -

Page 99: Nxt2 Timer Assembly (2815 Valve)

(2815 VALVE) 62115-01 Rev A Item No. Part No. Description 1....1 ..62115-01 ....Timer Assy, NXT2, 2815 Service Assemblies 2....1 ..62120 ....Control Panel Assy, NXT2, Programmed 3....1 ..44076 ....Wire Harness, Upper Drive Pentair Fleck NXT2 Timer • 15... -

Page 100: Nxt To Nxt2 Conversion Kits

1 ..62121-02 ....Conversion Kit, NXT2, Euro 1 ..62121-03 ....Conversion Kit, NXT2, Aust 1 ..62121-04 ....Conversion Kit, NXT2, Japan NOTE: All Conversion Kits include timer wire harness (not pictured), and appropriate power supply plug end (also not pictured 16 • Pentair Fleck NXT2 Timer... -

Page 101: Nxt2 Wiring Diagram

NXT2 WIRING DIAGRAM 44334 Rev B Pentair Fleck NXT2 Timer • 17... -

Page 102: Power Supply Connections

Hinge Mount: mount per valve model noted Wire Harness Meter Cable Power Supply 44404 Rev A 3150/3900 Valves: Communication Cables Wire Harness Hinge Mount: mount per valve model noted Meter Cable Power Supply 44403 Rev A 18 • Pentair Fleck NXT2 Timer... -

Page 103: Error Codes And Troubleshooting

System Type Mismatch on Network Settings. Microcontroller Error Calibration or manufacturing test was not performed Contact your Pentair representative. 100 Days Without Regen 100 Days have expired without a regeneration Trigger a manual regeneration Pentair Fleck NXT2 Timer • 19... - Page 104 P: 262.238.4400 | Customer Service: 800.279.9404 | tech-support@pentair.com | pentair.com All indicated Pentair trademarks and logos are property of Pentair. Third party registered and unregistered trademarks and logos are the property of their respective owners. © 2020 Pentair. All rights reserved.

- Page 105 Section 9: Softener Addendum Softener Log Sheet SOFTENER LOG SOFTENER LOG SHEET NO. Meter Gallons Inlet Outlet Salt Date Time Reading Delivered Pressure Pressure Used...

Need help?

Do you have a question about the FLECK 2900 and is the answer not in the manual?

Questions and answers