Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for American Hearth ADVTL27FP90N-1

- Page 1 This Owner's Manual is provided and hosted by Appliance Factory Parts. American Hearth ADVTL27FP90N-1 Owner's Manual Shop genuine replacement parts for American Hearth ADVTL27FP90N-1 Find Your American Hearth Fireplace Parts - Select From 88 Models -------- Manual continues below --------...

- Page 2 INSTALLATION INSTRUCTIONS AND OWNER’S MANUAL INSTALLER: Leave this manual with the appliance. CONSUMER: Retain this manual for future reference. DIRECT VENT ZERO WARNING CLEARANCE GAS FIREPLACE If not installed, operated and maintained in accordance with the manufacturer’s MODEL SERIES: instructions, this product could expose you MULTIFUNCTION REMOTE (MF) to substances in fuel or from fuel combustion ADVTL27FP90(N,P)-1...

- Page 3 BEFORE YOU START Gas Supply see page 12. Locating Fireplace see pages 12 & 13. Electrical Considerations see page 14. Installation see pages 15-19. 5. Vent System Identification see page 20. Venting Fireplace see pages 21-27. Framing and Finishing see pages 28-29. 8. Install Fiber Panels see page 30. Placing Glowing Embers see page 31. 10. Log Placement see pages 32-40.

-

Page 4: Table Of Contents

TABLE OF CONTENTS SECTION PAGE INTRODUCTION ....................................4 SPECIFICATIONS ....................................5 ACCESSORIES ....................................6 FIREPLACE DIMENSIONS ................................7 CLEARANCES....................................8-9 TERMINATION CLEARANCES ..............................10 VENT TERMINAL CLEARANCES ..............................11 GAS SUPPLY ....................................12-13 LOCATING FIREPLACE .................................13 ELECTRICAL CONSIDERATIONS ..............................14 INSTALLATION ..................................15-19 VENT SYSTEM IDENTIFICATION ..............................20 VENTING FIREPLACE ................................20-22 TOP VENT - HORIZONTAL TERMINATION ...........................23 TOP VENT - VERTICAL TERMINATION ............................24 VERTICAL TERMINATION ................................25-27... -

Page 5: Introduction

INTRODUCTION Instructions to Installer The installation must conform with local codes or, in the absence of Installer must leave instruction manual with owner after local codes, with the National Fuel Gas Code ANSI Z223.1/NFPA installation. 54* Natural Gas and Propane Installation Code *Available from the 2. Installer must have owner fill out and mail warranty card supplied American National Standards Institute, Inc. -

Page 6: Specifications

SPECIFICATIONS ADVTL27FP92N ADVTL27FP92P (NAT) (LP) Input BTU/Hr Maximum 36,000 35,000 Input BTU/Hr Minimum 10,000 9,000 KWH (Maximum) 10.55 10.26 KWH (Minimum) 2.93 2.63 Orifice (Front) Orifice (Back) 2.40mm Air Shutter Opening (Front) 1/4” Full Open Air Shutter Opening (Back) 3/16” Full Open Height without standoff 47-3/8” 47-3/8”... -

Page 7: Accessories

ACCESSORIES The following accessory parts can be obtained from your Empire Comfort Systems dealer. If you need additional information beyond what your dealer can furnish, contact Empire Comfort Systems Inc., 918 Freeburg Ave., Belleville, Illinois 62220-2623. MODEL NUMBER DESCRIPTION DF272NB Decorative Front - Beveled Window Frame, Brushed Nickel DF274NB Decorative Front - Floating Front, Brushed Nickel DF27CTBL Decorative Front - “Cathedral”, Hammered Black Copper DF27PTBL... -

Page 8: Fireplace Dimensions

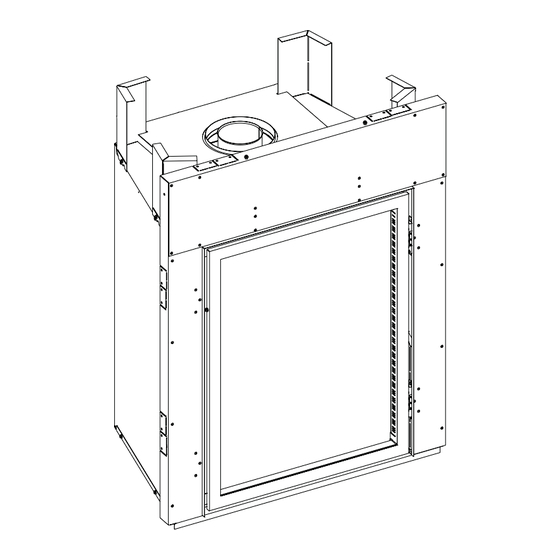

FIREPLACE DIMENSIONS DIMENSIONS (in inches) INDEX DIMENSION DESCRIPTION ADVTL27 LETTER The maximum height of firebox face (excluding standoffs) 47-3/8” The maximum width of the firebox face (excluding nailing flanges) 37-3/8” The maximum depth of the firebox 26” The height of the firebox opening 37” The width of the firebox opening 28-1/4” The interior depth of the firebox 20-1/2” The rear exterior width of the firebox 23-3/4” The height to the firebox standoffs Width from the left side of the box to the centerline of vent 18-11/16” Depth from back of box to centerline of top vent 8-11/16”... -

Page 9: Clearances

CLEARANCES CLEARANCE TO COMBUSTIBLES Back 2-3/4" 2-3/4" Side 2-3/4” Floor 0" COMBUSTIBLES ALLOWED Top Framing Edge 0" 26” FROM SURFACE OF FACE TO 2-3/4” COMBUSTIBLES FRAMING HEADER DRYWALL 3/4" SURFACE OF FACE 6" 6" FROM FACE OPENING NON-COMBUSTIBLE FINISH MATERIAL TO COMBUSTIBLES, BOTH SIDES MUST COVER THE SURFACE OF THE FIREPLACE FACE... - Page 10 CLEARANCES Clearances Clearance from top front edge of fireplace to ceiling is 40 inches. Clearance from side of fireplace to adjacent sidewall is 6 inches. 40” TO FIREPLACE OPENING 6” TO FIREPLACE OPENING ▼ Figure 4 COMBUSTIBLE MATERIAL No greeting cards, stockings or ornamentation of any type should be placed on or attached to the fireplace. The flow of heat out of the appliance can ignite combustibles. Figure 5 33741-11-0217 Page 9...

-

Page 11: Termination Clearances

TERMINATION CLEARANCES Termination clearance for buildings with combustible and noncombustible exteriors. Figure 6 Vertical Sidewall Installations The graph showing the relationship between vertical and horizontal Important! Minimum clearance between vent pipes and combustible side wall venting will help to determine the various vent lengths materials is 3 inch on top, and 1 inch (on bottom and sides). -

Page 12: Vent Terminal Clearances

VENT TERMINATION CLEARANCES Canadian Installations US Installations Canadian Installations US Installations A= Clearance above grade, I= Clearance to service veranda, porch, deck, or 12 in (30 cm) minimum 12 in (30cm) minimum 3 ft (91 cm) minimum 6 ft (183 cm) minimum regulator vent outlet balcony J= Clearance to nonme- 9 in (23 cm) minimum 12 in (30 cm) minimum 9 in (23 cm) minimum... -

Page 13: Gas Supply

GAS SUPPLY The gas pipeline can be brought in through the right side of the appliance only. Consult the current National Fuel Gas Code, ANSI Z223.1 installation code. RECOMMENDED GAS PIPE DIAMETER SCHEDULE 40 PIPE TUBING, TYPE L PIPE INSIDE DIAMETER OUTSIDE DIAMETER LENGTH 0-10 feet... -

Page 14: Locating Fireplace

GAS SUPPLY Installing a New Main Gas Cock (Check Local Code) The appliance and its individual shut off valve must be disconnected Each appliance should have its own manual gas cock. from supply piping system during any pressure testing of that system A manual main gas cock should be located in the vicinity of the unit. -

Page 15: Electrical Considerations

ELECTRICAL CONSIDERATIONS A factory installed junction box is located on the lower right side of CAUTION the fireplace. Wiring must be fed to the junction box and attached with wire nuts to the control module power leads already fed into All wiring should be done by a qualified electrician and shall the junction box. -

Page 16: Installation

INSTALLATION Framing and Finishing CAUTION MEASURE FIREPLACE DIMENSIONS AND VERIFY FRAMING METHODS, AND WALL COVERING DETAILS BEFORE FRAMING CONSTRUCTION BEGINS. Choose unit location. 2. Frame in fireplace with a header across the top. NOTE: Fireplace framing can be built before or after the fireplace is set in place. Framing should be positioned to accommodate wall covering and fireplace facing material. The fireplace framing should be constructed of 2 x 4 lumber. The framing headers may rest on the fireplace standoffs. Refer to Figures 15 and 16 for minimum framing dimensions. - Page 17 INSTALLATION Figure 18 Figure 20 Figure 21 Figure 19 Page 16 33741-11-0217...

- Page 18 INSTALLATION (continued) Figure 23 Figure 22 HORIZONTAL VENT CLEARANCES Vent Pipe Clearance Figure 24 Note: Maintain all clearances to combustibles as shown in Figures 1 and 2 on page 8. For horizontal vent, maintain a minimum 1 inch clearance to the bottom and sides of the vent, and 3 inches of clearance to combustibles above the vent pipe.

- Page 19 INSTALLATION (continued) Vent Runs VERTICAL, 90° ELBOW WITH HORIZONTAL TERMINATION In planning the installation for the fireplace, it is necessary to install (12 inches minimum vertical rise shown) certain components before the appliance is completely positioned and installed. These include the direct vent system, gas piping for the appliance and the electrical wiring. The appliance can be mounted on any of the following surfaces: 1. A flat, hard surface A raised wooden platform...

- Page 20 INSTALLATION (continued) CORNER INSTALLATION - VERTICAL, 90° ELBOW TO VERTICAL, 90° ELBOW TO HORIZONTAL OUT THE WALL HORIZONTAL OUT THE WALL (12 inches minimum rise before elbow) NOTE: A “B” dimension greater than 18 inches will require a vertical rise before the elbow that is greater than 12 inches. See Venting graph on page 22.

-

Page 21: Vent System Identification

VENT SYSTEM IDENTIFICATION Begin the vent system installation by selecting the type of venting When selecting a vent system for use with the fireplace, refer to the to be installed and the path that it will take. Verify that clearances “Vent Fireplace” section in this manual to determine what systems are met throughout the path of the venting system. are acceptable. Check all clearances and venting components. Identify problems existing in the vent system, if any. Use pages 20 Determine how the vent system will be terminated out the side of to 27 for venting to eliminate issues after installation. -

Page 22: Venting Fireplace

VENTING FIREPLACE Below Grade Installation When it is not possible to meet the required vent termination clearances of 12 inches above grade level, a snorkel kit is recommended. It allows installation depth down to 7 inches below grade level. The 7 inches is measured from the center of the horizontal vent pipe as it penetrates through the wall. - Page 23 VENTING FIREPLACE To Use the Vent Graph EXAMPLE C: Determine the height of the center of the horizontal vent pipe. If the horizontal run to the outer wall flange is 17 feet, the vertical Using this dimension on the Sidewall Vent Graph, locate the dimension from the floor of the unit to the center of the termination point it intersects with the slanted graph line. must not be less than 7 feet 6 inches.

-

Page 24: Top Vent - Horizontal Termination

TOP VENT - HORIZONTAL TERMINATION Two Elbows One Elbow NOTE: Subtract 3 feet from the total horizontal measurement for each 90° elbow installed horizontally. Subtract 1-1/2 feet from the total horizontal measurement for each 45° elbow installed hori- zontally. EXAMPLE VENT RUNS INITIAL PIPE A (Vertical) B (Horizontal) LENGTH 24”... -

Page 25: Top Vent - Vertical Termination

TOP VENT - VERTICAL TERMINATION No Elbows Three Elbows Note: Subtract 3 feet from the total horizontal measurement for each 90° elbow installed horizontally. Subtract 1-1/2 feet from the total horizontal measurement for each 45° elbow installed hori- zontally. DIMENSIONS MINIMUM MAXIMUM 10’ 40’ EXAMPLE VENT RUNS Figure 37 INITIAL PIPE A (Vertical) B (Horizontal) -

Page 26: Vertical Termination

VERTICAL TERMINATION Locate and mark the center point of the vent pipe using a nail on General Maintenance the underside of the roof. Drive the nail through the center point. Inspect venting system semi-annually as follows: Mark the outline of the roof hole around this center point. 1. - Page 27 VERTICAL TERMINATION (continued) Vertical Through the Roof Applications Your Gas Fireplace has been approved for: a) Vertical installations up to 40 feet in height. b) Two sets of 45° elbow offsets within these vertical installations. A vent pipe from 0 to a maximum of 8 feet can be used between elbows. c) Wall straps must be used to support offset pipe every 4 feet This application will require that you first determine the roof pitch and use the appropriate venting components.

- Page 28 VERTICAL TERMINATION (continued) The included flue restrictor disc may be used in vertical vent runs of 10 to 40 feet as measured from the bottom of the fireplace. Use the restrictor disc when a more yellow flame is desired. 33741-11-0217 Page 27...

-

Page 29: Framing And Finishing

FRAMING AND FINISHING Installing Support Brackets Install a horizontal pipe support used for each 3 feet of horizontal run to framing members. Allow 3 inches of clearance to combustibles above 8 inch diameter pipe and elbows and 1 inches of clearance on both sides and bottom. - Page 30 FRAMING AND FINISHING (continued) Vertical Firestops Vertical runs of this system which pass through ceilings require ONE ceiling firestop at the hole in each ceiling through which the vent passes. Position a plumb bob directly over the center of the vertical vent component and mark the ceiling to establish the center point of the vent.

-

Page 31: Fiber Panel Placement

FIBER PANELS NOTE: Install liner before positioning the logs in place. Figure 50 PLACING THE REQUIRED FIBER PANELS AND FLOOR LINER INTO FIREPLACE: Locate the Center Floor Liner, and place on the fireplace floor in front of the front burner. Locate the Left and Right Side Floor Liner and place on the bottom left and bottom right of fireplace floor. Shift the three Floor Liner sections as far forward as possible. Locate Lower Rear Panel and place tight against rear wall into rear bottom bracket. Locate Left Panel and place into position against left-side firebox wall. Secure using front upper bracket. -

Page 32: Glowing Embers

GLOWING EMBERS 1. Apply a single layer of small “dime-sized” pieces of rock wool (glowing embers) in the shaded areas shown below. NOTE: Pieces of glowing embers should be fluffed up prior to placement onto the burner. NOTE: Replacement of loose material (glowing embers) must be purchased from Empire Comfort Systems, Inc. Application of excess loose material (glowing embers) may adversely affect performance of the appliance. WARNING All previously applied loose material must be removed prior to reapplication. TOP View - Ember Placement Shown in Shaded Area Figure 51 33741-11-0217... -

Page 33: Log Placement

LOG PLACEMENT Before you begin: Do not, handle these logs with your bare hands! Always wear gloves to prevent skin irritation. After handling logs, wash your hands gently with soap and water. All Logs The positioning of the logs is critical to the safe and clean operation of this appliance. Sooting and other problems may result if the logs are not properly and firmly positioned in the appliance. - Page 34 LOG PLACEMENT FRONT Part Number 33892 - Across (A) Part Number 33892 - Across (A) Part Number 33890 - Right Rear (B) Part Number 33890 - Right Rear (B) Part Number 33894 - Center Front (C) Part Number 33894 - Center Front (C) Part Number 33889 - Left Rear (D) Part Number 33889 - Left Rear (D) Part Number 33893 - Left Front (E)

- Page 35 LOG PLACEMENT 2. Place Across Log (A) onto front burner pins. TOP VIEW FRONT VIEW Page 34 33741-11-0217...

- Page 36 LOG PLACEMENT 3. Place Right Rear Log (B) onto the pin on the right side of Across Log (A) and onto the pin on the right side of the rear burner. TOP VIEW FRONT VIEW 33741-11-0217 Page 35...

- Page 37 LOG PLACEMENT 4. Place Left Front Log (E) on the pin on Across Log (A) which is 2nd to the left. Angle Left Front Log (E) so that it rests on the floor brick. TOP VIEW FRONT VIEW Page 36 33741-11-0217...

- Page 38 LOG PLACEMENT 5. Place Center Front Log (C) onto front burner tab. Orient as shown. TOP VIEW FRONT VIEW 33741-11-0217 Page 37...

- Page 39 LOG PLACEMENT 6. Place Left Rear Log (D) onto left-most pin on rear burner and left-most pin on Across Log (A). TOP VIEW FRONT VIEW Page 38 33741-11-0217...

- Page 40 LOG PLACEMENT 7. Place Center Rear Log (F) onto rear burner pin which is 2nd to the left and onto log pin on Right Rear Log (B). TOP VIEW FRONT VIEW Attention: When ordering parts, it is very important that part number and description of part coincide. 33741-11-0217 Page 39...

- Page 41 LOG PLACEMENT TOP VIEW FRONT VIEW Page 40 33741-11-0217...

-

Page 42: Component Wiring Diagram

DVLL27 COMPONENT WIRING DIAGRAM COMBUSTION BLOWER USER INTERFACE/ PILOT BATTERY HOLDER LEARN GREEN BUTTON ORANGE YELLOW AUX. SPLIT FLOW SOLENOID WHITE BLACK GAS CONTROL VALVE LOOP WHITE ORANGE OPTIONAL BLOWER FLAME SENSOR BLACK TO JUNCTION WHITE GREEN IGNITOR Figure 54 INDEX NUMBER DESCRIPTION PART NUMBER... -

Page 43: Multifunction Remote Operating Instructions

MULTIFUNCTION REMOTE OPERATING INSTRUCTIONS Figure 55 Technical Data Remote Control Supply voltage 4.5 V (three 1.5 V AAA batteries) Ambient temperature ratings 0-50°C (32 - 122°F) Radio frequency 315 MHz WARNING THE TRANSMITTER AND RECEIVER ARE RADIO FRE- QUENCY DEVICES. PLACING THE RECEIVER IN OR NEAR METAL MAY SEVERELY REDUCE THE SIGNAL RANGE. - Page 44 MULTIFUNCTION REMOTE OPERATING INSTRUCTIONS Initializing the System for the First Time With the batteries already installed in the Transmitter, push Remove the wall cover. Remove cover on the wall mounted the On button. The Receiver will “beep” four times to indicate battery back-up holder. See Figure 57. Install the four AA the Transmitter’s command is accepted and sets to the par- batteries into the wall mounted battery back-up holder then ticular code of that Transmitter.

- Page 45 MULTIFUNCTION REMOTE OPERATING INSTRUCTIONS Turn On the Appliance With the system OFF, press the ON/OFF Button on the Transmit- ter. The Transmitter display will show some other active Icons on the screen. At the same time the Receiver will activate the appli- ance. A single “beep” from the Receiver will confirm reception of the command. Turn OFF the Appliance With the system ON, press the ON/OFF Button on the Transmit- ter.

- Page 46 MULTIFUNCTION REMOTE OPERATING INSTRUCTIONS The Thermostat Feature may be disabled if desired. Smart Thermostat (Transmitter Operation) With all the (3) AAA type batteries installed: The Smart Thermostat function adjusts the flame height in ac- 1. Take out one AAA battery. cordance to the difference between the set point temperature 2.

- Page 47 MULTIFUNCTION REMOTE OPERATING INSTRUCTIONS Blower Control (Fan) Remote Dimmer Control (Light) If the appliance is equipped with a hot air circulating fan, the The auxiliary function controls the AUX power outlet by the dim- speed of the fan can be controlled by the Proflame system. mable light control. To activate this function, use the Mode Button The fan speed can be adjusted through six speeds. To activate (Figure 56) to index to the AUX icon. See Figures 73 and 74.

- Page 48 MULTIFUNCTION REMOTE OPERATING INSTRUCTIONS Split Flow Control Remote Auxiliary Relay Control (optional with this fireplace) The secondary burner is controlled by the split Flow. To activate The auxiliary function controls the AUX relay outlet. To activate this function use the Mode Button (Figure 56) to index to the this function use the Mode Button (Figure 56) to index to the SPLIT FLOW mode icon.

- Page 49 MULTIFUNCTION REMOTE OPERATING INSTRUCTIONS Continuous Pilot/Intermittent Pilot (CPI/IPI) Selection Button Lock With the system in “OFF” position press the Mode Button (Figure This function will lock the Buttons to avoid unsupervised opera- 56) to index to the CPI mode icon. See Figures 79 and 80. tion. Pressing the Up Arrow Button will activate the CPI. Pressing the To activate this function, press the MODE and UP Buttons at the Down Arrow Button will return to IPI. A single “beep” will confirm same time.

- Page 50 MULTIFUNCTION REMOTE OPERATING INSTRUCTIONS Using the Fireplace without a Remote Control Lockout State Definition The fireplace can be turned ON (HI only) and OFF with the wall A lockout state is reached when an ignition error occurs. The switch. The fireplace flame ON/OFF is the only function that will lockout state will remain set in memory as long as the power sup- operate; no flame adjustment, light or blower will work when us- plies are applied.

-

Page 51: Control System Troubleshooting

CONTROL SYSTEM TROUBLESHOOTING If the IFC is signaling lock out: The Verify the electrical connections’ integrity and board should be unlocked to make sure they are in accordance with the relevant reinitiate a pilot flame ignition (for Is the IFC board in system wiring diagram. - Page 52 CONTROL SYSTEM TROUBLESHOOTING Replace IFC board. Main burner lights when the pilot only Replace the gas valve. should light. Verify the pilot flame fully engulfs the tip of the sense electrode. If not, replace the pilot assembly. Replace the pilot assembly. Carefully clean the electrical connections of the sense cable and the IFC board sense cable connection.

-

Page 53: Lighting Instructions

LIGHTING INSTRUCTIONS FOR YOUR SAFETY READ BEFORE LIGHTING WARNING: IF YOU DO NOT FOLLOW THESE INSTRUCTIONS EXACTLY, A FIRE OR EXPLOSION MAY RESULT CAUSING PROPERTY DAMAGE, PERSONAL INJURY, OR LOSS OF LIFE. A. This appliance must be lighted with the remote control. C. - Page 54 33741-11-0217 Page 53...

-

Page 55: Fireplace Parts View

FIREPLACE PARTS VIEW 20 21 Page 54 33741-11-0217... -

Page 56: Fireplace Parts List

FIREPLACE PARTS LIST INDEX PART INDEX PART DESCRIPTION DESCRIPTION 33824 FLOOR LINER, LEFT ORIFICE 2.40mm, NAT P181 (REAR) 33826 FLOOR LINER, CENTER ORIFICE #53, LP 33825 FLOOR LINER, RIGHT P320 (REAR) BRICK PANEL, 33782 R11675 ORIFICE HOLDER LEFT R7572 JAMB NUT BRICK PANEL, 33783 RIGHT 33633... -

Page 57: Maintenance And Service

MAINTENANCE AND SERVICE MAINTENANCE WARNING Maintenance frequency must be determined individually for each application. Some considerations are: This appliance is equipped for natural gas or propane gas. • Exposure to water, dirt, chemicals and heat can damage the Field conversion is not permitted. gas control and shut down the control system. •... - Page 58 MAINTENANCE AND SERVICE NOTE WARNING It is normal for appliances fabricated of steel to give off some The use of substitute glass will void all product warranties. expansion and/or contraction noise during the start up or cool Care must be taken to avoid breakage of the glass. down cycle. Similar noises are found with your furnace heat Under no circumstances should this appliance be operated exchanger or car engine.

- Page 59 MAINTENANCE AND SERVICE Figure 83 Figure 85 Wiring If any of the original wire supplied with this unit must be replaced, it must be replace with 18 GA. 150°C wire or its equivalent. Figure 84 Page 58 33741-11-0217...

- Page 60 MAINTENANCE AND SERVICE Accessing Gas Valve and Controls Remove the Offset Frame and Glass Frame. Remove the Burner Components Heat Shield. See Figure 86. 3. Remove logs from firebox. Remove the liner bracket on top of the right-hand liner panel and remove right-hand liner panel. Remove upper rear liner panel.

-

Page 61: Important Safety Information

IMPORTANT SAFETY INFORMATION Before enclosing the vent pipe assembly, operate CAUTION the appliance to ensure it is venting properly. If the glass is cracked or damaged in any way, it should be replaced only with a complete glass frame assembly WARNING from Empire. -

Page 62: Safety Information For Users Of Lp Gas

SAFETY INFORMATION FOR USERS OF LP GAS Propane (LP-Gas) is a flammable gas which can cause The odorant in escaped gas can adsorb or absorb onto or fires and explosions. In its natural state, propane is odor- into walls, masonry and other materials and fabrics in a room. less and colorless. -

Page 63: Requirements For Massachusetts

REQUIREMENTS FOR MASSACHUSETTS For all side wall horizontally vented gas fueled equipment 3. SIGNAGE. A metal or plastic identification plate shall be installed in every dwelling, building or structure used in permanently mounted to the exterior of the building at a whole or in part for residential purposes, including those minimum height of eight feet above grade directly in line owned or operated by the Commonwealth and where the with the exhaust vent termination for the horizontally... -

Page 64: Master Parts Distributor List

MASTER PARTS DISTRIBUTOR LIST To Order Parts Under Warranty, please contact your local Empire dealer. See the dealer locator at www.empirecomfort. com. To provide warranty service, your dealer will need your name and address, purchase date and serial number, and the nature of the problem with the unit. -

Page 65: Warranty

WARRANTY Empire Comfort Systems Inc. warranties this hearth product to be free from defects at the time of purchase and for the periods specified below. Hearth products must be installed by a qualified technician and must be maintained and operated safely, in accordance with the instructions in the owner’s manual. Empire will not warranty any Château, Boulevard, or Mantis fireplace that is not installed by the selling dealer or that dealer’s direct contract agents. This warranty applies to the original purchaser only and is not transferable. All warranty repairs must be accomplished by a qualified gas appliance technician. Limited Lifetime Parts Warranty – Combustion Chamber, Heat Exchanger, and Factory-Installed Glass If the combustion chamber, heat exchanger (see parts list) or factory-installed glass fails because of defective workmanship or material, Empire will repair or replace at Empire’s option.

Need help?

Do you have a question about the ADVTL27FP90N-1 and is the answer not in the manual?

Questions and answers