Table of Contents

Advertisement

Quick Links

INSTRUCTIONS-PARTS LIST

This manual contains important

warnings and information.

READ AND KEEP FOR REFERENCE.

INSTRUCTIONS

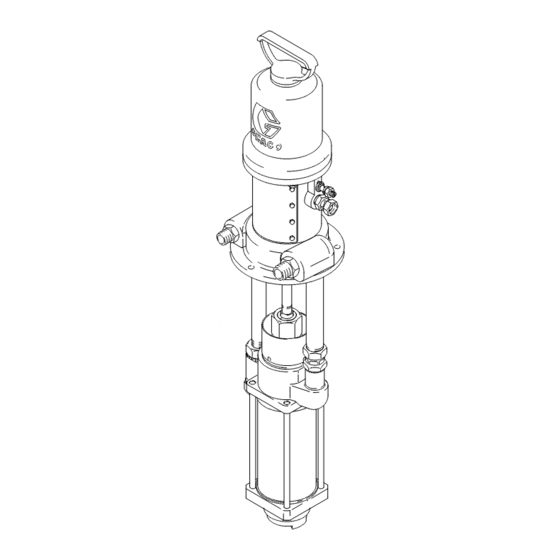

1.5:1 Ratio Monarkr Pump

180 psi (12 bar) Maximum Fluid Working Pressure

120 psi (8 bar) Maximum Air Input Pressure

Part No. 218794, Series C

Stainless Steel, 55 Gallon (200 Liter) Drum Size, UHMWPE and Leather Packed

Part No. 218763, Series C

Stainless Steel, Stubby Size, UHMWPE and Leather Packed

Table of Contents

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

GRACO INC. P.O. BOX 1441 MINNEAPOLIS, MN 55440- -1441

2

5

8

11

12

13

14

18

18

19

20

. . . . . . . . . . . . . . . . .

20

ECOPYRIGHT 1985, GRACO INC.

Graco Inc. is registered to I.S. EN ISO 9001

Model 218763

Shown

307653

Rev. F

06114

Advertisement

Table of Contents

Summary of Contents for Graco Monark 218794

-

Page 1: Table Of Contents

Toll-Free Graco Phone Number ....GRACO INC. P.O. BOX 1441 MINNEAPOLIS, MN 55440- -1441 ECOPYRIGHT 1985, GRACO INC. Graco Inc. is registered to I.S. EN ISO 9001... -

Page 2: Warnings

D This equipment is for professional use only. D Read all instruction manuals, tags, and labels before operating the equipment. D Use the equipment only for its intended purpose. If you are not sure, call your Graco distributor. D Do not alter or modify this equipment. - Page 3 WARNING FIRE AND EXPLOSION HAZARD Improper grounding, poor ventilation, open flames or sparks can cause a hazardous condition and result in a fire or explosion and serious injury. D Ground the equipment and the object being sprayed. Refer to Grounding on page 5. D If there is any static sparking or you feel an electric shock while using this equipment, stop spray- ing immediately.

- Page 4 Notes 307653...

-

Page 5: Installation

NOTE: Reference numbers and letters in parentheses in the text refer to the callouts in the figures and the parts drawing. NOTE: Always use Genuine Graco Parts and Acces- sories, available from your Graco distributor. If you supply your own accessories, be sure they are ade- 0864 quately sized and pressure rated for your system. - Page 6 Installation Bleed-Type Master Air Valve Fluid Shutoff Valves M Air Supply Line Main Fluid Return Line (required, for pump) G Fluid Filter Bleed-Type Master Air Valves Secondary Fluid Return Line Air Filter/Regulator Fluid Pressure Regulator (for accessories) Ground Wire (required; Air Line Lubricator Air Spray Gun Main Fluid Supply Line...

- Page 7 Installation Available Accessories (must be Fluid Line Accessories purchased separately) WARNING Air Line Accessories A fluid drain valve (D) is required in your system to WARNING help reduce the risk of serious injury, including splashing of fluid in the eyes or on the skin. A bleed-type master air valve (A) is required in your system to help reduce the risk of serious injury, The fluid drain valve assists in relieving fluid pres-...

-

Page 8: Operation

Operation Pressure Relief Procedure If the pump is not immersed, fill the packing nut/wet- cup 1/2 full with a compatible solvent. Keep the cup filled at all times to help prevent the fluid you are WARNING pumping from drying on the exposed displacement rod and damaging the throat packings. - Page 9 Operation Prime the Pump WARNING 1. See Fig. 2. Remove the spray nozzle from the To reduce the risk of serious injury whenever you gun. See the gun instruction manual. are instructed to relieve pressure, always follow the 2. Close all bleed-type air valves (A, N). Pressure Relief Procedure on page 8.

- Page 10 Notes 307653...

-

Page 11: Maintenance

Maintenance Shutdown and Care of the Pump Flush with a fluid that is compatible with the fluid you are pumping and with the wetted parts in your system. Check with your fluid manufacturer or supplier for WARNING recommended flushing fluids and flushing frequency. To reduce the risk of serious injury whenever you WARNING are instructed to relieve pressure, always follow the... -

Page 12: Troubleshooting

Troubleshooting 1. Relieve the pressure. WARNING To reduce the risk of serious injury whenever you are instructed to relieve pressure, always follow the 2. Check all possible problems and solutions before Pressure Relief Procedure on page 8. disassembling pump. Problem Cause Solution Pump fails to operate. -

Page 13: Service

Service Disconnecting the Displacement Pump 6. Turn on the air to the motor and run the pump slowly. Adjust the locknuts (5) on the return mount- NOTE: For displacement pump repair instructions, ing tube (7) as necessary until the pump operates refer to the separate displacement pump manual smoothly at minimum air pressure to the motor. -

Page 14: Parts

Parts Model 218794, Series C 1.5:1 Ratio Monark Pump, 55 Gallon (200 Liter) Drum Size; UHMWPE and Leather Packed Part Description 100579 PIN, cotter 118160 LOCKWASHER, ext shakeproof 156082 O-RING; nitrile rubber 171217 LOCKNUT; 3/4--11 160032 NIPPLE; 3/4 npt 180990 TUBE, return;... - Page 15 Parts Model 218763, Series C 1.5:1 Ratio Monark Pump, Stubby Size; UHMWPE and Leather Packed Part Description 100579 PIN, cotter 118160 LOCKWASHER, ext shakeproof 156082 O-RING; nitrile rubber 171217 LOCKNUT; 3/4--11 166443 NIPPLE, hex, reducing; 3/4 x 1/2 npt 180986 TUBE, return;...

- Page 16 Notes 307653...

- Page 17 Notes 307653...

-

Page 18: Dimensions

Dimensions Model No. 218794 48.25 in. 15.75 in. 32.5 in. (1226 mm) (400 mm) (826 mm) 218763 35.75 in. 15.75 in. 20 in. (908 mm) (400 mm) (508 mm) Model 218763 Shown Mounting Hole Layout 0.375” 2.254” (9.52 mm) (57.25 mm) diameter 2.254”... -

Page 19: Technical Data

Technical Data Category Data Ratio 1.5:1 Maximum fluid working pressure 180 psi (12 bar) Maximum air input pressure 120 psi (8 bar) Pump cycles per 1 gallon (3.8 liters) Fluid flow at 60 cycles per minute 6.8 gpm (25.7 liters/min) Fluid inlet size 1--1/2 npt(f) Fluid outlet size... -

Page 20: Graco Warranty

Graco distributor to the original purchaser for use. With the exception of any special, extended, or limited warranty published by Graco, Graco will, for a period of twelve months from the date of sale, repair or replace any part of the equipment determined by Graco to be defective.

Need help?

Do you have a question about the Monark 218794 and is the answer not in the manual?

Questions and answers