Summary of Contents for VAT 11.1 HV Series

- Page 1 Translation of Installation- Operating- and Maintenance instruction HV-Gate valve Solenoid and position indicator, 11146-PE48 250 mm / 10" 1113970EA...

- Page 2 VAT products. The VAT firmware contains an unlimited number of user licenses. The VAT firmware may only be used for the permitted purposes. The creation of copies of the VAT firm- ware is allowed. It is however strictly forbidden to give copies of the VAT firmware to other people.

-

Page 3: Table Of Contents

LIST OF CONTENTS List of contents 1 General information ............................. 1.1 Scope of delivery ............................ 1.2 Other applicable documents ........................1.3 Typographical conventions........................1.3.1 Important information ........................1.3.2 Danger levels ..........................1.4 Forwarding ............................. 1.5 Document number and index ......................... 2 Safety ................................ - Page 4 LIST OF CONTENTS 6.2 Response in the event of loss of compressed air ................. 17 6.3 Response in the event of loss of voltage ....................17 7 Troubleshooting ............................18 7.1 Error table .............................. 18 8 Maintenance ..............................19 8.1 Change drive and mechanism ....................... 19 8.2 Cleaning seals ............................

-

Page 5: General Information

This document contains the original Assembly and Operating Instructions (AOI). Scope of delivery The scope of delivery corresponds to your order with VAT Vakuumventile AG. When you receive your order, check it against your order list. If you find discrepancies between what was ordered and delivered, contact VAT Vakuumventile AG. -

Page 6: Forwarding

GENERAL INFORMATION Forwarding This document is part of the product and if the product is forwarded, the document must also be forwarded to the product recipient. If the product becomes part of a machine as a result of installation on or combination with other parts, or by another method, this document must also be forwarded when the machine is sold. -

Page 7: Safety

Personal protective equipment is not included in the scope of delivery. To ensure the product is not contaminated or damaged, VAT recommends that the operator pro- vides at least the following personal protective equipment for work with and on the product. If fur- ther protective clothing is required as a result of a special use of the product, the operator is re- sponsible for making this known. -

Page 8: Staff Obligations

SAFETY – Have all activities carried out by qualified staff. – Qualified staff are those people authorized to operate devices, systems and electrical cir- cuits in accordance with safety standards. – Keep unqualified staff away from danger zones. – Make sure that everybody who works on or with the product has read and understood the doc- ument. -

Page 9: Sparks

Improper handing of hazardous materials can cause injury and harm the environment. ► Remove, for example, any toxic, corrosive or microbiological hazardous materials before you send the product to VAT. Dispose of the product correctly; see section Disposal [ 26]. -

Page 10: Technical Data

TECHNICAL DATA Technical data Valve Drive pneumatic, double acting, with 3-position actua- Feedthrough Bellows Flange type ISO-F Nominal diameter (DN) 200 mm Valve body leak rate [20 °C] < 1 · 10-9 mbar ls-1 Valve seat leak rate [20 °C] <... -

Page 11: Control Valve

TECHNICAL DATA Response in the event of loss of voltage Valve open Valve closes Valve closed Valve remains closed Valve in center position Valve closes Control valve Type Max. voltage Defined by order Position indicator Max. current 1.2 A Type Micro switch ≤... -

Page 12: Design And Function

DESIGN AND FUNCTION Design and function Type label The article and serial number and the order number are indicated on the product or on a type label. Illustration 1: Type label Article and serial number Order number Principle of operation The drive moves the plate into the Open, into the Close position or into the freely definable posi- tion. -

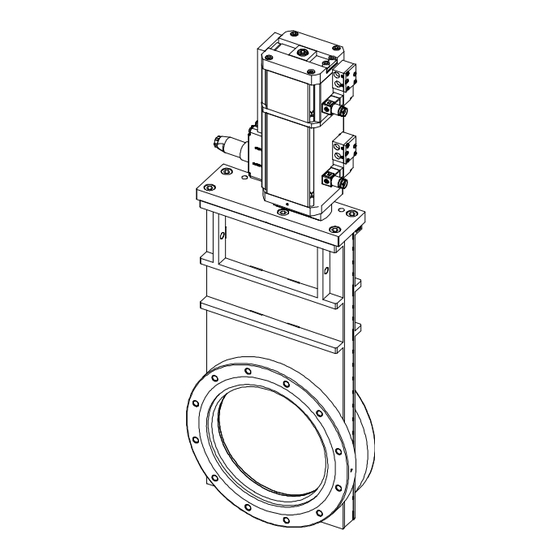

Page 13: Valve Structure

DESIGN AND FUNCTION Valve structure 1 Compressed air connection 5 Drive 2 Compressed air connection 6 Flange 3 Housing 7 Control valve 4 Position indicator 1113970EA... -

Page 14: Electrical Installation And Assembly

If the product or packaging shows damage, then photograph the damage and the type plate and report the damage to the VAT Service Center. 1. Check whether the packaging is damaged. If it is, report this to VAT. 2. Make sure that the protective sleeves are not damaged. -

Page 15: Connecting Compressed Air Supply

ELECTRICAL INSTALLATION AND ASSEMBLY Connecting compressed air supply With control valve An exhaust line is not required. 1. Connect compressed air at the IN connection. Without control valve 1. Connect compressed air at the Open and Close connections. Control valve delivered separately Compressed air connection on the pneumatic cylinder: ✓... -

Page 16: Installation Clearances

ELECTRICAL INSTALLATION AND ASSEMBLY 1. Connect the cable to the position indicator. Control valve The product has two control valves to move to the Open, Close and Intermediate positions. See section Moving parts [ Installation clearances During installation, ensure there is sufficient clearance. This ensures there is enough space for connections and air circulation. -

Page 17: Operation

OPERATION Operation Response in operation The drive regulates the opening and closing of the valve during operation. Response in the event of loss of compressed air The response in the event of loss of compressed air depends on the position of the plate. If the plate is closed and the supply of compressed air is interrupted, then the plate remains closed. -

Page 18: Troubleshooting

TROUBLESHOOTING Troubleshooting Error table Error Source Error elimination Section Cleaning seals [ Leak at plate Contamination in the Clean plate and seals. plate seat and on the plate Valve does not Voltage supply inter- Check voltage supply open/close rupted Connecting compressed Valve does not Compressed air supply Check compressed air... -

Page 19: Maintenance

The type of application may make it necessary to shorten the maintenance intervals. In this case, the maintenance schedule must be adjusted accordingly. In addition to the maintenance interval, the VAT Service Center also offers other services. If you require further information about the maintenance intervals or services, please contact VAT. -

Page 20: Cleaning Seals

MAINTENANCE Drive and mechanism are mounted. Cleaning seals 1. Clean the sealing surfaces using a lint-free and dust-free cloth and a little isopropanol. 2. Clean the O-ring using a lint-free and dust-free cloth. Changing the plate See also Change drive and mechanism [... - Page 21 MAINTENANCE See also Change drive and mechanism [ 1113970EA...

-

Page 22: Consumable And Spare Parts

Non-original spare parts and wear-sensitive parts! If you use non-original spare parts and wear-sensitive parts, you may damage the product. ► Only use original spare parts and wear-sensitive parts from VAT. Overview of consumable parts Consumable part kit Position Description... -

Page 23: Overview Of Auxiliary Devices

CONSUMABLE AND SPARE PARTS Overview of auxiliary devices Description Part number O-ring removal tool 234859 1113970EA... -

Page 24: Repair & Service

1. Select the desired Fixed Price Refurbishment service from our comprehensive service pro- gram for the refurbishment. 2. Contact your assigned sales person or the nearest VAT service center to learn about the op- tions for the product in question. VAT Service Center. -

Page 25: Transport Packaging And Shipping

– Fill out the form and send it in advance to VAT or the relevant sales company. – If the product is radioactively contaminated, ask VAT for the following form: Notification of con- tamination and radiation. -

Page 26: Disposal

DISPOSAL Disposal 12.1 Disposal The product and its components are made of various materials, which must be disposed of cor- rectly. 1. Note the regulations on waste disposal. 2. Dispose of the product and its components in accordance with local regulations. 3. - Page 27 Find out more and connect to your local VAT contact on WWW.VATVALVE.COM VAT Vakuumventile AG (Headquarters) Seelistrasse 1 9469 Haag Switzerland...

Need help?

Do you have a question about the 11.1 HV Series and is the answer not in the manual?

Questions and answers