Summary of Contents for Alfa Laval M200

- Page 1 Alfa Laval M Gear Gear Pump 3300-0000 Instruction Manual Lit. Code 200009584-1-EN-GB BRITISH ENGLISH...

- Page 2 © Alfa Laval AB 2023-06 This document and its contents are subject to copyrights and other intellectual property rights owned by Alfa Laval AB (publ) or any of its affiliates (jointly “Alfa Laval”). No part of this document may be copied, re-produced or transmitted in any form or by any means, or for any purpose, without Alfa Laval’s prior express written permission. Information and services provided in this document are made as a benefit and service to the user, and no representations or warranties are made about the accuracy or suitability of this information and these services for any purpose.

-

Page 3: Table Of Contents

6 Maintenance ......................21 Disassembly......................22 Assembly.........................23 6.2.1 Assemble Drive Shaft Assembly..............23 6.2.2 Assemble Pump..................25 Troubleshooting.......................27 7 Technical Data ......................29 Weights........................29 Dimensions......................30 8 Spare Parts .........................31 Ordering Spare Parts....................31 Alfa Laval Service....................31 9 Parts List and Exploded View ................ 33... - Page 4 This page is intentionally left blank.

-

Page 5: Declarations Of Conformity

1 Declarations of Conformity 1.1 EU Declaration of Conformity The Designated Company Alfa Laval Kolding A/S, Albuen 31, DK-6000 Kolding, Denmark, +45 79 32 22 00 Company name, address and phone number Hereby declare that Pump Designation M200; M210; M220 Type Serial number from E10.000 to E1.000.000... -

Page 6: Declaration Of Conformity

1 Declarations of Conformity 1.2 UK Declaration of Conformity The Designated Company Alfa Laval Kolding A/S, Albuen 31, DK-6000 Kolding, Denmark, +45 79 32 22 00 Company name, address and phone number Hereby declare that Pump Designation M200; M210; M220 Type Serial number from E10.000 to E1.000.000... -

Page 7: Safety

Not following the instructions can result in serious accidents. This documentation describes the authorized way to use the supplied product. Alfa Laval will take no responsibility for injury or damage if the equipment is used in any other way. This Instruction manual is designed to provide the user with the information to perform tasks safely for all phases in the lifetime of the supplied product. - Page 8 Always have the pump electrically connected by authorized personnel. (See the motor in- struction supplied with the drive unit) Alfa Laval recommends the supply disconnecting device shall be in accordance with EN 60204-1. Operation Never stand on the pump or pipelines.

- Page 9 Always ensure that the unit is securely fixed during transportation Always use original packaging or similar during transportation Always use a suitable transport device i.e. forklift truck or pallet lifter Storage Ideally, as a guide Alfa Laval recommend: • Store supplied product as supplied in original packaging •...

- Page 10 Ensure that screws for the protective device are securely tightened Procedure in case of non-acceptance: • Fix and/or replace the protective device How to contact Alfa Laval Contact details for all countries are continually updated on our website. Please visit www.alfalaval.com to access the information directly. 200009584-1-EN-GB...

-

Page 11: Warning Signs In Text

Safety 2 2.2 Warning Signs in Text Pay attention to the safety instructions in this manual. Below are definitions of the four grades of warning signs used in the text where there is a risk for injury to personnel or product damage. DANGER Indicates an imminently hazardous situation which, if not avoided, will result in death or serious injury. -

Page 12: Requirements Of Personnel

How to contact Alfa Laval Contact details for all countries are continually updated on our website. Please visit www.alfalaval.com to access the information directly. -

Page 13: Recycling Information

Besides the equipment itself, any hazardous residues from the process liquid must be considered and dealt with in a proper manner. When in doubt, or in the absence of local regulations, please contact your local Alfa Laval sales company. 200009584-1-EN-GB... - Page 14 This page is intentionally left blank.

-

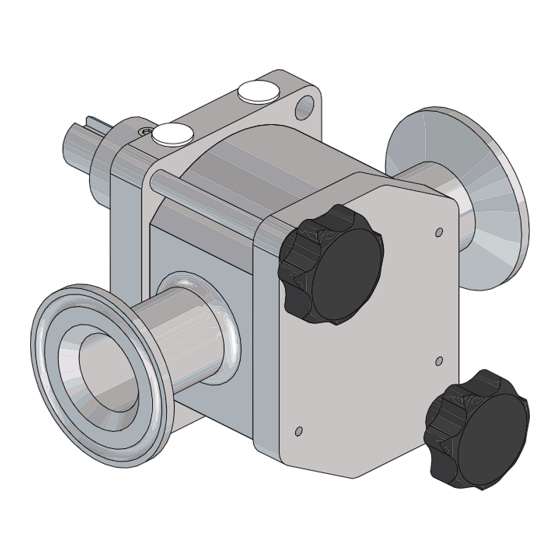

Page 15: Introduction

3 Introduction The Alfa Laval M Gear is an external gear pump that efficiently transfers low- volume fluids for filling applications. Precision alignment, easy cleaning and simple maintenance make the stainless-steel M Gear pump a solid choice for dosing, sampling and filling machines. This proven rotary positive displacement pump easily adapts to OEM filling machines. - Page 16 3 Introduction Pump Limits of Application and Use This pump has been designed for pumping a range of clean, semi-solid viscous products for transfer, dosing and sampling in the food, chemical and associates industries. Pressures up to 7 bar, speeds up to 1360 rpm and temperatures up to 60°C can be obtained on this pump range depending on model.

-

Page 17: Installation

4 Installation 4.1 Unpacking and Handling Receipt and unpacking On receipt always: • Check the delivery note against good received • If motorised check that the drive instructions are available • Inspect packing for signs of damage in transit • Carefully remove packing away from the pump •... - Page 18 This page is intentionally left blank.

-

Page 19: Operation

5 Operation 5.1 Commissioning and Start Up Pump Lubrication The M Gear pump range does not require any external lubrication. Pre-Start Up Checks • Check the pipework systems has been flushed to remove debris such as welding slag or other hard solids •... - Page 20 This page is intentionally left blank.

-

Page 21: Maintenance

6 Maintenance Maintenance Schedule The below checks are to be carried out when the pump is not operational and any electrical supply has been safely disconnected and isolated so accidental operation cannot occur. In certain circumstances the pump will pose a thermal hazard and as such should not be touched until allowed to reach a safe temperature before undertaking checks. -

Page 22: Disassembly

6 Maintenance 6.1 Disassembly Before dismantling the pump refer to safety precautions in Section Safety on page 7. Refer to exploded diagram and parts list in Section Parts List and Exploded View on page 33. NOTE It is recommended to mark positions of the gears, body and cover (e.g. Top/Bottom or Left/Right) prior to removal to ensure parts are refitted in the same position. -

Page 23: Assembly

Maintenance 6 Remove the drive shaft assembly (19) complete with the rear bush (9), gear (20) and seal assembly. NOTE: The back plate (2) can remian fixed to the motor (or other mounting as applicable) whilst dismantling is carried out. 3300-0014 Loosen the seal retaining screws (13) and remove the seal assembly and rear bush (9) - Page 24 6 Maintenance Fit O-ring (18) on to stationary seal ring (17) over the seal face end then fit stationary seal ring to the shaft, alinging the tabs on the seal ring with the slots in the rear bush. Clean seal face with a suitible solvent.

-

Page 25: Assemble Pump

Maintenance 6 Tighten retaining screws (13) equally and gradually until hand tight. 6.2.2 Assemble Pump Fit one rear bush (9) in to the bore in the back plate (2) with the flat side towards the middle of the pump. 3300-0021 Press, by hand, the drive shaft assembly into (through) the bore in the back plate (2) untill fully seated, making sure the flat sides of the... - Page 26 6 Maintenance Fit 1 of the O-rings (5) to the back of the body (1). The ports are offset from the centerline of the body, with the narrowest width towards the back (as shown). >X 3300-0024 Slide body (1) over the gears and locate it on the rear bushes.

-

Page 27: Troubleshooting

Maintenance 6 6.3 Troubleshooting Problem 1. No discharge 6. Pump overheats 11 .Excessive primary seal wear 12. Product loss through primary 2. Under capacity 7. Motor overheats seal 3. Irregular discharge 8. Excessice power absorbed 13. Seizure 4. Prime lost after starting 9. - Page 28 6 Maintenance Problem Causes Remedies 10 11 12 13 Flexible coupling mis- Check alignment & adjust • aligned mounts accordingly Insecure pump drive Fit lock washers to loose • • • • • • mounts fasteners & retighten Shaft bearing wear of Refer to pump manual for •...

-

Page 29: Technical Data

Pump Data Table Pump Mod- Speed Flow Rate (65 cp Prod- Port Size Max. Working Pressure Max. Speed uct) (rpm) (l/hr) usgpm inch rev/min 1.10 M200 1.43 1360 1360 2.13 1.76 M210 2.31 1360 1/2” / 1” 1360 3.43 3.39... -

Page 30: Dimensions

7 Technical Data 7.2 Dimensions 3300-0007 Dimensions (mm) Models M200 42.3 13.2 75.5 M210 42.3 13.2 75.5 M220 42.3 15.9 *1 = 1/2" BSP *2 = 1" Triclamp / SMS *3 = 1" DIN11851 Dimensions (inch) Mod- M200 1 2.36 2.44... -

Page 31: Spare Parts

Alfa Laval representative for availability. You can find our spare part catalogue at https://hygienicfluidhandling-catalogue.alfalaval.com/ Always use Alfa Laval genuine spare parts. The warranty of Alfa Laval products is dependent on use of Alfa Laval genuine spare parts. 8.1 Ordering Spare Parts When ordering spare parts, please always state: 1. - Page 32 This page is intentionally left blank.

-

Page 33: Parts List And Exploded View

9 Parts List and Exploded View Item Description Item Description Body Static Seat Back Plate O-ring Cover 19, 20, 21 Drive Shaft Assembly Bush, Front 20, 21, 22 Auxillery Shaft Assembly Joint ring Stud Motor Flange Bracket (if applicable) Nut, Quick Release Screw Plug Washer...

Need help?

Do you have a question about the M200 and is the answer not in the manual?

Questions and answers