Summary of Contents for Roger Technology F70/IPU36

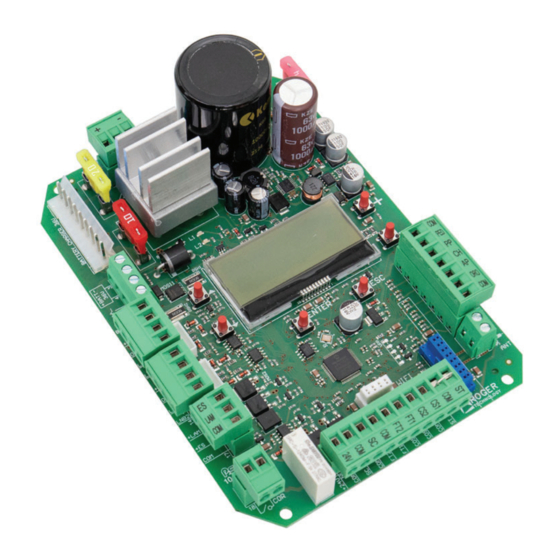

- Page 1 R1.50 IPU technology IS247 Rev.00 30/11/2023 F70/IPU36 centrale di comando per motori BRUSHLESS IPU TECHNOLOGY Istruzioni originali EN - Instructions and warnings for the installer...

-

Page 2: Table Of Contents

INDICE • INDEX • INDEX • INDEXER • ÍNDICE • ÍNDICE • INDEX • INDEKS ENGLISH Symbols Product description Updates of version R1.50 Technical characteristics of product Description of connections Commands and Accessories Function buttons and display Light signals Navigation in the menus 10 Menù... - Page 4 ATTENZIONE: la centrale F70/IPU36 non è compatibile con le serie BM30, BH30, BG30, MONOS, BE20, BR20, SMARTY, BR21, AYRON, BH23, BIONIK, BR41. ATTENTION: the F70/IPU36 control unit is not compatible with the BM30, BH30, BG30, MONOS, BE20, BR20, SMARTY, BR21, AYRON, BH23, BIONIK, BR41 series.

- Page 5 F70/IPU36/BOX PRI: 230V ~ 50/60Hz Bianco - Bianco T 2A Trasformatore Monofase Ta=55°C 120°C POT. 130VA Continuos Load FUSIBILE POT. 200VA Duty Cycle = ON 40(s)/OFF 60(s) CEI 61558-2-6 FUSE SEC: 26V ~ Nero - Nero 9642K003 230 Vac FUSIBILE...

- Page 6 F70/IPU36/BOX/SL FUSIBILE FUSE PRI: 230V ~ 50/60Hz Bianco - Bianco T 2A Trasformatore Monofase Ta=55°C 120°C POT. 130VA Continuos Load POT. 200VA Duty Cycle = ON 40(s)/OFF 60(s) CEI 61558-2-6 SEC: 26V ~ Nero - Nero 9642K003 FUSIBILE FUSE FUSIBILE...

- Page 7 Apertura parziale / Partial opening Passo passo / Step by step Lampeggiante / Flashing light rosso Chiusura / Closing 24 Vdc 5W (FIFTHY/24) +LAM Apertura / Opening Elettroserratura Electric lock 12 Vdc 15W * Orologio (N.A.) / Timer (N.O.) RG58 max 10 m Antenna 18 19 20 21 22 23 24 25 26 27 28 29...

- Page 8 COLLEGAMENTO CON 1 COPPIA FOTOCELLULE SINCRONIZZATE (MODALITÁ NORMALE, SOLO COPPIA MASTER) CONNECTION WITH 1 SYNCHRONISED PHOTOCELL PAIR (NORMAL MODE, MASTER PAIR ONLY) ROSSO = libero da jumper RED = jumper free JUMPER DI SINCRONIZZAZIONE (PER MASTER) SYNCHRONISATION JUMPER (FOR MASTER) 1 2 3 1 2 3 JUMPER DI ALLINEAMENTO...

- Page 9 COLLEGAMENTO CON 2 COPPIE FOTOCELLULE SINCRONIZZATE (MODALITÁ NORMALE, 1 MASTER E 1 SLAVE) CONNECTION WITH 2 SYNCHRONISED PHOTOCELL PAIRS (NORMAL MODE, 1 MASTER AND 1 SLAVE) ROSSO = libero da jumper RED = jumper free JUMPER DI SINCRONIZZAZIONE (PER MASTER) SYNCHRONISATION JUMPER 1 2 3 1 2 3...

- Page 10 TEST FOTOCELLULE · PHOTOCELLS TEST ( COLLEGAMENTO CON 1 COPPIA FOTOCELLULE SINCRONIZZATE (MODALITÁ NORMALE, SOLO COPPIA MASTER) CONNECTION WITH 1 SYNCHRONISED PHOTOCELL PAIR (NORMAL MODE, MASTER PAIR ONLY) ROSSO = libero da jumper RED = jumper free JUMPER DI SINCRONIZZAZIONE (PER MASTER) SYNCHRONISATION JUMPER (FOR MASTER)

- Page 11 TEST FOTOCELLULE · PHOTOCELLS TEST ( COLLEGAMENTO CON 2 COPPIE FOTOCELLULE SINCRONIZZATE (MODALITÁ NORMALE, 1 MASTER E 1 SLAVE) CONNECTION WITH 2 SYNCHRONISED PHOTOCELL PAIRS (NORMAL MODE, 1 MASTER AND 1 SLAVE) ROSSO = libero da jumper RED = jumper free JUMPER DI SINCRONIZZAZIONE (PER MASTER) SYNCHRONISATION JUMPER...

- Page 12 BATTERY SAVING ( BATTERY SAVING + TEST FOTOCELLULE · PHOTOCELLS TEST ( COLLEGAMENTO CON 1 COPPIA FOTOCELLULE SINCRONIZZATE (MODALITÁ NORMALE, SOLO COPPIA MASTER) CONNECTION WITH 1 SYNCHRONISED PHOTOCELL PAIR (NORMAL MODE, MASTER PAIR ONLY) ROSSO = libero da jumper RED = jumper free JUMPER DI SINCRONIZZAZIONE (PER MASTER) SYNCHRONISATION JUMPER...

- Page 13 BATTERY SAVING ( BATTERY SAVING + TEST FOTOCELLULE · PHOTOCELLS TEST ( COLLEGAMENTO CON 2 COPPIE FOTOCELLULE SINCRONIZZATE (MODALITÁ NORMALE, 1 MASTER E 1 SLAVE) CONNECTION WITH 2 SYNCHRONISED PHOTOCELL PAIRS (NORMAL MODE, 1 MASTER AND 1 SLAVE) ROSSO = libero da jumper RED = jumper free JUMPER DI SINCRONIZZAZIONE (PER MASTER)

- Page 14 PRIMARIO: 230V ~ 50/60Hz BIANCO T 2A Trasformatore Monofase 120°C CEI 61558-2-6 POT. 130VA I210004_1_01/12/21 Ta=55°C SECONDARIO: 26V NERO B71/BCIPU CARICA BATTERIE BATTERY CHARGER HT421 FUSE max. 3m T10A 2.5mm 5x20 BLACK Se richiesto dall'automazione, collegare una resistenza di adeguata potenza per assorbire l'energia in frenatura. If required by the automation, connect a resistor of 3 x 12V DC adequate power to absorb the braking energy.

- Page 15 ON-BOARD MOTOR COMMAND ELECTRONIC UNIT (F70/INV36/1) NOTA: la versione del FW dell'inverter (es. R1.20) non va di pari passo con la versione FW di F70/IPU36 NOTE: the FW version of the inverter (e.g. R1.20) does not match the FW version of the F70/IPU36...

- Page 16 MODALITÁ FUNZIONAMENTO B73/RGB B73/RGB OPERATING MODE LED ROSSO LAMPEGGIANTE LED ROSSO DI PRESENZA (lampeggio continuo) (lampeggio discontinuo) LED ROSSO FISSO RED LED FLASHING FIXED RED LED RED PRESENCE LED (continuous flashing) (discontinuous flashing) LED VERDE LAMPEGGIANTE LED VERDE DI PRESENZA (lampeggio continuo) (lampeggio discontinuo) LED VERDE FISSO...

- Page 17 F70/IPU36/BOX/P...

-

Page 18: Symbols

It is possible to use two different types of automation system on the same gate. ensuring that the gate leaves overlap correctly. ROGER TECHNOLOGY cannot be held responsible for any damage or injury due to improper use or any use other than the intended usage indicated in this manual. -

Page 19: Technical Characteristics Of Product

The total of the absorption values of all the accessories connected must not exceed the maximum power values shown in the table. The values are guaranteed with original ROGER TECHNOLOGY accessories ONLY. The use of non-original accessories may lead to malfunctioning. ROGER TECHNOLOGY declines all responsibility for incorrect or non-conforming installations. -

Page 20: Description Of Connections

Description of connections Typical installation It is the installer's responsibility to verify the adequacy of the cables in relation to the devices used in the installation and their technical characteristics. Recommended cable Power supply H07RN-F 2x1,5 mm double insulated cable Cable 4x1,5 mm²... - Page 21 Measure the voltage on the primary mains power connection with a tester. TRANSFORMER - 230V~ ±10% for the F70/IPU36 control unit. - 115V~ ±10% for the F70/IPU36/115 control unit. 220÷230 -COM...

-

Page 22: Commands And Accessories

Commands and Accessories If not installed, safety devices with NC contacts must be jumpered at the COM terminals, or disabled by modifying the parameters N.C. (Normally Closed). CONTACT DESCRIPTION 19(COR) 18 Output (potential free contact) for connecting courtesy light. 230V~ 100 W - 24 V~/ 40 W 19(COR) •... - Page 23 29(ST) 28(COM) STOP command input (N.C. or 8.2 kOhm). The current manoeuvre is arrested if the safety contact opens. N.B.: the controller is supplied with this contact already jumpered by ROGER TECHNOLOGY. – . (normally closed) incoming contact. 30 (ANT) 31 Antenna connector for slot-in radio receiver board.

-

Page 24: Function Buttons And Display

It is possible to reset to the standard factory parameters by pressing and holding the (UP ARROW) and (DOWN ARROW) keys for 4 seconds while starting up the F70/IPU36. The standard parameters can also be reset by means of parameter (see description in paragraph 10.2) -

Page 25: Navigation In The Menus

To return to the previous level, press ESC; the value set on the display will be saved in the memory. Menù The indicated data is only indicative 10.1 Menù Welcome Closed padlock: password protection active Open padlock (hook turned to the left): password protection disabled FW version Name of control unit F70/IPU36 R1.50... - Page 26 (e.g. par. "OK" = the value of the displayed parameter coincides F70/IPU36 R1.50 with that stored in the inverter of the indicated motor "E" = the value of the parameter is different "--"...

- Page 27 The message ERR indicates that there is at least one error on the parameters by the letters "EE If the error is in the EEPROM memory of F70/IPU36, a toothed cursor appears below the box; if the error is due to a discrepancy between the value in the F70/...

- Page 28 LOCK the display will be too. STATUS: 0 2 2 LAM, ES, SC, COR are outputs of F70/IPU36; in addition, if present, there are indications of inverter-driven outputs ENTER in motor 1 is powered (deadbolt unlocked). These numbers indicate the communication status at the F70/IPU36, inverter 1 and inverter 2 levels.

- Page 29 Encoder magnet missing or damaged; inverter not correctly positioned or secured on the motor reset of inverter functionality. Contact service Motor data incompatibility between inverter and F70/IPU36 EEPROM damaged detected, contact service Motor model selection is incorrect (model not managed by...

- Page 30 -IPU_UF voltage value too low excess current drawn by motors This page displays information on the quality of the RS485 communications between the F70/IPU36 and the inverter modules on board the motor. 100% 100% The percentage of successfully transmitted motor operating...

- Page 31 10.5 Alarm display menu The indicated data is only indicative F70/IPU36 R1.50 The status of MOTOR 1 is displayed to the left of the motor icon, while the status of MOTOR 2 (if present) is ENTER x4 click displayed to the right.

- Page 32 - SEL.MOT therefore F70/IPU36 is in the forced STOP state (it is not possible to start the automation system). Set the correct value of par.

- Page 33 VB:25.3V VL:25.3V Battery operation (charging) if a battery is connected to POWER terminals 3,4 of F70/IPU36 with battery charger enabled. IPU 28.9°C M1: 30.4°C M2: 0.°C Battery low (under the threshold set at par.

- Page 34 10.7 Settings menu The indicated data is only indicative SETTINGS INITIALIZE PASSWORD PROGRAM ENTER Use LANGUAGE selection LANGUAGE CONTRAST CONTRAST for the display screen DEGREES °C °C = Celsius RESET °F = Fahrenheit ENTER RESTORING THE FACTORY PARAMETERS By setting the value to ON, after 5 s the factory parameters are restored.

- Page 35 - PAR selects the motor model is not reset). After carrying out this operation, there may be some discrepancies between the parameters managed by the F70/IPU36 interface and those associated with the inverter (the message PARAMETERS appears on the display)

- Page 36 ENTER Password ON activation state Password OFF activation state To access the F70/IPU36 adjustments (parameter If it is set to OFF, it is not necessary to enter the password settings, travel programming, motor calibration, inverter to access the F70/IPU36 settings...

- Page 37 The factory password is set to 00000000 and it is equivalent to "protection OFF". To change the PASSWORD, go to "MODIFY", press ENTER and proceed with the entry as indicated in the UNLOCK menu. ENABLE UNLOCK -------- MODIFY -------- WARNING: the password is stored but the parameter settings remain accessible.

- Page 38 10.10 Travel acquisition menu / motor calibration The indicated data is only indicative The AUTOPROG menu provides a step-by-step guide to programming the SETTINGS automation system through a series of display messages and an automatic INITIALIZE check procedure (or, if necessary, manual actions on the part of the PASSWORD programmer, for example, activating the release).

- Page 39 UNLOCK MOT1 CLOSE THE GATE CALIBR MOT1 CONF. UNLOCK MOT1 LOCK MOTORS CONF. CLOSED PRESS ENTER PRESS ENTER ENTER ENTER ENTER PROGRAM. MOT1 APP- PROGRAM. MOT1 Programming example for a PM1:OPEN PM2:---- single leaf PRESS ENTER ENTER ENTER Once programming is complete the message RUN is replaced by the message PASS (if the process was completed successfully) or FAIL if it failed.

- Page 40 10.11 SERIAL communication menu The indicated data is only indicative The SERIAL menu may be used to enable the WIFI connection in order to use the B74/BCONNECT module; to do this, it is necessary to enable communications and select the TARGET B-CONN. SERIAL WIFI UPDATE...

- Page 41 WiFi menu (with B74/BCONNECT) The indicated data is only indicative By connecting the Roger B74/BCONNECT module to the F70/IPU36 WiFi connector, it is possible to update the Firmware for the F70/INV36/1, or the two inverter modules on board the motor (having activated the...

- Page 42 10.13 Update menu (FW inverter update / accessories) The indicated data is only indicative SERIAL WIFI UPDATE the motor (FIRMWARE M1, FIRMWARE M2), or of the potential of the B74/BCONNECT device on which the ENTER be downloaded in advance. FIRMWARE M1 1) Select the device on which you wish to perform the FIRMWARE M2 FW EXP1...

- Page 43 10.14 Counters menu The indicated data is only indicative COUNTERS EVENTS TIMES IDVER ENTER TARGET read from TARGET MANEUVER MANEUVER 00000052 executed). WORK.HOURS 000001 WORK. HOURS. DAYS ON 0000 with motors active. DAYS ON Return to the previous menu ENTER TARGET MOT1 (motor inverter 1) MANEUVER...

- Page 44 10.15 Events menu The indicated data is only indicative COUNTERS EVENTS TIMES IDVER ENTER INFO LOG TOT:10 VLD:10 READ LOG M:35 ACT:H:127 DATE AND TIME 15:24 STR:7/8/21 RESET LOG LOG: OFF NRS:-- ENTER ENTER INFO LOG H=hh M=mm READ LOG EVN: CID: DATE AND TIME...

- Page 45 Return to the previous menu If the exact DATE and TIME are set-up in the section, F70/IPU36 is capable of converting this information into the date and time when the LOG event occurred. By clicking the ENTER button you will switch to the display of the estimated...

- Page 46 10.16 Time management menu The indicated data is only indicative COUNTERS EVENTS TIMES IDVER ENTER THERMAL MOT.1: Total time that MOTOR 1 thermal THERMAL MOT.1 protection has been active due to overheating. THERMAL MOT.2 THERMAL MOT.2: Total time that MOTOR 2 thermal EXTRA TEMPERATURE protection has been active due to overheating.

- Page 47 HW: Hardware version of the board. IFW: TARGET:IPU R1.50 (*) the IFW value read by the inverter must be in the range (or equal to the value) read from F70/IPU36. Otherwise, HW:2 IFW:02-03 the INV.FW alarm is triggered (par. 10.5.1) SERN:200000 04/22 SERN: Week/year.

- Page 48 10.18 Alarm menu The indicated data is only indicative 10.18.1 General alarm GENERAL BATTERY LINE BLACKOUT: Shows the number of blackouts detected in the mains voltage. STATUS: ON: (if no mains power) OFF: (if there is mains power) ENTER LINE LACK: Shows the voltage surges (gaps) detected. STATUS: ON: (voltage hole detected in the last 60 seconds) OFF: (regular mains voltage)

- Page 49 10.18.2 Battery menu The indicated data is only indicative GENERAL BATTERY ENTER HIGH CURRENT: Displays the number of activations of HIGH CURRENT the protection on the charging circuit. LOW VOLTAGE LOW VOLTAGE: Displays the number of calibration errors of the current measurement circuit. To see/modify the other functions, move onto the one ENTER required (using the...

- Page 50 Index of parameters FACTORY PARAM. DESCRIPTION PAGE DEFAULT Automation type MOTOR 1 Automation type MOTOR 2 Automatic reclosing after pause time (from fully open gate) Automatic gate closing after mains power outage (black-out) Selecting step mode control function (PP) Condominium function for partial open command (PED) Enabling operator present function Gate open indicator / photocell test function and “battery saving"...

- Page 51 FACTORY PARAM. DESCRIPTION PAGE DEFAULT Setting start acceleration MOTOR 2 during closing Enable electric lock release reverse impulse MOTOR 1 opening speed setting (%) MOTOR 2 opening speed setting (%) MOTOR 1 closing speed setting (%) MOTOR 2 closing speed setting (%) MOTOR 1 end of manoeuvre constant approach speed setting MOTOR 2 end of manoeuvre constant approach speed setting Setting number of automatic closure attempts after activation of sensing edge...

- Page 52 FACTORY PARAM. DESCRIPTION PAGE DEFAULT Selecting courtesy light mode Enable safeguarded gate closure/opening Setting safeguarded closure/opening activation time Selecting limitations in battery operation Battery type selection and consumption reduction Selection of the battery operation management Enabling of regular maintenance activation Adjustment of regular maintenance activation hour counter Cyclical activation (test mode) accessories...

- Page 53 Parameter menu PARAMETER PARAMETER VALUE Selecting automation system model MOTOR 1 WARNING! If this parameter is not set correctly, the automation system may not function properly. N.B.: in the event of a reset to restore the default parameters, this parameter must be set again manually. Selecting automation system model MOTOR 2 WARNING! If this parameter is not set correctly, the automation system may not function properly.

- Page 54 Enabled. The open (AP) or close (CH) button must be pressed continuously to operate the gate. The gate stops when the button is released. Opening is in semi-automatic mode by AP command only, operator present function for the closing by CH command at the terminal board only.

- Page 55 Adjusting stop advance of MOTOR 1 when opening Adjusting stop advance of MOTOR 2 when opening The leaf stops against the opening stop. A leaf stop advance of 1 to 25 motor turns before the completely open position may be set. Setting automatic closing time The timer starts from the gate open state and continues for the set time.

- Page 56 Setting MOTOR 1 torque Increasing or decreasing the value of the parameter increases or decreases motor torque and, as a result, adjusts obstacle detection sensitivity. Use values below SOLO ONLY for particularly lightweight installations not exposed to severe weather conditions (strong winds or very cold temperatures).

- Page 57 MOTOR 1 end of manoeuvre constant approach speed setting Once deceleration is complete, the gate continues moving at a constant speed until it encounters the mechanical stop (or the limit switch, if installed). The space is regulated by the parameters from Y and Y . MOTOR 2 end of manoeuvre constant approach speed setting Once deceleration is complete, the gate continues moving at a constant speed until it encounters the mechanical stop (or the limit switch, if installed).

- Page 58 Photocell (FT2) mode with gate closed N.B.: this parameter is not visible if is set. If the photocell is obstructed, the gate cannot open. The gate opens when an open command is received, even if the photocell is obstructed. The photocell sends the gate open command when obstructed. Enable close command 6 s after activation of photocell (FT1-FT2) This parameter is not visible if is set.

- Page 59 Enable MOTOR 1 internal electric lock NOTE: this parameter is displayed only if required by the MOTOR 1 type (REVERSIBLE or HIGH-SPEED). Enable MOTOR 2 internal electric lock NOTE: this parameter is displayed only if required by the MOTOR 2 type (REVERSIBLE or HIGH-SPEED). Electric lock disabled.

- Page 60 • • pressing CHB on the remote control. Press CHB to activate partial opening. Selecting courtesy light mode other than Disabled. ACTIVE. The light remains lit for the entire duration of the manoeuvre. From 3 to 90 s. The light remains lit for the time period set after the manoeuvre is completed. From 2 to 9 minutes.

- Page 61 B74/BCONNECT and the corresponding WEB application Setting the value forces the F70/IPU36 to reset Restoring factory default values NOTE This procedure is only possible is NO data protection password is set.

- Page 62 Enable B73/RGB connected to MOTOR 1 Enable B73/RGB connected to MOTOR 2 Disabled. Enabled with signalling function RGB (RED - GREEN - BLUE). Select RG beacon operating mode Disabled. "Type A"..."type F" mode. Select RGB signalling operating mode Disabled "Type A"..."type H" mode. Enabling incoming colour transition at full aperture , only for modes type 'A', 'B', 'F', 'G' of RGB lights, when the indicated aperture percentage is reached, the colour transitions to the selected colour.

- Page 63 Enable maximum torque boost when starting MOTOR 1 If this parameter is enabled, each time the motor starts a manoeuvre, maximum torque is produced for a maximum of 5 seconds, or for the time necessary for the gate to open by approximately 65 cm. of the parameter Y setting.

- Page 64 F70/ that the connection is correct; try IPU36 and inverter or damaged switching the F70/IPU36 off, and then inverter (or communication section on again with inverter damaged on board F70/IPU36)

- Page 65 • • • Other signals: GREEN AND RED LED • • 4 reception phase (bootloader active) • • no longer available, motor disabled until new update) Mechanical release In the event of a power failure, it is possible to unlock the gate, as indicated in the automation use and maintenance manual.

- Page 66 Declaration of Conformity The undersigned Dino Florian, legal representative of Roger Technology - Via Botticelli 8, 31021 Mogliano V.to (TV) DECLARES that the F70/IPU36 digital control unit is compliant with the provisions established by Community directi-...

- Page 70 ROGER TECHNOLOGY Via S. Botticelli 8 • 31021 Bonisiolo di Mogliano Veneto (TV) • ITALIA P.IVA 01612340263 • Tel. +39 041.5937023 • Fax. +39 041.5937024 www.rogertechnology.com...

Need help?

Do you have a question about the F70/IPU36 and is the answer not in the manual?

Questions and answers