Advertisement

Quick Links

1. INTRODUCTION

This manual provides instructions and procedures necessary to install,

operate and troubleshoot the Moog Series 631K/D631K series intrinsic safety

protected Industrial Serovalve. Troubleshooting instructions are outlined to

permit the identification of the specific component(s) suspected of failure.

The 631K/D631K series valves are electrical equipment for hazardous areas

with intrinsic safety protection. Identification

CESI 02ATEX109 X,

nnnn (see product label, Ex. 0344). They are intended

for directional, position, velocity, pressure and force control in hydraulic control

systems that operate with mineral oil based fluids. Others upon request.

2. OPERATION

The Moog 631K/D631K Series Industrial Servovalve consists of a polarized

electrical torque motor and two stages of hydraulic power amplification. The

motor armature extends into the air gaps of the magnetic flux circuit and is

supported in this position by a flexure tube member. The flexure tube acts as a

seal between the electromagnetic and hydraulic sections of the valve. The two

motor coils surround the armature, one on each side of the flexure tube.

The flapper of the first stage hydraulic amplifier is rigidly attached to the

midpoint of the armature. The flapper extends through the flexure tube and

passes between two nozzles, creating two variable orifices between the nozzle

tips and the flapper. The pressure controlled by the flapper and nozzle variable

orifice is fed to the end areas of the second stage spool.

The second stage is a conventional 4-way spool design in which output

flow from the valve, at a fixed valve pressure drop, is proportional to spool

displacement from the null position. A cantilever feedback spring is fixed to

the flapper and engages a hole at the center of the spool. Displacement of the

spool deflects the feedback spring which creates a force on the armature/flapper

assembly.

Input signal induces a magnetic charge in the armature and causes a

deflection of the armature and flapper. This assembly pivots about the flexure

tube, and increases the size of one nozzle orifice and decreases the size of the

other.

This action creates a differential pressure from one end of the spool to

the other and results in spool displacement. The spool displacement transmits

a force to the feedback wire which opposes the original input signal torque.

CAUTION

DISASSEMBLY, MAINTENANCE, OR REPAIR OTHER THAN IN ACCORDANCE WITH THE

INSTRUCTIONS HEREIN OR OTHER SPECIFIC WRITTEN DIRECTIONS FROM MOOG WILL

INVALIDATE MOOG'S OBLIGATIONS UNDER ITS WARRANTY AND INTRINSICALLY SAFE

PROTECTION PERMIT NULL AND VOID.

II 1G Ex ia IIC T6 or T5 Ga

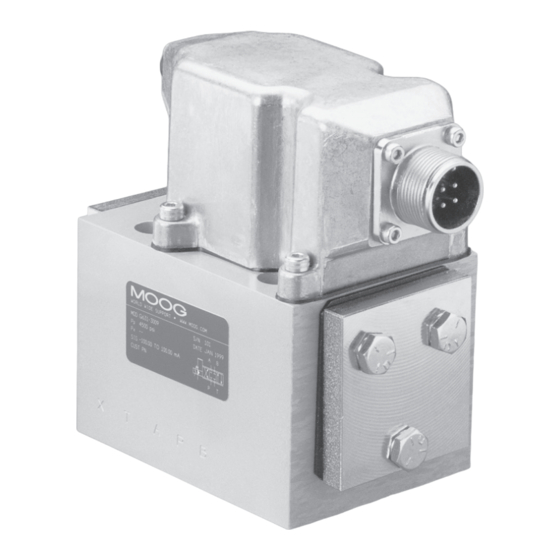

ELECTROHYDRAULIC VALVE CUT-AWAY

631K/D631K Series Installation

and Operation Instruction

Electrohydraulic Servovalve

Intrinsic Safety Protected

Null Access

Screw

Null Adjust

Torque Motor

Coil

Armature

Flexure Tube

Filter

X T

A

P

Figure 1 Moog Series 631K/D631K

Upper Polepiece

Flapper

Nozzle

Feedback Wire

Spool

Inlet Orifice

Filter Plate

(not shown)

B

Advertisement

Summary of Contents for Moog 631K Series

- Page 1 1. INTRODUCTION This manual provides instructions and procedures necessary to install, and Operation Instruction operate and troubleshoot the Moog Series 631K/D631K series intrinsic safety protected Industrial Serovalve. Troubleshooting instructions are outlined to Electrohydraulic Servovalve permit the identification of the specific component(s) suspected of failure.

- Page 2 6. INSTALLATION SAFE CIRCUIT SAFETY PARAMETERS The Moog 631K/D631K Series Servovalves may be mounted in any position, a. The electrical torque motor coil leads are attached to the valve connector provided the servovalve pressure, control and return ports match respective so external connections can provide series, parallel or single coil manifold ports.

- Page 3 11. AUTHORIZED REPAIR FACILITIES Moog does not authorize any facilities other than Moog or Moog subsidiaries to repair its servovalves. It is recommended you contact Moog at (716) 652- 2000 to locate your closest Moog repair facility. Repair by an independent (unauthorized) repair house will result in voiding the Moog warranty and could lead to performance degradation or safety problems.

- Page 4 External X open closed Moog Inc., East Aurora, NY 14052-0018 Telephone: 716/652-2000 Fax: 716/687-7910 Toll Free: 1-800-272-MOOG The products described herein are subject to change at any time without notice, including, but not limited to, product features, specifications, and designs.

Need help?

Do you have a question about the 631K Series and is the answer not in the manual?

Questions and answers