Summary of Contents for Micas M2-S6920-4S

- Page 1 M2-S6920-4S Switch Hardware Installation and Reference Guide Version V1.0 copyright © 2023 Micas...

-

Page 2: Copyright Statement

This document is provided “as is”. The contents of this document are subject to change without any notice. Please obtain the latest information through the Micas Networks website. Micas Networks endeavors to ensure content accuracy and will not shoulder any responsibility for losses and damages caused due to content omissions, inaccuracies or errors. - Page 3 Appendix B "10G, 25G, 40G and 100G Modules" Appendix C “Lightening Protection” Appendix D “Cabling Recommendations in Installation” Appendix E “Site Selection” Obtaining Technical Assistance Micas Networks Website: https://www.micasnetworks.com/ Technical Support Website: http://www.micasnetworks.com/support Case Portal: http://www.micasnetworks.com/case Community: http://www.micasnetworks.com/company/contact...

-

Page 4: Symbol Conventions

Describes the related configuration commands, including command modes, Command Reference parameter descriptions, usage guides, and related examples. Symbol Conventions Means reader take note. Notes contain helpful suggestions or references. Means reader be careful. In this situation, you might do something that could result in equipment damage or loss of data. -

Page 5: Product Overview

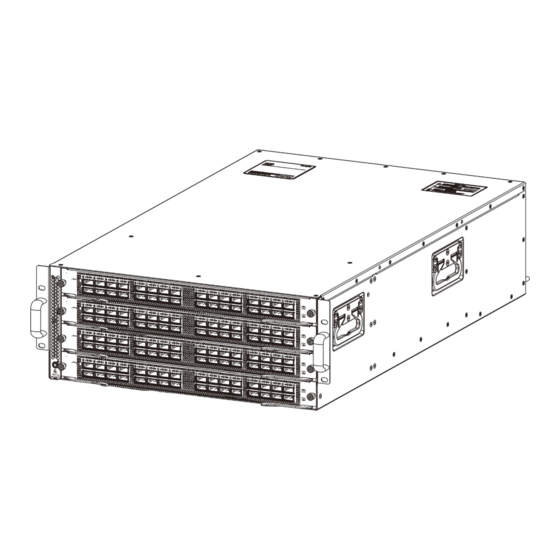

M2-S6920-4S switch is a data center oriented high density 100G aggregation switch, providing 100G access, low latency, and complete data center features. The M2-S6920-4S switch provides 128 100G ports and can be used to compose a high-performance and high-reliability data center network. -

Page 6: Product Appearance

442 mm x 735 mm x 173.5 mm, 4RU (17.40 in. x 28.93 in. x 6.83 in.) (L x W x H) M2-S6920-4S switch is a class A product. In a domestic environment, this product may cause radio interference in which case the user may be required to take adequate measures. -

Page 7: Rear Panel

Hardware Installation and Reference Guide Product Overview Figure 1-2 Front Panel of the S6920-4S Notes: Line Card Indicator Screws QSFP28 Port Line Card Handle QSFP28 Port Indicator Ground for ESD Wrist Strap Banana Jack The S6920-4S supports 100G QSFP28 module. Rear Panel Figure 1-3 Rear Panel of the S6920-4S Notes:... -

Page 8: Asset Tag

Users can mark the information such as asset name, category, code and registration date on the label which helps to improve asset management accuracy and efficiency. Figure 1-4 Asset Tag of the M2-S6920-4S External Ports The M2-S6920-4S provides the following ports: ... -

Page 9: Power Supply

40G/100Gbps. Power Supply The M2-S6920-4S switch supports power supply the PA1300I-F. The smart power supply module supports power management, and the host can read input power, input current, and temperature in real time. The power supply module supports hot swapping. -

Page 10: Heat Dissipation

Heat Dissipation The working temperature of the M2-S6920-4S switch is 0°C to 40°C (32°F to 104°F), and the heat dissipation design needs to ensure the stability, safety and maintainability in such environment. The M2-S6920-4S switch adopts fan ventilation and forced convection to ensure the device can work normally in specified environment. -

Page 11: Preparation Before Installation

Hardware Installation and Reference Guide Preparation before Installation 2 Preparation before Installation 2.1 Safety Precautions To avoid body injury and device damage, please carefully read the safety precautions before you install the M2- S6920-4S. The following safety precautions do not cover all possible dangers. 2.1.1 Installation Safety ... -

Page 12: Laser Safety

Do not let any clothes touch a circuit board. An antistatic wrist strap can only prevent human static electricity from damaging the circuit board but cannot prevent any static electricity on clothes. 2.1.5 Laser Safety Among the modules supported by the M2-S6920-4S, there are a great number of optical modules that are Class I laser product. Precautions: ... -

Page 13: Ventilation Requirements

Be sure that the cabinet is firm enough to bear the weight of the M2-S6920-4S and its installation accessories. Be sure that the dimensions of the cabinet is appropriate for installation of the M2-S6920-4S that can reserve a certain space for the front, back, left and right panels for heat dissipation. -

Page 14: System Grounding Requirements

2.2.5 System Grounding Requirements A good grounding system is the basis for the stable and reliable operation of the M2-S6920-4S. It is the key to prevent lightning stroke and resist interference. Please carefully check the grounding conditions on the installation site according to the grounding requirements, and perform grounding properly as needed. -

Page 15: Emi Consideration

Hardware Installation and Reference Guide Preparation before Installation 2.2.6 EMI Consideration Various interference sources, from either outside or inside the device or application system, affect the system in the conductive ways such as capacitive coupling, inductive coupling, and electromagnetic radiation. There are two types of electromagnetic interferences: radiated interference and conducted interference, depending on the type of the propagation path. -

Page 16: Unpacking And Checking

Fiber optic cleaning Tools Air-laid paper, fiber end microscope Meter Multimeter, errormeter, optic-power meter The M2-S6920-4S switch is not shipped with a tool kit. You need to prepare a tool kit by yourself. 2.5 Unpacking and Checking Goods Checklist Chassis, Yellow/green grounding cables;... -

Page 17: Product Installation

Product Installation 3 Product Installation The M2-S6920-4S Ethernet switch must be used and fixed in the room. Make sure you have carefully read part 2, and be sure that the requirements set forth in part 2 have been met. 3.1 Installation Procedure... -

Page 18: Cabinet Installation

Precautions Before mounting M2-S6920-4S into the cabinet, first verify that the front and back brackets of the cabinet are at the right locations. If the bracket is too far forward, the front panel of the equipment may be too close to the front door, so that the front door cannot be closed when the equipment is connected with network cables and pigtail fibers. -

Page 19: Installing Mounting Brackets

Mounting the Switch to a Rack The M2-S6920-4S switch is qualified for EIA standard and can be installed in a 19-inch wiring cabinet. During the process of installation, keep the front panel of the switch forward. It is recommended use tray to install the M2-S6920-4S switch and fix the tray on the bracket, or use the rear bracket provided with the switch. -

Page 20: Installing And Removing A Fan Module

Hardware Installation and Reference Guide Product Installation Distinguish the left and the right rear brackets according to the marked directions. The rear brackets provided are only applicable for cabinets with depth of 800mm to 1200mm. 3.5 Installing and Removing a Fan Module Wear anti-static gloves before the following operations. -

Page 21: Removing A Fan Module

Hardware Installation and Reference Guide Product Installation Power modules and fan modules with different air direction cannot be used together. Removing a Fan Module Loosen the captive screws of the fan module with a screwdriver. Hold the handle at the end of the fan module, and withdraw the fan module slowly. Install the fan filler panel and put the removed fan module into its package Figure 3-5 Removing a Fan Module Withdraw the fan module slowly. -

Page 22: Installing Power Cord Retainer

Hardware Installation and Reference Guide Product Installation Insert the power module smoothly. Please pay attention to the direction of the power panel to avoid wrong insertion. If it is difficult or even impossible to insert the module, pull out the module, make sure the expansion module and guide rail are well aligned, and then insert the module again. -

Page 23: Removing A Power Module

Hardware Installation and Reference Guide Product Installation Check whether the power cord container is correctly installed. If you can remove the strap without pressing buckle A, the strap may be installed incorrectly. Try the other side of the strap. Attach the power cord container to the installation hole of the power module. Plug the power cord into the connector. - Page 24 3.7 Grounding A PGND is installed on the back of M2-S6920-4S. First connect the PGND to the grounding terminal of the cabinet and then connect the grounding terminal to the grounding bar of the equipment room.

-

Page 25: Connecting The External Interface Cables

Hardware Installation and Reference Guide Product Installation Simple Connection Steps Connect the RJ45 connector to the Console interface of the management engine module with shipped console cable, and connect the DB9 connector to the NM or control terminal. By default, the baud rate is 115200, data bit 8, parity check none, stop bit 1, and flow control none. 3.9 Connecting the External Interface Cables Precautions ... -

Page 26: Verifying The Power Supply

Hardware Installation and Reference Guide Product Installation Verify if the external power supply matches the distribution panel of the cabinet. After equipment is installed, verify if the front/back cabinet doors can be closed. Verify that the cabinet has been fastened completely, and does not move or tilt. ... -

Page 27: System Debugging

Hardware Installation and Reference Guide System Debugging 4 System Debugging 4.1 Establishing the Configuration Environment Establishing the Configuration Environment Connect the PC to the console port of the switch through the console cable, as shown in Figure 4-1. Figure 4-1 Schematic diagram of the configuration environment Connecting the Console Cable Connect one end of the DB-9 jack of the console cable to the serial port of the PC. - Page 28 Hardware Installation and Reference Guide System Debugging Figure 4-2 Enter the name of the new connection and click OK. A window appears as shown in Figure 4-3. In the column of Connect Using field, select the serial port you want to use. Figure 4-3 After the serial port is selected, please click OK.

-

Page 29: Power-On Startup

Hardware Installation and Reference Guide System Debugging After the serial port parameters are set, click OK to enter hyper terminal window. 4.2 Power-on Startup Checking before Power-on Check if the switch is fully grounded. Check if the fan module and the power module are correctly installed. ... -

Page 30: Monitoring And Maintenance

5 Monitoring and Maintenance 5.1 Monitoring Indicator When the M2-S6920-4S is running, users can monitor the status of host and each module by inspecting corresponding indicators. When the Status indicator is red, it means the system has a fault, in which case you can determine and eliminate the fault by viewing with the management software. -

Page 31: Power Supply Maintenance

Replacing Lithium Battery The built-in lithium batteries can support the real time clock of the M2-S6920-4S switch without external power supply. Please contact the technical support representatives of Micas Networks for replacing lithium batteries. Technical staff of Micas Networks will replace the battery of the same model. -

Page 32: Troubleshooting

Check the indicators on the device and the modules Check the connection of the serial ports and its parameters Check the connection of the fibers or cables of various ports Contact Technical Support of Micas Networks for hardware problems - 30 -... -

Page 33: Common Troubleshooting Procedures

Check whether the configuration of the serial port on the hyper terminal is the same as that described in M2-S6920-4S Software Configuration Guide. If not, modify the serial port configuration parameters. If there is still no serial port printed information, please contact Micas Customer Service Department for technical support. - Page 34 Check whether the module is inserted correctly. If the newly inserted module still cannot be powered on even though the checking is ok, please contact Micas Customer Service Department for technical support. Fault 7: The link cannot be set up between fiber interfaces.

-

Page 35: Appendix A Connectors And Connection Me

Hardware Installation and Reference Guide Appendix A Connectors and Connection Me Appendix A Connectors and Connection Media 10GBASE-T/1000BASE-T/100BASE-TX Port 10GBASE-T/1000BASE-T/100BASE-TX is a port that supports self-adaptation of three rates, and automatic MDI/MDIX Crossover at these three rates. 10GBASE-T complies with IEEE 802.3an standard, and the supported cables and cabling distances are listed in the following table. - Page 36 Hardware Installation and Reference Guide Appendix A Connectors and Connection Me Figure A-1 Four twisted pairs of the 1000BASE-T In addition to the above cables, the 100BASE-TX can use up to 100m of 100-ohm CAT5. Figure A-2 shows the definition of pin signal concerning the 100BASE-TX: Figure A-2 Definition of pin signal concerning the 100BASE-TX Socket Plug...

- Page 37 Hardware Installation and Reference Guide Appendix A Connectors and Connection Me - 35 -...

-

Page 38: Appendix B Mini-Gbic, 10G, 40G And 100G

Hardware Installation and Reference Guide Appendix B Mini-GBIC, 10G, 40G and 100G Appendix B Mini-GBIC, 10G, 40G and 100G Module We provide mini-GBIC module, 10G SFP+ modules, 40G QSFP+ modules, 100G QSFP28 modules. According to the interface type of the switch module. You can select modules to suit your specific needs. The following models and technical specifications of mini-GBIC modules, 10G SFP+ modules, 40G QSFP+ modules, 100G QSFP28 modules are listed for your reference. - Page 39 Hardware Installation and Reference Guide Appendix B Mini-GBIC, 10G, 40G and 100G Type (μm) distance Light (dBm) Light (dBm) (MHz·km) 62.5 XG-SFP-SR- 2000 300m -7.5 MM850 connecto XG-SFP-LR-S 1310 10km -8.2 -10.3 M1310 connecto XG-SFP-ER-S 1550 40km -4.7 -11.3 M1550 connecto XG-SFP-ZR-S 1550...

- Page 40 Hardware Installation and Reference Guide Appendix B Mini-GBIC, 10G, 40G and 100G Models and Technical Specifications of the 40G QSFP+ Module 40G QSFP+ optical modules Intensity Intensity of Wavel Core Modular Optical Transmitte Model ength Size Bandwidth Cabling Supported Received Fiber Type d Light (nm)

- Page 41 Hardware Installation and Reference Guide Appendix B Mini-GBIC, 10G, 40G and 100G Copper Conductor Support Module Connector Data Rate Model Cable Wire Diameter Type Type (Gb/s) Length (m) (AWG) (Yes/No) 4lanes*25.7812 100GE, 1m, QSFP28 Passive QSFP28 5 (per lane) 4lanes*25.7812 100GE, 3m, QSFP28 Passive QSFP28...

-

Page 42: Appendix C Lightning Protection

Hardware Installation and Reference Guide Appendix C Lightning Protection Appendix C Lightning Protection Installing AC Power Arrester (lightning protection cable row) The external lightning protection cable row should be used on the AC power port to prevent the switch from being struck by lightning when the AC power cable is introduced from the outdoor and directly connected to the power port of the switch. - Page 43 Hardware Installation and Reference Guide Appendix C Lightning Protection Installing the Ethernet Port Arrester During the switch usage, the Ethernet port arrester should be connected to the switch to prevent the switch damage by lightning before the outdoor network cable connects to the switch . Tools: Cross or straight screwdriver, Multimeter, Diagonal pliers Installation Steps: Tear one side of the protection paper for the double-sided adhesive tape and paste the tape to the framework of the...

- Page 44 Hardware Installation and Reference Guide Appendix C Lightning Protection You should pay attention to the following conditions during the actual installation to avoid influencing the performance of the Ethernet port arrester: Reversed direction of the arrester installation. You shall connect the external network cable to the “IN” end and connect the switch Ethernet port to the “OUT”...

-

Page 45: Appendix D Cabling Recommendations In In

Hardware Installation and Reference Guide Appendix D Cabling Recommendations in In Appendix D Cabling Recommendations in Installation When the switches are installed in standard 19-inch cabinets, the cables are tied in the binding rack on the cabinet by the cable management bracket, and top cabling or bottom cabling is adopted according to the actual situation in the equipment room. - Page 46 Hardware Installation and Reference Guide Appendix D Cabling Recommendations in In Cables of different types (such as power cords, signal cables, and grounding cables) should be separated in cabling and bundling and no mixed bundling is allowed. When they are close, crossover cabling can be adopted. In the case of parallel cabling, power cords and signal cables should maintain a distance not less than 30 mm.

- Page 47 Hardware Installation and Reference Guide Appendix D Cabling Recommendations in In Cables not to be assembled or remaining parts of cables should be folded and placed in a proper position of the cabinet or cabling slot. The proper position indicates a position that will not affect device running or cause device damage or cable damage during commissioning.

- Page 48 Hardware Installation and Reference Guide Appendix D Cabling Recommendations in In Figure D-4 Cable fastening The hard power cable should be fastened at the terminal connection area to prevent stress on terminal connection and cable. Do not use self-tapping screws to fasten terminals. ...

-

Page 49: Appendix E Site Selection

Hardware Installation and Reference Guide Appendix E Site Selection Appendix E Site Selection The machine room should be at least 5km away from the heavy pollution source such as the smelter, coal mine and thermal power plant, 3.7km away from the medium pollution source such as the chemical industry, rubber industry and electroplating industry, and 2km away from the light pollution source such as the food manufacturer and leather plant.

Need help?

Do you have a question about the M2-S6920-4S and is the answer not in the manual?

Questions and answers