Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for DUUN VM410

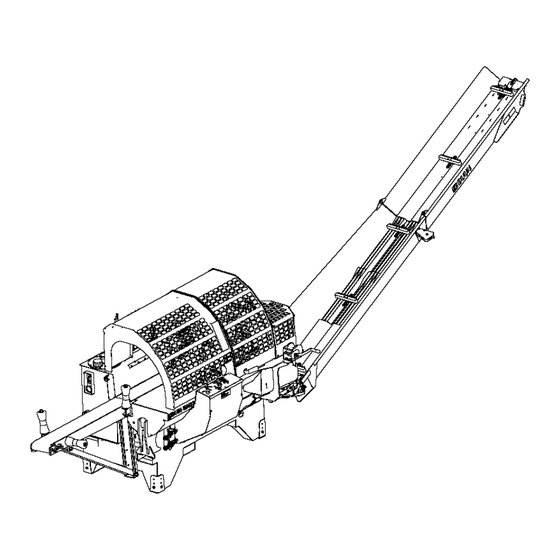

- Page 1 Duun Industrier as 7630 Åsen, Norway www.duun.no VM410 Instruction manual...

-

Page 2: Machine Indetification

Congratulations on your Duun VM410 firewood processor. All Duun tractor operated machines have been engineered and tested in close cooperation with representative users to produce functionally safe and user-friendly machines. Please read this instruction manual before using the machine. Good luck! Machine identification Serial number and manufacturer are indicated on badge (A). -

Page 3: Table Of Contents

CONTENT MACHINE INDETIFICATION SAFETY WARRANTY TERMS DELIVERY FORM OF DUUN FIREWOOD PROCESSOR TECHNICAL DATA TRANSPORT AND HANDLING PRIOR TO USE RANSPORT AND HANDLING BEFORE USE REPARATION FOR MOVEMENT BY TRACTOR RANSMISSION SECURITY YDRAULIC OIL QUALITY IL LEVEL CONTROL IL TEMPERATURE CONTROL... -

Page 4: Safety

Safety All operators, mechanics and the owner must always work carefully with agricultural machinery. Read and observe safety instructions in this instruction manual. Be particularly aware of warning signs with this symbol, it marks measures that must be carried out in order to avoid accidents. The symbol appears in the instruction manual and on warning signs on the machine. - Page 5 Safe connection and use Do not allow anyone to stay between the machine and the tractor when the machine is connected to the tractor. The same applies during the use of the machine. Make sure that the connection is carried out in a safe manner. Safety in case of interruptions and maintenance Remember always to stop the tractor’s engine...

- Page 6 Contact with current-carrying cables etc. during transport. Please note that the firewood processor can tip over the tractor during transport and there is a risk of contact with live wires, railway underpasses etc.! Conveyor belt – transporter Do not stay under the conveyor when it is tensioned to avoid damage of an uncontrolled fall during use.

- Page 7 Safe transportation Before the machine is moved, the feed belt and conveyor (both in the folded-up position as outlined) must be strapped together with a load strap to ensure that they cannot fall down. The loading stop has an attachment at the bottom of the feed belt and secures the belt from falling off during transport.

-

Page 8: Warranty Terms

Warranty terms Duun VM410 has 12 months guarantee against defects in materials and workmanship. Parts that are not originally manufactured by Duun Industrier as, for example, wheels, hydraulic parts, etc. are subject to these suppliers’ guarantees and terms. Parts that are considered wearing parts are not included in the warranty - these are specified in a separate table at the bottom of this page. -

Page 9: Delivery Form Of Duun Firewood Processor

DELIVERY FORM OF DUUN FIREWOOD PROCESSOR MACHINE INFORMATION Model _ _ _ _ _ _ _ _ _ _ _ Serial no. _ _ _ _ _ _ _ _ _ _ _ CUSTOMER INFORMATION Machine owner _ _ _ _ _ _ _ _ _ _ Address _ _ _ _ _ _ _ _ _ Aip code. -

Page 10: Technical Data

Technical data Features: VM410 Max cutting diameter 41 cm Max splitting force 11000 kg Chain drive Hydraulic Cutting length 20-50 cm Saw chain type 1,6 mm Chain speed 23 m/s Saw chain pitch 0,325" Total saw chain links 85 links Weight Approx. -

Page 12: Transport And Handling Prior To Use

Transportation and handling before use Transport and handling before use The hull for the VM410 is equipped with a fork pocket (A) for handling with a forklift or pallet forks. Be aware that a single firewood machine weighs approximately 900 kg. Use lifting... -

Page 13: Hydraulic Oil Quality

Hydraulic oil quality The machines' ability to function will mostly depend on the hydraulic oil being intact. The biggest dangers to the oil quality are: • Excessively high temperature which entails poor lubrication performance and risk of faults and break-down of expensive components such as valves, pumps and motors. -

Page 14: Power Transmission Shaft

NB! Too long shaft can lead to spraining of the shaft and risk of overloading the tractor's PTO and the gearbox in VM410. Please lubricate the PTO drive shaft before use. -

Page 15: Feeding Belt Preparation

Feeding belt preparation The feeding belt is folded in place by releasing the locking pin at letter G which locks it. The belt is tensioned by adjusting the screws at letter H. The belt is sufficiently tensioned if it feeds in the wood without friction. -

Page 16: Practical Use

Practical use Conditions The machine may not be used until the operator has done the following: • Has read the instruction manual and knows how the machine works and how to operate it. • Has made himself acquainted with and observed the information regarding safety described on pages 4 to 7 in the instruction manual. -

Page 17: The Main Functions - Feeding - Conveyor Belt Speed Regulation

The main functions – feeding – conveyor belt speed adjustment The wood material that is to be cut is fed on the feeding belt. The main functions are: A. To move the feeding belt forwards/backwards. B. Operate the cutting sword up and down. C. -

Page 18: Hydraulic Knife Lift

Hydraulic knife lift The splitting knife H is adjusted up H and down I with the lever equipped for this purpose. To change the knife, move the handle all the way to the top position (H). Release the bolt which holds the knife in the lower edge and lift out. -

Page 19: Safe Manually Operated Log Holder

Safe manually operated log holder Avoid using your hands near the saw chain. This is achieved by using the log holder A and the handle B for operating this. Cutting the last log, it is important to keep a "correct" long one at the end and cut a short length of wood as the penultimate one. -

Page 20: Chain Sharpening And Tightening

Blunt chains and skewly sharpened chains entail great wear on the saw chain sword and risk of extra costs and complications. To avoid this, the Duun VM410 is designed that the saw chain must always be removed from the machine for sharpening or replacement. -

Page 21: Adjustment Of The Chain Lubrication

To change the chain, release both screws B. The screw A is loosened so far that the chain can be unhooked at the rear for maintenance or replacement. To tighten the chain, loosen screws B and tighten with screw A. Check the chain tension by pulling the chain in the middle of the long side of the bar. -

Page 22: Service And Maintenance

Service and maintenance Before opening any covers and carrying out service and maintenance, always switch off the machine to avoid damage. NB! There are movable parts in the mechanism with great power and a risk of crushing. The machine should never be run with the covers removed. The machine is factory set. -

Page 23: Weekly Maintenance

Make sure that the chain oil tank does not run out of oil. Check if the oil is consumed and the chain is lubricated. Weekly maintenance Open all hatches and safety covers and blow clean of dirt and grime. Sawdust and dirt will settle inside the machine and it is important to remove this in order for the machine to have optimal cooling and for all functions to work. -

Page 24: Monthly Maintenance

Art.no. 2251065 Clean and lubricate the machine properly between each season. The VM410 has many bearing points, many of which are lightly loaded and are therefore equipped with one-time lubricated bearings. Other bearings are mainly flanged bearings that should be moderately lubricated. The main rule here... - Page 25 USER MANUAL FOR DISPLAY IN VM410 Applies to software version v0.0 – v0.5. Content ................................... 25 Startup ................................26 Safety Check ................................26 Release all buttons ..............................26 Safety Check OK ..............................26 Display menu ..............................26 Menu picture 1 ...............................

- Page 26 1. Startup Safety Check Starting the machine, for safety reasons, it is necessary to test the safety switch on the firewood processor's cover. The cover must be opened and closed. If for some reason there is a loss of supply voltage, this test will be required again. Release all buttons This is check that neither the buttons nor the joystick are in the affected position during start-up.

- Page 27 Menu picture 3 No of splits Counts the number of splits the firewood processor has been instructed to perform. Menu picture 4 Power ON time Counts the number of hours the machine has been powered on. Menu picture No of alarms: Voltage out of range Counts the number of times the supply voltage has been too low or too high.

- Page 28 Movement stopped The alarm will sound if the movement is not completed within a reasonable time. This applies to the movements for splitting and sawing. Resets by releasing the joystick and possibly reactivating it. Oil overheated If the hydraulic oil on the machine gets too hot, this alarm will sound. You can finish a movement you have started, but you cannot start a new one until the machine has cooled down.

-

Page 29: Declaration Of Cornformity

Declaration of conformity...

Need help?

Do you have a question about the VM410 and is the answer not in the manual?

Questions and answers