Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for Symphonic CSC313E

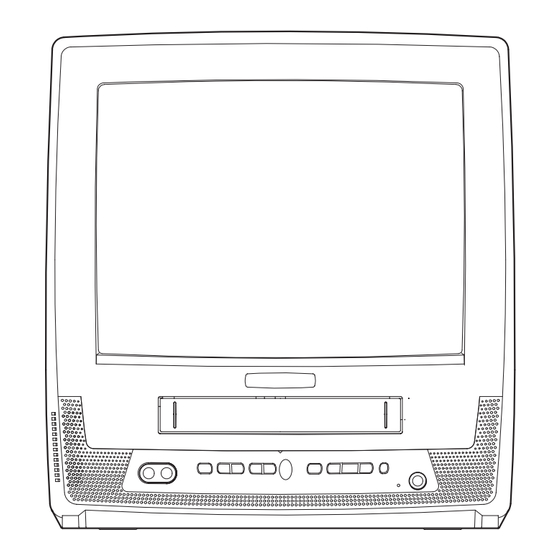

- Page 1 When servicing the deck I Specifications mechanism, refer to MK14 Deck I Preparation for Servicing Mechanism Section. I Adjustment Procedures I Schematic Diagrams Deck Mechanism Part No.: I CBA’s I Exploded Views N2426FT I Parts List 13″ COLOR TV/VCR COMBINATION CSC313E...

- Page 2 IMPORTANT SAFETY NOTICE Proper service and repair is important to the safe, reliable operation of all Funai Equipment. The service procedures recommended by Funai and described in this service manual are effective methods of performing service operations. Some of these service special tools should be used when and as recommended.

-

Page 3: Table Of Contents

MAIN SECTION 13″ COLOR TV/VCR COMBINATION CSC313E Main Section I Specifications I Preparation for Servicing I Adjustment Procedures I Schematic Diagrams I CBA’s I Exploded Views I Parts List TABLE OF CONTENTS Specifications ................1-1-1 Important Safety Precautions . -

Page 4: Specifications

SPECIFICATIONS *ˆ Mode---------SP mode unless otherwise specified * Test input terminal <Except Tuner>--------Video input (1 Vp-p) Audio input (-10 dB) <Tuner>------------------Ant. input (80 dBµV) Video: 87.5% Audio: 25 kHz dev. (1 kHz Sin) < DEFLECTION > Description Condition Unit Nominal Limit 1. - Page 5 < AUDIO> All items are measured across 8 Ω resistor at speaker output terminal. Description Condition Unit Nominal Limit 1. Audio Output Power (Max.) (R/P) 2. Audio S/N (W/LPF) (R/P) 3. Audio distortion (W/LPF) (R/P) 200 Hz (R/P) -2.0 -2.0±5.0 4.

-

Page 6: Important Safety Precautions

IMPORTANT SAFETY PRECAUTIONS Prior to shipment from the factory, our products are strictly inspected for recognized product safety and electrical codes of the countries in which they are to be sold. However, in order to maintain such compliance, it is equally important to implement the following precautions when a set is being serviced. - Page 7 Also, because the picture tube shields and power cord and maybe safety-serviced without mounting hardware perform an X-radiation an isolation transformer only if the AC power protection function, they must be correctly in plug is inserted so that the chassis is place.

- Page 8 recognized product safety and electrical codes of 2) Strip about 15 mm of the insulation from the the countries in which they are to be sold. ends of the wires. If the wires are stranded, However, in order to maintain such compliance, it twist the strands to avoid frayed conductors.

- Page 9 Safety Check after Servicing Examine the area surrounding the repaired location for damage or deterioration. Observe that screws, parts and wires have been returned to original positions. Afterwards, perform the following tests and confirm the specified values in order to verify compliance with safety standards. 1.

-

Page 10: Standard Notes For Servicing

STANDARD NOTES FOR SERVICING Circuit Board Indications How to Read the Values of the Rectangular Type Chip 1. The output pin of the 3 pin Regulator ICs is indicated as shown. Components Example: Top View Bottom View Input (a) Resistor 2. - Page 11 Replacement Procedures for 3. Installing the leadless component Leadless (Chip) Components a. Presolder the contact points of the circuit board. b. Press the part downward with tweezers and solder The Following Procedures are both electrodes as shown below. Recommended for the Replacement of the Note: Do not glue the replacement leadless Leadless Components Used in this Unit.

- Page 12 How to Remove / Install Flat Pack-IC pin or the solder lands under the IC when removing it. 1. Removal With Hot-Air Flat Pack-IC Desoldering Machine: Hot-air Flat Pack-IC 1. Prepare the hot-air flat pack-IC desoldering Desoldering machine, then apply hot air to the Flat Pack-IC Machine (about 5 to 6 seconds).

- Page 13 2. Installation 4. Release the flat pack-IC from the CBA using tweezers. (Fig. S-1-6) 1. Using desoldering braid, remove the solder from the foil of each pin of the flat pack-IC on the CBA With Iron Wire: so you can install a replacement flat pack-IC more 1.

- Page 14 Instructions for Handling Semi- conductors Electrostatic breakdown of the semi-conductors may occur due to a potential difference caused by electrostatic charge during unpacking or repair work. 1. Ground for Human Body Be sure to wear a grounding band (1 MΩ) that is properly grounded to remove any static electricity that may be charged on the body.

-

Page 15: Preparation For Servicing

PREPARATION FOR SERVICING How to Enter the Service Mode Adjustment Mode Caution 1: Head switching position adjustment: See adjustment instructions page 1-6-6. 1. Optical sensors system are used for Tape Start and End Sensor on this equipment. Read this No need to use. page carefully and prepare as described on this Purity check mode: Shows Red, Green, page before starting to service;... -

Page 16: Cabinet Disassembly Instructions

CABINET DISASSEMBLY INSTRUCTIONS 1. Disassembly Flowchart (2) Parts to be removed or installed. (3) Fig. No. showing procedure of part location This flowchart indicates the disassembly steps for the (4) Identification of parts to be removed, unhooked, cabinet parts and the CBA in order to gain access to unlocked, released, unplugged, unclamped, or item(s) to be serviced. - Page 17 (S-1) [1] Rear Cabinet (S-2) Fig. D1 (S-1) (S-1) (S-1) (S-2) (S-1) (S-1) [1] Rear Cabinet Fig. D2 1-5-2 T5516DC...

- Page 18 [2] Tray Chassis (S-3) (S-3) [3] Deck Unit (S-3) (S-6) [4] Main CBA (S-6) (S-6) (S-6) (S-5) (S-4) (S-7) Fig. D3 1-5-3 T5516DC...

- Page 19 Anode Cap. (S-8) CRT CBA (S-8) (S-8) (S-8) [5] CRT Fig. D4 1-5-4 T5516DC...

- Page 20 ANODE CL502A CN505 CL501A CRT CBA FOCUS SCREEN TO SPEAKER MAIN CBA CL403 TO DEGAUSS COIL CN801 CN601 AC CORD CL502B CL401 CL402 CN571 CL201 CL501B CYLINDER CAPSTAN ASSEMBLY MOTOR ACE HEAD FE HEAD DECK UNIT ASSEMBLY Fig. D5 1-5-5 T5516DC...

-

Page 21: Electrical Adjustment Instructions

ELECTRICAL ADJUSTMENT INSTRUCTIONS General Note: “CBA” is abbreviation for Note: The remote control with the unit cannot be used as service remote control unit. “Circuit Board Assembly.” Note: Electrical adjustments are required after How to Enter the Service mode: replacing circuit components and certain mechanical parts. - Page 22 3. H Adjustment 4. C-Trap Adjustment Purpose: To get correct horizontal position and size of Purpose: To get minimum leakage of the color signal screen image. carrier. Symptom of Misadjustment: Horizontal position and Symptom of Misadjustment: If C-Trap Adjustment is size of screen image may not be properly displayed.

- Page 23 5. Setting for Y DL Time TV, Y DL Time EXT, Y SW LPF, Black C-TRAP Adjustment (Factory mode) Stretch Off, Black Stretch CONT and C. Angle Data Values button button C-TRP 0 C-TRP 1 Purpose: To get minimum leakage of the color signal carrier.

- Page 24 6. V. Size Adjustment 8. H. Shift Adjustment Purpose: To obtain correct vertical height of screen Purpose: To obtain correct horizontal position and image. size of screen image. Symptom of Misadjustment: If V. Size is incorrect, Symptom of Misadjustment: Horizontal position and vertical height of image on the screen may not be size of screen image may not be properly displayed.

- Page 25 10. Sub-Brightness Adjustment 1. Degauss the CRT and allow CRT to operate for 20 minutes before starting the alignment. Purpose: To get proper brightness. 2. Set the screen control to minimum position. Input the Black raster signal from RF input. Symptom of Misadjustment: If Sub-Brightness is incorrect, proper brightness cannot be obtained by 3.

- Page 26 11. Focus Adjustment The following 2 adjustments normally are not attempted in the field. They should be done only Purpose: Set the optimum Focus. when replacing the CRT then adjust as a preparation. Symptom of Misadjustment: If Focus Adjustment is incorrect, blurred images are shown on the display.

- Page 27 15. Convergence Adjustment 4. Fix the C.P. Magnets by tightening the Ring Lock. 5. Remove the DY Wedges and slightly tilt the Purpose: To obtain proper convergence of red, green Deflection Yoke horizontally and vertically to and blue beams. obtain the best overall convergence. Symptom of Misadjustment: If Convergence 6.

-

Page 28: How To Initialize The Tv/Vcr Combination

HOW TO INITIALIZE THE TV/VCR COMBINATION To put the program back at the factory-default, initialize the TV/VCR Combination as the following procedure. 1. Use the service remote control unit. 2. Turn the power on. (Use main power on the TV unit.) 3. -

Page 29: Mechanical Trouble Indicator

MECHANICAL TROUBLE INDICATOR 1. Each Malfunction Indication POWER SAFETY POWER SAFETY 2 If the MONITOR is turned ON right after the Mechanical Malfunction occurs or POWER SAFETY is If P-SAFETY 2 port becomes continuously 2.5 V or turned ON, display the following character to show less for 120 msec. - Page 30 Mechanical Malfunction determination insertion start, the unit starts the CASSETTE OUT operation. 1. REEL Malfunction detection After switch over to CASSETTE OUT operation Countermeasure for REEL and CAPSTAN motor and then a laps of 5 sec. or more from the rotation malfunction (Except CASSETTE CASSETTE OUT operation start, if LD-SW LOADING function)

-

Page 31: Power Supply Troubleshooting Guide

POWER SUPPLY TROUBLESHOOTING GUIDE It is highly recommended that a variable isolation Repair method #1 transformer which can monitor current be used. (Power must be off) (Alternatively a variable AC source which monitors current will do). Read directions below before Short circuit in the secondary side. -

Page 32: Block Diagrams

BLOCK DIAGRAMS Servo/System Control Block Diagram 1-10-1 T5516BLS... - Page 33 Video Block Diagram 1-10-2 T5516BLV...

- Page 34 Audio Block Diagram 1-10-3 T5516BLA...

- Page 35 Chroma/Tuner Block Diagram 1-10-4 T5516BLC...

- Page 36 CRT/H.V. Block Diagram 1-10-5 T5516BLCRT...

- Page 37 Power Supply Block Diagram 1-10-6 T5516BLP...

-

Page 38: Schematic Diagrams / Cba's And Test Points

SCHEMATIC DIAGRAMS / CBA’S AND TEST POINTS Standard Notes WARNING Many electrical and mechanical parts in this chassis have special characteristics. These characteristics often pass unnoticed and the protection afforded by them cannot necessarily be obtained by using replacement components rated for higher voltage, wattage, etc. - Page 39 LIST OF CAUTION, NOTES, AND SYMBOLS USED IN THE SCHEMATIC DIAGRAMS ON THE FOLLOWING PAGES: 1. CAUTION: FOR CONTINUED PROTECTION AGAINST RISK OF FIRE, REPLACE ONLY WITH SAME TYPE_A,_V FUSE. ATTENTION: UTILISER UN FUSIBLE DE RECHANGE DE MÊME TYPE DE_A,_V. 2.

- Page 40 Main 1/5 & Sensor Schematic Diagram MAIN 1/5 Ref No. Position IC201 IC202 TRANSISTORS Q205 Q206 CONNECTOR CL201 TEST POINTS TP201 TP202 T5516SCM1 1-11-3...

- Page 41 Main 2/5 Schematic Diagram MAIN 2/5 Ref No. Position IC401 IC801 TRANSISTORS Q401 Q402 Q871 Q872 Q873 Q874 Q875 CONNECTORS CL401 CL402 CL403 CN801 TEST POINTS TP301 TP401 TP402 T5516SCM2 1-11-4...

- Page 42 Main 3/5 Schematic Diagram MAIN 3/5 Ref No. Position IC001 IC301 TRANSISTOR Q301 TEST POINT TP302 T5516SCM3 1-11-5...

- Page 43 VOLTAGE CHART (Power off mode) Main 4/5 Schematic Diagram Ref. No. IC601 11.0 10.0 16.0 MAIN 4/5 Ref. No. CAUTION ! Ref No. Position Ref No. Position IC602 Fixed voltage (or Auto voltage selectable) power supply circuit is used in this unit. NOTE: TRANSISTORS Ref.

- Page 44 Main 5/5 & CRT Schematic Diagram MAIN 5/5 Ref No. Position Ref No. Position TRANSISTORS IC551 CC-2 Q511 TRANSISTORS CC-2 Q521 AA-2 Q571 CC-2 Q531 Q572 CONNECTORS Q591 BB-3 CL501A CONNECTORS CL502A BB-2 CL501B BB-3 CN505 DD-2 BB-2 CL502B CN571 T5516SCM5 1-11-7...

- Page 45 CAUTION ! Main CBA Top View Sensor CBA Top View Fixed voltage (or Auto voltage selectable) power supply circuit is used in this unit. If Main Fuse (F601) is blown , check to see that all components in the power supply CAUTION ! : For continued protection against risk of fire, circuit are not defective before you connect the AC plug to the AC power supply.

- Page 46 Main CBA Bottom View Because a hot chassis ground is present in the power CAUTION ! supply circuit, an isolation transformer must be used. Fixed voltage (or Auto voltage selectable) power supply circuit is used in this unit. CAUTION ! : For continued protection against risk of fire, Also, in order to have the ability to increase the input If Main Fuse (F601) is blown , check to see that all components in the power supply...

- Page 47 CRT CBA Top View CRT CBA Bottom View CRT CBA Ref No. Position TRANSISTORS Q511 Q521 Q531 CONNECTORS CL501A CL502A CN505 WF15 WF14 WF16 Q521 Q511 Q531 Collector Collector Collector 1-11-10 BT5500F01015...

-

Page 48: Waveforms

WAVEFORMS Z13WF 1-12-1... -

Page 49: Wiring Diagram

WIRING DIAGRAM T5516WI 1-13-1... -

Page 50: System Control Timing Charts

SYSTEM CONTROL TIMING CHARTS Chart 1 EJECT ST-S "OFF" CASS.LOAD LD-FWD 0.2S LD-REV SFT-SW STOP(B) POWER LD-FWD 0.4S LD-FWD 0.2S LD-REV 0.2S LD-FWD 0.5S LD-REV STOP(A) PLAY LD-FWD PLAY LD-FWD RS1(RS2) LD-REV 0.2S LD-FWD FS1(FS2) PLAY PLAY PAUSE STILL PAUSE NOISE CANCEL PAUSE... - Page 51 Chart 2 STOP(A) STOP LD-REV 0.2S LD-FWD 0.2S STOP /EJECT 1.0S LD-FWD 0.5S LD-REV STOP(A) LD-REV 0.2S LD-FWD 0.2S STOP /EJECT LD-REV 1.0S LD-FWD 0.5S LD-REV STOP(A) LD-FWD PAUSE LD-FWD 2.5S Short REV LD-REV 0.2S LD-FWD REC PAUSE REC or PAUSE STOP /EJECT...

-

Page 52: Ic Pin Function Descriptions

IC PIN FUNCTION DESCRIPTIONS IC201 (TV/VCR Micro Controller IC) Signal Function Name “H” ≥ 4.5 V, “L” ≤ 1.0 V System Reset Signal (Reset IN RESET = “L”) Signal Function Name IN XC-IN Sub Clock 32 kHz IN LD-SW Loading Switch Input 36 OUT XC-OUT Sub Clock 32 kHz Not Used... - Page 53 Signal Function Name E2PROM/CHROMA IC Tuner 71 OUT SCL Communication Clock E2PROM/CHROMA IC Tuner Communication Data Not Used IN C-SYNC C-Sync Input Not Used Capstan Motor Control 76 OUT C-CONT Signal 77 OUT D-CONT Drum Motor Control Signal Not Used Not Used Take Up Reel Rotation IN T-REEL...

-

Page 54: Lead Identifications

LEAD IDENTIFICATIONS TT2138LS-YB11 2SK3563 MID-32A22F B C E S D G 2SC2120-O(TE2 F T) 2SA1175(F) LA78040A 2SC3331(T) 2SA950(O) KRA103M-AT/P 2SC1627Y-TPE2 2SC2482 TPE6 2SC2785(F) E C B E C B LTV-817B-F 1: A M37762M8A-8D4GP U 2: K 3: E KIA7805API 4: C AN17811A 1: IN 2: GND... -

Page 55: Exploded Views

EXPLODED VIEWS Cabinet SHINWHA TAPE SGT-730 (BLACK) V501-2 SHINWHA TAPE SGT-730 Details for L551 V501-1 (WHITE) and surrounding parts L551 TB24 CLN551 CRT CBA L551 TB24 DG601 SCOTCH TAPE #880 W601 V501 TB26 SENSOR CBA SP801 CL802 TB10 TB21 TB11 A1-5 MAIN CBA A1-1... - Page 56 Packing TAPE 1-17-2 T5516PEX...

-

Page 57: Mechanical Parts List

FRONT CABINET T5303UD 0EM000603 V501-1 C.P .MAGNET JH225-FN-00 XM04000BV003 A1-2 CONTROL PLATE T5512UN 1EM320195 V501-2 WEDGE FT-00110W XV10000T4001 A1-3 BRAND PLATE T5501UB ~SYMPHONIC~ 0EM409083 CRT TYPE C A1-4 CASSETTE DOOR T5303UD 0EM406915 L551# DEFLECTION YOKE KDY3GCE83X LLBY00ZMS027 A1-5 SPRING DOOR(Z10) T5200UA 0EM406687... - Page 58 L551: Deflection V501: CRT Type No. V501: CRT Part No. Yoke Part No. A34KPU02XX TCRT190GS016 LLBY00ZSY002 A34JXV70X TCRT190THA02 LLBY00ZSY002 CRT Warning Label Location CRT Type No. CRT Warning Label 20050826 1-18-2 T5516CA...

-

Page 59: Electrical Parts List

ELECTRICAL PARTS LIST PRODUCT SAFETY NOTE: Products marked with a Ref. No. Description Part No. # have special characteristics important to safety. C214 ELECTROLYTIC CAP . 220µF/10V M H7 CE1AMAVSL221 Before replacing any of these components, read C216 CHIP CERAMIC CAP . F Z 0.01µF/50V CHD1JZB0F103 carefully the product safety notice in this service C217... - Page 60 Ref. No. Description Part No. Ref. No. Description Part No. C352 ELECTROLYTIC CAP . 220µF/10V M H7 CE1AMAVSL221 C617# CAP ALUMINUM ELECTOLYTIC 470µF/35V M CE1GMASDL471 C353 ELECTROLYTIC CAP . 47µF/25V M H7 CE1EMAVSL470 C618# CAP ALUMINUM ELECTOLYTIC 1000µF/16V M CE1CMZPDL102 C410 ELECTROLYTIC CAP .

- Page 61 Ref. No. Description Part No. Ref. No. Description Part No. D311 SWITCHING DIODE 1SS133(T-77) QDTZ001SS133 IC401 IC Y/C/A LA71205M-MPB-E QSZBA0RSY037 D312 SWITCHING DIODE 1SS133(T-77) QDTZ001SS133 IC551# VERTICAL OUTPUT IC LA78040A QSBBA0SSY003 D313 SWITCHING DIODE 1SS133(T-77) QDTZ001SS133 IC601# PHOTOCOUPLER LTV-817B-F NPEB0LTV817F D314 SWITCHING DIODE 1SS133(T-77) QDTZ001SS133...

- Page 62 Ref. No. Description Part No. Ref. No. Description Part No. CHIP RES. 1/10W F 22k Ω CHIP RES.(1608) 1/10W 0 Ω R202 RRXAFB5J2202 R283 RRXAZB5Z0000 CHIP RES. 1/10W F 470 Ω CHIP RES.(1608) 1/10W J 10k Ω R203 RRXAFB5J4700 R291 RRXAJB5Z0103 CHIP RES.

- Page 63 Ref. No. Description Part No. Ref. No. Description Part No. CARBON RES. 1/4W J 4.7 Ω R578# RCX4JATZ04R7 R660 PCB JUMPER D0.6-P5.0 JW5.0T CARBON RES. 1/4W J 47 Ω CARBON RES. 1/4W J 8.2 Ω R579# RCX4JATZ0470 R661# RCX4JATZ08R2 CARBON RES. 1/4W J 47 Ω CARBON RES.

- Page 64 Ref. No. Description Part No. Ref. No. Description Part No. CARBON RES. 1/4W J 56k Ω FH601# FUSE HOLDER MSF-015 XH01Z00LY001 R523 RCX4JATZ0563 CARBON RES. 1/4W J 560 Ω FH602# FUSE HOLDER MSF-015 XH01Z00LY001 R525 RCX4JATZ0561 CARBON RES. 1/4W J 1.5k Ω CARBON RES.

- Page 65 CSC313E T5516CS 2005-09-07...

Need help?

Do you have a question about the CSC313E and is the answer not in the manual?

Questions and answers