Advertisement

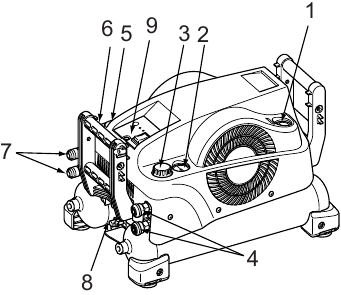

Explanation of general view

- Air Tank pressure gauge

- Regulated pressure gauge "HP"

- Air regulator "HP"

- Quick coupler "HP" (Air outlet)

- Regulated pressure gauge "RP"

- Air regulator "RP"

- Quick coupler "RP" (Air outlet)

- Drain valve

- Operation panel

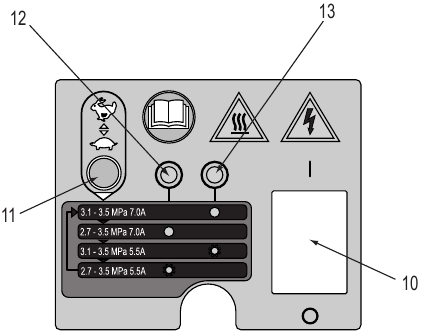

Operation panel

- Switch

- Mode select switch

- Mode LED (Blue)

2.7 - 3.5 MPa 7.0 A: Lighting

2.7 - 3.5 MPa 5.5 A: On and off light - Mode LED (Red)

3.1 - 3.5 MPa 7.0 A: Lighting

3.1 - 3.5 MPa 5.5 A: On and off light

SPECIFICATIONS

| Model | AC320H |

| Voltage-Single Phase | 220 - 240 V AC |

| Rated current | 7 A |

| Hz | 50 Hz ± 1 Hz |

| Motor Power | 2 HP |

| MAX Motor RPM | 2,500 min-1 |

| Cut-in Pressure | 2.7 - 3.1 MPa (27 - 31 bar) |

| Cut-out Pressure | 3.5 MPa (35 bar) |

| SCFM @ 100 PSIG (L/min @ 6.9 bar)* | 4.4 (124 L) |

| SCFM @ 330 PSIG (L/min @ 23 bar)* | 3.6 (102 L) |

| Bore x Stroke x Qty | 62 mm x 26 mm x 1 41 mm x 10 mm x 1 |

| Tank Size | 5.5 L x 2 |

| Weight | 18 kg |

| Dimensions (L x H x W) | 558 x 350 x 358 mm |

| Lubrication | Oil-Less |

| Protective earthing | Class I |

| Protective structure | IP 20 |

| Working temperature | 0°C to +40°C |

| Working humidity | 85% RH or less. No dew condensation. |

| Height above sea level | Up to 2,000 m |

| Storage temperature | -10°C to +50°C |

| Storage humidity | 85% RH or less. No dew condensation. |

| Outlet Max Pressure "HP" (Exclusively for High Pneumatic Use) | 2.45 MPa (24.5 bar) |

| Outlet Max Pressure "RP" (Exclusively for Regular Pneumatic Use) | 0.88 MPa (8.8 bar) |

| Noise: Sound Pressure Level (Lpa) Sound Power Level (Lwa) Uncertainty K | 65.2 dB (A) 85.2 dB (A) 0.85 dB (A) |

*

- In consequence of operating conditions, environments and the hours of operation, outlet pressure is changed.

- Due to our continuing programme of research and development, the specifications herein are subject to change without notice.

- Specifications may differ from country to country.

GLOSSARY

CUT-IN PRESSURE:

While the motor is off, air tank pressure drops as you continue to use your accessory or air tool. When the tank pressure drops to certain level the motor will restart automatically. This is called "cut-in pressure".

CUT-OUT PRESSURE:

When you turn on your air compressor, it begins to run, air pressure in the tank begins to build. It builds to a certain pressure before the motor automatically shuts off - protecting your air tank from pressure higher than its design rating. The pressure at which the motor shuts off is called "cut-out pressure".

CFM: Cubic feet per minute.

SCFM: Standard cubic feet per minute; a unit of measure of air delivery.

PSIG: Pounds per square inch gauge; a unit of measure of pressure.

Read the Safety Guidelines and ALL instructions carefully before operating.

Symbols

The following show the symbols used for the equipment. Be sure that you understand their meaning before use.

| Read instruction manual. |

| Risk of electric shock before doing any work on the compressor it must be disconnected from the power supply. |

| Risk of high temperatures the compressor contains some parts which might reach high temperatures. |

| Risk of accidental start-up Attention, the compressor could start automatically in case of a black-out and subsequent reset. Attention, the compressor could start automatically in case of a black-out and subsequent reset. |

| Wear safety glasses. |

IMPORTANT SAFETY INSTRUCTIONS

READ AND UNDERSTAND ALL INSTRUCTIONS

Failure to follow all instructions listed below may result in electric shock, fire, and/or serious injury.

SAVE THESE INSTRUCTIONS.

WORK AREA

- Keep your work area clean and well lit. Cluttered and dark areas invite accidents.

- Do not operate power tools in explosive atmospheres, such as in the presence of flammable liquids, gases, or dust. Power tools create sparks which may ignite the dust or fumes.

- Keep bystanders, children, and visitors away while operating a power tool. Distractions can cause you to lose control. Protect others in the work area from debris such as chips and sparks. Provide barriers or shields as needs. Children should never be allowed in the work area.

- The adequate room temperature is +5°C to +30°C. (0°C to +40°C at Maximum)

- This compressor is for indoor use. Do not install the compressor in any place exposed to rain or splashed water, high-humidity place or high temperature place. Never operate the compressor in damp or wet locations. If use in the wet condition, it could produce an electric shock or be short-circuited, resulting in ignition.

- Never use the machine in any unstable place. Never use it in a place where it could move or fall of itself. Be sure to install the compressor on a flat floor, with leg rubber underneath it; the allowable tilt angle of the floor is up to 10 degrees. If the installation floor is tilted and slippery, ensure that the compressor does not move during operation. Do not use it on a shelf or stand where it may fall or tumble.

IMPROPER OPERATION OR MAINTENANCE OF THIS PRODUCT COULD RESULT IN SERIOUS INJURY AND PROPERTY DAMAGE.

READ UNDERSTAND ALL WARNING AND OPERATING INSTRUCTIONS BEFORE USING THIS EQUIPMENT.

Risk of Unsafe Operation

WHAT CAN HAPPEN

Unsafe operation of your compressor could lead to serious injury to you or others.

HOW TO PRIVENT IT

- Review and understand all instructions and warnings in this manual.

- Become familiar with the operation and controls of the air compressor.

- Keep operating area clear of bystanders, pets, and obstacles.

- Keep children away from the air compressor at all times.

- Do not operate the product when fatigued or under the influence of alcohol or drugs. Stay alert at times.

- Never defeat the safety features of this product.

- Do not operate machine with missing, broken, or unauthorized parts.

- Use the outlet of the building installation with a proper protection for the power supply of this compressor. Failure to use a proper protection for the power supply, it may cause electric shock and damage to the compressor.

- Never connect the compressor to an engine generator or direct-current power supply. Operate the compressor by those power supply can cause damage the unit and burn out the motor.

- Never use a transformer for the power supply of this compressor. If using a transformer for the power supply of this compressor, it can lead to malfunction.

- If the compressor appears to be operating unusually, making strange noises, or otherwise appears defective, stop using it immediately and arrange for repairs by an authorized service facility.

Risk of Air Tank Bursting

WHAT CAN HAPPEN

The following conditions could lead to a weakening of the tank, and RESULT IN A VIOLENT TANK EXPLOSION RESULTING IN SERIOUS INJURY TO YOU OR OTHERS.

- Failure to properly drain condensed water from the tank, causing rust and thinning of the tank wall.

- Modifications or attempted repairs to the tank.

- Unauthorized modifications to the pressure censor, relief valve, or any other components, which control tank pressure.

- Move or transport the compressor with the air tank is filled up.

HOW TO PREVENT IT

- Drain air tank daily or after each use. If air tank develops a leak, have it repaired by authorized service facility.

- Do not drill into, weld or otherwise modify air tank or it will weaken. The tank can rupture or explode, replace with a new air tank by authorized service facility.

- Follow the equipment manufactures recommendation and never exceed the maximum allowable pressure rating of attachments. Never use the compressor to inflate small low-pressure objects such as children's toys, footballs, basketballs, etc.

- In order to avoid bursting the air tank by dropped or struck it, do not move and transport with the air tank is filled up.

Risk of Attachments and Accessories Bursting

WHAT CAN HAPPEN

Exceeding the pressure rating of air tools, spray guns, air operating accessories, tyres AND other inflatables can cause them to explode or fly apart, and could result in serious injury to you and others.

Risk of Electric Shock

WHAT CAN HAPPEN

- Your air compressor is powered by electricity. Like any other electricity device, if it is not used property, it may cause electric shock.

- Electrical grounding (PE): failure to provide adequate grounding to this product could increase the risk of electric shock.

- This compressor is for indoor use. Do not install the compressor in any place exposed to rain or splashed water, high-humidity place or high-temperature place. Never operate the compressor in damp or wet locations. If use in the wet condition, it could produce an electric shock or be short-circuited, resulting in ignition.

- Do not connect to the power supply with the cover of the compressor put off. Contact with electrical circuit, it may cause electric shock. Doing so can result in serious injury to you.

- Contact with electrical circuit inside the compressor when it is in shuts off within 10 seconds, could cause electric shock. Doing so can result in serious injury to you.

HOW TO PREVENT IT

- Any electrical wiring or repairs required to this product should be performed by qualified service personnel or qualified electrician, in accordance with national and local electrical codes.

- Make certain that the electrical circuit to which the compressor is connected provides proper electrical grounding, correct voltage, and adequate fuse protection.

- Never operate the compressor outdoors when it is raining, or in a wet environment.

- Never operate the compressor with guards or covers which are damaged or removed.

- Never put off the cover of the compressor except MAKITA authorized dealer.

- Never contact with electrical circuit when the compressor is in shuts off within 10 seconds.

Risk of Explosion or Fire

WHAT CAN HAPPEN

- It is normal for electrical contacts within the motor and motor driver, switch to spark, whenever the compressor starts or stops. Never operate the compressor in an atmosphere where flammable or explosive vapours are present. Doing so can result in serious injury to you or others.

- This compressor is for indoor use. Do not install the compressor in any place exposed to rain or splashed water, high-humidity place or high-temperature place. Never operate the compressor in damp or wet locations. If use in the wet condition, it could produce an electric shock or be short-circuited, resulting in ignition.

HOW TO PREVENT IT

- Always operate the compressor in a well-ventilated area, free of gasoline or solvent vapours.

- If spraying flammable materials, stop the operation of the compressor and disconnect from the main supply.

- Store flammable materials in a secure location away from compressor.

- Never operate the compressor outdoors when it is raining, or in a wet environment.

Risk of Damage

- Do not wipe plastic parts with solvent. Solvent such as gasoline, thinner, benzene, carbon tetrachloride, and alcohol may damage and crack plastic parts. Do not wipe them with such solvents. Wipe plastic parts in use with soft cloth and mild detergent so as not to damage them and dry them thoroughly.

- Never sit or place an object on the top of the machine. Neglect of this could cause a trouble or break it.

Risk of Breathing

WHAT CAN HAPPEN

- The compressed air from your compressor is not safe for breathing. The air stream may contain harmful vapours, or particles from the tank or other components and environment operating.

- Sprayed materials such as paint, paint solvents, paint remover, insecticides, weed killers etc., contain harmful vapours and poisons.

- Breathing compressor or sprayed materials vapor can result in serious injury.

HOW TO PREVENT IT

- Never inhale air from the compressor, either directly or from breathing device connected to the compressor. Work in an area equipped with good cross ventilation.

- Read and follow the safety instructions provided on the label or safety date sheet for the material you are spraying.

Use an approved respirator designed for use with your specific application.

Risk from Noise

WHAT CAN HAPPEN

The air compressor generates noise exceeding 80 dB (A) during operation. It may cause the operator and people around it to suffer hearing loss.

HOW TO PRIVENT IT

- Wear ear protection.

Risk from Compressed air

WHAT CAN HAPPEN

The compressed air stream can cause soft tissue damage, and can propel dirt, chips, loose particles and small objects at high speed, resulting in property damage or personal injury.

HOW TO PRIVENT IT

- Always wear approved safety glasses with side shields when using or maintaining the compressor.

- Never point any nozzle or sprayer toward any part of the body or other people or animals.

- Always turn the compressor off and bleed pressure from the air line before attempting maintenance, attaching tools or accessories.

Risk from Moving Parts

WHAT CAN HAPPEN

The compressor cycles automatically when the switch is in the on position. If you attempt repair or maintenance while the compressor is operating or plug in, you can expose yourself to moving parts. These moving parts can cause serious injury.

HOW TO PRIVENT IT

- Always unplug the compressor and release air pressure from the tank and any attachments before attempting any maintenance.

- Never operate the compressor with guards or covers which are damaged or removed.

- Keep your hair, clothing, and gloves away from moving parts. Loose clothes, jewellery, or long hair can be caught in moving parts.

- Air vents may cover moving parts and should be avoided as well.

- Arrange for any repairs by MAKITA authorized dealer.

- Never put off the cover of the compressor except MAKITA authorized dealer.

Risk of Burn

Do not operate the portable compressor with the doors or enclosures open.

WHAT CAN HAPPEN

Contact with hot parts such as the compressor head or outlet tubes could result in a serious skin burn.

HOW TO PRIVENT IT

- Never touch hot components during or immediately after operation of the compressor. Do not reach around protective shrouds or attempt maintenance until unit has been allowed cool.

- The handling and lifting: hold the handle only when move or transport the compressor. Do not move by dragged.

- To avoid injuring, do not touch the cylinder, cylinder head, exhaust hose or other over-headed parts and the protector of control box of the lower part when the compressor is in use or shuts off within one hour.

WHAT CAN HAPPEN

- Using it under high temperature or in the direct sunshine not only deteriorate its durability, but increase the temperature of main body, causing danger to your safety.

HOW TO PRIVENT IT

- Be sure to use it in the well-ventilated shade. The adequate room temperature is +5°C to +30°C (0°C to +40°C at maximum).

WHAT CAN HAPPEN

- Neglect of this may generate abnormal heat, causing a trouble or accident.

HOW TO PRIVENT IT

- Install the compressor at the distance of 1m or more from the wall to secure sufficient ventilation and cooling.

WHAT CAN HAPPEN

- If the compressor is operated abnormally, the air tank is heated and got high temperature.

Transport

- Do not apply vehicles for traction.

- Do not place compressor under inflammable, explosive or erosive service.

- Do not overturn it or lift it with hooks and ropes.

DUTY CYCLE

All Makita manufactured air compressor are recommended to be operated at no more than a 50% duty cycle. This means an air compressor that pumps air more than 50% of one hour is considered misuse because the air compressor is undersized for the required air demand.

GENERAL INFORMATION

This air compressor is equipped with an Oil-Less pump designed for durability and no maintenance. The compressor can be used for properly rated pneumatic nailers and staplers. An air pressure regulator is supplied for these applications.

Never use compressor for applications other than to operate a properly rated nailer and stapler. Use of the compressor for other applications could result in property damage and personal injury.

Separate air filter regulators combine the functions of air regulation and/or moisture and dirt removal should be used where applicable.

ON-RECEIPT INSPECTION

DAMAGE: Each air compressor outfit is carefully tested and checked before shipment. With importer handling, damage may result in transit and cause problems with compressor operation.

Immediately upon arrival, check equipment for both concealed and visible signs of damage to avoid expenses being incurred to correct such problems. This should be done regardless of any visible signs of damage to the shipping container. If this product was shipped directly to you, report any damages to the carrier and arrange for inspection of goods immediately.

STORAGE

Before you store the air compressor, make sure you do the following:

- Review the "Maintenance" and "Operating Procedures" sections and perform maintenance as necessary. Be sure to drain water from air tank. Protect the electrical cord and air hose from damage (such as being stepped on or run over). Store the air compressor in a clean and dry location.

DESCRIPTION OF OPERATION

DRAIN VALVE:

The drain valve is located between two sets of air tank and is used to drain condensation with locating at a level from the tank at the end of each use or daily.

OPERATION PANEL:

Operation Panel has power switch and mode select switch. You can change the operation mode "CUT-IN PRESSURE" and electrical current by mode select switch.

SWITCH:

Turn this switch to ON "|" to provide automatic power to the pressure switch and to OFF "O" to remove power when finished using the compressor or when compressor will be left unattended.

This switch has a function of reset. When a thermal protector operates, activating the function of reset, the power is removed. Whenever the thermal protector operates, a function of reset is activated. So even if you turn the switch to ON "|", compressor does not operate.

THERMAL PROTECTOR:

This compressor has a thermal protector. If the motor is overheated by any cause, the motor is stopped by operating a function of reset for a thermal protector. After the motor has cooled down, the thermal protector does not active.

PRESSURE CENSOR:

The pressure censor automatically starts the motor when the air tank pressure drops to the factory set "cut-in" pressure. It stops the motor when the air tank pressure reaches the factory set "cut-out" pressure.

RELIEF VALVE:

If the pressure censor dose not shut off the air compressor at its "cut-out" pressure setting, the relief valve will protect against high pressure by "popping out" at its factory set pressure which is slightly higher than the pressure censor "cut-out" setting.

OUTLET PRESSURE GAUGE:

The outlet pressure gauge indicates the air pressure available at the outlet side of the regulator. This pressure is controlled by the regulator and is always less or equal to the tank pressure. See "Operating Procedures".

TANK PRESSURE GAUGE:

The tank pressure gauge indicates the air pressure in the tank.

REGULATOR:

The air pressure coming from the air tank is controlled by the regulator knob. Turn the knob clockwise to increase pressure and counter-clockwise to decrease pressure. To avoid minor re-adjustment after making a change in pressure setting, always approach the desired pressure from a lower pressure. When reducing from a higher to a lower setting, first reduce the pressure less than the desired pressure. Depending on the air requirements of each particular accessory, the outlet regulated air pressure may have to be adjusted while you are operating the accessory.

COMPRESSED AIR OUTLET; "HP" marking

For High Pressure Pneumatic Tool Exclusive Use Outlet Max Pressure; 2.45 MPa (24.5 bar)

COMPRESSED AIR OUTLET; "RP" marking

For Regular Pressure Pneumatic Tool Use Outlet Max Pressure; 0.88 MPa (8.8 bar)

INSTALLATION AND BREAK-IN PROCEDURES

LOCATION OF THE AIR COMPRESSOR

Locate the air compressor in a clean, dry and well-ventilated area. The air filter must be kept clear of obstructions, which could reduce air delivery of the air compressor. The air compressor should be located at least 0.3 m away from the wall or other obstructions that would interfere with the flow of air. The compressor head and shroud are designed to allow for proper cooling. If humidity is high, an air filter can be installed on the air outlet adapter to remove excessive moisture. Place the air compressor on a level surface so that it rests securely on the rubber feet. Follow the instructions packaged with the air filter for proper installation.

LUBRICATION

This air compressor is equipped with an Oil-Less pump designed for durability and no maintenance.

Power supply

Operate the compressor at voltage specified on the nameplate. If using the compressor at a higher voltage than the rated, it will result in abnormally fast motor speed and may damage the unit and burn out the motor. Also if using the compressor at a low voltage, it will result in abnormally slow motor speed and may overheat and shut off the motor.

Extension Cords

To avoid voltage drop, power loss, and overheating of the motor, use extra air hose instead of an extension cord.

Low voltage can cause damage to the motor.

If an extension cord must be used;

- Make sure the extension cord is in good condition.

Please see the chart below for MINIMUM extension cord gauge requirement:

| Amp Rating Range (220 - 240V) | Total Length of Cord in Meter | |||||

| 10 m 25 ft. | 15 m 50 ft. | 20 m 75 ft. | 30 m 100 ft. | 50 m 1 50 ft. | 60 m 200 ft. | |

| 0 - 5 A | 1.5 mm2 | 1.5 mm2 | 1.5 mm2 | 2.5 mm2 | 4 mm2 | 4 mm2 |

| 5.1 - 8 A | 1.5 mm2 | 1.5 mm2 | 2.5 mm2 | 4 mm2 | 4 mm2 | 4 mm2 |

| 8 - 12 A | 2.5 mm2 | 2.5 mm2 | 4 mm2 | Not Recommended | ||

Piping

This air compressor is not designed for use with piping. Never use compressed air with any kind of piping connected.

Improper grounding can result in electrical shock. Do not modify the plug that has been provided. If it does not fit the available outlet, the correct outlet should be installed by a qualified electrician.

OPERATING PROCEDURES

Daily Start-up Checklist

CONNECTING HOSES

Risk of unsafe operation. Firmly grasp hose in hand when installing or disconnecting to prevent hose whip.

Losing control of the hose may result in personal injury and property damage.

- Before attaching air hose or accessories, make sure the switch is set to OFF "O" and drain valve is opened, the air regulator or shut-off valve is closed. Ensure compressor is disconnected from the main supply.

- Attach hose and accessories. Too much air pressure causes a hazardous risk of bursting. Check the manufacture's maximum pressure rating for air tools and accessories. The regulator outlet pressure must never exceed the maximum pressure rating.

- Connect a plug to the outlet.

- Start the compressor with turning the switch to ON "|". Select a operation mode by mode select switch. Close the drain valve. Motor will stop when tank pressure reaches "cut-off" pressure.

- Open the regulator by turning it clockwise. Adjust the regulator to the correct pressure setting. Your compressor is ready for use.

- Always operate the air compressor in well-ventilated areas; free of gasoline or solvent vapors. Do not operate the compressor near the spray areas.

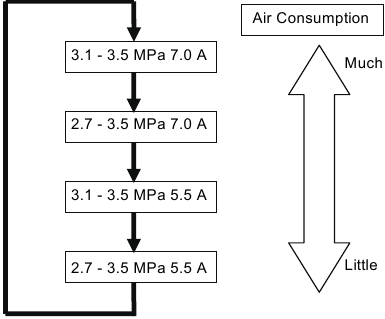

Operating mode

This compressor has a 4 type of operation modes. You are able to select the available operation mode from 4 functions.

| Operation Mode | LED Indication | Pressure | MAX Motor RPM | Rated current | ||

| Blue | Red | CUT-IN | CUT-OUT | |||

| 3.1 - 3.5 MPa 7.0 A | Lights out | Lighting | 3.1 MPa | 3.5 MPa | 2,500 min-1 | 7 A |

| 2.7 - 3.5 MPa 7.0 A | Lighting | Lights out | 2.7 MPa | 3.5 MPa | 2,500 min-1 | 7 A |

| 3.1 - 3.5 MPa 5.5 A | Lights out | On and off light | 3.1 MPa | 3.5 MPa | 1,800 min-1 | 5.5 A |

| 2.7 - 3.5 MPa 5.5 A | On and off light | Lights out | 2.7 MPa | 3.5 MPa | 1,800 min-1 | 5.5 A |

Operating Procedures

You are able to select the available operation mode by push the mode select switch one time as follow, and return a starting mode by push the mode select switch 4 times.

When you are finished:

DISCONNECTING HOSES

Risk of unsafe operation. Firmly grasp hoses in hand when installing or disconnecting to prevent hose whip.

Losing control of the hose may result in personal injury and property damage.

- Set the switch to OFF "O". Ensure compressor is disconnected from the main supply.

NOTE: Do not stop compressor by pulling out the plug.

- Drain water from air tank by opening drain cock valve at the side of air tank with locating at a level. WATER WILL CONDENSE IN THE AIR TANK. IF NOT DRAINED, WATER WILL CORRODE AND WEAKEN THE AIR TANK AND PARTS CAUSING A RISK OF AIR TANK RUPTURE.

Drain Air Tank Properly. Improper draining of the air tank can result in corrosion of a parts and possible damaging and bursting of the tank. Corrosion and damaging of a parts, tank bursting could lead to personal injury and property damage.

NOTE: If drain valve is plugged, release all air pressure with air tools and accessory equipments. If you are not able to do so, arrange for repairs by MAKITA authorized dealer.

- Using the air tool or accessory, bleed the tank pressure down to zero.

- Remove the air tool or accessory.

- After the water has been drained, close the drain valve. The air compressor can now be stored.

MAINTENANCE

Never use the air compressor which is operating abnormally.

If the air compressor appears to be operating unusually, making strange noises or vibration, stop using it immediately and arrange for repairs by MAKITA authorized dealer.

Use only genuine Makita replacement parts. Replacement parts not manufactured by Makita may void your warranty and can lead to malfunction and result in injuries. Genuine Makita parts are available from an authorized dealer.

UNIT CYCLES AUTOMATICALLY WHEN POWER IS ON. WHEN DOING MAINTENANCE, YOU MAY BE EXPOSED TO VOLTAGE SOURCES, COMPRESSED AIR OR MOVING PARTS. PERSONAL INJURIES CAN OCCUR. BEFORE PERFORMING ANY MAINTENANCE OR REPAIR, UNPLUG THE COMPRESSOR AND BLEED OFF ALL AIR PRESSURE.

Do not modify the compressor.

Do not modify the compressor. Always contact the authorized service facility any repairs.

Unauthorized modification may not only impair the compressor performance but may also result in accident or injury to repair personnel who do not have the required knowledge and technical expertise to perform the repair operations correctly.

To ensure efficient operation and longer life of the air compressor unit, a routine maintenance schedule should be prepared and followed. The following routine maintenance schedule is geared to a unit in a normal working environment operating on a daily basis. If necessary, the schedule should be modified to suit the conditions under which your compressor is used. The modifications will depend upon the hours of operation and extremely dirty and/or hostile environment will require a greater frequency of all maintenance checks.

ROUTINE MAINTENANCE SCHEDULE

- Drain water from the air tank, any moisture separators or air filter regulators.

- Check for any unusual noise and/or vibration.

- Check the pressure censor to make sure they are operating properly.

Risk of bursting.

Check the pressure censor. If the pressure censor or relief valve does not operate properly over pressurization of the air tank may result in rupture or explosion causing personal injury and property damage.

- Inspect air lines and fittings for leaks; correct as necessary. Each year of operation or if a problem is suspected:

- Check condition of air compressor pump intake and exhaust valves.

- Check condition of check valve. Replace if damaged or worn out.

- Keep all screws, bolts, and covers properly tightened.

Check their conditions periodically.

Keep All Screws, Bolts and Covers Properly Tightened. If screws, plates or covers become loose personal injury or property damage may occur.

- TROUBLE SHOOTING

Arrange for Make sure causes and repair for the solution of malfunction by MAKITA authorized dealer.

Wrong way to transport and lift will lead machine damaged.

| PROBLEM | CAUSE | CORRECTION |

| Will not start | Fuse blown or circuit breaker tripped Loose electrical connections; Extension cord not correct Overheated mot | Check for cause and replace or reset. Check wiring connections. See the section of "Extension cords" and make sure the extension cord is in good condition. Turn the switch ON after the motor is cooled down. |

| Mode LED blue and red lighting on and off at the same time, and will not start. It is not unusual that mode LED blue and red lighting on and off when turn on the switch immediately. | Motor driver perceives an unusual problems of motor, motor driver and main part of compressor or pressure censor. (over heat, overload) | Replace motor, motor driver and overloaded part of the compressor or pressure censor. |

| Low pressure | Air leak in relief valve Restricted air filter Defective check valve Air leak in joints and pipes Defacement in rings | Replace relief valve. Clean or replace air filter. Replace check valve. Tighten joints and pipes. Replace rings. |

| Relief valve releasing | Defective pressure censor or improper adjustment | Check for proper adjustment and if problem persists, replace pressure switch. |

Daily maintenance

- Before each use

- Be sure all nuts and bolts are tight.

- Check for unusual noise or vibration.

- After each use

Exhaust all the air in the air storage tank. Open the drain cock at the bottom of the air storage tank to drain condensation from tank. - Weekly maintenance

Check the air switch the designed rated pressure is 3.5 MPa. - Monthly maintenance

- Check that all nuts and bolts stay tight.

- Clean surface of air compressor.

Documents / ResourcesDownload manual

Here you can download full pdf version of manual, it may contain additional safety instructions, warranty information, FCC rules, etc.

Advertisement

Need help?

Do you have a question about the AC320H and is the answer not in the manual?

Questions and answers