Table of Contents

Advertisement

Quick Links

Installation Instructions

Original Instructions

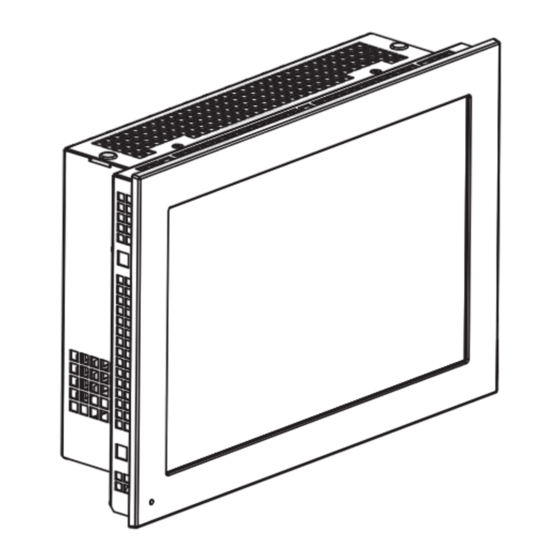

OptixPanel Standard Operator Panels

Bulletin 2800S

Safety instructions

ATTENTION: Read this document and the documents listed in the Additional Resources section about installation, configuration, and operation of this

equipment before you install, configure, operate, or maintain this product. Users are required to familiarize themselves with installation and wiring

instructions in addition to requirements of all applicable codes, laws, and standards. Activities including installation, adjustments, putting into service,

use, assembly, disassembly, safety, and maintenance are required to be carried out by suitably trained personnel in accordance with applicable code of

practice. If this equipment is used in a manner not specified by the manufacturer, the protection provided by the equipment may be impaired.

Environment and Enclosure Information

U Compliance

ATTENTION: This equipment is intended for use in a Pollution Degree 2 Industrial Environment, in Overvoltage Category II applications (as defined in

IEC 60664-1), at altitudes up to 2000 m (6561 ft) without derating. This equipment is considered Group 1, Class A industrial equipment according to EN

61326-1. Without appropriate precautions, there can be potential difficulties with electromagnetic compatibility in other environments caused by

conducted as well as radiated disturbance. This equipment is supplied as open-type equipment for indoor use. It must be mounted within an enclosure

that is suitably designed for those specific environmental conditions that will be present and appropriately designed to prevent personal injury resulting

from accessibility to live parts. The interior of the enclosure must be accessible only by the use of a tool. Subsequent sections of this publication may

contain additional information regarding specific enclosure type ratings that are required to comply with certain product safety certifications. In

addition to this publication, see the following:

• Industrial Automation Wiring and Grounding Guidelines, publication 1770-4.1, for more installation requirements.

• UL 50, UL 50E, CSA C22.2, No. 94.1, and CSA C22.2, No. 94.2, as applicable, for explanations of the degrees of protection provided by enclosures.

Equipment with the UL/cUL mark complies with the requirements of UL 61010-1, UL 61010-2-201, CSA C22.2 No. 61010-1, CSA C22.2 No. 61010-2-201. Copies of the certificate of

compliance are available at rok.auto/certifications.

Installation guidelines

ow these guidelines to make sure that your operator panel provides service with excellent reliability

WARNING: Special Conditions for Safe Use:

• The ambient temperature range is 0...50 °C (32...122 °F).

• Subject devices are to be installed in a tool-only accessible enclosure that provides a degree of protection not less than IP54 in accordance with IEC/EN

60079-0, Explosive atmospheres – Part 0: Equipment – General requirements and IEC/EN 60079-7, Explosive atmospheres – Part 7: Equipment

protection by increased safety "e". Enclosure is to be marked with the following: "Warning - Do not open when energized". After installation of subject

devices into the enclosure, access to termination compartments shall be dimensioned so that conductors can be readily connected. Grounding

conductor should have a minimum cross-sectional area of 1.5 mm² (16 AWG).

• Subject devices are for use in an area of not more than pollution degree 2 in accordance with IEC 60664-1.

• Subject devices are to use copper conductors with a minimum conductor temperature rating of 75 °C (167 °F).

• Subject devices are to be installed in the vertical orientation only.

AVERTISSEMENT:Conditions particulières d'utilisation sécuritaire :

• La plage de température ambiante est de 0...50 °C (32...122 °F).

• Les dispositifs en question doivent être installés dans un boîtier accessible uniquement aux outils qui offre un degré de protection au moins égal à IP54

conformément à la norme CEI/EN 60079-0, Atmosphères explosives – Partie 0 : Équipement – Exigences générales et à la norme CEI/EN 60079-7,

Atmosphères explosives – Partie 7 : Protection de l'équipement par une sécurité accrue « e ». L'annexe doit porter la mention suivante : « Avertissement

- Ne pas ouvrir lorsqu'il est sous tension ». Après l'installation des dispositifs en question dans l'enceinte, l'accès aux compartiments de terminaison

doit être dimensionné de sorte que les conducteurs puissent être facilement raccordés. Le conducteur de mise à la terre doit avoir une section

transversale minimale de 1,5 mm² (16 AWG).

• Les dispositifs en question doivent être utilisés dans une zone ne dépassant pas le degré de pollution 2 conformément à la norme CEI 60664-1.

• Les dispositifs visés doivent utiliser des conducteurs en cuivre dont la température nominale minimale est de 75 °C (167 °F).

• Les dispositifs en question ne doivent être installés qu'à la verticale.

Advertisement

Table of Contents

Summary of Contents for Rockwell Automation Allen-Bradley OptixPanel

- Page 1 Installation Instructions Original Instructions OptixPanel Standard Operator Panels Bulletin 2800S Safety instructions ATTENTION: Read this document and the documents listed in the Additional Resources section about installation, configuration, and operation of this equipment before you install, configure, operate, or maintain this product. Users are required to familiarize themselves with installation and wiring instructions in addition to requirements of all applicable codes, laws, and standards.

-

Page 2: Mounting Requirements

255.5 (10.05) 174.0 (6.85) 15.6 388.0 (15.27) 237.5 (9.35) 10.4 285.0 (11.22) 220 (8.66) 18.5 453.0 (17.83) 274.0 (10.78) 12.1 315.0 (12.40) 250 (9.84) 21.5 520.0 (20.47) 311.5 (12.26) 12.1 301.0 (11.85) 203.0 (7.99) Rockwell Automation Publication 2800S-IN001B-EN-P - June 2023... - Page 3 According to the tighten sequence in Figure 1, tighten the mounting clips (G) with the supplied hexagonal key and verify the torque of 0.2 N•m (1.8 lb•in) with a limiting screwdriver (requires a 1.5 mm hex key bit). Rockwell Automation Publication 2800S-IN001B-EN-P - June 2023...

- Page 4 Allows the total restoration of the firmware and factory settings with the deletion of all application data. button Power supply ON and Boot sequence FAIL. Restart / — Restart button pressed. Power LED Green Power supply ON and correct BOOT sequence. Rockwell Automation Publication 2800S-IN001B-EN-P - June 2023...

- Page 5 Half cover with cable tie slot — Half closing cover — Remove the DC terminal block (5) from the operator panel. Use wires not included, (1) (2) (3) with 1.5mm (16 AWG) cross section. Rockwell Automation Publication 2800S-IN001B-EN-P - June 2023...

- Page 6 Insert the zip tie around the LAN cable and the beveled edge of the plate (1) Metallic plates (qty: 2) [step (C)]. M3 screws (qty: 2) Tighten the tie (2) and remove the excess part [step (D)]. Zip ties (qty: 2) Rockwell Automation Publication 2800S-IN001B-EN-P - June 2023...

-

Page 7: Atex Certification

The systems must be installed, managed and updated only by qualified personnel. The non-compliance with the safety instructions present into this document can result in death or serious injury. No responsibility is assumed by Rockwell Automation for any consequence arising from the improper use of the system in respect to the contents of the present document. -

Page 8: Rockwell Automation Support

Rockwell Otomasyon Ticaret A.Ş. Kar Plaza İş Merkezi E Blok Kat:6 34752 İçerenköy, İstanbul, Tel: +90 (216) 5698400 EEE Yönetmeliğine Uygundur *PN-696495* Allen-Bradley, expanding human possibility, OptixPanel, and Rockwell Automation are trademarks of Rockwell Automation, Inc. PN-696495 Trademarks not belonging to Rockwell Automation are property of their respective companies.

Need help?

Do you have a question about the Allen-Bradley OptixPanel and is the answer not in the manual?

Questions and answers