Summary of Contents for Ross H Series

- Page 1 Operating Instructions | Air Preparation Products E-RE-61 11-2023 Air Preparation Products Operating Instructions Series H www.rosseuropa.com...

-

Page 2: Safety Instructions

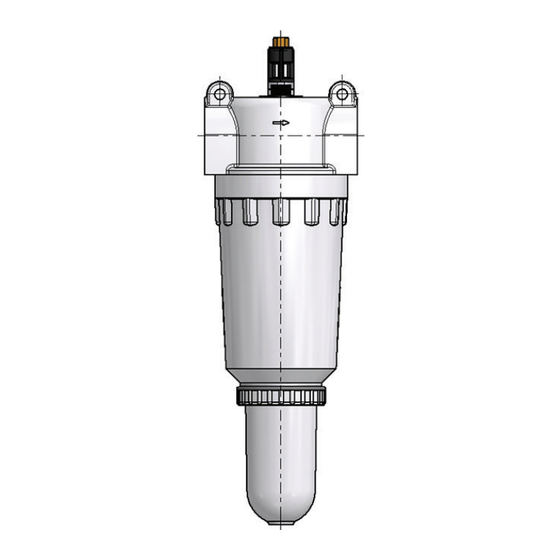

Operating Instructions | Air Preparation Products OPERATION ABOUT THESE INSTRUCTIONS These instructions contain important information on the safe The maintenance unit can be operated only within the spec- and appropriate installation and use of the BG maintenance ifications provided for it. Specifications can be found at the unit. - Page 3 Operating Instructions | Air Preparation Products ASSEMBLY CAUTION Wrong installation and flow direction are potentially hazardous. Install filters, filter regulators, and lubricators in mainte- nance units or as individual untis only in vertical position. Adhere to the flow direction (→) marked on each module. ...

-

Page 4: Installing The Control Panel

Operating Instructions | Air Preparation Products INSTALLING THE CONTROL PANEL NOTE: Material thickness of the mounting plate: max. 5 mm • Drill or punch a through borehole 31 mm in the mounting plate (b). • Insert individual device (a) (pressure regulator or filter- pressure regulator) through the through borehole. - Page 5 Operating Instructions | Air Preparation Products CONTAINER AND PROTECTIVE CAGE Dismantling • Screw off the union nut and remove it downwards. • Unscrew the protective cage, if present, and remove it downwards. • Take off the container and seal by moving downwards. Installing •...

- Page 6 Operating Instructions | Air Preparation Products EXCHANGING FILTER ELEMENT WARNING System is operating under pressure! Opening the system when it is under pressure could damage the maintenance unit and cause serious injury. Ensure that the system is pressure-free before opening ...

- Page 7 Operating Instructions | Air Preparation Products SEMI- AND FULLY AUTOMATIC CONDENSATE DRAIN CAUTION The condensate could cause damage to the compressed air system! Condensate is drained in semi-automatic drains only when the reservoir is un a pressure-free state. Over long periods of operation, the condensate can exceed maximum capa- city and get into the compressed air system.

- Page 8 Operating Instructions | Air Preparation Products SETTING THE AUTOMATIC MODE For semi-automatic condensate drain (I) Open drain screw by turning it all the way to the left. You may leave the screw one turn deep in the thread or remove it com- pletely.

- Page 9 Operating Instructions | Air Preparation Products LUBRICATOR WARNING System under pressure during operation! Opening the system while it is under pressure may cause damage to the devices (lubricator) and serious unjuries. CAUTION Harmful oil mists! Using oil produces harmful oil mists in the compressed ...

- Page 10 Operating Instructions | Air Preparation Products Manual filling during operation • Loosen filling screw. • Fill the reservoir until the oil reaches the maximum level. • Tighten filling screw again. Setting the oil amount The amount of oil can be adjusted during operation. •...

-

Page 11: Changing The Filter Element

Operating Instructions | Air Preparation Products START-UP CHANGING THE FILTER ELEMENT WARNING WARNING System is operating under pressure! System is operating under pressure! Opening the system when it ist under pressure could Incorrect installation could damage the maintenance unit and cause serious injury. -

Page 12: Technical Data

Operating Instructions | Air Preparation Products TECHNICAL DATA TROUBLESHOOTING Max. permissible pressure Malfunctioning Remedy Pressure/flow level Standard Filters 16 bar Clean or replace filters. is not reached or Metal container with manual or slowly decreases. 25 bar semiautomatic discharge Set a higher working pressure. - Page 13 ROSS ASIA K.K. Japan Phone: +81-42-778-7251 custsvc.ra@rosscontrols.com www.rossasia.co.jp ROSS UK Ltd. United Kingdom Phone: +44-1543-671495 sales.uk@rosscontrols.com www.rossuk.co.uk ROSS CONTROLS INDIA Pvt. Ltd. India Phone: +91-44-2624-9040 ross.chennai@rosscontrols.com www.rosscontrols.com ROSS SOUTH AMERICA Ltda. Brazil Phone: +55-11-4335-2200 vendas@rosscontrols.com www.rosscontrols.com.br ROSS FRANCE SAS...

Need help?

Do you have a question about the H Series and is the answer not in the manual?

Questions and answers