Table of Contents

Advertisement

Quick Links

Operator's Manual

SAE-500

POWER SOURCE

Register your machine:

www.lincolnelectric.com/register

Authorized Service and Distributor Locator:

www.lincolnelectric.com/locator

Save for future reference

Date Purchased

Code: (ex: 10859)

Serial: (ex: U1060512345)

IM988-A

| Issue D ate Nov-15

© Lincoln Global, Inc. All Rights Reserved.

TM

DC ARC WELDING

For use with machines having Code Numbers:

11476, 12515

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for Lincoln Electric 11476

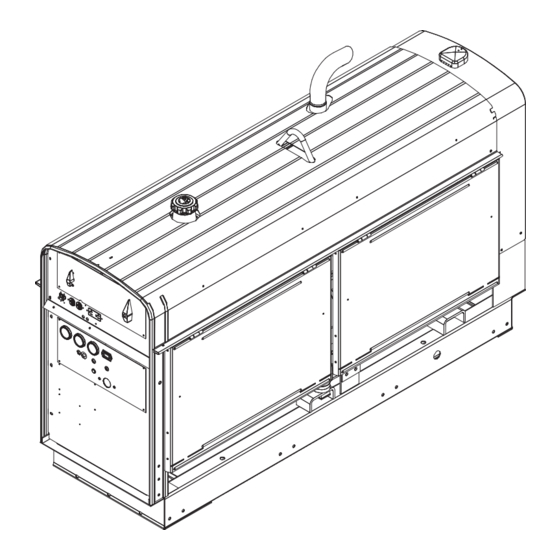

- Page 1 Operator’s Manual SAE-500 DC ARC WELDING POWER SOURCE For use with machines having Code Numbers: 11476, 12515 Register your machine: www.lincolnelectric.com/register Authorized Service and Distributor Locator: www.lincolnelectric.com/locator Save for future reference Date Purchased Code: (ex: 10859) Serial: (ex: U1060512345) IM988-A | Issue D ate Nov-15 ©...

- Page 2 THANK YOU FOR SELECTING A QUALITY PRODUCT BY KEEP YOUR HEAD OUT OF THE FUMES. DON’T get too close to the arc. LINCOLN ELEC TRIC. Use corrective lenses if necessary to stay a reasonable distance away from the arc. READ and obey the Safety Data PLEASE EXAMINE CARTON AND EQUIPMENT FOR Sheet (SDS) and the warning label DAMAGE IMMEDIATELY...

- Page 3 W117.2-1974. A Free copy of “Arc Welding Safety” booklet E205 is available from the Lincoln Electric Company, 2.d. All welders should use the following procedures in order to 22801 St. Clair Avenue, Cleveland, Ohio 44117-1199.

- Page 4 SAFETY ELECTRIC SHOCK ARC RAYS CAN BURN. CAN KILL. 3.a. The electrode and work (or ground) circuits are 4.a. Use a shield with the proper filter and cover plates to protect your electrically “hot” when the welder is on. Do eyes from sparks and the rays of the arc when welding or not touch these “hot”...

- Page 5 SAFETY WELDING AND CUTTING CYLINDER MAY EXPLODE IF SPARKS CAN CAUSE DAMAGED. FIRE OR EXPLOSION. 7.a. Use only compressed gas cylinders containing the correct shielding gas for the process used 6.a. Remove fire hazards from the welding area. If and properly operating regulators designed for this is not possible, cover them to prevent the welding sparks the gas and pressure used.

-

Page 6: Table Of Contents

TABLE OF CONTENTS Page Installation Instructions ..........Section A Technical Specifications . -

Page 7: Technical Specifications

INSTALLATION TECHNICAL SPECIFICATIONS - SAE-500™ (K1278-11) INPUT - DIESEL ENGINE Make/Model Description Speed (RPM) Displacement Starting Capacities System K1278-11 Kubota 4 cylinder High Idle 1800 220.9 cu. in 12VDC batteries Fuel: 29.0 gal. V3600-T-E3BG 57.8 HP @ Low Idle 1100 (3.62 L) (2) &... -

Page 8: Location/Ventilation

INSTALLATION Read this entire installation section before you This equipment is for industrial use only and it is not start installation. intended for use in residential locations where the electri- cal power is provided by the public low-voltage supply SAFETY PRECAUTIONS system. -

Page 9: High Altitude Operation

INSTALLATION HIGH ALTITUDE OPERATION VEHICLE MOUNTING At higher altitudes, output derating may be necessary. WARNING For maximum rating, derate the welder output 5% for every 500 meters (1640 ft.) above 400 meters (1312 Improperly mounted concentrated loads may cause ft.). unstable vehicle handling and tires or other compo- nents to fail. -

Page 10: Fuel

ENGINE BREAK-IN PERIOD teries with the correct polarity. Make sure that the batteries are level while charging. Lincoln Electric selects high quality, heavy-duty industrial GASES FROM BATTERY can explode. engines for the portable welding machines we offer. Keep sparks, flame and cigarettes away from bat- While it is normal to see a small amount of crankcase oil tery. -

Page 11: Spark Arrester

INSTALLATION WELDING OUTPUT CABLES USING A BOOSTER — connect positive lead to battery first then With the engine off, connect the electrode and work connect negative lead to negative cables to the studs provided. These connections battery lead at the lower control should be checked periodically and tightened if neces- panel support. -

Page 12: Operating Instructions

OPERATION OPERATING INSTRUCTIONS WELDING SPARKS can cause fire or explosion. Read and understand this entire section before operat- ing your equipment. • Do not weld near flammable material SAFETY INSTRUCTIONS WARNING • Do not weld on containers that have held flam- Do not attempt to use this equipment until you have mable material. -

Page 13: Design Features And Advantages

DESIGN FEATURES AND ADVANTAGES • Gauges for engine oil pressure, coolant tempera- ture and battery charging ammeter. • Engine hour meter standard. (code 11476) FOR STICK WELDING • Engine hour meter / fuel gauge standard. (code • Excellent DC constant current output for stick weld- 12515) ing applications. - Page 14 OPERATION ENGINE CONTROLS ENGINE PROTECTION SYSTEM The engine protection system shuts down the engine IGNITION SWITCH under high coolant temperature or low engine oil pres- sure conditions by allowing the fuel solenoid valve to When placed in the “ON” position, this switch ener- close.

-

Page 15: Remote Control

OPERATION How to Set the Controls One 15 amp, 230 VAC duplex receptacle provides 230 VAC for auxiliary power. A total of 13 amps can be Assume you want a normal soft arc and about 135 drawn from this receptacle. amps, using a 5/32”... -

Page 16: Engine Operation

OPERATION ENGINE OPERATION Observe the oil pressure. If no pressure shows within 30 seconds, stop the engine and consult the WARNING engine operating manual. To stop the engine, turn the “IGNITION” switch to “OFF”. Do not attempt to use this equipment until you If the engine protection warning light comes on have thoroughly read the engine manufacturer’s during cranking or after start up, the “IGNITION”... -

Page 17: Typical Fuel Consumption

OPERATION TYPICAL FUEL CONSUMPTION The typical fuel consumption of the SAE-500™ for var- ious operating scenarios is shown below: KUBOTA V3600-T-E3BG Low Idle - No Load 0.31 gal./ hr. 1100 RPM ( 1.17 L./hr.) High Idle - No Load 0.69 gal./hr. 1800 RPM (2.61 L./hr.) Welding Load... -

Page 18: Accessories

The use of an arc welder for pipe thawing is not approved by the CSA, nor is it recommended or supported by Lincoln Electric. ------------------------------------------------------------------------ K704 Standard Accessory Kit - Includes electrode and work cables, headshield, work clamp and elec- trode holder. -

Page 19: Maintenance

MAINTENANCE WARNING PERIODIC MAINTENANCE ELECTRIC SHOCK can kill. 1. Blow out the welder and controls with an air hose at least Do not touch electrically live parts once every two months. In particularly dirty locations, this cleaning may be necessary once a week. Use low pres- such as output terminals or inter- nal wiring sure air to avoid driving dirt into the insulation. -

Page 20: Pre Filter / Washer Separator

MAINTENANCE COMMUTATOR AND BRUSH COOLING SYSTEM WARNING The SAE-500™ is equipped with a pressure radiator. Keep the radiator cap tight to prevent loss of coolant. Uncovered rotating equipment can be dangerous. Clean and flush the cooling system periodically to pre- Use care so your hands, hair, clothing or tools do vent clogging the passage and overheating the engine. -

Page 21: Spark Arrester

MAINTENANCE GFCI RECEPTACLE TESTING AND RESET- ENGINE AND COMPRESSOR MAINTENANCE TING PROCEDURE COMPONENTS ITEM MAKE PART NUMBER The GFCI receptacle should be properly tested at least once every month or whenever it is tripped. To proper- Engine Air Filter Donaldson P822768 ly test and reset the GFCI receptacle: Fan Belt Kubota... -

Page 22: Troubleshooting Guide

HOW TO USE TROUBLESHOOTING GUIDE WARNING Service and Repair should only be performed by Lincoln Electric Factory Trained Personnel. Unauthorized repairs performed on this equipment may result in danger to the technician and machine operator and will invalidate your factory warranty. For your safety and to avoid Electrical Shock, please observe all safety notes and precautions detailed throughout this manual. - Page 23 TROUBLESHOOTING Observe all Safety Guidelines detailed throughout this manual PROBLEMS POSSIBLE RECOMMENDED (SYMPTOMS) CAUSE COURSE OF ACTION FUNCTION PROBLEMS Machine fails to hold the “heat” 1. Rough or dirty commutator. 1. True and clean commutator. constantly. 2. Brushes may be worn down to 2.

- Page 24 TROUBLESHOOTING Observe all Safety Guidelines detailed throughout this manual PROBLEMS POSSIBLE RECOMMENDED (SYMPTOMS) CAUSE COURSE OF ACTION FUNCTION PROBLEMS Welder runs but fails to generate 1. Generator or exciter brushes may 1. Be sure that all brushes bear on current. be loose or missing.

- Page 25 TROUBLESHOOTING Observe all Safety Guidelines detailed throughout this manual PROBLEMS POSSIBLE RECOMMENDED (SYMPTOMS) CAUSE COURSE OF ACTION FUNCTION PROBLEMS Welding current too great or too 1. “Current Control” shaft and handle 1. With current control against the minimum stop, set pointer to with- small compared to indication on the may have turned slightly in the dial.

- Page 26 TROUBLESHOOTING Observe all Safety Guidelines detailed throughout this manual PROBLEMS POSSIBLE RECOMMENDED (SYMPTOMS) CAUSE COURSE OF ACTION FUNCTION PROBLEMS No auxiliary power 1. Circuit Breakers open. 1. Check and reset breakers. If breakers keep tripping check con- nections to auxiliary receptacles. Also make sure load does nor exceed receptacle’s current rating.

- Page 27 WIRING DIAGRAMS SAE-500™...

- Page 28 WIRING DIAGRAMS > > SAE-500™...

- Page 29 DIMENSION PRINT SAE-500™...

- Page 30 WARNING Do not touch electrically live parts or Keep flammable materials away. Wear eye, ear and body protection. electrode with skin or wet clothing. Insulate yourself from work and AVISO DE ground. Spanish PRECAUCION No toque las partes o los electrodos Mantenga el material combustible Protéjase los ojos, los oídos y el bajo carga con la piel o ropa...

- Page 31 WARNING Keep your head out of fumes. Turn power off before servicing. Do not operate with panel open or Use ventilation or exhaust to guards off. remove fumes from breathing zone. AVISO DE Spanish PRECAUCION Los humos fuera de la zona de Desconectar el cable de No operar con panel abierto o respiración.

- Page 32 Lincoln Electric for advice or information about their use of our products. We respond to our customers based on the best information in our possession at that time. Lincoln Electric is not in a position to warrant or guarantee such advice, and assumes no liability, with respect to such information or advice.

Need help?

Do you have a question about the 11476 and is the answer not in the manual?

Questions and answers