Summary of Contents for Sipromac 350

- Page 1 VACUUM PACKAGING MACHINE MODELS 350 & 350D OWNERS MANUAL (MANUEL D’UTILISATION) (MANUAL DE UTILIZACIÓN)

- Page 3 IMPORTANT SAFETY INSTRUCTIONS SAVE THESE INSTRUCTIONS This symbol points out important safety instructions which, if not followed, could endanger the personal safety and/or property of yourself and others. Read and follow all instructions in this manual before attempting to operate your machine. Failure to comply with these instructions may result in personal injury.

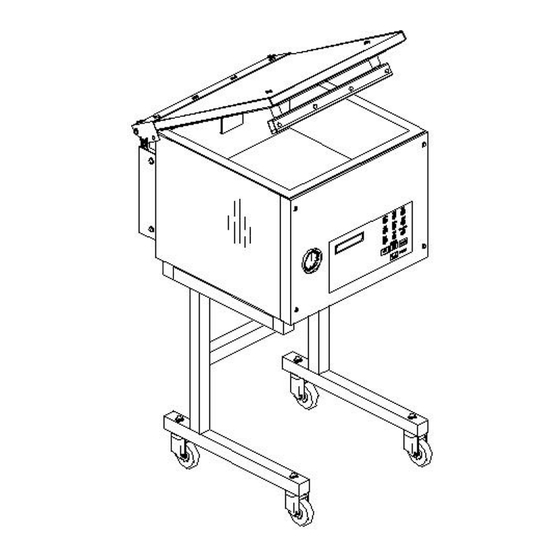

- Page 4 Save these instructions for future reference. INSTALLATION NOTICE FOR MODELS: 350, 350D IN ORDER TO RESPECT NSF REGULATIONS: The table, on which the machine has to be installed, should be of open frame type, to...

-

Page 5: Table Of Contents

Contents SETTING UP THE MACHINE ....................... 6 ELECTRICAL CONNECTION ....................... 6 OPERATION ............................7 ..........................7 ORKING PRINCIPLES ) ........................... 8 AS FLUSHING OPTION ) ......................... 8 LECTRICAL BAG CUT OPTION ) ......................8 RESSURE REGULATOR OPTION CONTROL ............................. 9 .............................. -

Page 6: Setting Up The Machine

Never exceed maximum quantity of oil indicated, when adding or changing oil. Verify weekly. Normal operating temperature for the 350/350D is 4C to 32C (39F to 90F). Vacuum pump is filled with synthetic oil that can be used in that range of temperature. -

Page 7: Operation

3. Operation a. Working principles A vacuum packaging cycle is made of 3 stages. First the vacuum is made, the air is completely taken out of the chamber and from bag containing the product (see figure 1). Then it is possible to inject neutral gas from the nozzles, gas flushing extended product shelf life and also act as a cushion for delicate product. -

Page 8: Gas Flushing (Option)

b. Gas flushing (option) There is an atmospheric pressure of 1 kg/cm (14 PSI) upon products when fully evacuated. Products which can be damaged by high pressure must be packaged with a partial vacuum, or the pressure must be counterbalance by inflating the bag with neutral gas. -

Page 9: Control

4. Control a. Basic Use power key to power the vacuum packaging machine. When the unit is energized, the identification of the last executed program is displayed on LCD screen. To disconnect, use the power key to turn off the machine, then remove plug from outlet. -

Page 10: Vacuum Level Setting

In program submenu, use esc key to get back to the programs menu. Strike any key to clear the error messages which may be displayed on LCD screen. Menu Structure can be found in section 4.H. Create a program: When executing the "create a program" function, the program submenu is acceded, starting with the identification. -

Page 11: Vacuum Plus Setting

automatically performed following the third digit entry (the new vacuum level is blinking). In the middle of an acquisition, use enter key to validate the vacuum level and key "ESC" to come backward and start over with a new acquisition. Set vacuum level to zero to bypass the pressure transducer and proceed only using the vacuum plus time. -

Page 12: Sealing Time Setting

e. Sealing time setting For a selected program set the sealing, starting with the seconds; the decimal point is automatically inserted following the first digit entry and the validation is automatically performed following the third digit entry (the new sealing time is blinking. -

Page 13: Menus Structure

h. Menus structure • Functions menu: "F1 CREATE A PRGM" "F2 DELETE A PRGM" • Programs menu: "Pxx NAME" Program submenu: "VACUUM: xx.x%" (10.0% - 99.5%) "VACUUM PLUS: xxs" (0s - 99s) "GAS FLUSH: xx.x%" (0.0% - 10% below the vacuum level) (units with gas option) "SEAL TIME: x.xxs"... -

Page 14: Daily Cleaning

For hygienic cleanliness, it is imperative to clean chamber and spacers daily. Also clean the lid rubber to assure tight seat of the lid. The 350/350D is made to be clean by hand with a damp cloth, no water can be apply directly on the machine. -

Page 15: Troubleshooting

WARNING: All electrical work described in this brochure should be done by a QUALIFIED and AUTHORIZED technician. 6. Troubleshooting a. Failure during packaging cycle COVER DOWN ERROR’’ message is display on LCD. The input signal of the down position switch has been lost during cycle execution. Check limit switch adjustment. -

Page 16: Faulty Valve

d. Faulty valve Check whether there is voltage on the magnetic valves during their period of operation. If there is no voltage a wire is broken or the PC board is damaged. If the lid does not open at the end of the cycle; air enters, but there is still 20 - 40% vacuum in chamber, vacuum valve does not close (needs to be serviced). - Page 17 Check vacuum connections for tightness. Check oil in pump (oil level in view glass; add if necessary. Regular change of oil - necessity indicated by change of color). Follow Busch maintenance schedule. Check vacuum in chamber with precision vacuumeter. Check desiccant filter for proper color, change if necessary. Check function of cycle with various settings of timers.This board software is allowing access to a "Diagnostics Menu".

- Page 18 005A0278 FILLER PLATE ASS'Y 005A0364 HALF FILLER PLATE ASS'Y 005A1584 MC-40 FRONT PANEL ASSEMBLY (BERKEL) 22 BERKEL 11 20 MACHINE DEPT. TOL. METRIC INCH SIPROMAC USINAGE ± 0.1 ± 0.004" TOLERIE ± 0.5 ± 0.020" SOUDAGE ± 0. 5 ± 0.020"...

- Page 19 001A0564 VALVE SUPPORT 051-0143 SCREW 10-24 x 3/8" PAN PHIL S/S 051-0571 NUT #10-24 S/S 8 10 MACHINE DEPT. TOL. METRIC INCH 350D SIPROMAC USINAGE ± 0.1 ± 0.004" TOLERIE ± 0.5 ± 0.020" SOUDAGE ± 0. 5 ± 0.020"...

- Page 20 005A1356 SEAL BAR ASSEMBLY W/SUPP. BAG CUT 125-1020 BUSCH KB-0020 115V/1PH/60HZ INSTALLER SUR LA VALVE LORS DE L'OPTION SOFT AIR DETAIL A 3 10 MACHINE DEPT. TOL. METRIC INCH SIPROMAC USINAGE ± 0.1 ± 0.004" TOLERIE ± 0.5 ± 0.020" SOUDAGE ± 0. 5 ± 0.020"...

- Page 21 125-1020 BUSCH KB-0020 115V/1PH/60HZ INSTALLER SUR LA VALVE LORS DE L'OPTION SOFT AIR DETAIL A 3 10 MACHINE DEPT. TOL. METRIC INCH 350D SIPROMAC USINAGE ± 0.1 ± 0.004" TOLERIE ± 0.5 ± 0.020" SOUDAGE ± 0. 5 ± 0.020"...

- Page 22 051-0232 SCREW 1/4-20x 1-1/4"SKT CAP SS 051-0580 NUT 1/4"-20 S/S 058-0030 NYLON SPACER 3/8IDx3/4ODx1/16 051-0287 BOLT 1/4-20 x 3-1/4" S/S MACHINE DEPT. TOL. METRIC INCH 300 & 350 SIPROMAC USINAGE ± 0.1 ± 0.004" TOLERIE ± 0.5 ± 0.020" SOUDAGE ±...

- Page 23 051-0232 SCREW 1/4-20x 1-1/4"SKT CAP SS 051-0580 NUT 1/4"-20 S/S 058-0030 NYLON SPACER 3/8IDx3/4ODx1/16 051-0287 BOLT 1/4-20 x 3-1/4" S/S MACHINE DEPT. TOL. METRIC INCH 300D & 350D SIPROMAC USINAGE ± 0.1 ± 0.004" TOLERIE ± 0.5 ± 0.020" SOUDAGE ± 0. 5 ±...

- Page 24 100-0225 CLOSE NIPPLE 1/4" NPT SS 051-0144 SCREW #10-24 N.C 1/2"PAN PHIL. S/S 051-0571 NUT #10-24 S/S PORT #3 PORT #2 MACHINE DEPT. TOL. METRIC INCH 300/350 SIPROMAC USINAGE ± 0.1 ± 0.004" TOLERIE ± 0.5 ± 0.020" SOUDAGE ± 0. 5 ±...

- Page 25 114-2020 FILTER / DRYER ¼"mnpt. X 1/4"t.p. COMP. PORT #3 PORT #2 45° TO FRONT BELLOW MACHINE DEPT. TOL. METRIC INCH 300D/350D SIPROMAC USINAGE ± 0.1 ± 0.004" TOLERIE ± 0.5 ± 0.020" SOUDAGE ± 0. 5 ± 0.020" ST-GERMAIN DE GRANTHAM...

- Page 26 INSTALLER POUR QUE LA BARRURE PUISSE BOUGER LIBREMENT SANS JEUX AXIAL. 051-01865 SCREW 1/4-20x 1/2"TRUSS SLOT SS INSTALL SO THAT THE LOCK CAN TURN WITHOUT AXIAL PLAY. MACHINE DEPT. TOL. METRIC INCH SIPROMAC 350 & 350D USINAGE ± 0.1 ± 0.004" TOLERIE ± 0.5 ± 0.020" SOUDAGE ±...

- Page 27 058-0120 CPVC SPACER 0.120" x 1/4" x 5/8" 179-0004 NITRILE 1/2'' X 1/8'' AUTOCOLLANT X 1210mm long -MC-40 OPTION- MACHINE DEPT. TOL. METRIC INCH VACUUM SIPROMAC USINAGE ± 0.1 ± 0.004" TOLERIE ± 0.5 ± 0.020" SOUDAGE ± 0. 5 ±...

- Page 28 100-0330 NIPPLE 1/2'' NPT X 3'' SS 101-0220 STRAIGHT ½"MNPTx3/4" HOSE BARB BRASS 104-0110 HOSE 3/4'' ID VACUUM TIGERFLEX 105-0238 EAR CLAMP 23.9-27.1 SS MACHINE DEPT. TOL. METRIC INCH 350/350D SIPROMAC USINAGE ± 0.1 ± 0.004" TOLERIE ± 0.5 ± 0.020" SOUDAGE ±...

- Page 29 051-0288 BOLT 1/4-20 x 3 1/2" S/S 051-0740 WASHER 1/4" FLAT S/S 051-0581 NUT 1/4"-20 NYLON LOCK S/S MACHINE DEPT. TOL. METRIC INCH VACUUM TABLE SIPROMAC USINAGE ± 0.1 ± 0.004" TOLERIE ± 0.5 ± 0.020" SOUDAGE ± 0. 5 ±...

- Page 41 006-0220 1 de 1 FULL FILENAME H:\DESSIN\DEPTDESS-2\PLAN ÉLECTRIQUE\006 + PART LIST 2010\350\006-0220 POW. 120V.VSD PAGE 14 (blk) (20 yel) (20 brn) (20 pur) (20 gry) category model volt. VACUUM PACK 120V/1PH/60HZ SIPROMAC system month circuit year block power MC-40 St-Germain de Grantham...

- Page 42 006-0200 1 de 1 FULL FILENAME H:\DESSIN\DEPTDESS-2\PLAN ÉLECTRIQUE\006 + PART LIST 2010\350\006-0200 350 POW 220V.VSD PAGE 220V 0152 0162 0122 0132 0112 0142 0222 0212 0232 0242 0233 0213 0223 0113 0133 0123 0214 0224 0025 0114 0124 0024 0034...

- Page 43 006-0237 1 de 2 PAGE FULL FILENAME H:\DESSIN\DEPTDESS-2\PLAN ÉLECTRIQUE\006 + PART LIST 2010\350\006-0237 CONT..VSD TRANSF.CONT. W001 MC40 GREY JP3/1 PURPLE JP3/1 BROWN JP3/1 YELLOW JP3/1 Atmosphere BLUE JP3/1 ORANGE JP3/1 Sealing GREEN JP3/1 Bellows JP3/1 WHITE Gas option JP3/1 OL/1...

- Page 44 006-0237 2 de 2 PAGE FULL FILENAME H:\DESSIN\DEPTDESS-2\PLAN ÉLECTRIQUE\006 + PART LIST 2010\350\006-0237 CONT..VSD MC40 BLACK WHITE N/A RED N/A GREEN shield ooooooo PC BOARD category VACUUM PACK model volt. SIPROMAC month system circuit year block control MC-40 St-Germain de Grantham...

- Page 45 INPUT CONTROL 033-0038 MICROPROCESSOR MC-40 SENSOR VACUUM CONTROL WITH SENSOR MC-40 033-00385 MICROPROCESSOR MC-40 NO SENSOR VAC. CONTROL W/O SENSOR MC-40 033-0015 MEMBRANE MC-40 SIPROMAC CONTROL SIPROMAC 033-0018 MEMBRANE MC-40 BERKEL CONTROL BERKEL 106-0020 VALVE 2WAY 24V 1/2 NPT(G94) 60HZ...

- Page 46 INPUT CONTROL 033-0038 MICROPROCESSOR MC-40 SENSOR VACUUM CONTROL WITH SENSOR MC-40 033-00385 MICROPROCESSOR MC-40 NO SENSOR VAC. CONTROL W/O SENSOR MC-40 033-0015 MEMBRANE MC-40 SIPROMAC CONTROL SIPROMAC 033-0018 MEMBRANE MC-40 BERKEL CONTROL BERKEL 106-0020 VALVE 2WAY 24V 1/2 NPT(G94) 60HZ...

- Page 48 NOTES...

Need help?

Do you have a question about the 350 and is the answer not in the manual?

Questions and answers