Subscribe to Our Youtube Channel

Summary of Contents for Moffat Burlodge Novaflex II

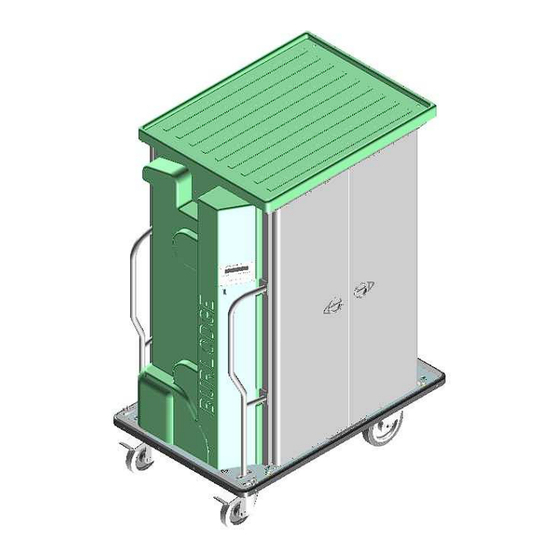

- Page 1 OPERATIONAL TECHNICAL MANUAL NOVAFLEX II Series Date of Issue 11/12/2013 R6 Page 1of 58...

-

Page 2: Table Of Contents

Table of Contents HEADING PAGE TABLE OF CONTENTS INTRODUCTION PRODUCT IDENTIFICATION TROLLEY IDENTIFICATION STANDARDS AND CERTIFICATION PACKAGING , HANDLING, FORWARDING AND TRANSPORT TROLLEY DESCRIPTION SAFE MODE CORRECT USE WORKING ENVIRONMENT TROLLEY DISPOSAL GENERAL SAFETY PRECAUTIONS WARNING SIGN AGAINST DANGER OF SCALDING CONNECTING TO THE POWER SUPPLY CONTROL PANEL FUNCTION MENU “F”... - Page 3 FLOW CHART DAILY CLEANING PROCEDURE CLEANING SCHEDULE POWER WASHING NOVAFLEX II CLEANING BY HAND NOVAFLEX II WASHING DETERGENT COMPATIBILITY DOLLYFLEX AND ISOFLEX POWER WASHING TRANSFLEX DIVIDERS TOWING ATTACHEMENT TOWING PROCEDURE FOR THE NOVAFLEX II TOWING PROCEDURE FOR THE DOLLYFLEX AND ISOFLEX TOWING SAFETY ERROR CODES FAULT FINDING...

-

Page 4: Introduction

Introduction In choosing the Burlodge Novaflex II trolley you have the most advanced, purpose designed unit of its kind available today. With careful use and regular maintenance your unit will give you many years of trouble free service. This manual is an integral part of the safety of your trolley and a guide for all operators and maintenance staff. It contains important information on the operation and maintenance of your Burlodge trolley. -

Page 5: Product Identification

Product Identification MANUFACTURER BURLODGE Srl ADDRESS Via CÁ BERTONCINA No 43 24068 Seriate (BG) Tel. 0039 035 4524900 Fax 0039 035 302994 TYPE OF DOCUMENT Operating and Maintenance Instructions TYPE Regeneration/Hot Line Single Tray Trolley MODEL Novaflex II SERIAL NUMBER YEAR OF MANUFACTURE Trolley Identification A data plate as shown below is attached above the cold right hand door and contains all the data necessary for... -

Page 6: Standards And Certification

Standards and Certification EC Directives and Standards Applied The Novaflex II has been designed to the following standard Low Voltage Directives • 2006/95/CE EMC Directives • 2004/108/CE Safety standards • EN60335-1:2002, EN 60335-1/A1:2004, EN 60335-1/A11:2004, EN 60335-1/A2:2006, • EN60335-1/A12:2006, EN 60335-1/A1/EC :2007, EN 60335-1/A13:2008, EN 60335-1/A14:2010 •... -

Page 7: Packaging , Handling, Forwarding And Transport

• CAN/CSA C22.2 No. 120 ISSUE : 1991/01/01 (R2008) ** Sanitation Standards • NSF/ANSI 592002e *** • NSF/ANSI 169-2009 *** • NSF/ANSI 4-2009 *** • NSF/ANSI 7-2009 *** Packaging , Handling, Forwarding and Transport When received, all shipments must be inspected for any damage to the pallets or packaging. Any damage found or any discrepancy in the number of items delivered must be noted on the carrier’s consignment note. -

Page 8: Trolley Description

With the use of a ramp, carefully wheel the trolley from the pallet paying particular attention to the refrigeration system underneath the trolley, (when applicable) At least 2 people may be required to unload the trolley from the pallet. Ensure that protective clothing and eyewear are worn and that the correct tools are used to carry out the above operation. -

Page 9: Safe Mode

Safe Mode It is essential to have the trolley in a safe condition before any cleaning or maintenance takes place. This is referred to in this manual as the SAFE MODE. The trolley is in the SAFE MODE under the following conditions: Fully isolated from any power source. - Page 10 If your trolley is fitted with the Battery Display System option remove the battery and dispose of it correctly, before dismantling the trolley. Do not dispose of it into a fire as it may explode, Do not short circuit and neither tamper or damage it. Date of Issue 11/12/2013 R6 Page 10of 58...

-

Page 11: General Safety Precautions

General Safety Precautions WARNING - The trolley must be properly connected to earth through the power supply cable. Always disconnect the trolley from the power supply before attempting to move it. Always hold the plug and not the cable when connecting and disconnecting the trolley. Always clean the optional food probe with a sterile alcohol wipe before and after every use, remove the probe and store it in a secure place. -

Page 12: Warning Sign Against Danger Of Scalding

Warning sign against danger of scalding Warning: To avoid scalding, do no not use loaded containers with liquids or cooking goods which becomes fluid by heating in higher levels than those which can be easily observed A label with the right marking ( as shown here at right side ) is added on ABS top at about height of 160 cm above the floor and over each trolley door Connecting to the Power Supply... -

Page 13: Control Panel

Control Panel Touch pads Controls And Displays The Novaflex II has the control panel shown in the following Figure Control Panel 1. Power On/Power Off touch pad. 2. Function pad *. 3. Display: it shows the two temperatures hot and cold side together 4. - Page 14 Display when trolley is in “Off” status Trolley connected to main supply but not operative Display outside an oven cycle: Left side indicates the oven chamber temperature Right side indicates the fridge chamber temperature Display during the oven cycle: Left side: indicates the remaining time up to the cycle end Center side: indicates the hot and cold temperatures Right side: indicates the oven cycle actually running (1,2 or 3).

-

Page 15: Function Menu "F

Function menu “F” *The Function Pad enables you to view different functions of the program. Press once: The temperature of the external food probe is displayed for two minutes after the last operation. If the probe is not connected they are three dashes in display 2 and the display will revert to normal mode after 2 seconds. -

Page 16: Programming

Programming Special Touch Pad Functions and Displays in Programming Mode. When in programming mode the touch pads on the control panel take on different functions compared to normal use. Cycle 1 touch pad reduces the set value of the parameter. Cycle 2 touch pad increases the set value of the parameter. -

Page 17: Programming The Oven Cycles And Automatic Starts ( Standard Procedure)

Programming the Oven Cycles and automatic starts ( standard procedure) Simultaneously firmly press cycle 1 and cycles 3 touch pads, and press the “ON” touch pad: the word “Program”, together with two icons appears on window. Release cycle 1 and 3 and immediately (within 2 seconds) press cycle 2 touch pad: the first program frame will appear. - Page 18 Frames 1 and 2 parameters are as per following table Frame 1 Frame 2 FUNCTIONS Symbol / Icon VALUES or position Default Individual Allowable on display Settings Settings range User must keep Function pad “F” pressed Together with Cycle 3 pad while in the 0 parameters Parameters appearing in Frame number 1 °C °F...

- Page 19 Group 3,4,5 ; Frames 3, 4 and 5 will look as shown below: FUNCTIONS Symbol / Icon VALUES or position Default Individual Allowable on display Settings Settings range °C °F Display Release Refrigeration pad Press Cycle 3 Each Time to Continue Parameters appearing in Frame number 3 ( “1”...

- Page 20 Groups 6, Frame 6 appears as shown below: Within the frame 6 is possible to program three automatic starts by day, intended as cycle number and time. The first row contains the numbers from 1 to 7, that correspond to the days of the week. The other 3 rows, divided in two columns, permit to select automatic start for breakfast, lunch and dinner.

-

Page 21: User's Recognition (Use Of Bcardwise Card)

The latest two frames permit to program the daylight savings jump dates and the actual time and date. Groups 8, Frame 8a &8b will look as shown below: When programming the daylight savings, keep note that the date to insert will correspond to the “Sunday” date; e.g., if the 1 hour shift is expected to happen during the night between 29 and 30 March, date to program is March 30. -

Page 22: Programming The Oven Cyles And Automatic Starts (Use Of Bcardwise Card)

To unlock the keypad inserts the BcardWise The display shows user name and code number The trolley will load an event “USER” recording the hour, minute and card number (in this example, 001). Now it is possible to use the keyboard N.B.: this event occurs only after each power ON and only after the first time the card is inserted. -

Page 23: Programming A New Machine And From A Reset

Programming a New Machine and From a Reset Appears the frame indicating “reset” Press key number “3” The frame “Serial no” will appear, the words “Serial No” will flash Press key number “3” to insert the first 2 digits of the serial number (move up and down with keys 1 and 2) In the same way insert the other 4 digits of the serial number Press 3 again to return to “Serial no”... -

Page 24: Detectable External Food Probe

Detectable external food probe The detachable external food probe is connected to the trolley by plugging it in to the external white probe socket, which is located on the front panel next to the touch pads. The probe is used to check the temperature of food products prior to and after regeneration. -

Page 25: Wastage

Do not place the probe or measure temperatures in side either the oven or cold chambers. Do not attempt to probe frozen products. Do not hold the switch down for more than two seconds. Do not over stretch the cable. Do use for any other purpose than food temperature testing. -

Page 26: Datalogger (Event Logger)

Datalogger (Event Logger) Datalogger allows all events to be recorded . Events can be shown on the display or can be transmitted or downloaded using the BCardWise+. Reading events on the trolley display Keep the cycle 1 touch pad depressed and press the “ON” touch pad. The word “Events”, together with a book icon, will appear on the display. -

Page 27: Downloading The Trolley Setup On The Bcardwise Card

Data has been correctly downloaded onto BCardWise+. Downloading the trolley setup on the BCardWise card This feature will allow the user to copy the setup from the trolley to the BCardWise card Keep the cycle 1 touch pad depressed and press the “ON” touch pad. The word “Events”, together with a book icon, will appear on the display. -

Page 28: Monitoring The Signal Communication (Bwise Option)

Press key “2” three times to access the fourth topic on the menu.. The current language will appear on the display. Press key “3”, the word will flash. Select a new language using keys “1” and “2”. Press key “3” to confirm the new language. Monitoring the signal communication (Bwise Option) This function allows the user to check if the trolley is reached by a data signal emitted by the computer where BWise is installed. -

Page 29: Special Features

Special features Boosting Cycle The Boosting cycle replaces the function of the normal cycle by overriding the set time with a 5-minute heating cycle at the set temperature of the selected cycle. If Cycle 1, Cycle 2 or Cycle 3 are selected after the normal cycle is finished, a five-minute boost cycle will commence. -

Page 30: Safety Parameters

Safety Parameters SECURITY 1: (SC1) The regeneration cycle will not start if the temperature of the cold section is above the set temperature (i.e. 10º C (50°F)) and “SC1” will be displayed on display instead of the hot side temperature. Selected time will be displayed on display. -

Page 31: Tray Layout

Tray Layout Keep the products that are to be kept cold and the products that are to be heated or boosted on separate sides of the tray allowing a space for the divider between the two sets of products. Tray supports Cold Product Products to be heated... -

Page 32: Transferring The Transflex Module With The Dolly

Load the tray with the items to be heated on the left-hand side, when loading from the front of Isoflex (the side which has the handles and swivel castors). Ensure the tray is fully home and the divider has dropped down into place, continue loading the trays progressively up. -

Page 33: Transferring To The Novaflex Ii The Isoflex

Caution never leave the handles in the down position at any time. To remove the Transflex module simply reverse the above instructions. However take care that at the end of the oven cycle the items in the oven section are hot. Once the Transflex has been transferred back to the Novaflex II ensure the handles of the Transflex have been pushed up and it is locked into position the unit is now ready for transport. -

Page 34: Connection To The Power Supply

Connection to the Power Supply Check that all the doors are tightly closed. Allow adequate space around the trolley so that it is safe and accessible and that the brakes have been applied. Ensure that the power supply is switched off. Ensure that the power cord is clear of any hazards and not being stressed. -

Page 35: Flow Chart

Flow Chart LOAD THE TRAYS CONNECT TO POWER PRESS ON PAD SELECT CYCLE STOP CYCLE DISCONNECT FROM POWER SERVE Date of Issue 11/12/2013 R6 Page 35of 58... -

Page 36: Daily Cleaning Procedure

Daily Cleaning Procedure Move the trolley to a safe area before cleaning. Ensure the trolley is in the SAFE MODE before commencing cleaning. If the Transflex is in the Novaflex II remove with the aid of the dolly following the instructions previously given in the Paragraph “Transferring the Module from the Novaflex II”. -

Page 37: Cleaning Schedule

Cleaning Schedule Cleaning Schedule After Every Meal Service COMPONENT NOTES Oven Compartment × × × Wipe dry after cleaning Chilled Compartment × × × Wipe dry after cleaning Interior Surfaces × × × Never use polish Silicon Gaskets × × ×... -

Page 38: Power Washing Novaflex

Power Washing Novaflex II Under no circumstances should the NovaFlex II be subject to any form of power washing The Novaflex II trolley was designed with an IPX4 waterproof degree. Cleaning by Hand Novaflex II Use two containers: one containing water plus detergent and one containing clean warm water with an added sanitizer (hard water should be avoided wherever possible), with separate soft lint free cloths. -

Page 39: Transflex Dividers

For manual cleaning please refer to instructions in Cleaning by Hand Transflex Dividers To remove the dividers for deep cleaning or replacement of the gasket: Remove the pin as shown in Figure 1. Pull the divider away from the centre bar. The divider can be cleaned either in a dishwasher or by hand. -

Page 40: Towing Procedure For The Dollyflex And Isoflex

Remove the safety pin. Press down the towing arm and release it from the towing pin, raise the arm to the upright position then lower the arm side ways to its storage position. Caution! The towing arm is spring loaded, so take additional care when carrying out this procedure. Apply the brakes before leaving the Novaflex II. -

Page 41: Towing Safety

Towing Safety DO ENSURE Extra care is taken in areas where there are patients and pedestrians. The floor is flat and even. All doors are closed. All unsecured items have been removed from the Novaflex II prior to transportation. The cable is stored in the correct position and cannot be snagged during transportation. That the towing arm is fully extended and located correctly. - Page 42 Oven set temperature has not been Program set incorrectly. achieved during the cycle. ACTION Refer to the PROGRAMMING section to reprogram the trolley to the correct Settings. Thermal Limit prevents the start of a Continuous use of a Regeneration cycle. Regeneration cycle ACTION Allow the oven section to cool down below 60°C / 140°F then restart cycle...

-

Page 43: Fault Finding

Fault Finding The two tables below are a guide for authorized technical personnel and should only be carried out by a competent electrician. Table one refers to checks that should be made before placing any service calls. TABLE ONE PROBLEM EXPLANATION POSSIBLE CAUSE No blue DISPLAY... -

Page 44: Regular Maintenance

Regular Maintenance The maintenance checks listed in the table below should be carried out as an interim service between the full six monthly service. It is also valid as quarterly checks in the first twelve months of use. At the end of this period a full service is required to the manufacturer’s specification. -

Page 45: Regular Maintenance Cont

Regular Maintenance Cont. Novaflex II Transflex and Dolly COMPONENT NOTES Towing Unit Pole End Check the spring to ensure it holds the pole at the correct tension so (Optional) that it does not drop down and it springs back instantly when pushed down. -

Page 46: Maintenance

Maintenance Safety Precautions And Preparing For Maintenance A maintenance program to maintain the trolley in optimal condition is clearly defined in four different categories. Daily cleaning (refer to Daily Cleaning Procedure and Cleaning By Hand sections) Periodic cleaning (refer to Daily Cleaning Procedure and Cleaning By Hand sections) User maintenance (refer to Interim Maintenance section) Maintenance schedule to manufacturer’s recommendations. -

Page 47: Regular Maintenance Transflex, Dollyflex And Isoflex

Regular Maintenance Transflex, Dollyflex and Isoflex Transflex Dollyflex and Isoflex COMPONENT NOTES Towing Unit Pole End Check the spring to ensure it holds the pole at the correct tension so (Optional) that it does not drop down and it springs back instantly when pushed down. -

Page 48: Evaporator Cleaning

Evaporator cleaning These operations shall be carried out according to the specific site HACCP procedures. Preparation: • Safety First! - Ensure the trolley is in the SAFE MODE before starting cleaning • Take the baffle off the side of the chamber removing the screws in corners and in the middle. Baffle Baffle Removed For safety reasons, trained staff only should clean the evaporators with the use of the proper cleaning materials... -

Page 49: Technical Assistance After Sales Service

Evaporator • Check the air distribution area and reassemble the baffle. • This procedure is valid for standard (bare aluminum) and hydrophilic (blue coated, see upper left picture) evaporators. DO NOT use aggressive products (ex.: acid) Technical Assistance After Sales Service Technical Assistance Burlodge offers a wide range of service contracts. -

Page 50: Warranty And Service Calls

Warranty and Service Calls Before you contact the Burlodge Service Department or Authorised Service Agent, please make sure that a competent electrician has carried out the following checks: check the power supply check the power cable, plug and internal fuses check for any visual damage Under no circumstances remove or interfere with any part of the Novaflex II even if it is disconnected from the power supply. -

Page 51: Spare Parts

Spare Parts Use only original Burlodge spare parts, they are an exact replacement. Use of other spare parts may compromise the safety and performance of the trolley. Burlodge, or its authorised service agents, must carry out any repairs during the period of warranty. Failure to comply with these requirements may invalidate the warranty and all certifications of the trolley. -

Page 52: Warranty

Warranty Standard Warranty The standard warranty is one-year parts and labor or as per contract. Commencing 14 months from the date of delivery or 12 months from the date of commissioning which ever expires first. All equipment except china, trays and consumable components is covered against faulty material or workmanship. In the unlikely event of any valid failures, Burlodge or its authorised agents will repair the trolley free of any charges. -

Page 53: Dimensions

Dimensions Novaflex II Novaf T 1620 Novaf.S.1380 1175 Dollyflex Novaflex Tray Pitch Description Pitch Novaflex s 16 tray Novaflex s 20 tray Novaflex s 24 tray Novaflex t 20 tray Novaflex t 26 tray Novaflex t 30 tray Isoflex HD Tall 1565 Short 1319 Date of Issue 11/12/2013... -

Page 54: Installation Europe

Installation Europe The plug and cord on the trolley will be of a type and rating that meet the required electrical voltage and current requirements of the trolley. The measured supply voltage must be within the range guaranteed by the local energy supplier and in any case not more than +/- 10% of the name plate rating. -

Page 55: Installation Canada / Usa

Installation CANADA / USA The plug and cord on the trolley will be of a type and rating that meet the required electrical voltage and current requirements of the trolley. The measured supply voltage must be within 10% of the name plate rating. Check the rating plate on each piece of equipment for further details. -

Page 56: Installation Japan

Installation JAPAN Plug Connections Novaflex II 200 V 50/60Hz 3P+N+E NOTE. If your trolley is supplied without a plug on the power supply cable or the plug must be replaced, ensure that the plug is an acceptable plug for the rated voltage and current and that respects the local safety standards. Check also with the trolley data plate. -

Page 57: Electrical Specification

Electrical Specification EUROPE Novaflex II 400v 50Hz 3P+N+E RÉF. FRIDGE Total Réfrig.only 400V 50Hz 3P+N+E AMPS AMPS BLN2S.320 BLN2S.710.00– single refrigeration BLN2S.320 BLN2S.720.00– double refrigeration BLN2T.320 BLN2S.110.00– single refrigeration BLN2T.320 BLN2S.120.00– double refrigeration Novaflex II 230v 50Hz 3P+E RÉF. FRIDGE Total Réfrig.only 230V 50Hz 3P+E... - Page 58 R2 : CAP 18 Aggiornata icona vers software CAP 20 Aggiornate indicazioni sonda esterna con selezione menu CAP 20 Inserite note per letture vassoi a,b,c,d CAP 21 Aggiornato datalogger CAP 22 Aggiornato scarico eventi su carta gialla CAP 25 Monitor di line opzione Bwise CAP 48 Errore carta non riconosciuta CAP 62 Aggiornati dati elettrici R3: 06/2008 WASTAGE ;...

Need help?

Do you have a question about the Burlodge Novaflex II and is the answer not in the manual?

Questions and answers