Table of Contents

Advertisement

Quick Links

INSTALLATION INSTRUCTIONS

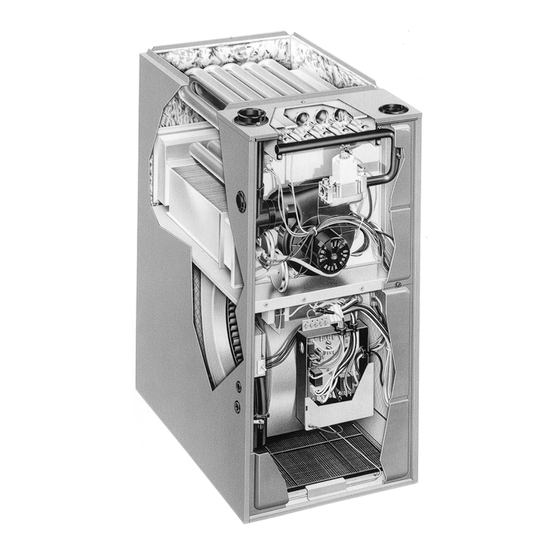

FOR UPFLOW & DOWNFLOW/HORIZONTAL HIGH

EFFICIENCY CONDENSING GAS FURNACES

GF951U & GF951D SERIES

ISO 9001:2008

U.L. recognized fuel gas and CO (carbon monoxide) detectors are recommended in all

applications, and their installation should be in accordance with the manufacturer's

recommendations and/or local laws, rules, regulations, or customs.

92-24161-91-04

SUPERSEDES 92-24161-91-03

Advertisement

Table of Contents

Summary of Contents for Rheem GF951U Series

-

Page 1: Safety Precautions

INSTALLATION INSTRUCTIONS FOR UPFLOW & DOWNFLOW/HORIZONTAL HIGH EFFICIENCY CONDENSING GAS FURNACES GF951U & GF951D SERIES U.L. recognized fuel gas and CO (carbon monoxide) detectors are recommended in all applications, and their installation should be in accordance with the manufacturer’s recommendations and/or local laws, rules, regulations, or customs. ISO 9001:2008 92-24161-91-04 SUPERSEDES 92-24161-91-03... -

Page 2: Installation Check List

INSTALLATION CHECK LIST REFER TO INSTALLATION INSTRUCTIONS GAS SUPPLY TERMINATIONS – DIRECT VENT Adequate pipe size VERTICAL Correct supply pressure (during furnace operation) Intake – 12" min. above roof/snow level Manifold pressure Correct relationship – exhaust to intake No gas leaks HORIZONTAL/VERTICAL –... -

Page 3: Safety Information

SAFETY INFORMATION SAFETY INFORMATION WARNING WARNING WARNING NEVER TEST FOR GAS LEAKS WHEN THIS FURNACE IS USE ONLY WITH TYPE OF GAS WITH AN OPEN FLAME. USE A APPROVED FOR THIS FURNACE. INSTALLED IN A RESIDENTIAL REFER TO THE FURNACE RATING COMMERCIALLY AVAILABLE GARAGE, IT MUST BE INSTALLED PLATE. - Page 4 SAFETY INFORMATION WARNING DUCT LEAKS CAN CREATE AN IMPORTANT! 4. INSPECTION. The state or local UNBALANCED SYSTEM AND gas inspector of the side wall DRAW POLLUTANTS SUCH AS THE COMMONWEALTH OF horizontally vented gas fueled DIRT, DUST, FUMES AND ODORS MASSACHUSETTS REQUIRES equipment shall not approve the INTO THE HOME CAUSING...

-

Page 5: Table Of Contents

IMPORTANT: All manufacturer CONTENTS products meet current Federal OSHA Guidelines for safety. California Safety Precautions ....................1 Proposition 65 warnings are required for certain products, which are not Installation Check List ....................2 covered by the OSHA standards. Safety Information ....................3 California's Proposition 65 requires warnings for products sold in California General Information....................6 that contain, or produce, any of over... -

Page 6: General Information

GENERAL INFORMATION The GF951U and GF951D series CSA-INTERNATIONAL Install this furnace in accordance with furnaces are design-certified by CSA 8501 East Pleasant Valley Road the American National Standard for use with natural and propane Cleveland, Ohio 44131-5575 Z223.1 – latest edition entitled gases as follows: “National Fuel Gas Code”... - Page 7 IMPORTANT matches what is required for the NOTICE job specification. INFORMATION ABOUT IMPROPER INSTALLATION, OR • Read the entire instructions before EFFICIENCY AND INDOOR INSTALLATION NOT MADE IN starting the installation. ACCORDANCE WITH THE CSA AIR QUALITY • Some building codes require extra INTERNATIONAL (CSA) cabinet insulation and gasketing CERTIFICATION OR THESE...

-

Page 8: Location Requirements And Considerations

LOCATION REQUIREMENTS AND CONSIDERATIONS GENERAL INFORMATION WARNING 1. IMPORTANT: If installing the 3. IMPORTANT: Install the furnace unit over a finished ceiling or level. If it is not level, condensate DO NOT USE THIS FURNACE living area, be certain to install an cannot drain properly, possibly DURING CONSTRUCTION IF AIR auxiliary condensate drain pan... - Page 9 c. The heat tape should be rated FIGURE 5 at 5 or 6 watts per foot at HORIZONTAL FURNACE INSTALLED W/SUPPORT BRACKETS 120V. IMPORTANT: Support this unit PIPE when installed. Since this furnace is suitable for attic or crawl space installation, it may be installed on combustible wood flooring or by INTAKE...

- Page 10 FIGURE 6 CLEARANCE TO COMBUSTIBLES, UPFLOW UNITS I392...

- Page 11 FIGURE 7 CLEARANCE TO COMBUSTIBLES, DOWNFLOW UNITS I393...

- Page 12 FIGURE 8 CLEARANCE TO COMBUSTIBLES, HORIZONTAL UNITS I520...

-

Page 13: Ducting

DUCTING UPFLOW UNITS 5. If summer air conditioning is desired, position the indoor coil Proper air flow is required for the 1. Position the unit to minimize long on the top of the unit. Insure that correct operation of this furnace. runs of duct or runs of duct with no air can bypass this coil. -

Page 14: Venting And Combustion Air Piping

4. Connect the furnace to the 4. Connect the return air ducting to 5. Be sure to have adequate space for the unit filter. supply air plenum. the return air opening at the right end of the unit. Make the NOTE: DO NOT take return air 5. - Page 15 OVERTEMPERATURE hoods and bathroom exhausts, Pipe and Fittings - ASTM-D1785, so they will operate at maximum D2466, D2665, D2231, D2661 and SAFETY SWITCHES speed. Do not operate a summer F628. Furnaces are equipped with safety exhaust fan. Close fireplace PVC Primer and Solvent Cement - switches in the control compartment dampers.

-

Page 16: Combustion And Ventilation Air

COMBUSTION AND VENTILATION AIR NON-DIRECT FURNACE INSTALLATIONS • Cleaning solvents (such as BTUH Minimum Sq. Feet Typical Room Size Input With 8' Ceiling With 8' Ceiling perchloroethylene) 45,000 14' x 20' OR 16' x 18' WARNING • Printing inks, paint removers, 60,000 15' x 25' OR 19' x 20' varnishes, etc. - Page 17 BTUH Free Area FIGURE 11 Input Each Opening AIR FROM HEATED SPACE 45,000 100 square inches 60,000 100 square inches 75,000 100 square inches 90,000 100 square inches 105,000 105 square inches B. USING OUTDOOR AIR FOR NOTE: COMBUSTION EACH OPENING SHALL HAVE A FREE AREA OF NOT IMPORTANT: Do not take air from LESS THAN ONE SqUARE...

- Page 18 Method 2 CONNECTION TO BTUH Free Area Round Pipe (Not Shown) Input Each Opening Size FURNACE One permanent opening, located 45,000 15.00 square inches 4" IMPORTANT: When indoor within 12 inches of the top of the 60,000 16.67 square inches 5"...

-

Page 19: Vent Pipe Installation

VENT PIPE INSTALLATION NON-DIRECT VENT TABLE 1 FOR NON-DIRECT VENT APPLICATIONS - AIR FOR COMBUSTION INSTALLATION PROVIDED FROM INDOORS GUIDELINES MAXIMUM ALLOWABLE LENGTH IN FEET OF EACH EXHAUST PIPE AND INTAKE PIPE IMPORTANT: Failure to correctly follow all venting guidelines may NUMBERS OF ELBOWS result in erratic furnace operation, 45°... - Page 20 “rub-a-tex” insulation may also be INSTALLATION CAN CAUSE 7. Avoid areas where dripping used as long as there is no heat STRUCTURAL OR EXTERIOR condensate may cause problems, tape applied to the vent pipe. For FINISH DAMAGE TO THE such as above planters, patios, or horizontal runs where water may BUILDING.

- Page 21 FIGURE 17 OTHER THAN DIRECT VENT TERMINAL CLEARANCES...

- Page 22 DIRECT VENT TABLE 2 INSTALLATIONS FOR DIRECT VENT APPLICATIONS - AIR FOR COMBUSTION PROVIDED FROM OUTDOORS WARNING MAXIMUM ALLOWABLE LENGTH IN FEET OF EACH EXHAUST PIPE AND INTAKE AIR PIPE READ AND FOLLOW ALL NUMBER OF ELBOWS INSTRUCTIONS IN THIS SECTION. VENT TERMINATION 45 or 90 Degrees FURNACE...

- Page 23 COMBUSTION AIR FOR STANDARD HORIZONTAL Refer to Table 2 for proper TERMINATIONS application. See Figure 24. DIRECT VENT INSTALLATIONS COMBUSTION AIR PIPING STANDARD HORIZONTAL THE COMBUSTION AIR SYSTEM When 3-in. pipe is used between the TERMINATIONS DESIGNED FOR THIS FURNACE furnace and outside wall, reduce it EXHAUST PIPING MUST BE USED.

- Page 24 • Insulate the entire length of vent FIGURE 18 pipe, between the elbow where the ALTERNATE HORIZONTAL DIRECT VENT TERMINATION pipe exits the wall and the elbow NOT APPLICABLE TO where the termination is made, with GF951D075 GF951D090 a closed-cell insulation, such as GF951D105 EXHAUST VENT “Arm-a-Flex”...

- Page 25 NOTE: The following IPEX brand CONCENTRIC concentric terminations (System 636) TERMINATIONS may be purchased in the field and VERTICAL/HORIZONTAL used in place of factory supplied kits: CONCENTRIC VENT 3” Concentric Kit – Item # 196006 KIT NO. RXGY-E03A This kit is for vertical/horizontal intake air/vent runs and may be installed through roofs and sidewalls.

- Page 26 FIGURE 20 STANDARD VERTICAL DIRECT VENTING 3" UPFLOW MODEL SHOWN (TYPICAL FOR DOWNFLOW MODELS) EXHAUST MAX. VENT COMBUSTION AIR PIPE 12" 3" MAX. SEPARATION 12" MIN. 3" EXHAUST MAX. VENT COMBUSTION AIR COMBUSTION PIPE AIR PIPE 12" 12" MIN. 30 MAX SEPARATION 12"...

- Page 27 FIGURE 22 DIRECT VENT TERMINAL CLEARANCES≤...

- Page 28 LOCATION REQUIREMENTS In addition to the minimum surfaces, unless a rust-resistant clearances listed above, the vent sheet metal or plastic backing HORIZONTAL DIRECT VENTS location should also be governed plate behind vent. See Figure 23. by the following guidelines. 5. Do not locate too close to shrubs CAUTION 1.

- Page 29 FIGURE 24 FIGURE 25 TWO FURNACE VENTING THROUGH ROOF TWO FURNACE VENTING THROUGH WALL TWO-PIPE VENTING TWO-PIPE VENTING EXHAUST VENT MODELS 04-06 TO BE REDUCED TO 2” PVC LAST 12”. 3” MINIMUM 24” MAXIMUM 3” MINIMUM 24” MAXIMUM CONCENTRIC VENTING CONCENTRIC VENTING 8”...

- Page 30 RXGY-G02 SIDE WALL VENT NOTE: Install the vent and air intake NOTE: The vent illustration in Figure piping into the vent plate openings. 27 can be used for Non-direct vent This termination for horizontal venting Seal all gaps between the pipes and terminations also.

- Page 31 CONNECTING TO FURNACE FIGURE 28 IMPORTANT: Clean and debur all UPFLOW COMBUSTION AIR AND VENT PIPE CONNECTION pipe cuts. The shavings must not be allowed to block the exhaust, inlet or condensate drain pipes. COMBUSTION “O” RING AIR ADAPTER TOP PLATE UPFLOW FURNACE NOTE: WHEN COMBUSTION AIR INLET IS IN...

-

Page 32: Condensate Drain/Neutralizer

CONDENSATE DRAIN/NEUTRALIZER GENERAL INFORMATION drain is present, install a riser which is a CONDENSATE OVERFLOW: With a minimum of 10 ⁄ ”. If the furnace is ⁄ inch riser installed above the tee, CAUTION installed in an attic, crawlspace or other a blocked drain will result in overflow area where freezing temperatures may from the riser. - Page 33 REVERSING THE TRAP insure a good seal in the burner the trap. Remove the double-elbow compartment. black molded hose from the trap and UPFLOW UNITS exhaust transition and discard. A length of ” black PVC pipe is also The trap may be moved to the right Remove the trap from its mounting provided in the RXGY-H01 downflow side for right side drainage.

-

Page 34: Converting Downflow To Horizontal

CONVERTING DOWNFLOW TO HORIZONTAL Refer to Figure 36 for Steps 6-11. CONDENSATE DRAIN nylon clamp. Then attach the long end of the molded hose to FOR HORIZONTAL 6. Locate the parts bag in the the 45° elbow molded into the INSTALLATION burner compartment. -

Page 36: Gas Supply And Piping

GAS SUPPLY AND PIPING GAS SUPPLY FIGURE 37 GAS PIPING INSTALLATION WARNING UPFLOW THIS FURNACE IS EqUIPPED AT THE FACTORY FOR USE ON GROMMET MAIN GAS NATURAL GAS ONLY. NOTE: WHEN GAS LINE VALVE TOP VIEW OF GAS LINE AND VALVE IS IN OPT. - Page 37 Install a ground joint union inside TABLE 3 the cabinet to easily remove the NATURAL GAS PIPE CAPACITY TABLE (CU. FT./HR.) control valve assembly. Install a manual shut-off valve in the gas Capacity of gas pipe of different diameters and lengths in cu. ft. per hr. with pressure drop of 0.3 in. and specific line outside the furnace casing.

-

Page 38: High Altitude Instructions

LP CONVERSION FIGURE 40 NOTE: See Page 47 for Canadian TYPICAL LP KIT CONTENTS High-Altitude Derate IMPORTANT: LP gas from trucks used to transport liquid-based fertilizers can contain chemicals that will damage the furnace. Verify that your gas supplier does not use the same trucks to transport materials other than LP. - Page 39 SETTING GAS PRESSURE The maximum gas supply pressure Supply Gas Pressure Measure- 6. Replace the pressure tap plug to the furnace should be 10.5" w.c. ment. A line pressure tap is on the before turning on the gas. natural gas, or 13" w.c. LP gas. The input side of the gas valve.

- Page 40 FIGURE 42 MANIFOLD PRESSURE READING FIGURE 43 UPFLOW GROUNDING CONNECTIONS LOW VOLTAGE TERMINALS JUNCTION CONDENSATE TRAP MOUNTING PLATE BLOWER COMPARTMENT CONTROL IS GROUNDED I409-3...

-

Page 41: Electrical Wiring

ELECTRICAL WIRING sense flame if L1 and L2 are reversed. integrated furnace control. The low See Figure 42. voltage wiring should be sized as shown. Make all electrical connections in WARNING NOTE: Do not use 24 volt control accordance with the latest edition of the National Electrical Code ANSI/NFPA70 wiring smaller than No. -

Page 42: Accessories

fireplace, sun rays, lamps, televisions, FURNACE TWINNING UT ELECTRONIC CONTROLS radios or air streams from registers. 1028-928 CONTROL BOARD INSTALLATIONS Refer to instructions packed with the 1. Single Stage Operation thermostat for “heater” selection or Twinning operation of two furnaces, (See Figure 46) adjustment. - Page 43 FIGURE 46 UT Electronic Controls 1028-928 CONTROL BOARD, TWINNING CONNECTION -- SINGLE STAGE OPERATION Control Board 1 Control Board 2...

- Page 44 FIGURE 47 UT ELECTRONIC CONTROLS 1028-928 CONTROL BOARD, TWINNING CONNECTION -- TWO-STAGE OPERATION Control Board 1 Control Board 2...

- Page 45 ALTERNATE METHOD FOR CANADIAN HIGH-ALTITUDE DERATE In Canada, unless an orifice change is Once this field adjustment has been specifically mandated by local codes, an made, the label shown in Figure 48 alternate method of altitude deration must be affixed in a conspicuous through a reduction in manifold pressure location on the front of the furnace is acceptable as described in...

-

Page 46: Start-Up Procedures

START-UP PROCEDURES This furnace is equipped with a direct 5. The inducer completes a 10- SEQUENCE OF OPERATION ignition device. Each time the room second post-purge, the inducer stops, and the control verifies that thermostat calls for heat, the ignitor UT Electronic Controls Direct Spark the pressure switch has opened. - Page 47 ADJUSTING OR CHECKING FURNACE INPUT The maximum gas supply pressure TABLE 8 to the furnace should be 7" w.c. METER TIME for natural gas. The minimum gas supply pressure for purposes of input METER TIME IN MINUTES AND SECONDS FOR NORMAL INPUT RATING OF FURNACES adjustment to the furnace should be EQUIPPED FOR NATURAL OR LP GAS 5"...

-

Page 48: Air Flow

AIR FLOW INSTALLER MUST ADJUST THE FIGURE 49 TEMPERATURE RISE TO THIS TEMPERATURE RISE MEASUREMENT "MIDDLE" POINT AS CLOSELY AS The importance of proper air flow over the POSSIBLE. ALSO, THE heat exchanger cannot be over TEMPERATURE RISE SHOULD emphasized. NEVER BE ABOVE OR FALL BELOW THE STATED RANGE. - Page 49 TABLE 10 90 PLUS AIR FLOW PERFORMANCE – GF951U & GF951D MODELS CFM Air Delivery Motor HP [W] External Static Pressure, Water Column Model Blower Size IN [MM] Spd Tap 1/2 [373] Med. Lo GF951U045AS36 11 x 7 Med. Hi 1140 1110 1085...

- Page 50 SETTING BLOWER GAS FURNACE (DIRECT FIGURE 51 TIMINGS DRIVE) INSTRUCTIONS UT Electronic Controls 1028-928 BLOWER OFF TIMINGS FOR CHANGING BLOWER The Honeywell UT ELECTRONIC SPEED CONTROLS and Invensys Climate Controls IFC’S (Integrated Furnace Controls) have three or four quick WARNING connect terminals for connecting the DISCONNECT THE ELECTRICAL motor speed leads.

-

Page 51: Maintenance

MAINTENANCE TABLE 9 FILTER SIZES WARNING UPFLOW FILTER SIZES FURNACE INPUT BOTTOM SIDE QUANTITY THESE INSTRUCTIONS ARE WIDTH MBTUH SIZE SIZE INTENDED AS AN AID TO ⁄ " 45, 60, 75 ⁄ " X 25" ⁄ " X 25" qUALIFIED SERVICE 21"... - Page 52 FIGURE 55 FILTER LOCATIONS UPFLOW JACKET JACKET ANGLE DRILL (2) JACKET 3/16" DIA. HOLES ANGLE DETAIL ATTACH WITH SHEET METAL 8.000 SCREWS (2 REQÕD) 4.875 FILTER ROD FILTER ROD SUPPORT SUPPORT ANGLE ANGLE 1.531 FILTER SUPPORT FILTER SUPPORT ANGLE ANGLE (SEE ANGLE DETAIL) (SEE ANGLE DETAIL) CUT-OUT AND DRILL DETAIL...

-

Page 53: Wiring Diagram

ENTRAINED IN ThE AIR mAy 4. Avoid excessive use of kitchen WARNING TEmPORARILy LODGE IN ThE AIR exhaust fans. HOLES IN THE VENT PIPE OR DUCT RUNS AND AT ThE SUPPLy 5. Do not permit the heat generated HEAT EXCHANGER CAN CAUSE REGISTERS. -

Page 54: Troubleshooting

FIGURE 56 GF951U & GF951D MODELS W/INTEGRATED FURNACE CONTROL (IFC) UT Electronic Controls 1012-925 (115 VAC IGNITER) INTEGRATED FURNACE CONTROL (IFC) WARNING TROUBLESHOOTING GUIDE HAZARDOUS VOLTAGE DISCONNECT POWER BEFORE SERVICING. NOTE: Most failures are not due to the IFC. Double check all other LINE VOLTAGE SERVICE MUST BE BY A TRAINED, QUALIFIED possibilities, including the ground connection, before replacing the IFC. - Page 55 FIGURE 57 GF951D MODELS WITH UT ELECTRONIC CONTROLS 1028-928 & SPARK IGNITION...

- Page 56 CM 0312...

Need help?

Do you have a question about the GF951U Series and is the answer not in the manual?

Questions and answers