Summary of Contents for Global ZZ 9567 DD-AUT

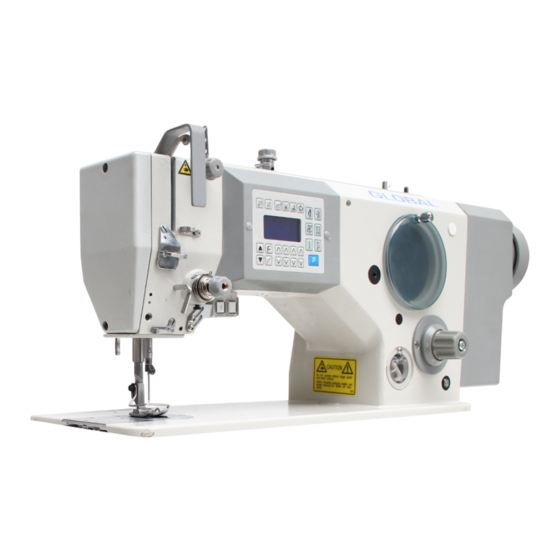

- Page 1 ZZ 9567 DD-AUT Instruction & parts manual Always switch off the electricity when working on the machine.

-

Page 3: Table Of Contents

CONTENT 1 Safety operating guide........2 2 Operating notice..........2 3 Operating condition...........2 4 Chief specification...........2 5 Install belt..........3 6 Install belt cover..........3 7 The needle bar position adjustment......4 8 Operation guide..........4 9 To lubricate the machine........4 10 The hook lubricating condition adjustment.....4 11 Time machine cleaning.........5 12 Wind the bobbin..........5 13 Install the needle..........6... - Page 4 36 Form stitch of patterns cam with part number....17 37 Backtacking with solenoid........18 38 Presser foot lifting..........19 39 Bobbin winder..........20 40 Thread trimming..........20 41 Machine electronic control and drive......21...

-

Page 5: Safety Operating Guide

Thank you to choose zigzag stitch series industrial sewing machine This is an instruction manual & parts list, it could help you how to use machine & how to care of machine correctly and make you convenience to look up parts. In order to avoid trouble occurring, please read this instruction manual carefully before operating machine, and please accept safety operating guides with come from special technicians or peoples of having operator experiences. -

Page 6: Install Belt

Stitch type double thread zig-zag lockstitch Stitch length max.5mm Foot lifting with hand lever 12mm Foot lifting with knee lever or solenoid Lubricating mode Semi-automatic lubricating Needle system 134;134-35 DC mot Manually controlled subclass or-positioning motor without further functions Solenoid-controlled subclass DC motor (AC servo) positioning motor with reverse run after thread trimming Sewing head weight... -

Page 7: The Needle Bar Position Adjustment

The needle bar stop position adjustment If the localizer adopts external hanging type, please refer to the motor instruction book for the adjustment method → “Up” Position When the pedal is kicked down by heel, the machine should stop at “Up” position, i.e. the highest position of take-up lever. →... -

Page 8: Time Machine Cleaning

Time machine cleaning The hook, feed dog and other parts of machine should be cleaned daily, and drop two or three coal oil into hook and other parts that need to be lubricated. Clean all the spilth after ending of highest speed operation of machine, then lubricate the machine with oil. -

Page 9: Install The Needle

Insert the needle Please use DPx17 NO. 90-120 needle, the thickness of needle should be decided according to the thickness of sewing material & thread. When insert the needle, rotate the hand wheel until the needle bar has reached its top position, loosen the screw on the lower part of the needle bar and insert the needle. Be sure that the long groove of the needle directly toward the operator and check whether the needle shank has reached the bottom of the needle hole. -

Page 10: To Thread Upper Thread

To thread upper thread Let the take up lever at its highest position. Then threading as shown in picture. Unwind a sufficient portion of thread, and pass it through the thread guide (1) and (2), then lead it through the tension assembly (6) and thread take up spring (5), thread guides (7), (4) and (3) into the thread take up lever. -

Page 11: The Thread Take Up Spring Tension Adjustment

The thread take up spring tension adjustment Loosen thread tension assembly screw (1), take away the thread tension assembly from machine to adjust the take up spring (4). Firstly loosen the screw (2) of bushing (3), and then adjust the angle position of lever (5). -

Page 12: Zig-Zag Stitch Width (Throw) And Position Setting

Setting of zig-zag stitch width (throw) and position Attention! At setting the zig-zag stitch width (throw) and position the needle must not be inside the sewn material. There is a threat of the needle breaking! Setting of zig-zag stitch width Press the lever (1) in the arrow direction (A) until it strikes the lever (2). -

Page 13: Tooth Clearance Setting Of Zigzag Stitch Gear

Tooth clearance setting of zigzag stitch gear The tooth clearance of zigzag stitch should be as small as possible. No overlap instead of clearance, however, may arise in any mutual position of the gears. → Dismantle the machine top cover. →... -

Page 14: Zigzag Stitch Width

→ Fix the lever (5) so that the mark (6) is located opposite the zero on the zigzag stitch scale (7). Zigzag stitch width The zigzag stitch width setting must be limited to the value prescribed for the applied sewing equipment with the setting tolerance -5% of the prescribed value. →... -

Page 15: Lateral Setting Of Needle Stab Position

Lateral setting of needle stab position Both dead centers of the needle lateral motion at the zigzag stitch sewing should be at the same distance from the throat plate needle hole edges. → Dismantle the cover (1) and the hole stop (2) from the rear side. →... -

Page 16: Lateral Setting Of Straight Stitches On Throat Plate Needle Hole Edges, Arresting Of Zigzag Stitch Setting Mechanism

Lateral setting of straight stitches on throat plate needle hole edges, arresting of zigzag stitch setting mechanism If the sewing equipment allows using the maximum zigzag stitch width, which is characteristic of the particular machine type, the position of the border straight stitches should be adjusted so that it aligns with the zigzag stitch border. If the throat plate needle hole is narrower than the maximum zigzag stitch width of the particular sewing machine type, the lever for the position setting of the border stitch must be fixed in the central position. -

Page 17: Bobbin Case Driver

Bobbin case driver The distance between the bobbin case driver and the bobbin case groove bottom should be (A)=0.7mm. → Dismantle the throat plate and tilt the machine. → Loosen the screw (1). → Shift the driver (2) to the distance (A)=0.7mm. →... -

Page 18: Timing Between Needle And Feed Dog Motion

Timing between needle and feed dog motion(see below picture) When needle point A reaches needle plate top surface B, feed dog surface C should be keep accordant on height with needle plate top surface. It is the standard synchronous relationship. Adjusting method as below: →... -

Page 19: Form Stitch Of Patterns Cam Series

Form stitch of patterns cam series The setting should be carried out in the sequence as described herein. Tooth clearance setting of form stitch gear The tooth clearance of the form stitch gear should be as small as possible. No overlap instead of clearance, however, may arise in any mutual position of the gears. -

Page 20: Setting Of Needle Stab Position

Setting of needle stab position If the wheel steering cam of the straight stitch is mounted, the needle should be located in both directions in center of the throat plate needle hole. → Adjust the needle position in feeding direction as per section 24 →... -

Page 21: Backtacking With Solenoid

Backtacking with solenoid At the maximum stitch length, at the backtacking mechanism dislocation with the solenoid, its movable core should not strike the fixed one. → Set the maximum stitch length. → Press the backtacking lever down to the stop and hold it in this position. →... -

Page 22: Presser Foot Lifting

Foot lifting with knee lever Regulation The foot stroke with the knee lever should be 12.5mm, the space (A) = approximately 2mm if the knee lever is in the initial position. → Lower the presser foot on the throat plate. →... -

Page 23: Bobbin Winder

Bobbin winder Regulation If the bobbin winder is switched off, the space between the driving and driven wheels of the bobbin winder should be as small as possible, but they must not touch each other. When winding the thread, the bobbin winder should automatically switch off when the thread is wound up to 0.5mm under the bobbin outer diameter. -

Page 24: Machine Electronic Control And Drive

Trimming lever Regulation The trimming lever (6) should be located as high as possible, but it should not rub the plate (5). The eccentric bolt (2) groove should be in horizontal position. → Tilt the machine. → Loosen the screw (3) and turn the eccentric bolt (4) so that the lever does not rub (6) the plate (5), however, it should be positioned as high as possible. - Page 25 Trimming cam Regulation If the trimmer is not active, then the shortest distance between the cam (3) and roller (4) should be 0.1mm. Timing of the cam: if the needle point is approximately (A) = 1mm over the throat plate, the cam screws should be turned downwards and their axes perpendicularly to the machine base plate.

- Page 26 ZIGZAG FLAT BED SEWING MACHINE PARTS LIST...

- Page 27 CONTENT Arm bed and its accessories ………………………… 2 Bobbin winder and Thread tension parts ……………4 Arm shaft and needle bar thread take up parts …… 6 Needle bar vibrating parts …………………………… 10 Needle bar vibrating parts …………………………… 12 F. Presser foot parts…………………………………… 14 Stitch length adjustment and backstitch parts ……...

- Page 28 A.Arm bed and its accessories Part No. Name 82800-DS 82800-D 82800-DY A01 7.02.11.059 Thread take up lever guard cover A02 7.02.15.1087 Screw A03 7.02.16.058 Plastic plug A04 7.02.16.032 Felt A05 7.02.16.500 Line card A06 7.02.15.1080 Upper clip of supply cord screw A07 7.02.16.167 Upper clip of supply cord A08 7.02.16.166...

-

Page 29: Arm Bed And Its Accessories

A.Arm bed and its accessories... - Page 30 B.Bobbin winder and thread tension parts Part No. Name 82800-DS 82800-D 82800-DY 7.02.11.590 Top cover 7.02.01.210 Top cover thread tension assy. Regulating handle Spring Tension disc Thread guide lever 7.02.08.369 Thread tension plate bushing 7.02.15.056 Screw 7.02.20.070 Thread winder thread cutter 7.02.15.1031 Thread cutter screw 7.02.01.213 Thread winder assy.

-

Page 31: Bobbin Winder And Thread Tension Parts

B.Bobbin winder and thread tension parts... - Page 32 C.Arm shaft and needle bar thread take up parts Part No. Name 82800-DS 82800-D 82800-DY C01 7.02.10.091 Thread take up lever support stud C02 7.02.15.411 Thread take up lever support stud screw C03 7.02.05.066 Thread take up lever assy. 7.02.05.530 Thread take up lever assy.

-

Page 33: Arm Shaft And Needle Bar Thread Take Up Parts

C.Arm shaft and needle bar thread take up parts... - Page 34 C.Arm shaft and needle bar thread take up parts Part No. Name 82800-DS 82800-D 82800-DY C39 7.02.15.428 Collar screw C40 7.02.08.102 Arm shaft bearing collar C41 7.02.07.051 Vibrating needle drive gear C42 7.02.15.126 Small gear screw C43 7.02.03.490 Arm shaft C44 7.02.15.797 Stopper plate screw C45 7.02.11.224...

- Page 35 C.Arm shaft and needle bar thread take up parts...

- Page 36 D.Needle bar vibrating parts Part No. Name 82800-DS 82800-D 82800-DY D01 7.02.15.405 Fixed bracket screw D02 7.02.18.071 Washer D03 7.02.13.043 Needle bar vibrating fixed bracket D04 7.02.01.039 Needle bar vibrating bracket D05 7.02.15.407 Needle bar vibrating bracket screw D06 7.02.15.391 Tighten screw D07 7.02.15.406 Tighten screw D08 7.02.08.096 Needle bar vibrating shaft bushing (left) D09 7.02.15.410 Needle bar vibrating shaft bushing screw...

-

Page 37: Needle Bar Vibrating Parts

D.Needle bar vibrating parts... - Page 38 E.Needle bar vibrating parts Part No. Name 82800-DS 82800-D 82800-DY E01 7.02.08.367 Eccentric bushing E02 7.02.15.268 Nut E03 7.02.15.047 Screw E04 7.02.13.440 Vibrating bracket E05 7.02.18.016 Washer E06 7.02.18.055 Elastic washer E07 7.02.15.008 Screw E08 7.02.10.303 Retainer ring E09 7.02.18.057 Washer E10 7.02.15.1031 Screw E11 7.02.06.084 Turntable E12 7.02.15.405 Turntable mounting screw...

-

Page 39: Needle Bar Vibrating Parts

E.Needle bar vibrating parts... - Page 40 F.Presser foot parts Part No. Name 82800-DS 82800-D 82800-DY F01 7.02.15.414 Presser foot pressure adjustive screw F02 7.02.15.415 Presser bar spring support screw F03 7.02.17.085 Presser bar spring F04 7.02.18.072 E-ring F05 7.02.10.092 Presser bar pin F06 7.02.16.033 Felt F07 7.02.12.045 Presser bar slide block F08 7.02.15.417 Presser bar slide block screw...

-

Page 41: Presser Foot Parts

F.Presser foot parts... - Page 42 G.Stitch length adjustment and backstitch parts Part No. Name 82800-DS 82800-D 82800-DY G01 7.02.19.040 Backstitch electromagnetic G02 7.02.10.304 Backstitch electromagnetic connecting pin G03 7.02.18.031 E-ring G04 7.02.13.443 Backstitch electromagnetic mounting plate G05 7.02.18.055 Spring washer G06 7.02.15.1085 Screw G07 7.02.15.1080 Screw G08 7.02.18.098 Spring washer...

-

Page 43: Stitch Length Adjustment And Backstitch Parts

G.Stitch length adjustment and backstitch parts... - Page 44 H.Lower shaft, feed dog and presser foot lifting parts Part No. Name 82800-DS 82800-D 82800-DY 7.02.16.067 Oil spile 7.02.03.079 Feed shaft 7.02.08.103 Feed shaft bushing (left) 7.02.15.428 Bushing screw 7.02.15.448 Feed crank (left) screw 7.02.05.081 Feed crank (left) 7.02.15.408 Feed dog holder adjustive pin screw 7.02.08.104 Feed shaft bushing (middle) 7.02.15.430...

-

Page 45: Lower Shaft, Feed Dog And Presser Foot Lifting Parts

H.Lower shaft, feed dog and presser foot lifting parts... - Page 46 I.Hook assembly Part No. Name 82800-DS 82800-D 82800-DY 7.02.18.026 Elastic stop ring 7.02.04.031 Bearing 7.02.06.041 Opener cam 7.02.15.434 Opener cam screw 7.02.04.033 Opener cam bearing 7.02.08.112 Opener cam bushing 7.02.08.111 Hook opener 7.02.15.017 Hook opener screw 7.02.07.058 Hook drive gear 7.02.15.126 Drive gear screw 7.02.04.026 Bearing 7.02.15.439 Felt fixed screw...

-

Page 47: Hook Assembly

I.Hook assembly... - Page 48 J.Hook assembly (Small hook) Part No. Name 82800-DS 82800-D 82800-DY 7.02.18.026 Elastic stop ring 7.02.04.031 Bearing 7.02.06.093 Opener cam 7.02.15.434 Opener cam screw 7.02.04.033 Opener cam bearing 7.02.08.112 Opener cam bushing 7.02.08.111 Hook opener 7.02.15.017 Hook opener screw 7.02.07.072 Hook drive gear 7.02.15.126 Drive gear screw 7.02.04.026 Bearing 7.02.15.439 Felt fixed screw...

-

Page 49: Hook Assembly (Small Hook)

J.Hook assembly (Small hook) - Page 50 K.Hook assembly(vibrating needle 8MM) Part No. Name 82800-DS 82800-DY vibrating needle 8MM 7.02.18.026 Elastic stop ring 7.02.04.031 Bearing 7.02.09.180 Collar 7.02.15.428 Collar screw 7.02.18.084 Hook saddle bottom cover washer 7.02.16.094 Felt 7.02.13.047 Hook saddle bottom cover 7.02.15.006 Hook orientation claw screw 7.02.07.325 Hook drive gear 7.02.15.126 Drive gear screw 7.02.04.026 Bearing...

-

Page 51: Hook Assembly(Vibrating Needle 8Mm)

K.Hook assembly(vibrating needle 8MM)... - Page 52 L.Thread trimming parts Part No. Name 82800-DS 82800-D 82800-DY 7.02.15.104 Screw 7.02.02.073 Slide plate 7.02.20.031 Fixed knife 7.02.15.103 Fixed knife screw 7.02.11.102 Movable knife guide plate 7.02.20.030 Movable knife 7.02.11.103 Movable knife support plate 7.02.11.098 Movable knife assistant support plate 7.02.18.061 Spring washer 7.02.15.101 Movable knife assistant support plate screw 7.02.15.102 Movable knife support plate screw...

-

Page 53: Thread Trimming Parts

L.Thread trimming parts... - Page 54 M.Tension release, electrocircuit board, oil circuit parts Part No. Name 82800-DS 82800-D 82800-DY 7.02.19.039 Thread releasing solenoid 7.02.15.1080 Screw 7.02.11.594 Mounting plate 7.02.15.797 Screw 7.02.15.432 Screw 7.02.16.505 Collection circuit board housing 7.02.15.1083 Support screw 7.02.15.017 Pressure plate screw 7.02.15.1162 Pressure plate screw 7.02.15.442 Pressure plate screw 7.02.11.595 Thread tension plate 7.02.11.596 Circuit board...

-

Page 55: Tension Release, Electrocircuit Board, Oil Circuit Parts

M.Tension release, electrocircuit board, oil circuit parts... - Page 56 N.Automatic drive parts Part No. Name 82800-DS 82800-D 82800-DY 7.01.02.030 Machine casting 7.02.04.210 Bearing 7.02.15.050 Screw 7.02.08.560 Trident coupling 7.02.16.521 Rubber pad 7.02.15.051 Screw 7.02.08.561 Motor coupling 7.02.09.170 Retaining ring 7.02.15.544 Screw 7.02.19.401 Motor 7.02.15.056 Tighten screw 7.02.07.320 Handwheel bushing 7.02.07.321 Handwheel 7.02.15.1120...

-

Page 57: Automatic Drive Parts

N.Automatic drive parts... - Page 58 O.Special parts for cam patterns zigzag machine Part No. Name Remark 7.02.15.382 Hexagonal nut 7.02.17.113 Spring washer 7.02.06.060 Cam 7.02.16.077 Seal cover 7.02.10.133 Worm wheel shaft 7.02.08.094 Worm wheel shaft bushing (back) 7.02.15.399 Screw M6×14 7.02.15.431 Screw M6(0.75)×10 7.02.15.384 Screw M6(0.75) 7.02.07.069 Worm wheel 7.02.15.405 Screw...

-

Page 59: Special Parts For Cam Patterns Zigzag Machine

O.Special parts for cam patterns zigzag machine... - Page 60 P.Accessories Part No. Name 82800-DS 82800-D 82800-DY vibrating needle 8MM 7.02.21.140 Needle 7.02.21.144 Bobbin 7.02.21.142 Open end wrench 7.02.21.003 Screw driver (big) 7.02.21.002 Screw driver (middle) 7.02.21.001 Screw driver (small) 7.02.21.238 Hexagonal wrench M6mm 7.02.21.143 Hexagonal wrench M5mm 7.02.21.099 Hexagonal wrench M5mm 7.02.21.209 Hexagonal wrench M3mm 7.02.21.098 Hexagonal wrench M2.5mm 7.02.21.080 Hinge...

-

Page 61: Accessories

P.Accessories...

Need help?

Do you have a question about the ZZ 9567 DD-AUT and is the answer not in the manual?

Questions and answers