Miller Invision 456P Owner's Manual

Hide thumbs

Also See for Invision 456P:

- Owner's manual (40 pages) ,

- Owner's manual (44 pages) ,

- Owner's manual (68 pages)

Table of Contents

Advertisement

Quick Links

Visit our website at

www.Miller-

Welds.com

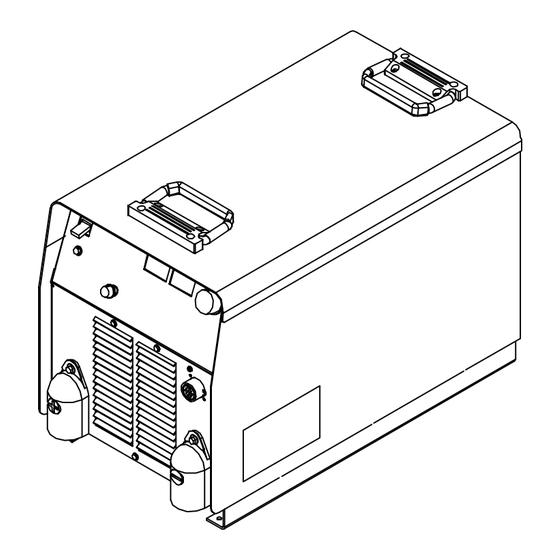

Invision 456P and

Phoenix 456 CC/CV

(575 Volt Models)

OM-186 989C

October 1998

Processes

Processes

Invision 456P:

MIG (GMAW) and Pulsed MIG

(GMAW-P) Welding

Flux Cored (FCAW) Welding

Phoenix 456 CC/CV:

Multiprocess Welding

Description

Invision 456P:

Phoenix 456 CC/CV:

Advertisement

Table of Contents

Troubleshooting

Need help?

Do you have a question about the Invision 456P and is the answer not in the manual?

Questions and answers