Table of Contents

Advertisement

Quick Links

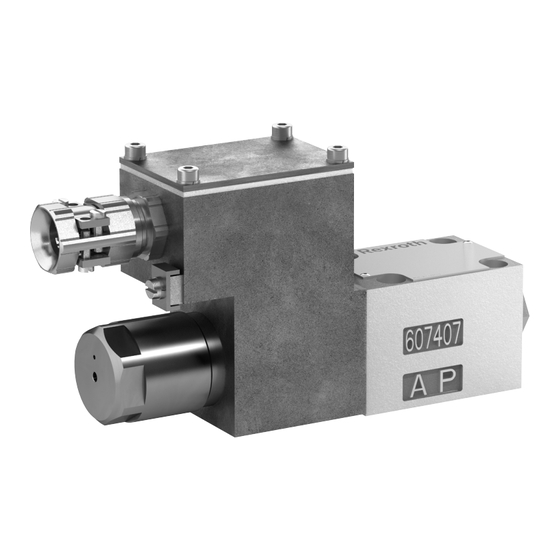

Directional seat valves,

direct-operated,

with solenoid actuation

(Area of application according to technical rules EAC TR CU 012/2011,

explosion protection marking: 2Ex e mc IIC T4 Gc X)

Type SED6 ..1X/...XE...SO710

Operating instructions

RE 22049-XE-710-B/02.20

Replaces: 11.15

Document no.: RA83517207_AB

English

Advertisement

Table of Contents

Summary of Contents for Bosch rexroth HYQUIP SED6 1X/ XE SO710 Series

- Page 1 Directional seat valves, direct-operated, with solenoid actuation (Area of application according to technical rules EAC TR CU 012/2011, explosion protection marking: 2Ex e mc IIC T4 Gc X) Type SED6 ..1X/...XE...SO710 Replaces: 11.15 Operating instructions Document no.: RA83517207_AB RE 22049-XE-710-B/02.20 English...

- Page 2 Our products are subject to a natural process of wear and aging. © All rights with Bosch Rexroth AG, also in case of applications for industrial property protection. It may not be reproduced or given to third parties without consent of Bosch Rexroth AG.

-

Page 3: Table Of Contents

10.1 Cleaning and care 10.2 Inspection and maintenance 10.3 Maintenance schedule 10.4 Repair 10.5 Rectifying external leakages 10.6 Spare parts Disassembly and removal Disposal 12.1 Environmental protection 12.2 Return to Bosch Rexroth AG 12.3 Packaging 12.4 Materials used RE22049-XE-710-B/02.20, SED6..1X/...XE...SO710, Bosch Rexroth AG... - Page 4 4/48 12.5 Recycling Extension and modification Troubleshooting 14.1 How to proceed for troubleshooting Technical data Appendix 16.1 List of addresses 16.2 Certificate according to technical rules EAC TR CU 012/2011 (excerpt) Index Bosch Rexroth AG, SED6..1X/...XE...SO710, RE22049-XE-710-B/02.20...

-

Page 5: About This Documentation

The hazard avoidance measures described must be observed. RE22049-XE-710-B/02.20, SED6..1X/...XE...SO710, Bosch Rexroth AG... - Page 6 The numbers indicate that the actions must be carried out one after the other. 1.3.3 Abbreviations The following abbreviations are used in this documentation: Table 4: Abbreviations Abbreviation Meaning European Standard International Organization for Standardization International Electrotechnical Commission Bosch Rexroth AG, SED6..1X/...XE...SO710, RE22049-XE-710-B/02.20...

-

Page 7: Safety Instructions

The valve may only be operated in a technically perfect condition and used as described in these operating instructions. The connection conditions, application conditions and performance data defined in these operating instructions must not be changed. RE22049-XE-710-B/02.20, SED6..1X/...XE...SO710, Bosch Rexroth AG... -

Page 8: Improper Use

• Non-compliance with the specified performance limits Changes are only permitted according to chapter 13 "Extension and modification". Bosch Rexroth AG does not assume any liability for damage caused by improper use. The user assumes all risks involved with improper use. 2.4 Qualification of personnel... -

Page 9: General Safety Instructions

• Only use original Bosch Rexroth accessories and spare parts in order to prevent any hazard to persons due to unsuitable spare parts. • Comply with the technical data and environmental conditions specified in the product documentation. -

Page 10: Product-Specific Safety Instructions

▶ Provide a suitable touch guard. ▶ During operation, only touch the valve solenoid with heat-protective gloves. Allow the valve solenoid to cool down to room temperature before touching it directly with your hands during maintenance works. Bosch Rexroth AG, SED6..1X/...XE...SO710, RE22049-XE-710-B/02.20... - Page 11 ▶ Only use the valve within the intended IP protection class or lower. ▶ Before the assembly, ensure that all seals and caps of the plug-in connections are tight and intact. RE22049-XE-710-B/02.20, SED6..1X/...XE...SO710, Bosch Rexroth AG...

-

Page 12: Notices On The Valve Use

We recommend using separate return lines. 2.8 Personal protective equipment The machine end-user must provide the personal protective equipment (such as gloves, working shoes, safety goggles, working clothes, etc...). Bosch Rexroth AG, SED6..1X/...XE...SO710, RE22049-XE-710-B/02.20... -

Page 13: Obligations Of The Machine End-User

The machine end-user is obliged to check in the order confirmation whether the delivered valve corresponds to the required area of application. The end-user of the Bosch Rexroth valve is responsible that • the valve is only being used according to the intended use as defined in these operating instructions. -

Page 14: General Information On Damage To Property And Damage To Product

Ensure that no cleaning agents are able to penetrate the hydraulic system. Environmentally harmful hydraulic fluid Leaking hydraulic fluid leads to environmental pollution. ▶ Immediately remedy possible leakage. ▶ Dispose of the hydraulic fluid in accordance with the currently applicable national regulations in your country. Bosch Rexroth AG, SED6..1X/...XE...SO710, RE22049-XE-710-B/02.20... -

Page 15: Scope Of Delivery

▶ Check the scope of delivery for possible transport damage, see chapter 6 "Transport and storage". In case of complaints, please contact Bosch Rexroth AG, see chapter 16.1 "List of addresses". Accessories such as valve subplates and valve mounting screws are not included in the scope of delivery and must be ordered separately. See chapter 7.6 "Required accessories"... -

Page 16: Product Identification

Marking according to technical rules EAC TR CU 012/2011 Other marking according to technical rules EAC TR CU 012/2011 Rated voltage Rated current Protection class by housing Graphical pre-fuse symbol 106.1 КЛАПАН ВЗРЫВОЗАЩИЩЕННЫЙ (explosion-protected valve) 106.2 Certification body and approval number Maximum pre-fuse Bosch Rexroth QR code EAC mark Bosch Rexroth AG, SED6..1X/...XE...SO710, RE22049-XE-710-B/02.20... -

Page 17: Transport And Storage

Do not transport the valve using components with low stability, e.g. solenoids, connectors or cables. Sharp edges! Danger of cut injuries! ▶ Wear suitable protective equipment for the transport of the safety valve. Further information regarding transport is available from Bosch Rexroth, see chapter 16.1 "List of addresses". RE22049-XE-710-B/02.20, SED6..1X/...XE...SO710, Bosch Rexroth AG... -

Page 18: Storing The Hydraulic Valve

12 months After expiry of the maximum storage time, we recommend having the valve checked by your competent Bosch Rexroth service. In case of questions regarding spare parts, please contact the Bosch Rexroth service responsible for your valve, see chapter 10.6 "Spare parts". -

Page 19: Assembly

The valve solenoid must not be painted or otherwise coated with non-conductive substances. This leads to a loss of the explosion protection. ▶ The valve housing may only be painted according to the provisions of ISO 80079-36, section 6.7; otherwise, explosion protection can no longer be ensured. RE22049-XE-710-B/02.20, SED6..1X/...XE...SO710, Bosch Rexroth AG... -

Page 20: Installation Conditions

Check the scope of delivery for completeness and possible transport damage. ▶ Also observe the safety instructions in chapter 2.6 "Product-specific safety instructions". ▶ Transport protection elements (e.g. cover plates, protective plugs) must be removed prior to use in an explosive atmosphere. Bosch Rexroth AG, SED6..1X/...XE...SO710, RE22049-XE-710-B/02.20... -

Page 21: Required Tools

Table 9: Special tool Material number Special tool R900024943 Address for ordering The address of our responsible sales organizations can be found on the Intranet at accessories and valves www.boschrexroth.com and in the appendix 16.1 "List of addresses". RE22049-XE-710-B/02.20, SED6..1X/...XE...SO710, Bosch Rexroth AG... -

Page 22: Assembling The Valve

▶ Do not remove the protective caps of the valve until assembly. ▶ After disassembly, seal the hydraulic fluid bores with suitable cap elements. ▶ Immediately remove hydraulic fluid that has leaked out. Bosch Rexroth AG, SED6..1X/...XE...SO710, RE22049-XE-710-B/02.20... - Page 23 When using the subplates mentioned under 7.6 "Required accessories", tighten all four valve mounting screws with a tightening torque of 7 Nm ± 0.7 Nm (with a friction coefficient of μ = 0.09...0.14). This tightening torque refers to total the maximum admissible operating pressure. RE22049-XE-710-B/02.20, SED6..1X/...XE...SO710, Bosch Rexroth AG...

- Page 24 Make sure that all pipes and hose lines and every combination of connection pieces, couplings or connection points with hoses or pipes are checked for their operational safety by a person with appropriate knowledge and experience. Bosch Rexroth AG, SED6..1X/...XE...SO710, RE22049-XE-710-B/02.20...

- Page 25 The use of connection lines with shielding or sheathing can lead to potential backfeeding and is thus an explosion hazard! ▶ Only use connection lines without shielding or armoring. For information on the prescribed pre-fuse, see "Data sheet 22049-XE-710". RE22049-XE-710-B/02.20, SED6..1X/...XE...SO710, Bosch Rexroth AG...

- Page 26 15 cm of the cable and line entry. Connection of the valve solenoid is polarity-independent. Valve solenoids for connection to alternating voltage have a bridge rectifier which is integrated in the vale solenoid. Bosch Rexroth AG, SED6..1X/...XE...SO710, RE22049-XE-710-B/02.20...

- Page 27 Remove the outer sheath of the connection line and the insulation of the individual conductors. Press the wire end ferrules to the individual conductors. For the stripping lengths, refer to Fig. 4 and Table 10. Fig. 4: Stripping lengths RE22049-XE-710-B/02.20, SED6..1X/...XE...SO710, Bosch Rexroth AG...

- Page 28 Remove the plug screw (hexagon, wrench size 22). Remove the cable and line entry. To do this, unscrew the cable and line entry from the double nipple (2). Make sure not to lose the O-ring (1) between the housing and double nipple. Bosch Rexroth AG, SED6..1X/...XE...SO710, RE22049-XE-710-B/02.20...

- Page 29 Assemble the O-ring onto the pole tube and slide it forward up to the solenoid coil. Re-tighten the mounting nut of the valve solenoid (hexagon nut, wrench size 32, tightening torque 4 + 1 Nm). Afterwards, there must be no visible gap between the solenoid coil and the valve housing. RE22049-XE-710-B/02.20, SED6..1X/...XE...SO710, Bosch Rexroth AG...

-

Page 30: Commissioning

The following applies to all valves irrespective of the type of connection: connection line ▶ The connection line must be checked for proper condition by or under the guidance and supervision of a specialized electrician before the initial commissioning or any re-commissioning. ▶ Replace damaged connection lines. Bosch Rexroth AG, SED6..1X/...XE...SO710, RE22049-XE-710-B/02.20... - Page 31 Ensure that no hydraulic fluid leaks at the valve and the connections during operation. ▶ Check for internal leakage. The check must be carried out according to the possibilities present at the hydraulic system. Internal leakage can be valve-specific but does not necessarily affect the functionality of the valve. RE22049-XE-710-B/02.20, SED6..1X/...XE...SO710, Bosch Rexroth AG...

-

Page 32: Operation

The valves are equipped with a manual override. Using this manual override, the switching function of the valve can also be triggered if the solenoid is not energized. The manual override is only intended for manual operation. It is not suitable for frequently recurring manual operation. Bosch Rexroth AG, SED6..1X/...XE...SO710, RE22049-XE-710-B/02.20... -

Page 33: Maintenance And Repair

Check that all seals and caps of the plug-in connections are firmly fitted so that no humidity can penetrate the valve during cleaning. ▶ Remove external dirt and keep sensitive and important parts like valve solenoids clean. ▶ Remove dust and dirt accumulations from the valve at regular intervals. RE22049-XE-710-B/02.20, SED6..1X/...XE...SO710, Bosch Rexroth AG... -

Page 34: Inspection And Maintenance

In case of visible damage, remove the valve and have it repaired. Check all screws and connections for tight seat. Check all connection lines for damage. Replace the connection line if there is any visible damage. Bosch Rexroth AG, SED6..1X/...XE...SO710, RE22049-XE-710-B/02.20... -

Page 35: Maintenance Schedule

Tightening torque of the cover screws: 1...1.1 Nm. 10.3 Maintenance schedule Valves require low maintenance if used as intended. For a long and reliable operation of the valve, Bosch Rexroth recommends regularly checking the hydraulic system and the valve. 10.3.1 Checking for leakage Check the valve for leakage. -

Page 36: Rectifying External Leakages

In case of questions about spare parts, please contact your responsible Bosch Rexroth Service: Bosch Rexroth AG Service Hydraulics Bürgermeister-Dr.-Nebel-Str. 8 97816 Lohr am Main Tel: +49 (0) 9352/40 50 60 service@boschrexroth.de For the addresses of our sales and service network please refer to: www.boschrexroth.com/adressen Bosch Rexroth AG, SED6..1X/...XE...SO710, RE22049-XE-710-B/02.20... -

Page 37: Disassembly And Removal

Close the hydraulic channels of the subplate (on the customer side) to avoid contamination. If the valve is exchanged, all further steps are analogous to mounting, see chapter 7 "Assembly". RE22049-XE-710-B/02.20, SED6..1X/...XE...SO710, Bosch Rexroth AG... -

Page 38: Disposal

The materials for disposable packaging are mostly cardboard, wood, and expanded polystyrene. They can be recycled without any problems. For ecological reasons, disposable packaging should not be used for returning products to Bosch Rexroth. 12.4 Materials used Hydraulic components from Bosch Rexroth do not contain any hazardous materials that could be released during intended use. - Page 39 If so: What were they? – Was the valve and/or the machine used as intended? – How did the fault become apparent? ▶ Try to get a clear idea of the cause of error. Ask the direct (machine) operator if required. RE22049-XE-710-B/02.20, SED6..1X/...XE...SO710, Bosch Rexroth AG...

- Page 40 15 Technical data For the technical data of your valve, please refer to "Data sheet 22049-XE-710". Bosch Rexroth AG, SED6..1X/...XE...SO710, RE22049-XE-710-B/02.20...

- Page 41 Headquarters Bosch Rexroth AG Zum Eisengießer 1 97816 Lohr am Main Germany Phone +49 (0) 9352/40 30 20 Email my.support@boschrexroth.de The addresses of our sales and service network and sales organizations can be found at www.boschrexroth.com/adressen RE22049-XE-710-B/02.20, SED6..1X/...XE...SO710, Bosch Rexroth AG...

- Page 42 42/48 Appendix 16.2 Certificate according to technical rules EAC TR CU 012/2011 (excerpt) Bosch Rexroth AG, SED6..1X/...XE...SO710, RE22049-XE-710-B/02.20...

- Page 43 Appendix 43/48 RE22049-XE-710-B/02.20, SED6..1X/...XE...SO710, Bosch Rexroth AG...

- Page 44 44/48 Appendix Bosch Rexroth AG, SED6..1X/...XE...SO710, RE22049-XE-710-B/02.20...

- Page 45 Valve insert Valve subplate ▶ L List of addresses 41, 42 ▶ M Maintenance Maintenance and repair Maintenance schedule Manual override Materials used ▶ N Name plate ▶ O Obligations of the machine end-user Operation RE22049-XE-710-B/02.20, SED6..1X/...XE...SO710, Bosch Rexroth AG...

Need help?

Do you have a question about the rexroth HYQUIP SED6 1X/ XE SO710 Series and is the answer not in the manual?

Questions and answers