Alfa Laval LKH-5 Instruction Manual

Gm centrifugal pump

Hide thumbs

Also See for LKH-5:

- Installation manual (60 pages) ,

- Instruction manual (56 pages) ,

- Instruction manual (76 pages)

Summary of Contents for Alfa Laval LKH-5

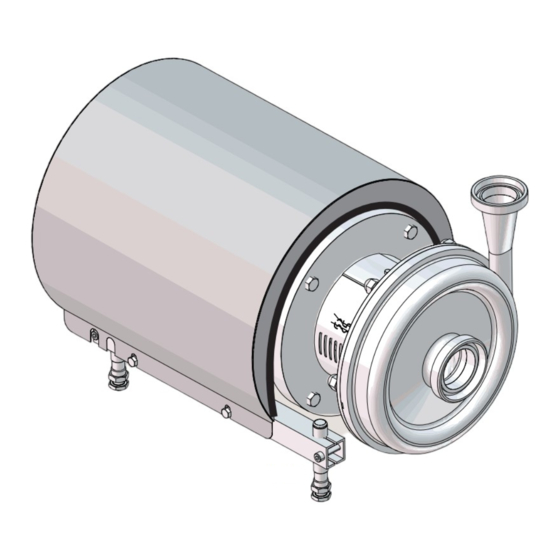

- Page 1 Instruction Manual GM Centrifugal Pump 3010-0008 ESE02002-EN4 2017-06 Original manual...

-

Page 3: Table Of Contents

Table of contents The information herein is correct at the time of issue but may be subject to change without prior notice 1. EC Declaration of Conformity ............... 2. Safety ....................2.1. Important information ................2.2. Warning signs ..................2.3. Safety precautions ................3. -

Page 4: Ec Declaration Of Conformity

1 EC Declaration of Conformity Revision of Declaration of Conformity 2009-12-29 The Designated Company Alfa Laval Kolding A/S Company Name Albuen 31, DK-6000 Kolding, Denmark Address +45 79 32 22 00 Phone No. hereby declare that Pump Designation GM, GM-A Type From serial number 10.000 to 1.000.000... -

Page 5: Safety

2 Safety Unsafe practices and other important information are emphasised in this manual. Warnings are emphasised by means of special signs. Always read the manual before using the pump! 2.1 Important information WARNING Indicates that special procedures must be followed to avoid serious personal injury. CAUTION Indicates that special procedures must be followed to avoid damage to the pump. -

Page 6: Safety Precautions

Always handle lye and acid with great care. Never use the pump for products not mentioned in the Alfa Laval pump selection program. The Alfa Laval pump selection program can be acquired from your local Alfa Laval sales company. Maintenance: Always read the technical data thoroughly. -

Page 7: Installation

Check the delivery for: 1. Complete pump. CAUTION 2. Delivery note. Alfa Laval cannot be held responsible for incorrect unpacking. 3. Motor instructions. 4. Test certificate, IF ORDERED! Step 2 Remove any packing materials from the inlet and the outlet. -

Page 8: Installation

Alfa Laval cannot be held responsible for incorrect installation. WARNING: Alfa Laval recommend the installation of a lockable repair breaker. If the repair breaker is to be used as an emergency stop, the colours of the repair breaker must be red and yellow. - Page 9 3 Installation Study the instructions carefully and pay special attention to the warnings! Always check the pump before operation. - See pre-use check in section 3.3 Pre-use check - GM-A. Step 5 Avoid stressing the pump. Pay special attention to: - Vibrations.

-

Page 10: Pre-Use Check - Gm-A

- At end of use, the equipment shall be recycled according to relevant local regulations. Beside the equipment itself, any hazardous residues from the process liquid must be considered and dealt with in a proper manner. When in doubt, or in the absence of local regulations, please contact your local Alfa Laval sales company. -

Page 11: Operation

4.1 Operation/control Step 1 Always read the technical data thoroughly. See chapter 6 Technical data CAUTION Alfa Laval cannot be held responsible for incorrect operation/control. Step 2 Danger of burns! Never touch the pump or the pipelines when pumping hot liquids or when sterilising. -

Page 12: Trouble Shooting

4 Operation Pay attention to possible faults. Study the instructions carefully. 4.2 Trouble shooting NOTE! Study the maintenance instructions carefully before replacing worn parts. Problem Remedy Cause/result Overloaded motor - Pumping of viscous liquids - Smaller impeller - Pumping of high-density liquids - Low outlet pressure (counter pressure) - Higher counter pressure (throttling) Cavitation: - Damage... -

Page 13: Recommended Cleaning

4 Operation The pump is designed for cleaning in place (CIP). CIP = Cleaning In Place. Study the instructions carefully and pay special attention to the warnings! NaOH = Caustic Soda. = Nitric acid. 4.3 Recommended cleaning Step 1 Danger, caustic Always handle lye and acid with great care. -

Page 14: Maintenance

(see chapter 7 Parts list and service kits). Ordering spare parts Contact your local Alfa Laval sales company. Note: If the pump is supplied with FEP O-rings, Alfa Laval recommend the casing O-ring is replaced when the pump is maintained. - Page 15 5 Maintenance Maintain the pump carefully. Study the instructions carefully and pay special attention to the warnings! Always keep spare shaft seals and rubber seals in stock. See separate motor instructions. Check the pump for smooth operation after service. Shaft seal Rubber seals Motor bearings Preventive maintenance...

-

Page 16: Dismantling Of Pump/Shaft Seals

5 Maintenance Study the instructions carefully. The items refer to the parts list and service kits section. Handle scrap correctly. : Relates to the shaft seal. 5.2 Dismantling of pump/shaft seals Step 1 1. Remove cap nuts (13). 2. Remove collets (14a) (GM only) or yoke (14b) (GM-A only). 3. -

Page 17: Assembly Of Pump/Shaft Seal

5 Maintenance Study the instructions carefully. The items refer to the parts list and service kits section. Lubricate the rubber seals before fitting them. 5.3 Assembly of pump/shaft seal Step 1 1. Fit pump shaft (7) on the motor shaft. 2. -

Page 18: Technical Data

6 Technical data It is important to observe the technical data during installation, operation and maintenance. Inform personnel about the technical data. 6.1 Technical data The GM centrifugal pump is specially designed for food, chemical, pharmaceutical and other industries where acid-resistant steel is resistant to the product to be pumped. -

Page 19: Torque Specifications

6 Technical data It is important to observe the technical data during installation, operation and maintenance. Inform personnel about the technical data. 6.2 Torque specifications The table below specifies the tightening torques for the screws, bolts and nuts in this pump. Always use below torques if no other values are stated. -

Page 20: Noise Emission

6 Technical data It is important to observe the technical data during installation, operation and maintenance. Inform personnel about the technical data. 6.4 Noise emission Pump Type Sound pressure level (dBA) LKH-5 LKH-10 LKH-15 LKH-20 LKH-25 LKH-35 LKH-40 LKH-45 LKH-50... -

Page 21: Parts List And Service Kits

7 Parts list and service kits The drawing shows GM/GM-A pump, sanitary version. The items refer to the parts lists in the following sections 7.1 GM/GM-A TD201-027_1... -

Page 22: Gm Centrifugal Pump

7 Parts list and service kits The drawing shows GM pump, sanitary version. The items refer to the parts lists in the following sections 7.2 GM Centrifugal Pump... - Page 23 7 Parts list and service kits The drawing shows GM pump, sanitary version. The items refer to the parts lists in the following sections Parts list Service kits Denomination GM-1 & 2 Pos. Denomination Service kit Motor 0.55 kW 220-240/380-420 Service kit, NBR.

-

Page 24: Gm-A Centrifugal Pump

7 Parts list and service kits The drawing shows GM-A pump, sanitary version. The items refer to the parts lists in the following sections 7.3 GM-A Centrifugal Pump... - Page 25 7 Parts list and service kits The drawing shows GM-A pump, sanitary version. The items refer to the parts lists in the following sections Parts list Service kits Denomination GM-1A & 2A Pos. Denomination Service kit Motor IEC71 Service kit, NBR........9611921046 Stud bolt Service kit, EPDM.

- Page 28 © Alfa Laval Corporate AB This document and its contents is owned by Alfa Laval Corporate AB and protected by laws governing intellectual property and thereto related rights. It is the responsibility of the user of this document to comply with all applicable intellectual property laws. Without limiting any rights related to this document, no part of this document may be copied, reproduced or transmitted in any form or by any means (electronic, mechanical, photocopying, recording, or otherwise), or for any purpose, without the expressed permission of Alfa Laval Corporate AB.

Need help?

Do you have a question about the LKH-5 and is the answer not in the manual?

Questions and answers