Summary of Contents for Enerpac EP3304S

- Page 1 Instruction Sheet E-Series Electric Dump and Hold Pump L4351 Rev. C 01/20 To protect your warranty, use only ENERPAC hydraulic oil. • EP3304S Models For use with single-acting hydraulic cylinders and tools.

-

Page 2: Table Of Contents

Table of Contents: 1.0 SAFETY .............3 6.3 Pendant ..........10 1.1 Important Safety Instructions ....3 6.4 Solenoid Operated Control Valve ..11 1.2 General Hydraulic Safety Precautions ..3 6.5 Variable Speed Control ......11 1.3 Electrical Safety ........4 6.6 Constant Speed and Constant Power Modes ............11 1.4 Additional Precautions ......5 7.0 OPERATION ............12... -

Page 3: Safety

If training is needed, contact your local Enerpac distributor or It is your window to see what is happening in the system. -

Page 4: Electrical Safety

After the reconnection, the pump should comply in any manner. Return the pump to the nearest Enerpac with all local codes and ordinances. authorized service center for examination, repair, or electrical... -

Page 5: Additional Precautions

Disconnect Electrical Power: To avoid the components. Servicing of these items must be performed only possibility of a dangerous and potentially lethal by an Enerpac Authorized Service Center or other qualified electrical shock, disconnect pump power cord service facility. from AC electrical power supply and wait at least 2 minutes before opening the pump case. -

Page 6: Product Data

Advance / Hold / Retract hydraulic cylinders 3/8" NPTF 40.1 18.2 Enerpac HF (solenoid-operated dump) and tools Approximate weight of pump including oil. Approximate usable oil capacity of pump hydraulic reservoir. Pump total oil capacity (including reservoir and pump element housing) is approximately 1.14 gallons [4.33 liters]. -

Page 7: Pump Performance Curves

2.3 Pump Performance Curves Pump model numbers ending in “B” and “B-G” (IMPERIAL) (METRIC) 120V FLOW . PRESSURE 120V FLOW . PRESSURE 2000 2000 4000 4000 6000 6000 8000 8000 10,000 10,000 Pressure (bar) ▶ Pressure (psi) ▶ 100% of rated output 100% of rated output 50% of rated output 50% of rated output... -

Page 8: Major Features And Components

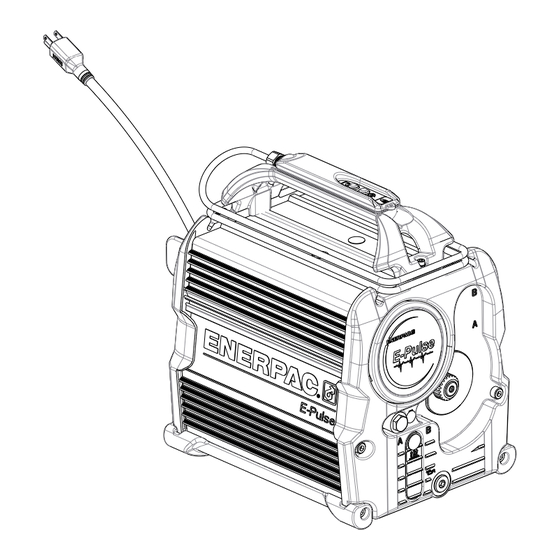

3.0 MAJOR FEATURES AND COMPONENTS Key: 1. Pendant and Cable 2. Carrying Handle and Pendant Cable Storage 3. Cover Plate 4. Control Valve Manual Override 5. Hyd. Reservoir Air Breather and Filter 6. Hyd. Reservoir Oil Drain/Fill Plug 7. Oil Level indicator 8. -

Page 9: Product Description

Refer to Figure 2 for a diagram of the pump's major features and components. 4.2 Intended Use The E-Series electric dump and hold pump (EP3304S models) is intended for use with single-acting hydraulic cylinders and tools in applications where a hydraulic hold function is required. The hold function is designed to keep the load stationary after lifting or pressing operations have been completed. -

Page 10: Hydraulic Reservoir

3 seconds after power is connected, indicating that the electronic 5.5 Power Requirements controls have powered-up and that the pump is ready for use. The EP3304S dump and hold pump is available in a choice of NOTICE A fault code indicates an abnormal condition that three different electrical power configurations: will result in immediate pump motor shutdown. -

Page 11: Solenoid Operated Control Valve

• The control valve does not contain a venturi valve. Flow control devices (user-supplied) must be installed in the system if flow metering is desired. • The pump is equipped with a hold holding feature but contains no safety locking valve. After lifting, the load must be supported by suitable mechanical load holding devices. -

Page 12: Operation

7.0 OPERATION 7.1 Before Start-up Check the hydraulic oil level. Add oil if necessary. Refer to Sections 10.1 through 10.3. Connect hydraulic hose to pump as described in Section 5.2. Connect pump to a compatible AC power supply of the proper voltage. -

Page 13: Pump Operation

If the pump does not relieve hydraulic pressure when functions. the dump button is pressed and held (with AC power connected), discontinue use and take the pump to an Enerpac Authorized • Additional flow control devices (optional accessories - refer to Service Center for diagnosis and repair. -

Page 14: Hydraulic System Maintenance

E-Series pumps. This oil is suitable for most applications and working environments. NOTICE • Use of oils other than Enerpac HF may result in damage to pump hydraulic components and will void the Enerpac product Screwdriver warranty. Enerpac recommends using only Enerpac HF oil in the E-Series pumps. -

Page 15: Adding Oil

NOTICE Be sure that the oil is clean. If the oil has a milky, Funnel cloudy or dark appearance, it should be changed immediately as (user-supplied) described in Section 10.4. 1/4" - 1/2" Dia. 10.3 Adding Oil [6.3-12.7 mm] Be sure that hydraulic cylinder or tool is fully retracted. Drain/Fill Be certain that pump is off and that all hydraulic pressure is Plug... -

Page 16: Oil Change

If the control valve will not operate electrically via the pendant Remove the oil drain/fill plug. Allow all used oil to drain controls, take the pump to an Enerpac service center for completely from the reservoir into the pan or container. It diagnosis and repair. -

Page 17: Troubleshooting

Failure to observe and comply with the following precautions could result in death or serious personal injury. Property For repair service, contact your nearest Enerpac Authorized damage could also occur. Service Center. Only an Enerpac Authorized Service Center should be permitted to service the pump and its components. - Page 18 Pump needs priming. Refer to Section 10.5 for priming procedure. e. Pump bypass valve malfunction. Contact Enerpac Authorized Service Center. f. Pump oil intake suction filter is dirty. Contact Enerpac Authorized Service Center. g. Pump internal leakage. Contact Enerpac Authorized Service Center.

- Page 19 Avoid setting relief valve at the pump bypass bypass valve setting. setting of 3000 psi [207 bar] whenever possible d. Damaged and/or loose components Contact Enerpac Authorized Service Center. inside pump, vibrating and/or making contact. e. Pump elements worn or damaged.

-

Page 20: Pump Fault Codes (User-Level)

AC power cord is connected to start pump again. outlet. • If problem persists, contact BUTTON FAULT 1 red blink followed by a Enerpac Authorized Service 1 second pause. Sequence Center. repeats until problem is corrected. Check pendant and pendant cable for obvious signs of damage or wear. - Page 21 Notes:...

- Page 22 Notes:...

- Page 23 Notes:...

- Page 24 www.enerpac.com...

Need help?

Do you have a question about the EP3304S and is the answer not in the manual?

Questions and answers