Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

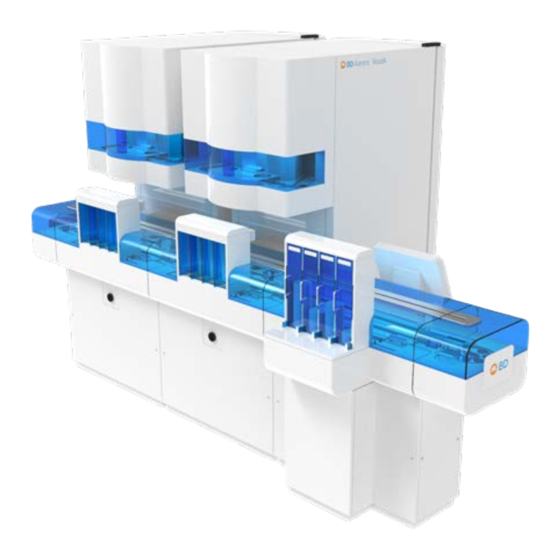

Summary of Contents for BD Kiestra ReadA

- Page 1 Kiestra™ ReadA User's Manual L011043(04) 2024-01 446948 English bd.com/e-labeling...

- Page 2 Calibrating the BD Kiestra™ Optis™ camera topic. BD, the BD Logo, BD Kiestra Optis, Kiestra, and Synapsys are trademarks of Becton, Dickinson and Company or its affiliates. All other trademarks are the property of their respective owners. © 2024 BD. All rights reserved.

-

Page 3: Table Of Contents

Module startup Module description 2.3.1 BD Kiestra™ ReadA incubator 2.3.1.1 Audible alerts and visual indicators 2.3.1.2 Components 2.3.2 Plate flow within the BD Kiestra™ ReadA incubator 2.3.3 BD Kiestra™ ReadA software application 2.3.3.1 General application layouts 2.3.3.2 Application toolbar 2.3.3.3 Application button bar 2.3.3.4 Machine tab 2.3.3.5... - Page 4 BD Kiestra™ ReadA User's Manual 5.4.3 Humidification pan 5.4.3.1 Cleaning the humidification pan 5.4.3.2 Refilling the humidification pan 5.4.4 BD Kiestra™ Optis™ camera 5.4.4.1 Cleaning the BD Kiestra™ Optis™ camera 5.4.4.2 Calibrating the BD Kiestra™ Optis™ camera Incidental cleaning Decontamination Troubleshooting Resolving errors...

-

Page 5: Instructions For Use Guidance

EU Only: Users shall report any serious incident related to the device to the Manufacturer and National Competent Authority. Outside EU: Contact your local BD representative for any incident or inquiry related to this device. Technical Service and Support: In the United States contact BD at 1.800.638.8663 or bd.com. -

Page 6: Notes, Cautions, And Warnings

INFORMATION ON AN ACTIVITY WHICH POTENTIALLY COULD CAUSE INJURY TO THE USER IS PRESENTED AS A WARNING. Symbols glossary Some symbols listed below may not apply to this product. US Customers only: For symbols glossary, refer to bd.com/symbols-glossary. Symbol Meaning CE marking; Signifies European technical conformity In vitro diagnostic medical device This only applies to US: “Caution: Federal Law restricts this device to... - Page 7 1 - Instructions for use guidance Symbol Meaning Batch code Catalogue number Serial number <Box #> / <Total Boxes> OSHA NRTL safety approval, tested and certified to UL and CSA safety ® standards by TÜV Rheinland OSHA NRTL safety approval, tested and certified to UL and CSA safety standards by TÜV SÜD Consult instructions for use or consult electronic instructions for use.

-

Page 8: Depiction Of Patient Information

BD Kiestra™ ReadA User's Manual Symbol Meaning Frame/chassis Hot surface Class 2 laser Low clearance Moving parts - pinch point On/Off Pinch point Refer to accompanying documentation Sharp point UV lamp Indicates internal high voltage cables that remain powered after the... -

Page 9: Introduction

Module startup The BD Kiestra™ Track module provides electrical power to the BD Kiestra™ ReadA module and must be powered on before trying to startup ReadA. Refer to the BD Kiestra™ Track User's Manual for details on turning on Track. When power is applied to the ReadA module, the following operations are performed: Hardware is checked and initialized. -

Page 10: Components

The images can be manually evaluated in the BD Synapsys™ Informatics Solution, or can be used for automated image evaluation using additional applications provided by BD. - Page 11 The numbers on the bottom of the tag (5) indicate the rows included in the rack. Contact BD to request incubator rack identification tags if necessary. Infeed and outfeed Transfers plates into and out of the ReadA.

-

Page 12: Plate Flow Within The Bd Kiestra™ Reada Incubator

BD Kiestra™ ReadA User's Manual 2.3.2 Plate flow within the BD Kiestra™ ReadA incubator Plate storage 1. The plate is transported from the side lane of the Track (1) to the infeed of the ReadA (2). 2. ReadA scans the plate barcode to assign a storage location. -

Page 13: Bd Kiestra™ Reada Software Application

The ReadA software application is accessed through the Track graphical user interface (GUI), which is displayed on a touchscreen monitor mounted to the Main Base cabinet of BD Kiestra™ Track. The touchscreen monitor supports multitouch gestures and is operated without the use of a keyboard or mouse. -

Page 14: General Application Layouts

BD Kiestra™ ReadA User's Manual 2.3.3.1 General application layouts BD Kiestra™ Track GUI The ReadA software application is accessed through the Track GUI. Figure 2 - ReadA tab on Track GUI 1. Select ReadA to display a list of the ReadA modules attached to the Track. - Page 15 2 - Introduction Remote access window The ReadA application opens within a remote access window, which has its own toolbar. Figure 3 - Remote Access window and toolbar 1. Select the in the tab at top-middle of the remote access window to close it and return to the Track GUI.

- Page 16 BD Kiestra™ ReadA User's Manual ReadA application main window The ReadA application is divided into six main areas: the title bar, toolbar, button bar, tab menu, tab content area, and the general module status area. If a user level is not configured to have access to a particular item, it will not be visible.

-

Page 17: Application Toolbar

2 - Introduction 7. The right side of the tab content area (7) displays general module status, and is always displayed regardless of which tab is selected: Machine state (8): E.g., Production, Stopped, Initializing Machine status (9): Shows the PLC activity, the production start time, length of the current production run, and communication with other devices Production counters (10): Shows incubator capacity and the number of plates processed at the various transit points... - Page 18 BD Kiestra™ ReadA User's Manual Tools menu options Option Description Deregister ReadA must be stopped in order to deregister a single plate from the container from database. When you deregister a plate, the incubation time is machine interrupted. Upon selection, the following pop-up window appears: 1.

- Page 19 When the plate is later moved from its rack position and returned to the incubator, the ReadA will not be able to find the plate position in the reserved rack. Optis™ ReadA must be stopped in order to calibrate the BD Kiestra™ Optis™ calibration tool camera. See 5.4.4.2 Calibrating the BD Kiestra™ Optis™...

-

Page 20: Application Button Bar

BD Kiestra™ ReadA User's Manual 2.3.3.3 Application button bar A button can only be selected when a user is logged in and the button is enabled (i.e., text is clearly visible and icon is colored). Figure 6 - Button bar options 1. -

Page 21: Machine Tab

2 - Introduction 2.3.3.4 Machine tab This tab appears when the application is started. It displays the status of the ReadA, plates being processed, and performance indicators. Figure 7 - Machine tab 1. The left side of the window shows the Process overview (1), a visual representation of the current processes. -

Page 22: Logging Tab

BD Kiestra™ ReadA User's Manual 2.3.3.5 Logging tab This tab displays a complete log of tasks and actions performed on the module, as well as errors and warnings. When an error occurs, this tab automatically appears and shows the specific error information. Refer to 6.3 Error messages... -

Page 23: Debug Log Tab

2 - Introduction 2.3.3.6 Debug Log tab This tab displays a detailed production log. Figure 9 - Debug Log tab 1. The Debug Log is defaulted to the Main Log tab, which shows all log activities. 2. Select Errors to filter the information only to activities regarding errors. 3. -

Page 24: Csa Tab

BD Kiestra™ ReadA User's Manual 2.3.3.8 CSA tab The Container Store Availability (CSA) tab displays which rack positions are occupied, which are available, and the status of individual plates. Figure 10 - CSA tab 1. The left side of the screen allows you to change the view (Flat slots, Rack use overview, Rack with slots). -

Page 25: Configuration

Configuration The configuration of the ReadA will be performed by a team of BD associates. - Page 26 BD Kiestra™ ReadA User's Manual...

-

Page 27: Operation

Operation This section provides instructions for routine operation of ReadA. WARNING ALL PATIENT SPECIMENS AND MICROBIAL CULTURES ARE POTENTIALLY INFECTIOUS AND SHOULD BE TREATED WITH UNIVERSAL PRECAUTIONS. REFER TO THE CDC MANUAL BIOSAFETY IN MICROBIOLOGICAL AND BIOMEDICAL LABORATORIES, 6TH EDITION, 2020, AS WELL AS OTHER RECOMMENDED LITERATURE. -

Page 28: Turning On Module

ReadA. The Track power supply panel also houses the CO switch. Refer to the BD Kiestra™ Track User's Manual for instructions to turn on Track and the CO , if required. 2. Locate the ReadA power supply panel on the front of the ReadA, below the Track. If a plate cart is blocking the panel, unlock the wheels and gently pull it away from the module and out of the way. -

Page 29: Signing In And Out

Windows taskbar to enter your username and password and select OK. See 2.3.3 BD Kiestra™ ReadA software application for more detailed information on accessing the virtual keyboard. 3. If the ReadA PC was recently restarted, the ReadA application will need to be opened from the remote desktop. -

Page 30: Starting Operation

BD Kiestra™ ReadA User's Manual Starting operation NOTE For correct functioning, it is imperative that no plate is present between the scan position and the camera before starting ReadA. Feed plates into ReadA only via a Destacker. Figure 11 - Start button on ReadA software application... -

Page 31: Stopping Operation

4 - Operation Stopping operation Stopping the ReadA should be done in a controlled manner through the ReadA software application. Transport and imaging of plates will stop, but the incubator will remain operational, with plates in the camera compartment continuing to be stored in the proper incubation atmosphere. -

Page 32: Turning Off Module

BD Kiestra™ ReadA User's Manual Turning off module BD recommends that ReadA remains powered on at all times in order to safeguard incubation conditions; however, it can be shut down when absolutely necessary. Only an authorized user should shut down ReadA. -

Page 33: Cleaning And Maintenance

Cleaning and maintenance It is recommended that ReadA components be cleaned according to the procedures described in this manual. ReadA requires little user maintenance to provide reliable performance. WARNING ALL PATIENT SPECIMENS AND MICROBIAL CULTURES ARE POTENTIALLY INFECTIOUS AND SHOULD BE TREATED WITH UNIVERSAL PRECAUTIONS. REFER TO THE CDC MANUAL BIOSAFETY IN MICROBIOLOGICAL AND BIOMEDICAL LABORATORIES, 6TH EDITION, 2020, AS WELL AS OTHER RECOMMENDED LITERATURE. -

Page 34: Frequency Of Routine Cleaning

5.1.2 Cleaners and disinfectants BD recommends the use of a single agent that combines functions to facilitate fast and effective cleaning and disinfection. Any exceptions to that recommendation are specified in this protocol. -

Page 35: Dry Cleaning

5 - Cleaning and maintenance 5.2.1 Dry cleaning In order to remove dust and small particles from modules and work surfaces, use: A small brush or microfiber wipe to clean sensors Microfiber wipes to clean scanner windows A vacuum cleaner with a HEPA filter (supplemented by a brush if necessary) for dusty areas When using a brush, be careful not to move dirt to a clean location. -

Page 36: Protocol A: Cleaning All Racks With Automated Unloading

BD Kiestra™ ReadA User's Manual 2. Protocol C: Cleaning one part of a ReadA at a time; if there is insufficient incubator capacity (CO or both), a lab may choose to clean only one part of a ReadA at a time. -

Page 37: Protocol B: Cleaning All Racks With Manual Unloading

5 - Cleaning and maintenance 8. Place plates removed from the ReadA into a Destacker to have them stored in another ReadA with the same atmospheric conditions. If no other ReadA is available, store the plates on a plate cart and place them back into a Destacker after step 19. 9. -

Page 38: Protocol C: Cleaning Selected Racks

BD Kiestra™ ReadA User's Manual 11. Clean the inside of the ReadA by spraying the recommended cleaner/disinfectant onto a microfiber wipe and wiping down the inside of the ReadA (top, walls, and bottom). 12. Clean the racks. 13. When cleaning is completed, replace the racks. Make sure the flat side is up. - Page 39 5 - Cleaning and maintenance 5. Select Tools [F7] > Rack reservation & removal. Identify the racks with status Reserved and remove those racks from the ReadA. Set the racks aside. 6. Clean the section from which the racks have been removed by spraying the recommended cleaner/disinfectant onto a microfiber wipe and wipe down the inside of the ReadA (top, walls, and bottom).

-

Page 40: Cleaning And Maintaining Bd Kiestra™ Reada Components

12. Select Apply changes to save the new status. 13. Select Start [F2] to start the application and continue ReadA operation. Cleaning and maintaining BD Kiestra™ ReadA components This section contains information on how to properly clean and maintain specific ReadA components, in order to keep the module in good working condition. -

Page 41: Humidification Pan

5 - Cleaning and maintenance 5.4.3 Humidification pan The bottom plate inside the incubator houses the humidification pan. The humidification pan is used to maintain adequate moisture levels for the plates in the ReadA. 1. Bottom plate of the incubator 2. -

Page 42: Refilling The Humidification Pan

BD Kiestra™ ReadA User's Manual 1. Select Stop [F4] in the ReadA application button bar. 2. Select Process Vision [F12] > PV Container Store. 3. In the Z-Axis section of the screen, select Step Up until the value shows 6890, or alternatively, enter 6890 in the input field with the virtual keyboard. -

Page 43: Bd Kiestra™ Optis™ Camera

5.4.4.1 Cleaning the BD Kiestra™ Optis™ camera 1. Once logged into the ReadA application, select Stop [F4]. 2. Select Unlock door [F8] to unlock the incubator door and the cover over the camera unit. - Page 44 BD Kiestra™ ReadA User's Manual 7. Raise the square tube that is connected to the HEPA filter slightly upward, then pull forward and remove. 8. Raise the exposure box and lock it in position following these steps: Pull the small pin on the left side of the exposure box compartment.

- Page 45 5 - Cleaning and maintenance Release the pin, and gently allow the exposure box to lower into locked place. 9. Remove the white cover and clean the cover with a microfiber wipe moistened with water. 10. Check that the flippers are in the open position. 11.

-

Page 46: Calibrating The Bd Kiestra™ Optis™ Camera

BD Kiestra™ ReadA User's Manual 12. Remove the black indexing disc and clean the disc with a microfiber wipe moistened with water. 13. Clean the glass plate with a microfiber wipe moistened with water. 14. If microbial contamination occurs or is suspected in the camera area, spray a microfiber wipe with the recommended cleaner/disinfectant and wipe the area. - Page 47 5 - Cleaning and maintenance Plates required for calibrating the BD Kiestra™ Optis™ camera In order to calibrate the Optis™ camera, you must have the following calibration plates: pixel calibration plate, the color calibration plate, and the homogeneity plate. Pixel calibration plate...

- Page 48 BD Kiestra™ ReadA User's Manual Calibrating the BD Kiestra™ Optis™ camera The ReadA application notifies the user with a warning message when a camera calibration needs to be performed. Figure 14 - Optis™ calibration 1. A warning message (1) is displayed in the ReadA application when a camera calibration needs to be performed.

- Page 49 Step 1: Welcome The calibration of Optis™ starts with cleaning the camera unit. 1. Follow the steps described, utilizing 5.4.4.1 Cleaning the BD Kiestra™ Optis™ camera as necessary. 2. Once all steps are complete, select the checkbox to indicate The camera unit has been cleaned.

- Page 50 BD Kiestra™ ReadA User's Manual Step 3: Camera Camera calibration calibrates the homogeneity detection accuracy. Calibration 1. Prepare to place the homogeneity plate in the module. 2. Select Start Camera Calibration (2/3) (1). Follow the directions and select OK in the subsequent information dialogues.

- Page 51 5 - Cleaning and maintenance Step 5: Color Color calibration is the last step in the process and ensures color Calibration correctness of the camera. 1. Prepare to place the 5-mm color calibration plate in the module. 2. Select Start Color Calibration (1). Follow the directions and select OK in the subsequent information dialogues.

- Page 52 BD Kiestra™ ReadA User's Manual Calibration Errors If the calibration procedure cannot be completed successfully, an error message will be displayed in the calibration wizard or status screen. Figure 15 - Error displayed in calibration wizard Figure 16 - Error displayed in ReadA status screen 6.4 BD Kiestra™...

-

Page 53: Incidental Cleaning

5 - Cleaning and maintenance Incidental cleaning In the event of a spill, wipe up the spill with a microfiber wipe soaked with a cleaner/disinfectant. CAUTION Never spray or pour cleaner/disinfectant on or into the module or any part of the module. -

Page 54: Decontamination

BD Kiestra™ ReadA User's Manual Decontamination Decontaminate after spills, splashes, or obvious contamination, and before transporting the equipment out of the laboratory. WARNING CONSIDER ALL ORGANISMS AS POTENTIALLY INFECTIOUS AND HANDLE ACCORDING TO STANDARD MICROBIOLOGICAL PRACTICES, SPECIAL PRACTICES, AND SAFETY EQUIPMENT RECOMMENDED FOR BIOSAFETY LEVEL 2 (BSL-2) CONTAINMENT.*... - Page 55 5 - Cleaning and maintenance CAUTION Do not use abrasive or corrosive cleaners (including bleach) inside the equipment. Do not spray or pour liquid directly on surfaces. Exposure to vaporized decontamination methods is not advised, as this may cause damage to the equipment.

- Page 56 BD Kiestra™ ReadA User's Manual...

-

Page 57: Troubleshooting

When an error condition occurs, the user is alerted in multiple ways: 1. An audible alert sounds, if it is enabled. 2. The instrument status tile on the BD Synapsys™ Informatics Solution dashboard displays an error status on the corresponding ReadA module. - Page 58 BD Kiestra™ ReadA User's Manual Figure 17 - ReadA Error display 1. Once logged into the ReadA application, select Beeper off [F6] to turn off the audible alarm. 2. The Logging tab automatically appears when an error occurs. The screen provides the...

-

Page 59: Creating An Error Report

Figure 18 - Error report screen 1. In the Error Report screen, log the error resolution, select an error type from the Error Type list, and identify the user who resolved the error. 2. Select OK. This information may be sent to BD. -

Page 60: Error Messages

BD Kiestra™ ReadA User's Manual Error messages Error codes, error messages, possible causes, and error resolutions are listed in the following table: Error Error Message Possible Cause Error Resolution Code The pressure is below There is not enough E002 the minimum required Check the air supply. - Page 61 6 - Troubleshooting Error Error Message Possible Cause Error Resolution Code Container store: E021 cylinder not in rest position Container store: E026 motor z- or rotation- axis positioning error Container store: 1. Remove obstruction. motor z-axis E027 positioning timeout 2. Select Reset Error [F5]. Possible obstruction.

- Page 62 BD Kiestra™ ReadA User's Manual Error Error Message Possible Cause Error Resolution Code Container store: E036 motor z-axis invalid 1. Remove obstruction. position request error 2. Select Reset Error [F5]. Possible obstruction. Container store: 3. Select Start [F2] to restart the...

- Page 63 6 - Troubleshooting Error Error Message Possible Cause Error Resolution Code 1. Select Reset Error [F5]. 2. Open the ReadA incubator and identify the location the gripper is trying to transfer a plate into. a. If there is a plate in the location, close the door and select Start [F2] to restart the module.

- Page 64 BD Kiestra™ ReadA User's Manual Error Error Message Possible Cause Error Resolution Code 1. Select Reset Error [F5]. 2. Select the Machine tab and note the barcode of the plate from the Transfer queue. 3. Select Tools [F7] > Deregister container from machine.

- Page 65 6 - Troubleshooting Error Error Message Possible Cause Error Resolution Code E067 Camera infeed: E072 receive timeout (dish E074 not detected) Camera infeed: E077 cylinder not in position 1. Remove obstruction. Camera infeed: E078 cylinder not in rest 2. Select Reset Error [F5]. Possible obstruction.

- Page 66 BD Kiestra™ ReadA User's Manual Error Error Message Possible Cause Error Resolution Code 1. Select Reset Error [F5]. 2. Select the X icon in the top right corner of the ReadA application title bar to close the application. Camera: camera...

- Page 67 6 - Troubleshooting Error Error Message Possible Cause Error Resolution Code 1. Remove the plate from the infeed stopper. 2. Add the plate to a Destacker to Possibly a plate has be processed by the Track Infeed: possible E185 become stuck at the again.

-

Page 68: Bd Kiestra™ Optis™ Error Messages

BD Kiestra™ ReadA User's Manual Error Error Message Possible Cause Error Resolution Code 1. Remove obstruction. Outfeed: conveyor 2. Select Reset Error [F5]. E230 motor current limit Possible obstruction. 3. Select Start [F2] to restart the overload module. BD Kiestra™ Optis™ error messages... - Page 69 Not authorized to access image destination folder Not authorized to access destination folder:... SHQIAcq.dll missing Contact BD. Lights control plugin is not loaded! Is it missing? Missing some SHQI destination setting fields Images destination is low on space General database read error...

- Page 70 BD Kiestra™ ReadA User's Manual Error Error Message Error Resolution Code 1. Select Reset Error [F5]. 2. Select the X icon in the top right corner of the ReadA application title bar to close the application. Unable save generated JPEG image (unable validate if the data was actualy saved to 3.

-

Page 71: Contacts

Voice: 1-800-638-8663 Mail: Technical.Services@bd.com Rua Alexandre Dumas 1976 bd.com 04717-004 Sao Paulo, S.P. Brazil Voice: (55) 11 5459833 BD Kiestra B.V. Fax: (55) 11 2478644 Marconilaan 6 9207 JC Drachten, The Netherlands 30 Tuas Avenue 2 Voice: +31 (0)512 540 623 Singapore 639461 Mail: Lab_Automation_phone_support@bd.com... - Page 72 BD Kiestra™ ReadA User's Manual...

-

Page 73: Limited Warranty

BD Kiestra™ ReadA resulting from the insertion or removal of cables that connect a module to systems other than those approved or supplied by BD or the failure of the owner to maintain reasonable care and precautions in the operation and maintenance of the module will void this warranty and terminate the obligations of the manufacturer as stated herein. - Page 74 BD Kiestra™ ReadA User's Manual...

-

Page 75: Installation Requirements

A network switch inside the Track main base cabinet A direct connection with the System Control Unit (SCU) The module is to be installed and moved by BD representatives only. WARNING THE MODULE MUST BE ELECTRICALLY CONNECTED TO EARTH-GROUND AT ALL TIMES. -

Page 76: Module Specifications

Voltage fluctuations ± 10% of the nominal voltage Constant capacity, free of moisture and oil, minimum of class 4 (ISO 8573-1) CAUTION Only use the BD supplied power cord to connect the module. Module Operating Requirements Audible Noise <60 dB... - Page 77 9 - Installation requirements Incubation Specifications consumption <1Kg//24hr (for 5% CO (± 1%) at 35 °C Incubation atmosphere or CO Temperature range 30–40 °C, ± 1 °C Plate Specifications Height, including lid 13.0–16.2 mm Diameter of bottom 85–91 mm 89–93 mm (when using two or more different kinds of plates, the Diameter of lid difference between lid diameters should not exceed 2 mm) Top rim...

- Page 78 BD Kiestra™ ReadA User's Manual...

-

Page 79: Cleaning Table

Cleaning table Cleaning Method Cleaning Frequency Component Weekly Monthly Quarterly Infeed conveyer Vacuum Outfeed conveyer Vacuum Camera in- and outfeed Vacuum conveyer Sensors on in-, out-, and camera Brush conveyer Microfiber Scanners wipe Seals Humidification pan Incubator outside and top Vacuum Camera layer –... - Page 80 BD Kiestra™ ReadA User's Manual...

-

Page 81: Ordering Information

11 - Ordering information Ordering information Catalog Number Name 446948 BD Kiestra™ ReadA 496016 Incubator Rack Identification Tags... - Page 82 BD Kiestra™ ReadA User's Manual...

-

Page 83: Glossary

A camera located in the ReadA module that photographs plates at predefined times, using a high-resolution camera and a variety of lighting conditions. BD Kiestra™ ReadA BD Kiestra™ in-vitro diagnostic module used to incubate plates and create images of plates, and is intended to be used in clinical laboratories. BD Kiestra™ Track BD Kiestra™... - Page 84 BD Kiestra™ ReadA User's Manual HEPA High Efficiency Particulate Air filter Humidification pan Component at the bottom of the ReadA incubator used to maintain adequate moisture levels for the plates in the ReadA. Instructions for Use. Refers to product instructions in printable form (e.g., user's manual PDF) or digital (e.g., online help).

- Page 85 12 - Glossary Programmable Logic Controller Remote access window Software application that allows a user to interact with and remotely control another computer. Sample A specimen that has been prepared for diagnostic testing. Scanner Component designed to read the barcode on a plate. Sensor Component designed to detect the presence of a plate.

- Page 86 BD Kiestra™ ReadA User's Manual Work Cell Automation...

-

Page 87: Index

Index Camera Cleaning camera cleaners and disinfectants cleaning strategies cleaning table decontamination disinfection door seals dry cleaning external surfaces frequency humidification pan incidental methods protocol A protocol B protocol C wet cleaning/disinfecting Configuration Contacts Conventions Depiction of patient information... - Page 88 BD Kiestra™ ReadA User's Manual Humidification pan Installation requirements Intended use Maintenance camera calibration refilling humidification pan Module specifications camera specifications environmental requirements incubation specifications module operating requirements physical dimensions plate specifications storage conditions utility requirements Operation signing in and out...

- Page 89 13 - Index Plate flow imaging storage transfer ReadA incubator audible alerts and indicators components ReadA software application application button bar application toolbar CSA tab Debug Log tab general application layouts Logging tab Machine tab Sensor Charts tab Startup Symbols glossary Troubleshooting camera error messages creating an error report...

- Page 90 BD Kiestra™ ReadA User's Manual resolving errors Warranty...

Need help?

Do you have a question about the Kiestra ReadA and is the answer not in the manual?

Questions and answers