Advertisement

Quick Links

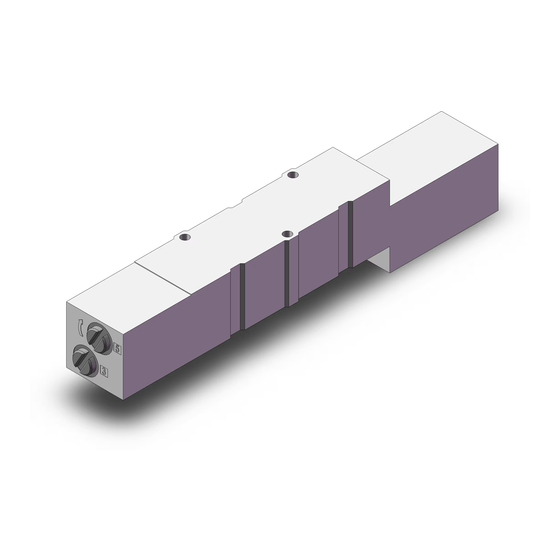

VQ1000V-TF2Z493EN

ORIGINAL INSTRUCTIONS

Instruction Manual

5 port solenoid valve

Series VQ(C)4000/5000

The intended use of this product is to control the movement on an

actuator.

1 Safety Instructions

These safety instructions are intended to prevent hazardous situations

and/or equipment damage. These instructions indicate the level of

potential hazard with the labels of "Caution," "Warning" or "Danger."

They are all important notes for safety and must be followed in addition

*1)

to International Standards (ISO/IEC)

, and other safety regulations.

*1)

ISO 4414: Pneumatic fluid power - General rules relating to systems.

ISO 4413: Hydraulic fluid power - General rules relating to systems.

IEC 60204-1: Safety of machinery - Electrical equipment of machines.

(Part 1: General requirements)

ISO 10218-1: Robots and robotic devices - Safety requirements for

industrial robots - Part 1: Robots.

• Refer to product catalogue, Operation Manual and Handling

Precautions for SMC Products for additional information.

• Keep this manual in a safe place for future reference.

Caution indicates a hazard with a low level of risk which, if

Caution

not avoided, could result in minor or moderate injury.

Warning indicates a hazard with a medium level of risk

Warning

which, if not avoided, could result in death or serious injury.

Danger indicates a hazard with a high level of risk which, if

Danger

not avoided, will result in death or serious injury.

Warning

• Always ensure compliance with relevant safety laws and

standards.

• All work must be carried out in a safe manner by a qualified person in

compliance with applicable national regulations.

Caution

• The product is provided for use in manufacturing industries only. Do

not use in residential premises.

2 Specifications

2.1 Valve specifications

Metal seal

Rubber seal

Valve Type

5 Port Solenoid Valve

Fluid

Air

Note 1)

Single

0.15 to 1 (0.1 to 1

)

Internal pilot operating

Double

0.15 to 1 (0.1 to 1

Note 1)

pressure range [MPa]

3 position

0.15 to 1

Operating pressure

External

-100 kPa to 1

range

pilot [MPa]

Pilot pressure range

Same as internal pilot operating pressure range

Minimum operating frequency

1 cycle / 30 days

2

20 Hz

VQ(C)4000

position

Maximum

single/

operating

10 Hz

VQ(C)5000

double

frequency

3

10 Hz

VQ(C)4000

position

5 Hz

VQ(C)5000

Duty cycle

Contact SMC

Response time

Refer to catalogue

Flow rate

Refer to catalogue

Ambient/fluid temperature

-10 to +50°C (-5 to +50°C for VQC5000)

2 Specifications - continued

Lubrication

Non-locking Push type, Locking type (Tool

Manual override

Impact/Vibration resistance

Mounting orientation

Enclosure (based on

IEC60529)

Table 1.

Note 1) For VQ(C)5000 metal seal

Note 2) Use dry air to prevent condensation at low temperatures.

Note 3) Impact resistance: No malfunction resulted from the impact test using a

drop impact tester. Test was performed one time each in the axial and right angle

directions of the main valve and armature for both energized and de-energized

states. (Values quoted are for a new valve)

Vibration resistance: No malfunction occurred in a one-sweep test between 45

and 2000 Hz. Test was performed in the axial and right angle directions of the main

valve and armature for both energized and de-energized states. (Values quoted are

for a new valve)

Note 4) Refer to 2.3 for applicable variations.

2.2 Solenoid specifications

Rated coil voltage [VDC]

Allowable voltage fluctuation

Coil insulation type

Power consumption

24 VDC

(Current) [W]

12 VDC

Surge voltage suppressor

Indicator light

Table 2.

Note 1) Valve state is not defined if electrical input is outside the specified operating

range.

2.3 Manifold specifications

2.3.1 VQ4000/5000

VQ400

Series

0

D-sub

IP40

Terminal block

IP65

1)

Electrical entry

box

and ingress

Individual

protection

terminal block kit

(Based on

Lead wire

IP65

IEC60529)

1)

cable

EX123, EX124

1)

IP65

)

Connector

IP65

1(P), 3(R1), 5(R2)

1/2

C6,

C8,

C10,

C12

Port

Side ported

1/4

2(A),4

size

3/8

(B)

N7,

N9,

N11

Bottom

1/4

ported

Table 3.

Note 1) When W type is chosen.

2.3.2 VQC4000/5000

0.2 to 1

Series

VQC4000 VQC5000

)

D-sub,

0.2 to 1

Flat ribbon

IP40

cable,

EX260

EX245

IP65

Electrical entry

EX126

and ingress

EX250

protection

EX260

(Based on

EX500

5 Hz

IEC60529)

EX600

IP67

Lead wire

Circular

connector

3 Hz

Terminal

block box

Note 2)

2 Specifications - continued

Not required

1(P),3(R)

required, Manual)

Note 3)

150/30 m/s²

Port

size

Refer to 3.2 and 7.4

2(A),4(B)

IP40 (IP65 and IP67 compatible)

Note 4)

2(A),4(B

2.4 Indicator light and override positions

In the double solenoid type, A side and B side energization are indicated

by two colours which match the colours of the manual overrides.

Manual override

(Green)

12, 24

(Note 1)

±10 % of rated voltage

Class B or equivalent

0.95 (standard), 0.4 (low wattage)

Figure 1. ON/OFF indicator and override buttons of VQ(C)5000.

0.95 (standard), 0.4 (low wattage)

Varistor

LED

2.5 Pneumatic symbols

Refer to catalogue and special drawings for 'Pneumatic symbols'.

2.6 Special products

Special products (-X) might have specifications different from those

shown in this section. Contact SMC for specific drawings.

3 Installation

3.1 Installation

VQ4000

VQ5000

VQ500

Maximum number of

0

stations (solenoids)

• Do not install the product unless the safety instructions have been read

18 (36)

12 (24)

and understood.

18 (36)

12 (24)

• When using double solenoid type for the first time, actuators may travel

IP40

12 (24)

in an unexpected direction depending on the switching position of the

16 (32)

12 (24)

valve. Implement countermeasures to avoid any danger that may

18 (36)

12 (24)

occur due to the actuator's operation.

16 (32)

3/4

3.2 Environment

3/8

• Do not use in an environment where corrosive gases, chemicals, salt

1/2

water or steam are present.

• Do not use in an explosive atmosphere.

• Do not expose to direct sunlight. Use a suitable protective cover.

1/2

• Do not install in a location subject to vibration or impact in excess of

the product's specifications.

• Do not mount in a location exposed to radiant heat that would result in

temperatures in excess of the product's specifications.

• Products with IP65 and IP67 enclosures (based on IEC60529) are

VQC4000 VQC5000

protected against dust and water; however, these products cannot be

Maximum number of

used in water.

stations (solenoids)

• Products compliant with IP65 and IP67 satisfy the specification through

mounting the product properly. Be sure to read the Specific Product

12 (24)

Precautions for each product

• When using built-in silencer type manifold with an IP67 enclosure,

8 (16)

keep the exhaust port of the silencer from coming in direct contact with

water or other liquids.

• If using in an atmosphere where there is possible contact with water

12 (24)

drop-lets, oil, weld spatter, etc., take suitable preventative measures.

• When the solenoid valve is mounted in a control panel or is energized

for a long time, make sure that the ambient temperature is within the

10 (20)

valve's specified range.

• The metal seal valve is provided with a hole to discharge the pilot EXH.

When using in atmospheres containing water and dust, mount

horizontally.

3 Installation - continued

• Do not use in high humidity environment where condensation can

D

P: 1/2

side:1/2

R: 3/4

U side:

• Contact SMC for altitude limitations.

3/4

C6, C8,

Side

C10, C12

3/8, 1/2

3.3 Piping

ported

1/4

3/8

Bottom

1/4

1/2

ported

• Before connecting piping make sure to clean up chips, cutting oil, dust

Table 4.

• When installing piping or fittings, ensure sealant material does not

• Tighten fittings to the specified tightening torque.

Double solenoid

3.4 Lubrication

Indicator light

Manual override

A: Orange

(Orange)

B: Green

• SMC products have been lubricated for life at manufacture, and do not

• If a lubricant is used in the system, refer to catalogue for details.

3.5 One-touch fittings

When fittings are used, they may interfere with one another depending

Warning

on their types and sizes. Therefore, the dimensions of the fittings to be

used should first be confirmed in their respective catalogues.

3.5.1 Tube attachment and detachment

Refer to the Specific Precautions of Fittings and Tubing in the catalogue.

3.5.2 Precautions on other tube brands

• When using non-SMC brand tubes, refer to the Specific Precautions of

Warning

3.6 Light/Surge voltage suppressor

The valve is fitted with varistor surge suppressors, see Figure 2 and 3.

Refer to 3.8 for Residual voltage value.

3.6.1 Single solenoid

Warning

3.6.2 Double solenoid

SOL

The surge suppressors fitted to the valve are intended to protect the

output device so that the surge generated inside the valve does not affect

the output device. External overvoltage or overcurrent might damage the

surge suppressor, the valve and the output device itself. Additional safety

measures should be taken to prevent the effect of overcurrent on the

valve and connected devices.

occur.

Caution

etc.

enter inside the port. When using seal tape, leave 1 thread exposed

on the end of the pipe/fitting.

Tightening Torque [N∙m]

Connection thread size (R, NPT)

M5

1 to 1.5

1/8

3 to 5

1/4

8 to 12

3/8

15 to 20

1/2

20 to 25

Table 5.

Caution

require lubrication in service.

Caution

Caution

Caution

Fittings and Tubing in the catalogue.

Caution

SOL

LED (orange)

COM: + (-)

Figure 2.

A-side: - (+)

B-side: - (+)

SOL

COM: + (-)

A-side LED (orange)

B-side LED (green)

Figure 3.

Caution

Page 1 of 3

Advertisement

Summary of Contents for SMC Networks VQ4000 Series

- Page 1 VQ1000V-TF2Z493EN 2 Specifications - continued 2 Specifications - continued 3 Installation - continued ORIGINAL INSTRUCTIONS • Do not use in high humidity environment where condensation can Lubrication Not required P: 1/2 side:1/2 Non-locking Push type, Locking type (Tool 1(P),3(R) occur. Manual override R: 3/4 U side:...

- Page 2 VQ1000V-TF2Z493EN 3 Installation - continued 3 Installation - continued 6 Maintenance - continued 6 Maintenance - continued 3.7 Mounting 3.13 Manual override 6.2 Replacement parts 6.2.3 Plug lead type Caution Warning 6.2.1 Installation/removal of light cover Caution • Regardless of an electric signal for the valve, the manual override is Caution Refer to catalogue for additional information.

- Page 3 VQ1000V-TF2Z493EN 7 Limitations of Use - continued Energy source Single Double 3 position status Spool returns to the Spool stops moving Air supply Spool returns to off off position by air after electricity cut present, position by spring force and spring (Position cannot be electricity cut force...

Need help?

Do you have a question about the VQ4000 Series and is the answer not in the manual?

Questions and answers