Summary of Contents for INHECO TEKMATIC Thermoshake AC LC

- Page 1 User and Installation Manual Thermoshake AC LC Shaker with Clamping Mechanism Part No.: 7100170 Doc ID: 901753-000 01/2024...

-

Page 2: Company Information

Technical Support & Trouble www.inheco.com/tech-support.html Shooting Instructions: INHECO Industrial Heating and Cooling GmbH reserves the right to modify their products for quality improvement. Please note that such modifications may not be documented in this manual. This manual and the information herein have been assembled with due diligence. -

Page 3: Table Of Contents

INHECO Table of Contents Table of Contents Company information ............................1 About this manual ............................1.1 General information............................ 1.2 Contact information ............................ 1.3 Abbreviations and glossary ........................1.4 Warranty..............................2 Safety instructions ............................2.1 Product-specific risks ..........................2.2 Technical alterations ..........................10 2.3 Malfunctions ............................... - Page 4 INHECO Table of Contents 7.2 Refilling internal cooling liquid reservoir..................... 30 7.2.1 Refill Tools delivered with Thermoshake AC LC................30 7.2.2 Refill Procedure ..........................30 7.2.3 Refill Check with MTC / STC Touch Screen Display ..............31 7.2.4 Refill Check with MTC / STC Demo Tool..................32 7.3 Refill cooling liquid of liquid cooled MTC / STC devices ................

-

Page 5: About This Manual

Thermoshake AC LC to new users. – Contact INHECO if there are any uncertainty in operation or handling of the Thermoshake AC LC. This manual is valid for the following device:... -

Page 6: Abbreviations And Glossary

All devices cooled with the "Heat Exchanger Liquid cooling" MTC / STC devices Millimeter Multi TEC Control controls up to 6 INHECO devices individually Offset The difference between the set temperature and actual value once the temperature is stable Protective Earth PT100 PT100 is a Resistive-Temperature-Detector (RTD). -

Page 7: Warranty

Broken seals on INHECO devices lead to the loss of warranty as well. INHECO will only accept parts / devices for return that do not pose a threat to the health of our staff. In particular, the devices may not have been used in Biosafety Level 3 and 4 environments or have been exposed to radioactive or radiation materials. -

Page 8: Safety Instructions

– Ensure that there is no other device installed next to the device increasing the inlet air temperature for the device above the specified temperatures. In case of doubt, please contact INHECO for further analysis. – Do not insert any parts into the ventilation opening. - Page 9 – Make sure that the Thermoshake AC LC does not come in contact with liquids while the device is connected to the power outlet. – Use the original power cable provided by INHECO to ensure safe and proper operation. – The product must be connected directly to an approved power source, for example to a three-wire grounded socket for the 230 V / 110 V / 90 V line.

-

Page 10: Technical Alterations

Safety instructions | 2 2.2 Technical alterations – Do not alter the product. Any modification or change not approved by INHECO leads to the loss of warranty and INHECO´s liability Return device for repair. – Use only original parts provided by INHECO. Parts provided by other suppliers can impair the functionality of the unit. -

Page 11: Information Symbols

INHECO Safety instructions | 2 2.5 Information symbols The information symbols listed here may appear in this document. General Information Symbols Information symbol Description IMPORTANT NOTE This information symbol indicates important instructions that should be observed in order to avoid problems with the product. -

Page 12: Product Description

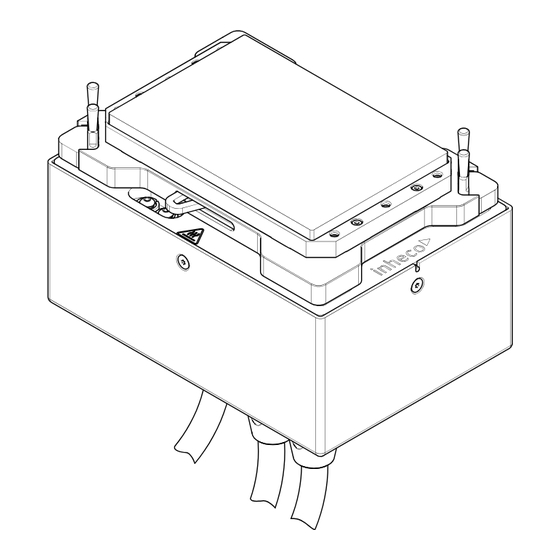

INHECO Product description | 3 3 Product description 3.1 Intended use Combined heater / coolers and shakers add efficiency and precision to liquid handling decks for many life science research applications in molecular biology, biochemistry and clinical chemistry. They give labs more control of the process, and that helps achieve more accurate and repeatable results. -

Page 13: Scope Of Supply

In case of parcel or product damages, make photos of the damaged boxes and products and email them to sales@TekMatic.com immediately. Transportation damages must be reported to INHECO within 7 days of delivery. The following components should be included in each shipment: Illustration 2: Scope of Supply... -

Page 14: Functional Elements

INHECO Product description | 3 3.3 Functional elements 3.3.1 Clamping Mechanism The automated clamping mechanism is suited for ANSI / SLAS standard plates and it will make sure that the plates will keep in position during shaking. After shaking is stopped the clamp mechanism will automatically open. -

Page 15: Fixation Pins

INHECO Product description | 3 3.3.2 Fixation Pins Illustration 5: Fixation Pins of Clamp Mechanism Pinching of finger WARNING While the clamp mechanism is closing you might pinch your finger or your glove. Closing or opening takes about 2-5 sec. 3.3.3 Cold plate (temperature area) Illustration 6: Heated area of the Thermoshake AC LC... -

Page 16: Liquid Cooling

New labels can be ordered at INHECO. In case the label is missing and you do not know the part number and serial number, they can also be read out with the software (MTC / STC Demo Tool) which can be downloaded from INHECO´s customer area on www.inheco.com. -

Page 17: Technical Data

INHECO Product description | 3 Illustration 9: Example for shipment labels on the package Illustration 10: Other Labels on the product 3.5 Technical data Thermoshake AC LC Product number 7100161 Height (bottom to contact surface) 90.6 mm [3.567 in] Height with standard fixation pins 96.9 mm... - Page 18 INHECO Product description | 3 Thermoshake AC LC Product number 7100161 Maximum load 1.0 kg [2.2 lbs] Shaker frequency 300 to 3000 rpm Weight reduces the max. speed Shaking amplitude 2 mm [0.07874 in] Shaking pattern Orbital Table 4: Technical information regarding shaking for all devices Depending on the load, as otherwise liquid might get spilled or adapter might not be hold tight to the clamp mechanism.

-

Page 19: Installation

→ Removal of fixation pins, page 20. Visit www.inheco.com to find the custom- fit adapter for your disposable and contact sales@TekMatic.com in case you need a custom-fit holder. -

Page 20: Removal Of Fixation Pins

/ assay. The adapter may facilitate accurate positioning for easy robotic handling plate. Visit www.inheco.com to find the adapter which fits your tube, reservoir or plate. In case you do not find your disposable on the list of adapters, ask sales@TekMatic.com for a custom design. -

Page 21: Mechanical Integration

INHECO Installation | 4 Illustration 13: Device with installed PCR adapter plate (3 screw holes used) 4.1.5 Mechanical integration The Shaking device is usually integrated into liquid handling workstations. The way of fixation depends on the hardware provided by the automation platform manufacturer. -

Page 22: Software Installation

Zero-position. 4.2 Software Installation INHECO offers a software called Demo Tool to provide limited functional control (also possible via touchscreen of the MTC / STC) and the opportunity to send manually entered firmware commands to the devices. -

Page 23: Initial Operation

5 Initial operation 5.1 Connecting devices to the MTC / STC In order to connect an INHECO heating / cooling / shaking device, the TEC Control Unit has to be equipped with the corresponding Slot Module. There are blue, black, and yellow Slot Modules available. -

Page 24: Connecting Devices With The Heat Exchanger

INHECO Initial operation | 5 5.2 Connecting devices with the Heat Exchanger The cooling liquid circuit of the Heat Exchanger and the liquid cooled MTC/STC device are closed for transport by the quick-release couplings. Step 1: Remove the locking clip (Illustration 18 (1)) Step 2: Carefully disconnect the quick couplings of the Heat Exchanger and liquid cooled MTC/STC device. -

Page 25: Programming The Movement Pattern

INHECO Initial operation | 5 Step 1: To further increase safety, lock the connection with the provided locking clip (1). Illustration 18: Locking clip Locking clip Secure connection Risk of insufficient function NOTICE If there is not sufficient cooling liquid running through the liquid loop the function of the cooled MTC device might be impaired. -

Page 26: Operation

Demo Tool available as download from the customer area at www.inheco.com or by the software of your liquid handling workstation. The INHECO Demo Tool software and the touchscreen allow programming basic temperature and shaking sequences. More complex control sequences can be performed with the software of your robotic platform provider or if you write your own software based on our Firmware Command Set and DLL. -

Page 27: Getting The Shaking Device In Closed Position

INHECO Operation | 6 6.2 Getting the Shaking device in closed position For transportation of the Shaking device the shaker needs to be in closed position. There are several ways to do so. Illustration 20: Clamp mechanism "Closed" With commands Use the commands xSSR0 and xASE1. As the clamp mechanism closes as soon as the shaking starts. -

Page 28: Getting The Shaking Device In Opened Position

INHECO Operation | 6 6.3 Getting the Shaking device in opened position In case the clamp mechanism has a problem to open there are several ways to open it: Illustration 21: Clamp mechanism "Open" with lever (Arrow) With commands via Demotool Use the commands xSSR0 and xASE0 (x= slot ID) as soon as the shaking is stopped. -

Page 29: Maintenance

For updates of the Demo Tool Software, contact: sales@TekMatic.com. 7.1.1 Installation of the Software "MTC / STC Demo Tool" The Demo Tool can be downloaded from INHECO´s customer area on www.inheco.com. In this section you will also find the Demo Tool Manual with detailed instructions of the software. -

Page 30: Refilling Internal Cooling Liquid Reservoir

To ensure that the Thermoshake AC LC does not run dry INHECO implemented a sensor to check the liquid level of the cooling liquid. The sensor can be addressed with a command to report the cooling liquid level. -

Page 31: Refill Check With Mtc / Stc Touch Screen Display

INHECO Maintenance | 7 Only open the reservoir for the refill process. Never leave the reservoir open. NOTICE Illustration 23: Screw plugs of the cooling fluid reservoir Screw plugs 7.2.3 Refill Check with MTC / STC Touch Screen Display Error 7 displayed on the MTC / STC touch screen indicates the refill requirement. -

Page 32: Refill Check With Mtc / Stc Demo Tool

7.2.4 Refill Check with MTC / STC Demo Tool The MTC / STC Demo Tool and the Demo Tool Manual can be downloaded from INHECO´s website www.inheco.com. Login / password can be requested from sales@TekMatic.com. The Demo Tool offers two options to check the refill requirement: –... - Page 33 INHECO Maintenance | 7 Illustration 25: Example: Details of Error 07: no. of occurrences: 003, in case of an increase in 2nd report to 004 → refill is required Maximum number of occurrences is 255. If this number is reached the error Info memory of the slot module has to be erased.

- Page 34 INHECO Maintenance | 7 The command field shows either the default command 0RFV1 or the last Info command you have entered. Overwrite this last command. Illustration 26: Command section after command was sent. Command and reply displayed in reply message field.

-

Page 35: Refill Cooling Liquid Of Liquid Cooled Mtc / Stc Devices

In → Refilling internal cooling liquid reservoir, page 30 the refill of the internal cooling was explained. To learn more about the external cooling liquid loop and how to refill refer to the manual from our INHECO Heat exchanger liquid cooling small. -

Page 36: Decontamination

Maintenance | 7 7.6 Decontamination Decontamination is required before return of a device to INHECO in case it has been exposed to human or animal blood / fluid / tissue or has been exposed to biological, chemical, or radioactive materials. -

Page 37: Transportation And Storage

Maintenance | 7 Ask sales@TekMatic.com or visit www.inheco.com/service/returns-rma.html for the return procedure before you return a device to INHECO. Do not return any devices without INHECO’s RMA number. INHECO’s RMA number must be shown on the outside of the return package. -

Page 38: Trouble Shooting And Support

– INHECO product number of the device (shown on device label) – INHECO product name of the device (shown on device label) – INHECO serial number of the device (shown on device label or via software) – Detailed error description –... -

Page 39: Accessoires

MTC/STC device to the Heat Exchanger Please source Liquid cooling small this cooling liquid locally. It is commonly used as car coolant. Thermal Adapter A list of adapters (inserts, nests) can be downloaded from INHECO´s webpage www.inheco.com or requested from sales@TekMatic.com. Manual_Thermoshake-AC-LC_10-2023...

Need help?

Do you have a question about the TEKMATIC Thermoshake AC LC and is the answer not in the manual?

Questions and answers