Table of Contents

Advertisement

S e r v i c e L i t e r a t u r e

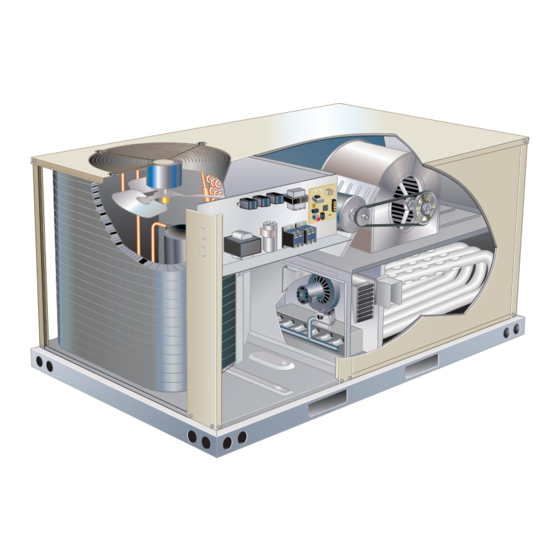

The ZGB packaged gas units are available in standard

cooling efficiency (036S, 048S, 060S, 074S). Cooling ca-

pacities are 3, 4, 5 and 6 tons (10.6 to 20.3kW).

All units are available in single-stage 65,000 BTUH (19

kW), single-stage 108,000 BTUH (32 kW) and two-stage

81/108,000 BTUH (24/32 kW) heat capacities. ZGB048,

060 and 074 units are available in singe-stage 150,000

BTUH (44 kW) and two-stage 113/150,000 BTUH (33/44

KW) heat capacities. Gas heat sections are designed with

aluminized steel tube heat exchangers.

Information contained in this manual is intended for use

by qualified service technicians only. All specifications are

subject to change. Procedures outlined in this manual are

presented as a recommendation only and do not super-

sede or replace local or state codes.

If the unit must be lifted for service, rig unit by attaching

four cables to the holes located in the unit base rail (two

holes at each corner). Refer to the installation instructions

for the proper rigging technique. Stacking brackets can be

removed or left on the unit permanently. If brackets are

removed, any screws removed during installation must be

replaced.

WARNING

Improper installation, adjustment, alteration, service

or maintenance can cause property damage, personal

injury or loss of life. Installation and service must be

performed by a licensed professional HVAC installer or

equivalent, service agency, or the gas supplier.

WARNING

Electric shock hazard. Can cause injury

or death. Before attempting to perform

any service or maintenance, turn the

electrical power to unit OFF at disconnect

switch(es). Unit may have multiple power

supplies.

CAUTION

As with any mechanical equipment, contact with

sharp sheet metal edges can result in personal

injury. Take care while handling this equipment and

wear gloves and protective clothing.

UNIT INFORMATION

UNIT INFORMATION

Corp1807-L2

Revised 09/2021

ZGB036, 048, 060, 074

Page 1

WARNING

To prevent serious injury or death:

1- Lock-out/tag-out before performing maintenance.

2- If system power is required (e.g., smoke detector

maintenance), disable power to blower, remove

fan belt where applicable, and ensure all

controllers and thermostats are set to the "OFF"

position before performing maintenance.

3- Always keep hands, hair, clothing, jewelry, tools,

etc., away from moving parts.

Table of Contents

Options / Accessories . . . . . . . . . . . . . . . . . . . . . Page 2

Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 4

Spec. Gas Heat High Altitude. . . . . . . . . . . . . . . . . . . Page 7

Blower Data . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . .Page 7

Electrical Data . . . . . . . . . . . .. . . . . . . . . . . . . . . . . .Page 21

I Unit Components. . . . . . . . . . .. . . . . . . . . . . . . . . . .Page 25

II Placement and Installation . . . . .. . . . . . . . . . . . . .Page 35

III Start-Up and Installation . . . . . . . . . . .. . . . . . . . .Page 35

IV Charging. . . . . . .. . . . . . . . . . . . . . . . .. . . . . . . . . .Page 37

V System Service Checks. . . . . . . . . . . .. . . . . . .Page 41

VI Maintenance. .. . . . . . . . .. . . . . . . . .. . . . . . . . .. Page 43

VII Accessories . . . .. . . . . . . . .. . . . . . .. . . . . . . . .. Page 45

VIII Diagrams . .. . . . ... . . . . . .. . . . ... . . . . . .. . . . .Page 51

ZGB SERIES

3, 4, 5 and 6 Ton

10.6 to 20.3 kW

Advertisement

Table of Contents

Need help?

Do you have a question about the ZGB Series and is the answer not in the manual?

Questions and answers