Summary of Contents for Lincoln Electric D350 Series

- Page 1 FANS FIXED FANS SERIES D350 to D800 SAFETY INSTRUCTIONS FOR USE AND MAINTENANCE 8695 8594 EDITION : EN Instructions for use REF : REVISION : D DATE : 10-2021 Original instructions...

- Page 2 Thank for the trust you have expressed by purchasing this equipment, which will give you full satisfaction if you follow its instructions for use and maintenance. Its design, component specifications and workmanship comply with applicable European directives. Please refer to the enclosed CE declaration to identify the directives applicable to it.

-

Page 3: Table Of Contents

8695 8594 CONTENTS A - INTRODUCTION .......................... 1 USING THE MANUAL ......................1 MACHINE GUARANTEE ......................1 ASSISTANCE ........................... 1 DESCRIPTION OF PICTOGRAMS ..................1 DESCRIPTION OF PICTOGRAMS ..................1 B - GENERAL SAFETY INSTRUCTIONS ..................2 ELECTRICAL SAFETY ......................2 PERSONAL PROTECTION ..................... - Page 4 8695 8594 REVISIONS REVISION C 12/19 DESIGNATION PAGE Complete update REVISION D 10/21 DESIGNATION PAGE Created in English FIXED FANS...

- Page 5 8695 8594 LINCOLN ELECTRIC FRANCE SAS Avenue Franklin Roosevelt 76120 – LE GRAND QUEVILLY FIXED FANS SERIES D350 to D800 DECLARATION CE DE CONFORMITE CE/EU DECLARATION OF CONFORMITY Dear customer, This CE/EU declaration of conformity certifies that the supplied equipment complies with applicable laws and regulations when used in accordance with the enclosed instructions.

- Page 6 8695 8594 FIXED FANS...

-

Page 7: A - Introduction

Before the filter is used by a new user, make sure that they have read this manual and understood all the explanations provided. For any further information, please feel free to contact the technical departments of LINCOLN ELECTRIC. MACHINE GUARANTEE This machine is guaranteed for 12 months from the date of purchase. -

Page 8: B - General Safety Instructions

8695 8594 / D B - GENERAL SAFETY INSTRUCTIONS ELECTRICAL SAFETY Connection to the mains Before you connect your machine, please make sure that: — The meter, the overintensity protection system and the electrical installation are compatible with its maximum power rating and its supply voltage. -

Page 9: Personal Protection

8695 8594 / D PERSONAL PROTECTION Risks of external injury relating to welding operations Whole body — The operator must be clothed and protected to suit the requirements of the job. — Make sure that no part of the bodies of operators and helpers can come in contact with metal pieces or parts that are live or are liable to become live accidentally. - Page 10 8695 8594 / D Specific case of chlorine solvents in welding: (used for cleaning or degreasing). — The fumes from these solvents can be changed into toxic gases when subjected to arc radiation, including from a distance. — Such solvents may therefore not be used in locations where electric arcs occur, if the solvents are not in a sealed enclosure.

-

Page 11: Filtration Of Fumes And Dust

— Not obstruct the air outlet of the machine — Not introduce external elements into the filter (paper, cloths, cigarette butts etc.) — Replace the filter medium with new original LINCOLN ELECTRIC medium, which alone can guarantee the filtration characteristics. -

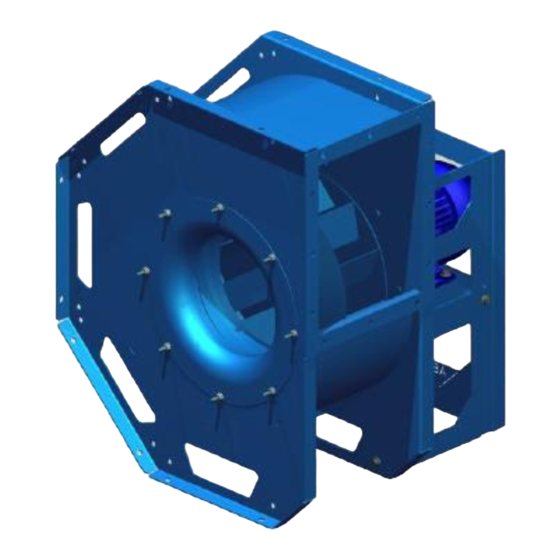

Page 12: C - Description Generale

8695 8594 / D C - DESCRIPTION GENERALE For your safety and optimum performance, please read this manual carefully before using the filter. Overview These high-efficiency centrifugal fans are designed to extract clean or very dusty air in civilian or industrial air conditioning systems. -

Page 13: D - Technical Description

8695 8594 / D D - TECHNICAL DESCRIPTION OVERALL DIMENSIONS OF FANS, SERIES D350/D800 FIXED FANS... -

Page 14: Noise And Efficiency Of Fans, Series D350/D800

8695 8594 / D NOISE AND EFFICIENCY OF FANS, SERIES D350/D800 FIXED FANS... -

Page 15: Operating Curves Of Fans, Series D350/D800

8695 8594 / D OPERATING CURVES OF FANS, SERIES D350/D800 FIXED FANS... -

Page 16: E - Starting Up

8695 8594 / D E - STARTING UP GENERAL Upon receipt, make sure that the packaging is not damaged, that the fan has not suffered any impact that would lead to malfunctioning and that the rotor turns freely with no friction. The fan must match the required specifications. -

Page 17: Connection To The Mains

8695 8594 / D CONNECTION TO THE MAINS Check that the electrical specifications of the motor match those of the power system (voltage, frequency) The maximum voltage variation is + or - 10% The cable section must be adapted to the power and consumption of the motor (allow 4 to 5 A/mm²). For CE electrical conformity of the fan, the power cabinet containing the padlockable disconnector must be installed less than one metre away from the fan in a free field. -

Page 18: Three-Phase Motor Wiring Diagram

8695 8594 / D THREE-PHASE MOTOR WIRING DIAGRAM For single-phase motors and motors with special connections, follow the diagrams supplied with the motor Check the connection of the motor to the ground and the fastening of the lugs. Make sure that the power cable cannot interfere with or rub against the rotating parts of the fan. Shut the motor terminal box. Check the fastening of the stuffing boxes. -

Page 19: F - Maintenance

8695 8594 / D F - MAINTENANCE VERIFICATION All maintenance operations must be carried out with the power to the system switched off. The fitter or user may not modify the construction of the fan in any way. If necessary, contact the manufacturer and send back the equipment. -

Page 20: Spare Parts

8695 8594 / D SPARE PARTS DESCRIPTIONS REFERENCES 1) MOTOR PLEASE ENQUIRE 2) FAN SUPPORT SEAT PLEASE ENQUIRE 3) FAN IMPELLER PLEASE ENQUIRE 4) FAN SCROLL PLEASE ENQUIRE 5) FAN OUTLET GRILLE PLEASE ENQUIRE 6) FAN INLET MOUTH PLEASE ENQUIRE 7) AIR INLET GRILLE PLEASE ENQUIRE 8) ANTI-VIBRATION MOUNT... -

Page 21: Part Numbers

8695 8594 / D PART NUMBERS FIXED FANS... -

Page 22: Procedure For Replacing The Motor

8695 8594 / D PROCEDURE FOR REPLACING THE MOTOR This maintenance operation must be carried out with the power to the system switched off, by qualified personnel only. Overall remarks on fans: The fan is connected to the collector system at the air inlet and outlet by flexible sleeves. The impeller is keyed to the motor shaft and blocked by a screw at the end of the shaft. - Page 23 8695 8594 / D FIXED FANS...

-

Page 24: Personal Notes

8695 8594 / D PERSONAL NOTES Lincoln Electric France S.A.S. Avenue Franklin Roosevelt 76120 Le Grand Quevilly 76121 Le Grand Quevilly cedex www.lincolnelectriceurope.com FIXED FANS...

Need help?

Do you have a question about the D350 Series and is the answer not in the manual?

Questions and answers