Summary of Contents for INHECO CPLC Ultraflat MTC

- Page 1 CPLC Ultraflat MTC Heating and Cooling Unit Part No.: 7100115, 7100117 ► User´s Manual Doc ID: 900410-001 June 2021 Version 1.0...

- Page 2 – available from INHECO. This manual and the information herein have been assembled with due diligence. INHECO GmbH does not assume liability for any misprints or cases of damage resulting from misprints in this manual. If there are any uncertainties, please feel →...

-

Page 3: Table Of Contents

.......................... 5 XPLANATION OF YMBOLS 1.3....................6 XPLANATION OF BBREVIATIONS AND LOSSAR 1.4.............................. 6 ARRANTY 1.5. INHECO ........................6 OW TO CONTACT PRODUCT DESCRIPTION ..........................7 2.1............................7 NTENDED 2.2............................ 8 COPE OF ELIVERY 2.3..........................8... - Page 4 8.5............................ 21 XCHANGER 8.6............................22 OOLING IQUID APPENDIX ..............................23 9.1. EC D ............................ 23 ECLARATION 9.2..........................24 OCUMENT HISTORY INHECO Doc ID: 900410-001 June 2021 Versioin 1.0...

-

Page 5: Important Notes

The word NOTE indicates important steps or measures that need to be followed to ensure the correct function of the unit. Contact INHECO in case there are any uncertainties of how to operate or how to handle the unit. Your opinion about this manual provides us with valuable insights on how we can improve this document. -

Page 6: Explanation Of Abbreviations And Glossar

Broken seals on INHECO devices lead to the loss of warranty as well. INHECO will only accept parts / devices for return that do not pose a threat to the health of our staff. In particular, the devices may not have been used in Biosafety Level 3 and 4 environments or have been exposed to radioactive or radiation materials. -

Page 7: Product Description

The CPLC must be used exclusively by laboratory professionals trained in laboratory techniques with labautomation systems and having studied the instructions for use of this instrument as well as the instructions of the workstation the device is used in. INHECO Doc ID: 900410-001 June 2021 Version 1.0... -

Page 8: Scope Of Delivery

If it has become illegible or falls off, it must be replaced by a new identification label. New labels can be ordered at INHECO. In case the label is missing and you do not know the part number and serial number, they can also be read out with the software (MTC/STC Demo Tool) which can be downloaded from INHECO´... -

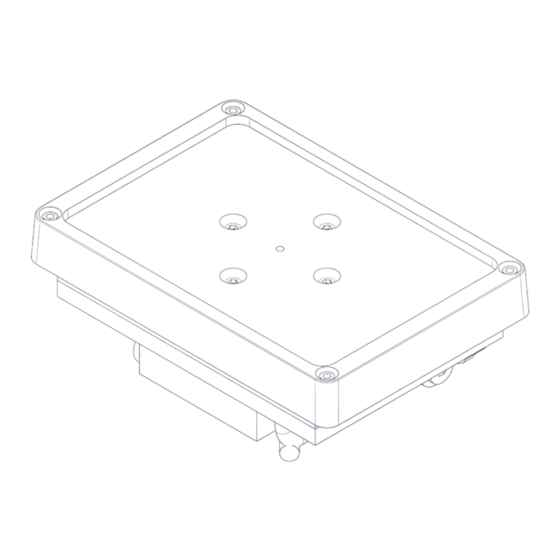

Page 9: Technical Data

Figure 4: Drawing of the device CPLC Ultraflat 7100115 (left) and 7100117 (right); the top view is the same for both variants; values are shown in mm. INHECO Doc ID: 900410-001 June 2021 Versioin 1.0... -

Page 10: Safety Instructions

+110°C [+230°F]. It takes a while to cool down after the device has been used. Electric Shock Hazard INHECO Doc ID: 900410-001 June 2021... -

Page 11: Technical Alterations

3.2. Technical Alterations Do not alter the product. Any modification or change which is not approved by INHECO leads to the loss of warranty. Broken seals on INHECO devices lead to the loss of warranty as well. Use only original parts provided by INHECO. Parts provided by other suppliers can impair the functionality of the unit. -

Page 12: Hardware Installation

4.2.1. How to connect device to the MTC/STC In order to connect an INHECO heating/cooling/shaking device, the TEC Control Unit has to be equipped with the corresponding Slot Module. There are blue, black, and yellow Slot Modules available. The following table shows the appropriate Slot Module for each heating/cooling/shaking device. -

Page 13: Labware Use

The mounting frame for PCR Adapter is already fixed on the CPAC devices when they are purchased directly from INHECO. A different set up might be delivered if the CPAC devices were ordered from your workstation provider. In this case the PCR Adapter or another adapter might already be pre-installed. - Page 14 Figure 9: Assemble PCR Adapter with mounting frame (to enclose the PCR Adapter) and 4 screws and tighten the four screws at the corner finger tight (respectively with 0,25Nm). Figure 10: PCR-Adapter placed on CPAC with mounting frame. INHECO Doc ID: 900410-001 June 2021 Versioin 1.0...

-

Page 15: Installation Of Flat Bottom Adapter

Figure 11: Unscrew the 4 screws at the corner and remove mounting frame. Figure 12: Assemble the outer frame of flat bottom adapter with 2 screws. Figure 13: Assemble the plate of flat bottom adapter with 1 screw in the middle. INHECO Doc ID: 900410-001 June 2021 Versioin 1.0... -

Page 16: Installation Of Other Adapter

If another Adapter is pre-assembled, please disassemble this adapter first. Figure 15: Unscrew the 4 screws at the corner and remove mounting frame. hole for adapter plate fixation Figure 16: Screw holes for other adapter. INHECO Doc ID: 900410-001 June 2021 Versioin 1.0... -

Page 17: Mechanical Integration

• for CPLC Ultraflat 4 screws are necessary Figure 17: Drilling Scheme for CPLC Ultraflat Contact INHECO for further information how to place the devices onto the working table to prevent damage from the device or/and to assure that the CPLCs are working with the given specifications. -

Page 18: Software Installation

The devices can be operated by touchscreen at the front panel of the MTC/STC, by the Demo Tool software delivered by INHECO or by the software of your liquid handling workstation. The INHECO Demo Tool software and the touchscreen allow programming basic temperature and shaking sequences. -

Page 19: Maintenance

In case of an operation failure follow the trouble-shooting instructions of this chapter. INHECO needs the below mentioned information including the serial numbers of your devices and the error code report. With this information INHECO can help you to trouble-shoot the reason for the operation failure. -

Page 20: Installation Of The Software "Mtcistc Demo Tool

Exchange of parts or broken seals can lead to the loss of warranty. Spare Parts must be ordered from INHECO. INHECO will only accept parts / devices for return that do not pose a threat to the health of our staff. In particular, the devices may not have been used in Biosafety Level 3 and 4 environments or have been exposed to radioactive or radiation materials. -

Page 21: Transportation And Storage

INHECO. Do not return any devices without INHECO’s RMA number. INHECO’s RMA number must be shown on the outside of the return package. Returns without RMA number are not being processed by INHECO. - Page 22 Liquid Cooling small ambient air 8.6. Cooling Liquid Product Name Description Part Number MANNOL Antifreeze Transfers heat load from the liquid cooled MTC/STC 2300104 AG11 (-40) device to the Heat Exchanger Liquid Cooling small Longterm INHECO Doc ID: 900410-001 June 2021 Versioin 1.0...

- Page 23 9. Appendix 9.1. EC Declaration INHECO Doc ID: 900410-001 June 2021 Versioin 1.0...

-

Page 24: Version

March 2021 2.5 Technical Data: max. current adjusted April 2021 Safety Instructions in chapter 3.1, 4.5 and 7.1 extended April 2021 4.5 4.5. Mechanical Integration: Pictogram corrected June 2021 EC Declaration added INHECO Doc ID: 900410-001 June 2021 Versioin 1.0...

Need help?

Do you have a question about the CPLC Ultraflat MTC and is the answer not in the manual?

Questions and answers