Summary of Contents for Fronius Ignis 150

- Page 1 Operating Instructions Ignis 150 Ignis 180 Operating Instructions 42,0426,0512,EN 001-13112023...

-

Page 3: Table Of Contents

Before commissioning Safety Intended use Setup regulations Generator-powered operation Controls, connections and mechanical components Safety Ignis 150 controls, connections and mechanical components Ignis 180 controls, connections and mechanical components Control panel MMA welding Preparation MMA welding SoftStart / HotStart function... - Page 4 Average shielding gas consumption during MIG/MAG welding Average shielding gas consumption during TIG welding Technical data Explanation of the term "duty cycle" Ignis 150 Ignis 180 Ignis 180 MV Overview with critical raw materials, year of production of the device...

-

Page 5: Safety Rules

Safety rules Explanation of DANGER! safety notices Indicates immediate danger. ▶ If not avoided, death or serious injury will result. WARNING! Indicates a potentially hazardous situation. ▶ If not avoided, death or serious injury may result. CAUTION! Indicates a situation where damage or injury could occur. ▶... -

Page 6: Proper Use

Proper use The device is to be used exclusively for its intended purpose. The device is intended solely for the welding processes specified on the rating plate. Any use above and beyond this purpose is deemed improper. The manufacturer shall not be held liable for any damage arising from such usage. Proper use includes: carefully reading and following all the instructions given in the operating in- structions... -

Page 7: Mains Connection

Before leaving the workplace, ensure that people or property cannot come to any harm in your absence. Mains connec- Devices with a higher rating may affect the energy quality of the mains due to tion their current consumption. This may affect a number device types in terms of: Connection restrictions Criteria with regard to the maximum permissible mains impedance Criteria with regard to the minimum short-circuit power requirement... -

Page 8: Noise Emission Values

Keep all persons, especially children, out of the working area while any devices are in operation or welding is in progress. If, however, there are people in the vi- cinity: Make them aware of all the dangers (risk of dazzling by the arc, injury from flying sparks, harmful welding fumes, noise, possible risks from mains cur- rent and welding current, etc.) Provide suitable protective equipment... -

Page 9: Danger From Flying Sparks

Flammable vapours (e.g. solvent fumes) should be kept away from the arc's radi- ation area. Close the shielding gas cylinder valve or main gas supply if no welding is taking place. Danger from fly- Flying sparks may cause fires or explosions. ing sparks Never weld close to flammable materials. -

Page 10: Meandering Welding Currents

Protection class I devices require a mains supply with ground conductor and a connector system with ground conductor contact for proper operation. Operation of the device on a mains supply without ground conductor and on a socket without ground conductor contact is only permitted if all national regula- tions for protective separation are observed. -

Page 11: Emc Measures

EMC device classification as per the rating plate or technical data. EMC measures In certain cases, even though a device complies with the standard limit values for emissions, it may affect the application area for which it was designed (e.g. when there is sensitive equipment at the same location, or if the site where the device is installed is close to either radio or television receivers). -

Page 12: Requirement For The Shielding Gas

During operation Ensure that all covers are closed and all side panels are fitted properly. Keep all covers and side panels closed. Welding wire emerging from the welding torch poses a high risk of injury (piercing of the hand, injuries to the face and eyes, etc.) Therefore, always keep the welding torch away from the body (devices with wirefeeder) and wear suitable protective goggles. -

Page 13: Danger From Shielding Gas Cylinders

Use filters if necessary. Danger from Shielding gas cylinders contain gas under pressure and can explode if damaged. shielding gas cyl- As the shielding gas cylinders are part of the welding equipment, they must be inders handled with the greatest of care. Protect shielding gas cylinders containing compressed gas from excessive heat, mechanical impact, slag, naked flames, sparks and arcs. -

Page 14: Safety Measures In Normal Operation

Before transporting the device, allow coolant to drain completely and detach the following components: Wirefeeder Wirespool Shielding gas cylinder After transporting the device, the device must be visually inspected for damage before commissioning. Any damage must be repaired by trained service techni- cians before commissioning the device. -

Page 15: Safety Inspection

(e.g. relevant product standards of the EN 60 974 series). Fronius International GmbH hereby declares that the device is compliant with Directive 2014/53/EU. The full text on the EU Declaration of Conformity can be found at the following address: http://www.fronius.com Devices marked with the CSA test mark satisfy the requirements of the relevant standards for Canada and the USA. -

Page 16: Data Protection

Data protection The user is responsible for the safekeeping of any changes made to the factory settings. The manufacturer accepts no liability for any deleted personal settings. Copyright Copyright of these operating instructions remains with the manufacturer. The text and illustrations are all technically correct at the time of printing. We reserve the right to make changes. -

Page 17: General

General Device concept The welding system has the following properties: Compact dimensions Robust plastic housing Extremely reliable even under harsh operating conditions Carrying strap for easy transport on construction sites, etc. Protected controls Current sockets with bayonet latch In conjunction with the digital resonance inverter, an electronic regulator adapts the welding system characteristic to suit the welding electrode during welding. -

Page 18: Application Areas

Do not use the functions described here until you have fully read and understood the following documents: These Operating Instructions All the Operating Instructions for the system components of the welding system, especially the safety rules Do not dispose of used devices with domestic waste. Dispose of them according to the safety rules. -

Page 19: Before Commissioning

Before commissioning Safety WARNING! Danger from incorrect operation and work that is not carried out properly. This can result in serious personal injury and damage to property. ▶ All the work and functions described in this document must only be carried out by technically trained and qualified personnel. -

Page 20: Generator-Powered Operation

Generator- The welding system is generator-compatible. powered opera- tion In order to dimension the required generator output, the maximum apparent power S of the welding system is required. 1max The maximum apparent power S of the welding system can be calculated as 1max follows: 1max... -

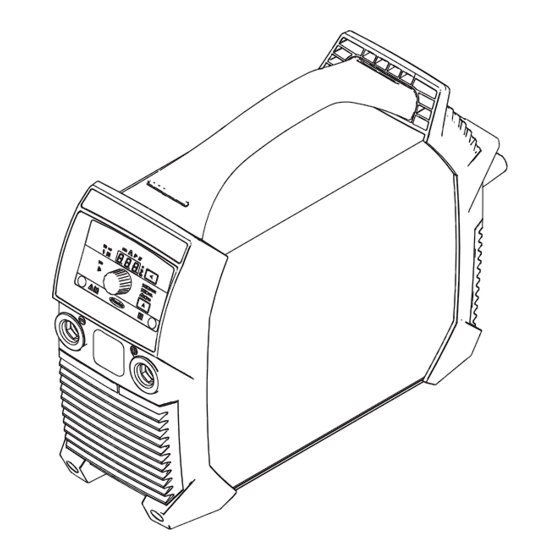

Page 21: Controls, Connections And Mechanical Components

Controls, connections and mechanical compon- ents Safety WARNING! Danger from incorrect operation and work that is not carried out properly. This can result in serious personal injury and damage to property. ▶ All the work and functions described in this document must only be carried out by technically trained and qualified personnel. -

Page 22: Ignis 150 Controls, Connections And Mechanical Components

(-) current socket with bayonet latch TIG Multi Connector Ignis 150 RC only - for connecting a remote control After connecting a remote control to the welding system ‘rc’ appears on the welding system display the welding current can only be adjusted using the remote control... -

Page 23: Ignis 180 Controls, Connections And Mechanical Components

Ignis 180 con- trols, connec- tions and mech- anical compon- ents Control panel (-) current socket with bayonet latch TIG Multi Connector Ignis 180 RC only - for connecting a remote control After connecting a remote control to the welding system ‘rc’... -

Page 24: Control Panel

Control panel STICK Setting value indicator shows which setting value is selected: Arc-force dynamic Welding current SoftStart / HotStart function Pulse welding (only available for manual metal arc welding) Unit indicator shows the unit of the value that is currently being changed with the adjusting dial (7): Time (seconds) Percent... - Page 25 Adjusting dial for continuous adjustment of the selected setting value (1) Status indicators display various operating modes of the welding system: lights up when the safety device for voltage reduction is activated (VRD devices only) Setup lights up in Setup mode Temperature lights up when the device is outside the permissible tem- perature range...

-

Page 26: Mma Welding

MMA welding Preparation CAUTION! Danger from electric shocks. As soon as the welding system is switched on, the electrode in the electrode holder is live. This can result in injury and damage to property. ▶ Ensure the electrode does not touch any persons or electrically conductive or earthed parts (the housing, etc.) -

Page 27: Mma Welding

MMA welding Use the welding process button to select one of the following processes: MMA welding - the MMA welding indicator lights up after selection MMA welding with Cel electrode - the MMA welding with Cel electrode indicator lights up after selection Press the setting value button until the welding current indicator lights up Adjust the welding current using the adjusting dial... -

Page 28: Arc-Force Dynamic

= 80 A starting current = SoftStart 135 % = 135 A starting current = HotStart 200 % = 160 A starting current on Ignis 150 = HotStart, maximum current limit is reached! 200 % = 200 A starting current on Ignis 180 = HotStart... -

Page 29: Pulse Welding

Arc-force dynamic = 60, set welding current = 100 A for the Ignis 150: actual increase is just 80 A as the maximum current limit is reached! for Ignis 180: arc-force dynamic with 120 A current increase Pulse welding Pulse welding is welding with a pulsing welding current. - Page 30 Adjustable parameters: F-P: Pulse frequency (1/F-P = time interval between two pulses) I-P: Pulse current SoftStart/HotStart Fixed parameters: I-G: Base current dcY: Duty cycle To use pulse welding: Press the setting value button until the pulse welding indicator lights up Turn the adjusting dial until the desired frequency value (Hz) is reached Welding system is ready for welding...

-

Page 31: Tig Welding

TIG welding General NOTE! Do not use pure tungsten electrodes (colour-coded green) if the TIG welding process has been selected. Connecting the WARNING! gas cylinder Danger from falling gas cylinders. This can result in serious injury and damage to property. ▶... - Page 32 CAUTION! Danger from electric shocks. As soon as the welding system is switched on, the electrode in the welding torch is live. This can result in injury and damage to property. ▶ Ensure the electrode does not touch any persons or electrically conductive or earthed parts (the housing, etc.)

-

Page 33: Setting The Gas Pressure On The Welding Torch With Gas Cut-Off Valve

Setting the gas Open the gas cut-off valve pressure on the shielding gas flows welding torch Set the desired gas flow rate on with gas cut-off the pressure regulator valve Close the gas cut-off valve Welding torch with gas cut-off valve TIG welding Select TIG welding with the welding process button the TIG welding indicator lights up... - Page 34 Welding During welding, raise the welding torch the arc length is increased significantly Lower the welding torch the arc length is decreased significantly the TIG Comfort Stop function is activated Keep the welding torch at the same height the welding current continually decreases (DownSlope) until the arc goes Wait for the gas post-flow time to finish and lift the welding torch away from the workpiece Max.

- Page 35 Gas post-flow: The gas post-flow must be carried out manually.

-

Page 36: Welding Process Setup Menu

Welding process Setup menu Accessing the Use the Welding Process button to select the process whose Setup menu Setup parameters are to be changed: MMA welding MMA welding with Cel electrode TIG welding Press the Setting Value and Welding Process buttons at the same time The code for the first parameter in the Setup menu is dis- played on the control panel... - Page 37 Para- meter Description Range Unit Anti-stick When the anti-stick function is active, the arc is extinguished after 1.5 seconds in the event of a short circuit (sticking of the electrode) Factory setting: ON (activated) Start ramp To activate/deactivate grinding mode Factory setting: ON (activated) Break voltage (Voltage cut off) 25 - 90 Volts...

-

Page 38: Parameters For Tig Welding

Parameters for Para- TIG welding meter Description Range Unit Comfort Stop Sensitivity Volts 0.6 - 3.5 Factory setting on Ignis: 1.5 volts Factory setting on Ignis 180: 1.5 volts Factory setting: 35 V (for 2-step mode, 4-step mode and pedal remote control) For details, see the TIG Comfort Stop section... -

Page 39: Setup Menu - Level 2

This prevents the auto- 20 / OFF matic circuit breaker from tripping imme- (TP 180 diately MV only) Ignis 150 - Ratio between set fuse and welding current: Mains voltage Welding cur- Duty cycle fuse rent elec-... - Page 40 OFF (TP 180 A 220 A 180 MV only) 120 V* 15 A 85 A 130 A 16 A 95 A 140 A 20 A (TP 120 A 170 A 180 MV only) OFF (TP 120 A 170 A 180 MV only) * Depending on the triggering characteristic of the automatic circuit breaker, the full duty cycle of 40% cannot be achieved on 120 V grids (e.g.

-

Page 41: Care, Maintenance And Disposal

Care, maintenance and disposal Safety WARNING! Danger from incorrect operation and work that is not carried out properly. This can result in serious personal injury and damage to property. ▶ All the work and functions described in this document must only be carried out by technically trained and qualified personnel. -

Page 42: Maintenance Every 2 Months

Maintenance Clean air filter: every 2 months Disposal Dispose of in accordance with the applicable national and local regulations. -

Page 43: Troubleshooting

Troubleshooting Safety WARNING! Danger from incorrect operation and work that is not carried out properly. This can result in serious personal injury and damage to property. ▶ All the work and functions described in this document must only be carried out by technically trained and qualified personnel. - Page 44 It is also possible that several error numbers are present. These appear when turning the adjusting dial. Make a note of the error numbers shown on the display, and of the serial number and configuration of the welding system, and contact our after-sales service team with a detailed description of the error.

-

Page 45: No Function

Cause: Mains voltage too high Remedy: Pull out the mains plug immediately; ensure that the welding system is being operated on the correct mains voltage E36, E41, E45 Cause: Mains voltage outside tolerance or maximum load of grid is too low Remedy: Ensure that the welding system is being operated on the correct mains voltage;... -

Page 46: Faulty Operation

No welding current Device switched on, indicator for the selected welding process is lit, overtemper- ature indicator lit Cause: Duty cycle exceeded - device overloaded - fan running Remedy: Keep within duty cycle Cause: Thermostatic automatic circuit breaker has switched off the device Remedy: Wait until the welding system comes back on automatically at the end of the cooling phase (do not switch off the device - the fan will... - Page 47 Poor weld properties (severe spattering) Cause: Incorrect electrode polarity Remedy: Reverse electrode polarity (refer to manufacturer's instructions) Cause: Poor grounding (earthing) connection Remedy: Fasten earthing clamps directly to workpiece Cause: Setup parameters not ideal for selected welding process Remedy: Select the optimal settings in the Setup menu for the selected weld- ing process Tungsten electrode melting Tungsten inclusions in base metal during the ignition phase...

-

Page 48: Average Consumption Values During Welding

Average consumption values during welding Average wire Average wire electrode consumption at a wire speed of 5 m/min electrode con- 1.0 mm wire 1.2 mm wire 1.6 mm wire sumption during electrode dia- electrode dia- electrode dia- MIG/MAG weld- meter meter meter Steel wire electrode... -

Page 49: Technical Data

Look in the technical data for a ED value of 100% for the current ambient temperature. Reduce the output or amperage in line with this value so that the device can remain in use without observing a cooling phase. Ignis 150 Mains voltage (U 1 x 230 V Max. effective primary current (I... -

Page 50: Ignis 180

Cos phi 0.99 32 mOhm Max. permitted mains impedance Z at PCC Recommended residual current circuit breaker Type B Welding current range (I ) rod electrode 10-150 A Welding current range (I ) TIG 10-150 A 35 % 60 % 100 % Welding current for MMA welding 10 min / 40 °C (104 °F) -

Page 51: Ignis 180 Mv

Mains voltage tolerance -20% / +15% Grid frequency 50/60 Hz Cos phi 0.99 285 mOhm Max. permitted mains impedance Z at PCC Recommended residual current circuit breaker Type B Welding current range (I ) rod electrode 10-180 A Welding current range (I ) TIG 10-220 A Welding current for MMA welding 10 min / 40 °C... - Page 52 Mains fuse 16 A slow- 20 A slow- 15 A slow- blow blow blow Mains voltage tolerance -20% /+15% Grid frequency 50/60 Hz Cos phi 0.99 Max. permitted mains impedance 285 mOhm at PCC Recommended residual current Type B circuit breaker Welding current range (I 10 - 180 A 10 - 120 A...

-

Page 53: Overview With Critical Raw Materials, Year Of Production Of The Device

An overview of which critical raw materials are contained in this device can be terials, year of found at the following Internet address. production of www.fronius.com/en/about-fronius/sustainability. the device To calculate the year of production of the device: Each device is provided with a serial number...

Need help?

Do you have a question about the Ignis 150 and is the answer not in the manual?

Questions and answers