Table of Contents

Troubleshooting

Summary of Contents for Miller INTEGRA 350 Professional

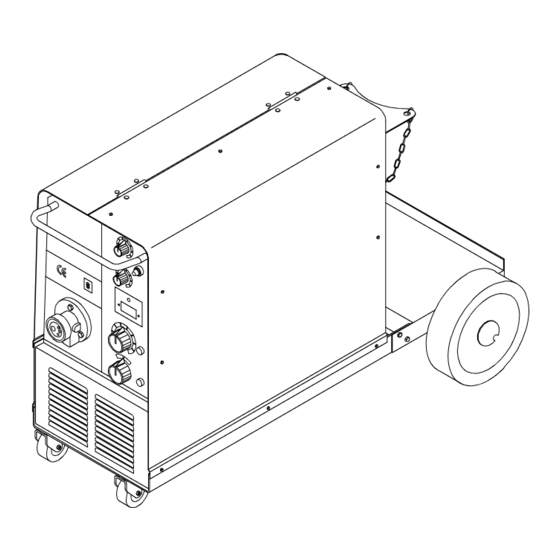

- Page 1 OM-196 808C December 2000 Effective with serial number : 178 505 Processes MIG (GMAW) Welding Flux Cored (FCAW) Welding Description Arc Welding Power Source and Wire Feeder INTEGRA 350 Professional Visit our website at www.MillerWelds.com...

- Page 2 1929, he made sure his products offered long-lasting value and superior quality. Like you, his customers couldn’t afford anything less. Miller products had to be more than the best they could be. They had to be the best you could buy.

-

Page 3: Table Of Contents

TABLE OF CONTENTS SECTION 1 – SAFETY PRECAUTIONS - READ BEFORE USING ..1-1. Symbol Usage ..........1-2. - Page 4 MILLER Europe S.P.A. Manufacturer’s Address: Via Privata Iseo, 6/E 20098 San Giuliano Milanese, Italy Declares that this product: INTEGRA 350 Professional Conforms to the following Directives and Standards: Directives Electromagnetic Compatibility Directives: 89/336/EEC Low Voltage: 73/23/EEC Machinery Directives: 89/392/EEC And their amendments 91/368/EEC, 93/31/EEC, 93/44/EEC, 93/68/EEC...

-

Page 5: Section 1 - Safety Precautions - Read Before Using

SECTION 1 – SAFETY PRECAUTIONS - READ BEFORE USING som _nd_4/98 1-1. Symbol Usage Means Warning! Watch Out! There are possible hazards with this procedure! The possible hazards are shown in the adjoining symbols. This group of symbols means Warning! Watch Out! possible Y Marks a special safety message. - Page 6 ARC RAYS can burn eyes and skin. BUILDUP OF GAS can injure or kill. D Shut off shielding gas supply when not in use. Arc rays from the welding process produce intense D Always ventilate confined spaces or use visible and invisible (ultraviolet and infrared) rays that can burn eyes and skin.

-

Page 7: Additional Symbols For Installation, Operation, And Maintenance

1-3. Additional Symbols For Installation, Operation, And Maintenance FIRE OR EXPLOSION hazard. MOVING PARTS can cause injury. D Do not install or place unit on, over, or near D Keep away from moving parts such as fans. combustible surfaces. D Keep all doors, panels, covers, and guards D Do not install unit near flammables. -

Page 8: Emf Information

1-5. EMF Information Considerations About Welding And The Effects Of Low Frequency 1. Keep cables close together by twisting or taping them. Electric And Magnetic Fields 2. Arrange cables to one side and away from the operator. Welding current, as it flows through welding cables, will cause electro- magnetic fields. -

Page 9: Section 2 - Installation

SECTION 2 – INSTALLATION 2-1. Specifications Rated Input Amperage at Rated Output Rated Output Max. Open 100% Circuit Voltage 230 V 400 V Model Dimension (mm) Weight (kg) 210 A 270 A 300 A 32 A 19 A 332 x 650 x 705 24.5 V 27.5 V 29 V... -

Page 10: Volt-Ampere Curves

2-3. Volt-Ampere Curves The volt-ampere curves show the normal minimum and maximum voltage and amperage output capa- bilities of the welding power source. Curves of other settings fall be- tween the curves shown. 2-4. Installing Gas Supply Chain gas cylinder to running gear, wall, or other stationary support so cylinder cannot fall and break off valve. -

Page 11: Installing Drive Roll And Wire Inlet Guide

2-5. Installing Drive Roll and Wire Inlet Guide Securing Screws Inlet Wire Guide Loosen screws. Slide tip as close to drive rolls as possible without touch- ing. Tighten screws. Wire Tension Wheel Drive Roll Install correct drive rolls for wire size and type. -

Page 12: Selecting A Location And Connecting Input Power

2-9. Selecting a Location and Connecting Input Power Have only qualified persons make this installation. Rating Label Supply correct input power. 18 in (457 mm) for airflow GND/PE GND/PE Connect First ST-801 721 2-10. Installing Work Clamp Wire Feeder Connection Work Connect Negative Power Source Terminal... -

Page 13: Section 3 - Operation

SECTION 3 – OPERATION 3-1. Controls Handle Wire Speed Control Fuse Spot Timer Digital Ammeter/Voltmeter High Temperature Shutdown Light Voltage Control Switch Pilot Light Power Switch and Selector Range 10 Torch Connector OM-196 808 Page 9... -

Page 14: Section 4 - Maintenance And Troubleshooting

SECTION 4 – MAINTENANCE AND TROUBLESHOOTING 4-1. Routine Maintenance Y Disconnect power before maintaining. 3 Months Repair or replace Replace unreadable labels. cracked weld cable. Clean and tighten weld terminals. 6 Months Blow out or vacuum inside. During heavy service clean monthly. 4-2. -

Page 15: Troubleshooting

4-4. Troubleshooting Trouble Remedy No weld output; wire does not feed. Be sure line disconnect switch is On (see Section 2-9). Replace building line fuse or reset circuit breaker if open (see Section 2-9). Reset circuit breaker CB1. Secure gun trigger connections. Check and replace Power switch if necessary. -

Page 16: Section 5 - Electrical Diagram

SECTION 5 – ELECTRICAL DIAGRAM cod.956.142.388 Figure 5-1. Circuit Diagram OM-196 808 Page 12... -

Page 17: Section 6 - Parts List

SECTION 6 – PARTS LIST Sheet Metal Parts Item Ref. Code Qty. Item Ref. Code Qty. 000151187 PV.0.0.18 156012104 ZC.0.0.12 116122307 ZC.0.0.6 156034001 BP.2.0.19 656043027 057014063 UV.0.7 156023154 056054068 ZC.0.0.11 056054067 ZW.0.0.3 116121116 ZC.0.0.7 116005165 DZ.0.0.25 156002018 QF.0.0.13 150005001 116122308 ZC.0.0.8 156011002 116005319... - Page 18 Main Assembly Qty. Item Ref. Code Item Ref. Code Qty. 156018033 056061042 UV.0.0.7 156009079 056126069 ZC.0.0.2 156032064 GF.1.04 056067188 UV.0.0.9 156009075 GF.1.0.2 000046432 OL.0.0.14 000010191 FU.1.0.6 056092039 EZ.4.0.5 000058628 FU.1.0.7 M 42V 057010046 ZC.0.3 656102001 BH.0.0.8 057062006 ZC.4.2 116009041 CV.0.0.2 056018002 ZC.4.0.3 000058628...

- Page 19 Effective January 1, 2000 This limited warranty supersedes all previous Miller warranties and is exclusive with no other guarantees or warranties expressed or implied. LIMITED WARRANTY – Subject to the terms and conditions APT, ZIPCUT & PLAZCUT Model Plasma Cutting below, Miller Electric Mfg.

- Page 20 Phone: 414-735-4505 USA & Canada FAX: 920-735-4134 International FAX: 920-735-4125 European Headquarters – United Kingdom Phone: 44 (0) 1204-593493 FAX: 44 (0) 1204-598066 Miller Europe Italy Phone: 39 (0) 2982901 PRINTED IN USA 2000 Miller Electric Mfg. Co. 1/00...

Need help?

Do you have a question about the INTEGRA 350 Professional and is the answer not in the manual?

Questions and answers