Summary of Contents for Inficon UL3000 Fab ULTRA

- Page 1 Translation of the original operating instructions UL3000 Fab ULTRA ™ Helium Leak Detector with ULTRATEST Sensor Technology Catalog No. 550-260 From software version iinb73en1-09-(2109) 1.51 (Operating unit)

- Page 2 INFICON GmbH Bonner Strasse 498 50968 Cologne, Germany...

-

Page 3: Table Of Contents

INFICON Table of Contents Table of Contents 1 About this manual............................. 8 1.1 Target groups ............................ 8 1.2 Warnings.............................. 8 1.3 Definition of terms............................. 8 2 Safety ................................ 11 2.1 Intended use ............................ 11 2.2 Duties of the operator .......................... 13 2.3 Owner requirements .......................... 13 2.4 Dangers .............................. 14 3 Scope of delivery, Transport, Storage ...................... 15... - Page 4 Table of Contents INFICON 5.1 Setup .............................. 38 5.2 Connect the supplied accessories ...................... 42 5.3 Fastening bracket for sniffer line SL3000 (accessory, optional) ............. 48 5.4 Connecting to the power supply system .................... 49 5.5 Checking the operation of the device ..................... 49 6 Operation................................ 51 6.1 Switching on ............................ 51...

- Page 5 INFICON Table of Contents 6.3.5.1 Consider the background of the test chamber .............. 69 6.3.6 HYDRO•S ........................... 69 6.3.6.1 Set HYDRO•S ........................ 69 6.3.6.2 Use HYDRO•S ........................ 70 6.3.7 Setting the machine factor ...................... 70 6.3.8 Set external calibration leak...................... 71 6.3.9 Change pressure limits ....................... 71 6.3.10 Set and use the function ZERO ....................

- Page 6 Table of Contents INFICON 6.8.2 Call calibration log........................ 87 6.8.3 Call maintenance log ........................ 87 6.8.4 Call result log .......................... 87 6.9 Device settings ............................ 88 6.9.1 Viewing and customizing individual parameters ................. 88 6.9.2 Saving and managing sets of parameters .................. 88 6.9.3 Exporting or importing sets of parameters ..................

- Page 7 INFICON Table of Contents 10.2.1 Create a connection between the device and the I/O module .......... 128 10.2.2 Configuring analog outputs ....................... 128 10.2.3 Configure digital inputs ...................... 130 10.2.4 Configuring digital outputs ...................... 131 10.2.5 Setting up the I/O module protocol ................... 133 10.3 Bus module............................ 133...

-

Page 8: About This Manual

1 | About this manual INFICON 1 About this manual This document applies to the software version stated on the title page. Product names may occur in the document, which are added for identification purposes only and belong to the respective owner of the rights. - Page 9 INFICON About this manual | 1 Automatic tuning / mass setting This function adjusts the mass spectrometer so that a maximum leak rate indicator is achieved. In order to detect a maximum ion current with the ion detector, the control computer adjusts the voltage for accelerating the ions within the selected mass range accordingly.

- Page 10 1 | About this manual INFICON Minimum detectable leak rate The minimum detectable leak rate which can be detected by the leak detector under ideal conditions (< 5 x 10 mbar l/s). MASSIVE After selecting the vacuum range "MASSIVE" gross leaks can now be measured from atmospheric pressure.

-

Page 11: Safety

INFICON Safety | 2 2 Safety 2.1 Intended use The device is a leak detector for detecting and measuring leaks in test objects. The device is suitable for leak detection using the vacuum method and the sniffer method. • Operate the device only according to this instruction manual. - Page 12 2 | Safety INFICON • Operation without exhaust pipe in poorly ventilated rooms, depending on the type of gases used Note: This device is not intended to be used in living areas. 12 / 152 UL3000-Fab-ULTRA-Operating-instructions-iinb73en1-09-(2109)

-

Page 13: Duties Of The Operator

INFICON Safety | 2 2.2 Duties of the operator • Read, observe, and follow the information in this manual and in the work instructions provided by the owner. This concerns in particular the safety and warning instructions. • Always observe the complete operating instructions for all work. -

Page 14: Dangers

2 | Safety INFICON 2.4 Dangers The measuring instrument was built according to the state-of-the-art and the recognized safety regulations. Nevertheless, improper use may result in risk to life and limb on the part of the user or third parties, or damage to the unit or other property may occur. -

Page 15: Scope Of Delivery, Transport, Storage

INFICON Scope of delivery, Transport, Storage | 3 3 Scope of delivery, Transport, Storage Scope of delivery Item Quantity UL3000 Fab ULTRA Exhaust hose adapter ISO-KF flange DN25 Hooks Power cable strain relief Screws M6 x 12 Guard washer S6... - Page 16 3 | Scope of delivery, Transport, Storage INFICON WARNING Risk of injury due to improper transport of a gas cylinder on the mobile leak detector ► When mounting the bottle holder on the leak detector, follow the sequence of action steps as described in the separate mounting instructions.

- Page 17 INFICON Scope of delivery, Transport, Storage | 3 CAUTION Risk of injury due to limited parking brakes Without properly functioning parking brakes, unintentional movements of the device and injuries may occur. ► To ensure proper functioning of the parking brakes, remove the adhesive strips from the wheels.

-

Page 18: Description

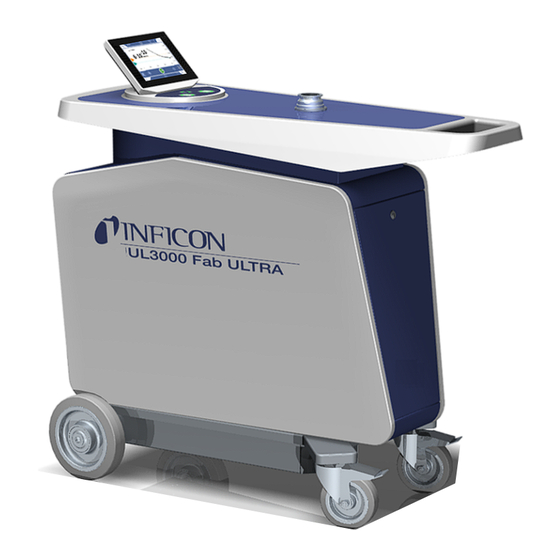

4 | Description INFICON 4 Description 4.1 Function The device is a leak detector for detecting and measuring leaks in test objects. The device is suitable for leak detection using the vacuum method and the sniffer method. It uses the ULTRATEST sensor technology. -

Page 19: Operation Mode "Sniffing

INFICON Description | 4 4.2.2 Operation mode "Sniffing" To scan test objects under overpressure with a sniffer probe, you can connect the SL200 sniffer line or the SL3000 sniffer line. SL200 The vacuum connection of the sniffer line SL200 is connected to the upper side of the device on the inlet flange. -

Page 20: Operation Mode "Auto Leak Test

4 | Description INFICON Acknowledge calibration via a button on the sniffer probe 4.2.3 Operation mode “Auto Leak Test” In this mode, you can perform tests on hermetically sealed components with automated processing. If the optional test chamber TC1000 is used, the test starts automatically when the cover is closed. - Page 21 INFICON Description | 4 Fig. 2: Front view with open flap. UL3000-Fab-ULTRA-Operating-instructions-iinb73en1-09-(2109) 21 / 152...

- Page 22 4 | Description INFICON Fig. 3: Back view. The picture shows standard accessories and optional accessories. 22 / 152 UL3000-Fab-ULTRA-Operating-instructions-iinb73en1-09-(2109)

-

Page 23: Control Unit

INFICON Description | 4 4.3.2 Control unit Fig. 4: Control unit - front view The control unit consists of a touchscreen and a control panel with the buttons START, Stop and ZERO (background suppression) on the housing. See also "Assembly of the touchscreen [} 27]", see also "START button [} 24]". -

Page 24: Start Button

4 | Description INFICON Fig. 5: Control unit - rear view HDMI interface • For connection to the HDMI interface of a touch monitor, maximum cable length 3 m. See also "Use external monitor [} 91]". 2 / 3 USB 2.0 Interfaces •... -

Page 25: Stop Button

INFICON Description | 4 • If you press the START button on the control panel during measurement, the maximum leak rate display is updated. Function Touchscreen Control panel Starting START button Display maximum leak rate Cannot be operated Press the START button via touchscreen again. -

Page 26: Meaning Of The Button Leds

4 | Description INFICON The actual measured leak rate is considered to be a background signal. Depending on the selected variant of operation mode the background signal is hidden until the display limit of the respective vacuum range is reached. -

Page 27: Meaning Of The Status Led

INFICON Description | 4 4.3.2.5 Meaning of the status LED The status LED is located on the back of the instrument inside of the connector block for the equipment and control signals, see also "Connections for accessories and control signals [} 31]”. - Page 28 4 | Description INFICON Previous page Measurement value Access control Leak rate Next page Navigation button WLAN User name Max. Settings Navigation button Leak rate Operation Supervisor Measurement value Inlet pressure ZERO Setpoints ZERO Switching: Line chart Bar chart ULTRA...

-

Page 29: Vacuum Connections

INFICON Description | 4 Call up help for the current function Confirm entry or selection Load Save Edit Copy Delete WLAN Next page Previous page Table 2: Function buttons Other symbols Authorization “User“ Authorization “Operator“ Authorization “Supervisor“ View the time or set the time See also "Overview of Rights Groups [} 52]". -

Page 30: Exhaust

4 | Description INFICON 4.3.3.2 Exhaust WARNING Danger of poisoning due to harmful gases Depending on the connected container and the gas contained therein, harmful gases can get into the ambient air via the exhaust filter of the leak detector. -

Page 31: Connections For Accessories And Control Signals

INFICON Description | 4 4.3.4 Connections for accessories and control signals SNIFFER Power switch ACCESSORIES Connection for mains cable Venting connection REMOTE CONTROL SERVICE Purge gas connection Fig. 6: Connections for accessories and control signals SNIFFER For connecting the sniffer line SL3000... -

Page 32: Markings On The Device

4 | Description INFICON 4.3.5 Markings on the device Device cannot be scrapped with the normal domestic waste. 4.4 Technical specifications Mechanical data UL3000 Fab ULTRA Dimensions (L × W × H) 1050 mm × 472 mm × 990 mm Weight 132 kg Inlet flange... - Page 33 INFICON Description | 4 Physical data UL3000 Fab ULTRA Minimum detectable leak rate, vacuum 5·10 mbar l/s mode Response time, blind-flanged < 1 s Maximum inlet pressure (Vacuum range Ambient pressure MASSIVE) Helium pumping speed (Vacuum range 4l/s ULTRA) Air suction capacity of the backing pump...

-

Page 34: Factory Settings

4 | Description INFICON 4.5 Factory settings Leak rate setpoint 1 1 x10 mbar l/s Leak rate setpoint 2 1 x10 mbar l/s Leak rate setpoint 3 1 x10 mbar l/s Leak rate setpoint 4 1 x10 mbar l/s Automatic purge... - Page 35 INFICON Description | 4 Digital input pin 10 (IO1000) No function Machine factor vacuum mass 2 Machine factor vacuum mass 3 Machine factor vacuum mass 4 Leak rate filter I•CAL Cathode Cathode 1 auto (can only be changed by service) Lower pressure limit SL200 capillary 0.1 mbar...

- Page 36 4 | Description INFICON Particle protection Background suppression internal only Ventilation delay manually Device at the LD connection I/O module Maintenance messages all activated Vacuum ranges MASSIVE, GROSS, FINE and ULTRA (all ON) Bus module address Calibration leak external vacuum Hydrogen...

- Page 37 INFICON Description | 4 Decades Autoscale Lower diagram limit 1 × 10 Time axis 30 s Bar chart Scaling Logarithmic Decades Autoscale Lower diagram limit 1 × 10 Circle chart Decades Autoscale Lower diagram limit 1 × 10 Data recording Export format...

-

Page 38: Installation

5 | Installation INFICON 5 Installation 5.1 Setup DANGER Danger due to electric shock The mains cable connected at both ends may be damaged or the wall socket may be torn out if the leak detector is moved and the mains cable is tensioned as a result. - Page 39 INFICON Installation | 5 WARNING Fire hazard due to overload, short circuit and overheating ► Observe the permissible ambient conditions. ► Ensure sufficient ventilation, especially on the ventilation slots on the left and right of the device: There should be free space in the front, to the rear and sides of the unit of at least 10 cm.

- Page 40 5 | Installation INFICON CAUTION Danger of bruising extremities Feet can be rolled over and crushed. ► Keep feet away from the rollers. ► Do not pull the device. ► Hold the device by the provided handle only and slide it.

- Page 41 INFICON Installation | 5 Observe the information on transporting the device, see also “Scope of delivery, Transport, Storage“. Procedure • So that measurement results are not falsified, use in an area that has a constant ambient temperature if possible. • For proper functioning of wheels and brakes, remove the adhesive strips from the wheels.

-

Page 42: Connect The Supplied Accessories

5 | Installation INFICON 5.2 Connect the supplied accessories Install the “Hook for power line and sniffer line” Scope of delivery (amount): Hook (4x), screw M6 x 12 (4x), lock washer S6 (4x) Required tools (supplied): Wrench T30 • In order to be able to fix the mains cable and, if necessary, a sniffer line on the device, mount the hooks on the device as shown. - Page 43 INFICON Installation | 5 Fig. 8: Hook at the instrument or at the optional bottle holder. UL3000-Fab-ULTRA-Operating-instructions-iinb73en1-09-(2109) 43 / 152...

- Page 44 5 | Installation INFICON Install the “Power line strain relief” Scope of delivery (amount): Strain relief (1x), screw M6 x 12 (1x), lock washer S6 (1x) Required tools (supplied): Wrench T30 • To avoid the risk of tripping mount the “strain relief power supply” at the device.

- Page 45 INFICON Installation | 5 Install the "Bracket for corrugated tube" Scope of delivery (amount): Holder complete (1x), screws M6 x 12 (3x), lock washer S6 (3x), self-tapping screws (2x) Required tools (supplied): Wrench T25 and T30 For fixing a corrugated hose between the inlet flange of the device and the test chamber or test object respectively.

- Page 46 5 | Installation INFICON Fig. 9: The bracket for corrugated tube is mounted. WARNING Shortening of the corrugated hose during evacuation A corrugated hose connected to the inlet is shortened during evacuation. ► Mount the corrugated hose in such a way that it cannot endanger the stability of the device or flake off when it is shortened.

- Page 47 INFICON Installation | 5 WARNING Danger of poisoning due to harmful gases Depending on the connected container and the gas contained therein, harmful gases can get into the ambient air via the exhaust filter of the leak detector. ► Make sure you have protection measure to prevent inhaling hazardous gases.

-

Page 48: Fastening Bracket For Sniffer Line Sl3000 (Accessory, Optional)

5 | Installation INFICON 5.3 Fastening bracket for sniffer line SL3000 (accessory, optional) WARNING Risk of injury due to sniffer tip When stumbling, for example over lines, the sniffer tip can cause serious injuries, especially in eye contact. ► To avoid injury from the sniffer tip, align the sniffer tip in the bracket so that it points away from the operator. -

Page 49: Connecting To The Power Supply System

INFICON Installation | 5 5.4 Connecting to the power supply system DANGER Danger due to electric shock Improperly grounded or fused products may be dangerous to life in case of a fault. The use of the device is not permitted without a connected protective ground conductor. - Page 50 5 | Installation INFICON ð After switching on pieces of status information are shown on the touchscreen about the speed of the turbo molecular pump, the foreline pressure, the emission and the active cathode. The start process takes about 3 minutes and is completed with a short acoustic signal.

-

Page 51: Operation

INFICON Operation | 6 6 Operation 6.1 Switching on NOTICE Damage to the backing pump due to cold ambient temperature If the ambient temperature is below 10 °C, the device will show a warning on the display after switching on. It is possible to start up the device anyway by confirming this message. -

Page 52: Basic Settings

6 | Operation INFICON 6.2 Basic settings You are able to save the actual settings of the device at any time, so that you can use them at a later time, see also "Saving and managing sets of parameters [} 88]". -

Page 53: Select, Modify, Create User Profile

INFICON Operation | 6 • Perform software updates, • Modify date/time. 6.2.3.2 Select, modify, create user profile ü Operator or Supervisor rights > User accounts > Manage user accounts ð Existing users and associated groups are displayed in list form. -

Page 54: Modify Personal Settings

6 | Operation INFICON To assign the required rights to the user, select a group. Via select between the groups User, Operator and Supervisor. See "Overview of Rights Groups [} 52]". In the field "Language" assign a language to the user via and . -

Page 55: Switch On Automatic Login

INFICON Operation | 6 6.2.5 Switch on Automatic Login You can specify if a user of your choice is automatically logged in after the device is switched on without the login window. ü Supervisor rights ü The requested user was already created. See "Select, modify, create user profile [} 53]". -

Page 56: Changing The Presentation Of The Line Graph

6 | Operation INFICON 6.2.6.1 Changing the presentation of the line graph Supervisor ULTRA Fig. 11: Presentation of the line graph ü Operator or Supervisor rights > Display > Line chart In the field "Scaling" select between "Linear" and "Logarithmic". Select between the different viewable ”Decades”. -

Page 57: Changing The Presentation Of The Bar Graph

INFICON Operation | 6 6.2.6.2 Changing the presentation of the bar graph Fig. 12: Presentation as bar graph ü Operator or Supervisor rights > Display > Bar chart In the field "Scaling" select between "Linear" and "Logarithmic". Select between the different viewable ”Decades”. -

Page 58: Changing The Presentation Of The Circle Graph

6 | Operation INFICON 6.2.6.3 Changing the presentation of the circle graph Fig. 13: Presentation of the circle graph ü Operator or Supervisor rights > Display > Circle chart If you want to fix the number of displayed decades in the pie chart, under "Decades“... -

Page 59: Result Display Of The Auto Leak Test

INFICON Operation | 6 ð The internal background is created from the remaining gas, which has not yet been pumped out. Very clean systems show a background in the range of 1 x mbar l/s. Under normal conditions there is a background of 1 x 10 mbar l/s or 1x10 mbar l/s. -

Page 60: Change Audio Settings

6 | Operation INFICON After switching the operation mode "Sniffer" in addition to the modes mentioned above you can also select between the units "oz/yr", "g/a" and "ppm". You can also choose between the following pressure units: “mbar”, “Pa”, “atm” and “Torr”. -

Page 61: Change The Protection Settings

INFICON Operation | 6 ð The "Minimum volume" is the volume for the audible alarm which cannot be undershot. If you select a value greater than 0, the lowest volume level is shown on the measurement screen after pressing the volume icon. This allows you to prevent a non-authorized person from setting a value that is below the ambient noise level. - Page 62 6 | Operation INFICON from becoming contaminated by Helium. The helium entering the specimen can be pumped out using an external pump. If no external pump is being used, we recommend that the test object is vented before continuing with the measurement.

-

Page 63: Set Maintenance Interval "Filter Sniffer Tip" Or "Air Filter

INFICON Operation | 6 6.2.11 Set maintenance interval "Filter sniffer tip" or "Air filter" To adjust the maintenance interval to the degree of contamination at the location of the device, you can choose between a default value or a self-selected maintenance interval. -

Page 64: Activating Or Deactivating Calibration Requests

6 | Operation INFICON 6.2.13 Activating or deactivating calibration requests If the option "calibration request” is not active (factory setting), you only get a calibration request in the following cases: • The operation mode “Auto Leak Test“ has been switched on and the testing time of Auto Leak Test has been changed. -

Page 65: Use Favorites

INFICON Operation | 6 ð Locked. The device can only be operated via the touchscreen. The START, Stop and ZERO buttons on the control panel are locked. The buttons of the remote control can also not be used. Save 6.2.15 Use Favorites To shorten the time spent searching menus for frequently used functions, create freely assignable menu keys in the "Favorites"... - Page 66 6 | Operation INFICON ð Option deactivated: No note Save 66 / 152 UL3000-Fab-ULTRA-Operating-instructions-iinb73en1-09-(2109)

-

Page 67: Settings For The Measurements

INFICON Operation | 6 6.3 Settings for the measurements 6.3.1 Select operation mode ü Operator or Supervisor rights > Operation mode Choose between “Vacuum”, “Sniff / SL200”, “Auto Leak Test“ and “Sniff / SL3000”. Save 6.3.2 Select gas DANGER Danger from a Hydrogen explosion Hydrogen can explode in combination with oxygen. -

Page 68: Activate Vacuum Ranges

6 | Operation INFICON > Setpoints Adjust. Save 6.3.4 Activate vacuum ranges Vacuum ranges You can activate the vacuum ranges MASSIVE, GROSS, FINE and ULTRA for your measurements. All 4 areas can be activated at the same time. If several areas are activated, they switch automatically depending on the inlet pressure. -

Page 69: Consider The Background Of The Test Chamber

INFICON Operation | 6 6.3.5.1 Consider the background of the test chamber If unexpected results, such as many failed tests are displayed in succession, we recommend performing a "Reference measurement". You can repeat such a measurement at regular intervals. ü Test chamber is mounted, empty and closed. -

Page 70: Use Hydro•S

6 | Operation INFICON 6.3.6.2 Use HYDRO•S ü HYDRO•S is set to “Manual”, see “Set HYDRO•S [} 69]”. HYDRO•S manual ü Gas type helium (mass 4) is selected, see Select gas [} 67]. ü Operation mode “Vacuum” is active. ü Vacuum range ULTRA is reached. -

Page 71: Set External Calibration Leak

INFICON Operation | 6 ü The operation mode "Vacuum" is set. > Setup > Measurement > Calibration leak ð The field “Machine factor helium” is shown. Adjust. Save 6.3.8 Set external calibration leak To use an external calibration leak for calibration, enter the leak rate of the calibration leak. -

Page 72: Set And Use The Function Zero

6 | Operation INFICON ð If required, you can set the pressure limits individually. See also "Factory settings [} 34]". To set the values for argon by pressing a button, press the "Argon Standard" key. ð Then the following settings deviating from the factory settings for air are used: MASSIVE ->... -

Page 73: Vent, Purge, Regenerate

INFICON Operation | 6 How do I switch the Press the ZERO button on the control panel for more than 2 seconds or on the ZERO function OFF? touchscreen “Vacuum" operation If you use the "I•ZERO 2.0" setting, after pressing the ZERO button the displayed mode, effect of ZERO background signal is faded out depending on the current drift. - Page 74 6 | Operation INFICON Purge By activating the flushing function (with dry backing pumps), a small gas flow is let into the backing pump in the "standby" state. The function may be useful to remove condensed water vapor from the pump chamber of the backing pump or to reduce the helium background.

-

Page 75: Change Leak Rate Filter

INFICON Operation | 6 6.3.12 Change leak rate filter The leak rate filter “I•CAL” is preset. I•CAL ensures that the averaging time is optimally adapted to the leak rate range. The abbreviation I•CAL stands for “Intelligent Calculation Algorithm for leak rates”. -

Page 76: Determine The Background Of The Inlet Area

6 | Operation INFICON opacity (grayed out) to normal opacity. To make the background display visible in standby mode, activate the corresponding function, see “Change general display settings [} 58]”. ð Inlet area Additionally to the deduction of the internal background, pressing START with every measurement also deducts the background of the inlet area. -

Page 77: Change The Sniffer Line Pressure Monitoring

INFICON Operation | 6 Select "Sniffer line light brightness". ð You have a choice of OFF / 1 - 6. Switch-on the "Sniffer line beep" sniffer audio. ð As choices there are "Off" or "Beep when setpoint 1" available. Save 6.3.15 Change the sniffer line pressure monitoring... -

Page 78: Internal Calibration

6 | Operation INFICON ► When using hydrogen or helium-3 ( He) as tracer gas an internal calibration is not possible. In this case, use an external calibration leak. ► The operation modes "Vacuum" and "Sniffing" must be separately calibrated when using an external calibration. -

Page 79: Measure Internal Calibration Leak

INFICON Operation | 6 Select the cross-hair icon Select “Proof“. ð The check is started and the calibration factor is recalculated. ð The newly calculated calibration factor is displayed. ð If the newly calculated calibration factor deviates considerably from the stored calibration factor, a prompt for new calibration is displayed. -

Page 80: Measuring

6 | Operation INFICON 6.4 Measuring ü The inlet flange on the upper side of the device is prepared for the pending measurement. Your test specimen or the SL200 sniffer line is normally connected there. ü Alternatively, the sniffer line SL3000 is connected to the back of the device (optional). -

Page 81: Measuring Helium Ambient Concentration

INFICON Operation | 6 6.5 Measuring helium ambient concentration The natural content of helium in the ambient air is about 5.2 ppm. You can examine the ambient air for an increased helium content (helium contamination) to determine the appropriate time for further measurements. -

Page 82: Display Measurement Cycles

6 | Operation INFICON To record immediately after starting a measurement, activate the option "Enabled". Note: Data recording occurs during the measurements, i.e. while the measurement screen is displayed. See also "Display measurement cycles [} 82]". ð This option is deactivated as standard. To start or stop a recording without activating this option press in the measurement display. -

Page 83: Export Measurement Data Via Network

INFICON Operation | 6 ð Alternatively, you can edit "Free text 1" and "Free text 2" from the "Measurement cycles" window. Select an entry by tapping on it and press To change the displayed period in the detailed view on the chart, swipe to the right or left on the display. -

Page 84: Measurement Data Database: Information

6 | Operation INFICON When accessing via LAN, use the IP address found under > Device > Network. When accessing via WLAN, use the URL found under > Setup > Network > WLAN. Example 1: http://192.168.11.124:3000/md?f=csv_en&c=4&d=mr Returns measured values and metadata of the measurement cycle with ID 4 in the format “csv_en”. -

Page 85: Information

INFICON Operation | 6 If storage is needed for the recording and the maximum database size (in measurement values) has been exceeded, the oldest records are automatically deleted so that 5% of the specified capacity is freed for new data. -

Page 86: Retrieve Information About The Device

6 | Operation INFICON ► > Accessories > Bus module ð If a bus module is connected, you will find details. 6.7.4 Retrieve information about the device Diverse information on the device is shown: Software and serial numbers, network information and operating hours. -

Page 87: Call Information On The Hydro•S

INFICON Operation | 6 ► > Energy > Power 6.7.7 Call information on the HYDRO•S The internal parameters for HYDRO•S are displayed. ► > HYDRO•S 6.7.8 Call information on the SL3000 Sniffer line ► > Sniffer line 6.8 Log 6.8.1 Call the error and warning log ►... -

Page 88: Device Settings

6 | Operation INFICON 6.9 Device settings 6.9.1 Viewing and customizing individual parameters You are able to get a quick overview of the actual settings of the device and you can make modifications, if needed. ü You have the required right to change the specific parameter. -

Page 89: Exporting Or Importing Sets Of Parameters

INFICON Operation | 6 , to activate a set of parameters. , to delete a set of parameters. 6.9.3 Exporting or importing sets of parameters You are able to transfer saved sets of parameters from the internal memory to an attached USB flash drive and to import the sets again. -

Page 90: Update The User Interface Software

6 | Operation INFICON 6.10.1 Update the user interface software Import software updates using a USB flash drive. NOTICE Loss of data due to disconnection ► Do not switch off the device and do not remove the USB flash drive while the software is being updated. -

Page 91: Update The Software In Expert Mode

INFICON Operation | 6 ð After completion there is an automatic restart of the system. 6.10.3 Update the software in expert mode ü Supervisor rights > Update > Update operating unit/basic unit > Operating unit expert update ð Software versions already available on the device are shown in a list. -

Page 92: Switch Back To The Internal Monitor

To check the function and the operating state of the measuring system at a glance, call up the simplified diagram of the vacuum diagram. ► > Vacuum diagram Fig. 14: The most important components of the vacuum diagram in UL3000 Fab ULTRA devices 1 Inlet flange 6 Fore-vacuum pressure gauge 2 Inlet pressure gauge... -

Page 93: Resetting To Factory Settings

INFICON Operation | 6 4 Mass spectrometer 9 Fore pump 5 Turbo molecular pump 10 V1 … V10: Solenoid valves for controlling gas flows 6.13 Resetting to factory settings You can restore the device to factory settings. Loss of settings and measurement data After resetting to factory settings only the manufacturer factory settings are in the memory of the device. -

Page 94: Switching Off The Device

6 | Operation INFICON 6.15 Switching off the device NOTICE Turbo molecular pump can be damaged The running turbo molecular pump can be damaged by jerky movements or foreign objects. ► Avoid any jerking movements or vibrations to the device during operation and for up to 2 minutes after switching off. -

Page 95: Warning And Error Messages

INFICON Warning and error messages | 7 7 Warning and error messages During operation, the display shows information that helps you operate the device. Measurement values are displayed along with current device modes, operating instructions as well as warnings and error messages. The device is equipped with extensive self-diagnostic functions. -

Page 96: Warning And Error Messages Ul3000/Ul6000

7 | Warning and error messages INFICON 7.1 Warning and error messages UL3000/UL6000 Type Notification Possible sources of Remedy error W102 Timeout during The EEPROM on the • Contact customer service communication with VI-Board is defective or EEPROM on VI-Board... - Page 97 INFICON Warning and error messages | 7 Type Notification Possible sources of Remedy error W110 Real-time clock was reset! The real-time clock has • Enter the correct date and time Enter date and time not been set • Check that the message does not appear...

- Page 98 7 | Warning and error messages INFICON Type Notification Possible sources of Remedy error W125 I/O module no longer Connection to I/O • Check the connection to the I/O module connected module interrupted • Replace the connection cable to the I/O...

- Page 99 INFICON Warning and error messages | 7 Type Notification Possible sources of Remedy error W153 Operating unit software A more up-to-date • Contact the customer service for the version is obsolete operating unit software latest operating unit software is available. For...

- Page 100 7 | Warning and error messages INFICON Type Notification Possible sources of Remedy error W211 5V internal supply voltage Short circuit or • Contact customer service out of range overload in the internal 5V supply W212 5V sniffer line supply voltage Sniffer line defective •...

- Page 101 INFICON Warning and error messages | 7 Type Notification Possible sources of Remedy error W224 Internal voltage Short circuit or • Contact customer service 24V_PRESSURE (Pirani) overload in the voltage out of range 24V_PRESSURE (Pirani) supply W240 Voltage +15V out of range Short circuit at •...

- Page 102 7 | Warning and error messages INFICON Type Notification Possible sources of Remedy error W302 Suppressor voltage too low Short circuit of • Contact customer service suppressor or preamplifier VI-Board or MSB • Contact customer service defective W303 Suppressor voltage too high MSB defective •...

- Page 103 INFICON Warning and error messages | 7 Type Notification Possible sources of Remedy error E340 Emission error Pressure too high with • Contact customer service aged cathode W342 Cathodes not connected Both cathodes • Contact customer service defective during self-...

- Page 104 7 | Warning and error messages INFICON Type Notification Possible sources of Remedy error E404 TMP current consumption Pressure in the TMP is • Contact customer service too high too high W405 No TMP run-up Inlet pressure during • Check that the backing pump is working...

- Page 105 INFICON Warning and error messages | 7 Type Notification Possible sources of Remedy error E451 Temperature prewarning of The ambient • Reduce the temperature in the backing pump temperature is too high environment where the device is located Ambient temperature is •...

- Page 106 7 | Warning and error messages INFICON Type Notification Possible sources of Remedy error E457 Fault in backing pump: The backing pump in • Make sure that you use the supplied Power failure the leak detector has a power cord faulty mains input •...

- Page 107 INFICON Warning and error messages | 7 Type Notification Possible sources of Remedy error E463 Temperature error of The ambient • Reduce the temperature in the backing pump temperature is too high environment where the device is located Fan blocked or •...

- Page 108 7 | Warning and error messages INFICON Type Notification Possible sources of Remedy error E504 Pressure sensor p3 not Pressure sensor not • Contact customer service connected connected or cable defective VI-Board or MSB • Contact customer service defective E505...

- Page 109 INFICON Warning and error messages | 7 Type Notification Possible sources of Remedy error W542 Flow through capillary too Capillary broken or • Use another sniffer line, if possible high leaky • Contact customer service The pressure limit for a •...

- Page 110 7 | Warning and error messages INFICON Type Notification Possible sources of Remedy error W630 Calibration request Operation mode or • Perform a calibration mass has changed HYDRO•S has been • Perform a calibration switched on (if function available) Auto Leak Test is •...

- Page 111 INFICON Warning and error messages | 7 Type Notification Possible sources of Remedy error W710 MSB temperature is too high The ambient • Reduce the temperature in the temperature is too high environment where the device is located Air filter dirty •...

-

Page 112: Cleaning And Maintenance

8 | Cleaning and maintenance INFICON 8 Cleaning and maintenance All cleaning and maintenance work described here must be carried out without opening the device! DANGER Risk of death from electric shock There are high voltages inside the device. Touching parts where electrical voltage is present can result in death. -

Page 113: Replacement Of The Filter Mat On The Bottom Of The Device

INFICON Cleaning and maintenance | 8 Remove the used air filter from the plastic grid and insert a new one. Refit the plastic grid together with the new air filter. 8.3 Replacement of the filter mat on the bottom of... - Page 114 8 | Cleaning and maintenance INFICON Loosen the screws, which fix the filter mat on the metal sheet. Replace the filter mat. Secure the filter mat with the screws, insert the metal sheet and fix it with the knurled screw.

-

Page 115: Replacing The Sl200 Sniffer Line Filter

INFICON Cleaning and maintenance | 8 8.4 Replacing the SL200 sniffer line filter Structure of the sniffer Fig. 15: Sniffer tip 1 Capillary filter (plastic; standard) 4 Cross-head screws 2 Felt pads 5 Sinter filter 3 Capillary filter (metal with gasket;... -

Page 116: Replacing The Sl3000 Sniffer Line Filter

8 | Cleaning and maintenance INFICON • Unscrew the capillary filter and replace it with a new one. Do not forget the gasket for the metal version! Check or replace the Switch off the leak detector or disconnect the sniffer line from the device. - Page 117 INFICON Cleaning and maintenance | 8 Table 3: Capillary filter 1 Sniffer line end 4 Plastic capillary filter 2 cone seal 5 Water conservation tip 3 Metal capillary filter Capillary filter and water conservation tip are screwed onto the sniffer line end. The filter inserts are inserted and lie in front of a small metal grill that is also inserted.

-

Page 118: Creating Screenshots

8 | Cleaning and maintenance INFICON If you have activated the display of maintenance requests, set the maintenance interval to the desired new period. Also see "Activate or deactivate maintenance requests [} 63] " and "Set maintenance interval "Filter sniffer tip" or "Air filter"... -

Page 119: Sending For Repair Or Maintenance

Maintenance inside the device should only be performed by the manufacturer. We recommend having the device serviced every 4000 hours or annually. You can send in your device to INFICON so it can be maintained or repaired. For further details see "Sending in the device [} 122]”. -

Page 120: Maintenance Plan

• I Customer or higher level legend • II Customer with instruction or higher level • III INFICON Service Technician • X Carry out maintenance as per operating hours or duration • X Maintenance after operating hours, not after duration •... - Page 121 INFICON Cleaning and maintenance | 8 To the Kashiyama NeoDry backing pump When pumping clean gases such as dry air and inert gases, the recommended schedule for preventive maintenance is 3 years. When pumping condensable gases such as water vapour and gas-mixed solvents as well as aggressive or corrosive gases, it may be necessary to reduce the maintenance interval to one year.

-

Page 122: Decommissioning The Measuring Instrument

9 | Decommissioning the measuring instrument INFICON 9 Decommissioning the measuring instrument 9.1 Disposing of the device The device can either be disposed of by the operator or be sent to the manufacturer. The device consists of materials that can be recycled. This option should be exercised to prevent waste and also to protect the environment. - Page 123 INFICON Decommissioning the measuring instrument | 9 UL3000-Fab-ULTRA-Operating-instructions-iinb73en1-09-(2109) 123 / 152...

-

Page 124: Accessories And Interfaces

10 | Accessories and interfaces INFICON 10 Accessories and interfaces 10.1 Accessories and spare parts The parts listed below can additionally be ordered: Bus module BM1000 PROFIBUS 560-315 BM1000 PROFINET IO 560-316 BM1000 DeviceNet 560-317 BM1000 EtherNet/IP 560-318 I/O module... - Page 125 INFICON Accessories and interfaces | 10 Sniffer tip, rigid, 500 mm. 45° angled(ST 500) 12272 Further accessories for the SL3000 Felt For Capillary Filter SL3xx, 50 pc. 200001116 Capillary filter, metal(1 unit) 12217 Capillary Filter SL 300, set 5 pieces(Plastic capillary filter)

- Page 126 10 | Accessories and interfaces INFICON Helium bottle holder The Helium bottle holder allows the transport of a Helium supply with a spray gun along with the leak detector. Only small to medium size bottles (max. 10 I, 200 bar) fit without compromising the stability of the device.

- Page 127 INFICON Accessories and interfaces | 10 Fig. 21: Fasten the transmitter with Velcro in a free place Search for the wireless remote control from the leak detector If you have misplaced the RC1000WL wireless remote control, you can trigger from your leak detector acoustic signals of this remote control.

-

Page 128: I/O Module

ü Supervisor rights Connect the INFICON I/O module with a data cable to the LD socket on the rear of the device, see "Connections for accessories and control signals [} 31]". > Setup > Accessories > Device selection Select the "IO module". - Page 129 INFICON Accessories and interfaces | 10 Pressure p1 / Pressure 1 ... 10 V; 0.5 V / decade; logarithmic 1 V = 1 x 10 mbar Leak rate mantissa 1 ... 10 V; linear; in the Useful only if the other analog output is assigned selected unit "Leak rate exponent".

-

Page 130: Configure Digital Inputs

10 | Accessories and interfaces INFICON Leak rate log. 0 ... 10 V; logarithmic; The upper limit (= 10 V) and the scale (V / decades) are set via the parameters "Exponent upper limit" and in the selected unit "Analog output scaling". -

Page 131: Configuring Digital Outputs

INFICON Accessories and interfaces | 10 ð The modes "Standard" or the mode "Inverse" are available for selection. To mode "Inverse": In the following table overview, the arrow pointing the transfer direction in the column "Transition" must be reversed. Save... - Page 132 10 | Accessories and interfaces INFICON Function State: Description Off (open) open: always open Ready for operation closed: Emission switched on, calibration process inactive, no error open: Emission switched off or calibration process active or error Emission on closed: Emission switched on...

-

Page 133: Setting Up The I/O Module Protocol

On the USB stick enclosed with the device and the bus module BM1000 you will find further files on the subject of bus modules. This also includes the GSD file for PROFIBUS, which is located in the “..\Manuals\Interface Description“ folder. For the different bus modules from INFICON see also “Accessories and spare parts [} 124]“. UL3000-Fab-ULTRA-Operating-instructions-iinb73en1-09-(2109) -

Page 134: Creating A Connection Between The Device And The Bus Module

To establish the connection between the leak detector and the bus module, proceed as follows: Switch off the leak detector. Connect the INFICON bus module via a data cable to the LD socket of the device, see “Connections for accessories and control signals [} 31]“. Switch on the leak detector. -

Page 135: Network

INFICON Accessories and interfaces | 10 10.4 Network 10.4.1 Operate leak detector via web browser (LAN) NOTICE Operating system can be attacked via USB or Ethernet The Linux operating system used in the leak testing is not updated automatically and can therefore contain security gaps. -

Page 136: Setting The Lan Connection In The Pc Or Tablet

10 | Accessories and interfaces INFICON 10.4.1.2 Setting the LAN connection in the PC or Tablet LAN connection - quick start If you have performed the steps described here once, it is sufficient to enter the IP address for many devices in case of repetition. -

Page 137: Operate Leak Detector Via Web Browser (Wireless Lan)

INFICON Accessories and interfaces | 10 10.4.2 Operate leak detector via web browser (wireless LAN) NOTICE Operating system can be attacked via USB or Ethernet The Linux operating system used in the leak testing is not updated automatically and can therefore contain security gaps. This vulnerability may be exploited through the Ethernet and USB interfaces of the leak testing to provide unauthorized access to the system. -

Page 138: Setting The Wireless Lan Connection In The Pc Or Tablet

10 | Accessories and interfaces INFICON To set-up that the device supports the WLAN connection activate the option "Enable Wireless LAN". In the field “WiFi Name (SSID)” enter the desired network name and in the field “WiFi Network key” the desired Network key. -

Page 139: Allow Client Access

INFICON Accessories and interfaces | 10 10.4.2.3 Allow client access ü Supervisor rights > Setup > Network > Client access To allow the leak detector to be operated by PC or Tablet, activate the "Client Access" option. ð If the option "Client Access" is not activated, the leak detector cannot be operated via PC or Tablet. -

Page 140: Appendix

11 | Appendix INFICON 11 Appendix 11.1 Menu path Pressing the navigation button brings you back to the measurement display regardless of whether you were previously in a menu or sub-menu. 11.1.1 Diagnostics > Confirmed warnings ð Can only be seen when active. - Page 141 INFICON Appendix | 11 > User accounts > Log off > User accounts > Manage Automatic Login > User accounts > Manage user accounts > User accounts > Change own PIN > User accounts > Change own language > User accounts > Favorites >...

-

Page 142: Information

11 | Appendix INFICON > Setup > Accessories > I/O module > Configuration of digital outputs > Setup > Accessories > I/O module > Configuration of digital Inputs > Setup > Accessories > RC1000 > Parameter sets > Parameter list >... -

Page 143: Ce Declaration Of Conformity

INFICON Appendix | 11 11.2 CE Declaration of Conformity UL3000-Fab-ULTRA-Operating-instructions-iinb73en1-09-(2109) 143 / 152... -

Page 144: Certificate (Tüv Rheinland)

11 | Appendix INFICON 11.3 Certificate (TÜV Rheinland) 144 / 152 UL3000-Fab-ULTRA-Operating-instructions-iinb73en1-09-(2109) -

Page 145: Rohs

INFICON Appendix | 11 11.4 RoHS UL3000-Fab-ULTRA-Operating-instructions-iinb73en1-09-(2109) 145 / 152... - Page 146 11 | Appendix INFICON 146 / 152 UL3000-Fab-ULTRA-Operating-instructions-iinb73en1-09-(2109)

-

Page 147: Index

INFICON Index Index Display runtimes 85 Display temperature value 85 Access controls 52 Auto Leak Test Operation mode (Definition) 20 Evacuation time gross leak 62 Result display 59 Evacuation time measurements 62 Select operation mode 67 Exhaust 30, 46 Settings 68... - Page 148 Index INFICON Pressure monitoring 77 Replacing the filter 115 Note on the exhaust hose connection 65 Sniffer line SL200 125 Sniffer line SL3000 125 Software Update basic unit 90 Operating options 64 User interface update 90 Operation Supervisor 52, 54 PC, Tablet 138...

- Page 149 INFICON Index Allow client access 136, 139 Configure leak detector 137 Settings PC or tablet 138 ZERO 80 Button 25 Factory setting 72 UL3000-Fab-ULTRA-Operating-instructions-iinb73en1-09-(2109) 149 / 152...

- Page 150 Index INFICON 150 / 152 UL3000-Fab-ULTRA-Operating-instructions-iinb73en1-09-(2109)

Need help?

Do you have a question about the UL3000 Fab ULTRA and is the answer not in the manual?

Questions and answers