Advertisement

W74

Thank You!

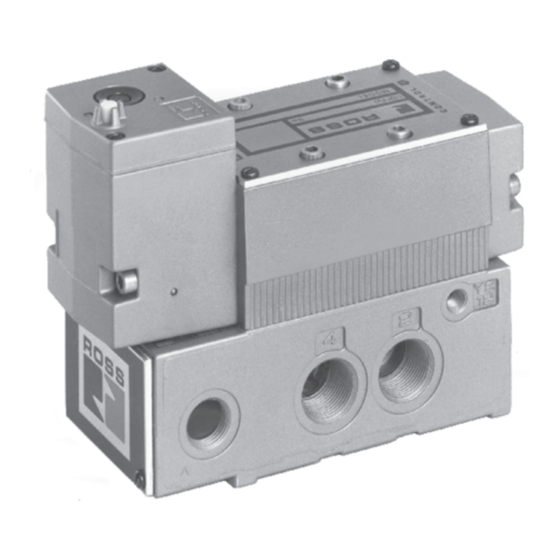

You have purchased a premium-quality ROSS

a single-spindle poppet valve built to the highest standards.

With care in its installation and maintenance you can expect it to

have a long and economical service life. So before you go any

further, please take a few minutes to look over the information in

this document. Then, save it for future reference and for the useful

service information it contains.

Please read and make sure you understand all installation instructions before proceeding with the installation.

Additional technical documentation is available for download at rosscontrols.com.

If you have any questions about installation or servicing your valve, please contact ROSS or

your authorized ROSS distributor, see contact information listed at the back of this document,

Pneumatic equipment should be installed only by persons

trained and experienced in such installation.

Operating Pressures and Temperatures:

ranges for pressure and temperatures are given in the

Valve Specifications on page 2. Exceeding the values

shown can shorten valve life.

If the model number on your valve ends with 336, 337, 338,

or 339 your valve is designed for high temperature service.

If the model number on your valve ends with 331, 332, 333,

or 334 your valve is designed for standard temperatures.

If the model number ends with any other group of digits you

have ordered a valve with special characteristics. Consult

ROSS to verify the characteristics of your particular valve.

Air Lines: Before installing a valve in a new or an existing

system, the air lines must be blown clean of all contaminants.

It is recommended that an air filter be installed in the inlet

line close to the valve.

Valve Inlet (Port 1): Be sure that the supply line is of

adequate size and does not restrict the air supply because of

a crimp in the line, sharp bends, or a clogged filter element.

Valve Outlets (Ports 2 & 4): For faster pressurizing and

exhausting of the mechanism being operated by the valve,

locate the valve as close as possible to the mechanism.

The lines must be of adequate size and be free of crimps

and sharp bends.

Valve Exhausts (Ports 3 & 5): Exhaust air flow must not

be restricted for proper valve performance. However, any

properly sized silencer, such as a ROSS silencer, should

be used to reduce impact noise without providing excessive

back pressure.

ROSS CONTROLS

®

ANSI Valves

Series

pneumatic valve. It is

®

VALVE INSTALLATION

or visit rosscontrols.com to find your distributor.

Allowable

ROSS W74 Series

valves and bases

(bases sold separately).

Electrical Supply: The voltage and hertz ratings of the valve

solenoids (if any) are shown on the pilot housings. Electrical

supply must correspond to these ratings. Otherwise life of

the solenoids will be shortened.

Electrical power from the valve's base goes to the solenoid(s)

via the plug-in connector at the valve-base interface. If

power is supplied by a transformer it must be capable

of handling the inrush current without significant voltage

drop. See Valve Specifications on page 2 for information

on in-rush current.

Pilot Supply:

Pressure Control: For valves with single remote pressure

control, connect the control line to port 14 in the sub-base

or manifold. For valves with double remote pressure control,

connect the control lines to ports 12 and 14 in the base.

See Valve Specifications on page 2 for required pressures.

Solenoid Pilot: Pressure for the pilot valves is supplied

from the inlet port. Be sure that the external pilot supply

port in the base is plugged or pilot air will escape. If the

valve must operate with an inlet pressure less than the

required pilot pressure (see Valve Specifications on page

2), an external pilot supply must be provided. Connect to

the appropriate port in the base.

Non-Air Service: Such applications require an external

pilot supply for solenoid valves. Connect to the appropriate

port in the base.

Pipe Installation: To install pipe in valve or base ports,

engage pipe one turn, apply pipe thread sealant (tape

not recommended), and tighten pipe. This procedure will

prevent sealant from entering and contaminating the valve.

rosscontrols.com

Advertisement

Table of Contents

Summary of Contents for Ross W74 Series

- Page 1 Please read and make sure you understand all installation instructions before proceeding with the installation. Additional technical documentation is available for download at rosscontrols.com. If you have any questions about installation or servicing your valve, please contact ROSS or your authorized ROSS distributor, see contact information listed at the back of this document, or visit rosscontrols.com to find your distributor.

- Page 2 The valve can be reconditioned with Cleaning Valve: If the air supplied to the valve has not been the use of ROSS service kits. See page 3 for information well filtered, the interior of the valve may accumulate dirt and about such kits.

- Page 3 Valve Model Valve Body Gasket & Valve-Base Solenoid Number Service Kit Seal Kit Gasket Number ROSS would be happy to service this valve for you at W7456A2331 712K77 — 553B11 — its factory repair center. If you purchased your valve...

- Page 4 ROSS’ obligation under this warranty is limited to repair or replacement of the product or refund of the purchase price paid solely at the discretion of ROSS and provided such product is returned to ROSS freight prepaid and upon examination by ROSS is found to be defective.

Need help?

Do you have a question about the W74 Series and is the answer not in the manual?

Questions and answers