Table of Contents

Advertisement

Quick Links

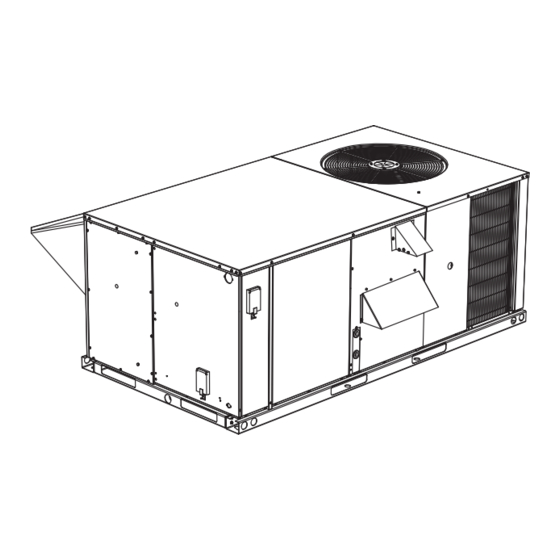

R-410A

SERIES 5

J**ZR

3 - 5 Ton

60 Hertz

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Installation Safety Information. . . . . . . . . . . . . . . . . . . . . . . 5

Limitations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Location. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Rigging And Handling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Ductwork . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Condensate Drain . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Compressors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Filters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Power And Control Wiring. . . . . . . . . . . . . . . . . . . . . . . . . 13

Optional Electric Heat . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Options/Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Checking Supply Air CFM . . . . . . . . . . . . . . . . . . . . . . . . . 41

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Sequence Of Operations Overview. . . . . . . . . . . . . . . . . . 42

1 J03 thru 05 ZR Unit Limitations . . . . . . . . . . . . . . . . . . . . . 6

2 Weights and Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . 8

3 J03 thru 05 ZR Unit Accessory Weights . . . . . . . . . . . . . . 8

4 J03 thru 05 ZR Unit Clearances . . . . . . . . . . . . . . . . . . . 10

5 J03 thru 05 ZR Utilities Entry . . . . . . . . . . . . . . . . . . . . . 11

6 Control Wire Sizes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

7 Electrical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

8 J03 thru 05 ZR Physical Data . . . . . . . . . . . . . . . . . . . . . 28

9 Electric Heat Minimum Supply Air . . . . . . . . . . . . . . . . . . 30

10 Gas Heat Application Data . . . . . . . . . . . . . . . . . . . . . . . 30

11 Gas Pipe Sizing - CapacIty of Pipe . . . . . . . . . . . . . . . . . 31

12 Altitude/Temperature Correction Factors . . . . . . . . . . . . 35

13 J**ZR Blower Performance Side Duct . . . . . . . . . . . . . . 38

14 J**ZR Blower Performance Bottom Duct . . . . . . . . . . . . 39

15 Belt Drive RPM Selection . . . . . . . . . . . . . . . . . . . . . . . . 40

1 J03 thru 05 ZR Component Location . . . . . . . . . . . . . . . . 6

2 Unit 4 Point Load Weight . . . . . . . . . . . . . . . . . . . . . . . . . 8

3 Unit 6 Point Load Weight . . . . . . . . . . . . . . . . . . . . . . . . . 8

4 Center of Gravity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Physical Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Hood Physical Dimensions . . . . . . . . . . . . . . . . . . . . . . 10

8 J03 thru 05 ZR Disconnect Location . . . . . . . . . . . . . . . 10

9 J03 thru 05 ZR Unit Side Duct Openings . . . . . . . . . . . . 11

10 J03 thru 05 ZR Roof Curb . . . . . . . . . . . . . . . . . . . . . . . 11

11 Condensate Drain . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

12 Compressor Restraining Bracket . . . . . . . . . . . . . . . . . . 13

TABLE OF CONTENTS

Cooling Sequence Of Operation . . . . . . . . . . . . . . . . . . . . 42

Reheat Mode Sequence Of Operation . . . . . . . . . . . . . . . 42

Cooling Operation Errors . . . . . . . . . . . . . . . . . . . . . . . . 43

Electric Heating Sequence Of Operations. . . . . . . . . . . . . 44

Electric Heat Operation Errors . . . . . . . . . . . . . . . . . . . . 44

Gas Heating Sequence Of Operations . . . . . . . . . . . . . . . 45

Gas Heat Operation Errors . . . . . . . . . . . . . . . . . . . . . . . . 46

Flash Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Resets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Heat Anticipator Setpoints. . . . . . . . . . . . . . . . . . . . . . . . . 47

Start-up (Cooling) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Start-up (Gas Heat) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Checking Gas Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Charging The Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Fan On And Off Delays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

LIST OF TABLES

16 Indoor Blower Specifications (Belt Drive) . . . . . . . . . . . . 40

17 Power Exhaust Specifications . . . . . . . . . . . . . . . . . . . . . 41

18 Additional Static Resistance . . . . . . . . . . . . . . . . . . . . . . 42

19 Electric Heat Limit Setting . . . . . . . . . . . . . . . . . . . . . . . . 45

20 Electric Heat Anticipator Setpoints . . . . . . . . . . . . . . . . . 45

21 Single Stage Gas Heat Limit Control Setting . . . . . . . . . 47

22 2 Stage Gas Heat Limit Control Setting . . . . . . . . . . . . . 47

23 Gas Heat Anticipator Setpoints . . . . . . . . . . . . . . . . . . . . 47

24 Gas Rate-Cubit Feet per Hour . . . . . . . . . . . . . . . . . . . . 49

25 J03ZR Charging Table . . . . . . . . . . . . . . . . . . . . . . . . . . 50

26 J04ZR Charging Table . . . . . . . . . . . . . . . . . . . . . . . . . . 51

27 J05ZR Charging Table . . . . . . . . . . . . . . . . . . . . . . . . . . 51

28 Unit Control Board Flash Codes . . . . . . . . . . . . . . . . . . . 58

29 Ignition Control Board Flash Codes . . . . . . . . . . . . . . . . 58

LIST OF FIGURES

13 Typical Field Power and Control Wiring . . . . . . . . . . . . . 15

14 Side Entry Gas Piping . . . . . . . . . . . . . . . . . . . . . . . . . . 31

15 Bottom Entry Gas Piping . . . . . . . . . . . . . . . . . . . . . . . . 31

16 Vent And Combustion Air Hood . . . . . . . . . . . . . . . . . . . 33

17 Enthalpy Set Point Chart . . . . . . . . . . . . . . . . . . . . . . . . 34

18 Economizer Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

19 Belt Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

20 Altitude/Temperature Correction Factors . . . . . . . . . . . . 36

21 Pressure Drop Across Coil . . . . . . . . . . . . . . . . . . . . . . . 41

22 Gas Valve Piping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

23 Typical Single Stage Gas Valves . . . . . . . . . . . . . . . . . . 48

24 Typical 2 Stage Gas Valves . . . . . . . . . . . . . . . . . . . . . . 48

25 Proper Flame Adjustment . . . . . . . . . . . . . . . . . . . . . . . 48

26 Typical Flame Appearance . . . . . . . . . . . . . . . . . . . . . . 49

27 Unit Control Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

860273-JIM-A-1012

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for Johnson Controls Unitary Products 5 Series

-

Page 1: Table Of Contents

R-410A SERIES 5 J**ZR 3 - 5 Ton 60 Hertz TABLE OF CONTENTS General ......... . 2 Cooling Sequence Of Operation . -

Page 2: General

Wear safety glasses and work gloves. Use quenching cloth and building, electrical, and mechanical codes. have a fire extinguisher available during brazing operations. Johnson Controls Unitary Products... - Page 3 • Technical Guide - J03 thru 05 ZJ/ZR/XP, 349666 • General Installation - J03 thru 05 ZR, 860273 This system uses R-410A Refrigerant which operates at higher pressures than R-22. No other refrigerant may be used in this system. Johnson Controls Unitary Products...

- Page 4 Y = Options 4 & 5 Z = Options 3, 4 & 5 Options 1 = Disconnect 2 = Non-Pwr'd Conv. Outlet 3 = Smoke Detector S.A. 4 = Smoke Detector R.A. 5 = Pwr'd Conv. Outlet Johnson Controls Unitary Products...

-

Page 5: Installation

30° F. 208/230-3-60 and 380/415-3-50 units with factory installed Powered Convenience Outlet Option are wired for 230v and 415v power supply respectively. Change tap on transformer for 208-3-60 or 380-3-50 operation. See unit wiring diagram. Johnson Controls Unitary Products... -

Page 6: J03 Thru 05 Zr Unit Limitations

Table 1: J03 thru 05 ZR Unit Limitations Unit Limitations Size Unit Voltage Applied Voltage Outdoor DB Temp (Tons) Max (°F) 208/230-1-60 208/230-3-60 (3.0) 460-3-60 575-3-60 208/230-1-60 208/230-3-60 (4.0) 460-3-60 575-3-60 208/230-1-60 208/230-3-60 (5.0) 460-3-60 575-3-60 Johnson Controls Unitary Products... -

Page 7: Location

7.3, or 7.4 of Gas Installation Codes, CSA-B149.1 (in Canada) - cable damage with plywood or other suitable material. Latest Edition, and/or applicable provisions of the local building codes. Refer to Table 4 for clearances required for combustible construction, servicing, and proper unit operation. Johnson Controls Unitary Products... -

Page 8: Weights And Dimensions

Unit Accessory Shipping Operating Economizer Power Exhaust Electric Heat Gas Heat 1. Weight given is for the maximum heater size available (30KW). 2. Weight given is for the maximum number of tube heat exchangers available (5 tube). Johnson Controls Unitary Products... -

Page 9: J03 Thru 05 Zr Cooling Only/Electric Heat Front View Physical Dimensions

860273-JIM-A-1012 Figure 5: J03 thru 05 ZR Cooling Only/Electric Heat Front View Physical Dimensions Figure 6: J03 thru 05 ZR Cooling Only/Gas Heat Front View Physical Dimensions Johnson Controls Unitary Products... -

Page 10: J03 Thru 05 Zr Unit Clearances

A, B, or C roof covering material. and Motor Access Panel for 2. Units must be installed outdoors. Overhanging structures Unit with “Belt-Drive” Option or shrubs should not obstruct condenser air discharge Figure 8: J03 thru 05 ZR Disconnect Location outlet. Johnson Controls Unitary Products... -

Page 11: J03 Thru 05 Zr Utilities Entry

Gas Piping (Bottom) 1. Opening in the bottom to the unit can be located by the slice in the insulation. 2. Do not remove the 2” knockout ring. Figure 10: J03 thru 05 ZR Roof Curb Johnson Controls Unitary Products... -

Page 12: Ductwork

Units are shipped with compressor mountings which are factory-adjusted and ready for operation. Units with scroll compressors have a shipping bracket which must be removed after the unit is set in place. See Figure 12. Figure 11: Condensate Drain Johnson Controls Unitary Products... -

Page 13: Filters

Voltage tolerances which must be maintained at the compressor terminals during starting and running conditions are indicated on the unit Rating Plate and Table 1. Johnson Controls Unitary Products... -

Page 14: Control Wire Sizes

18 AWG 150 Feet The thermostat should be located on an inside wall approximately 56 inch above the floor where it will not be 1. From the unit to the thermostat and back to the unit. Johnson Controls Unitary Products... -

Page 15: Typical Field Power And Control Wiring

24 volt wire. 24 VOLT TRANSFORMER Yellow WIRES LOCATED IN PROGRAMMABLE UNIT CONTROL BOX * DEHUMIDISTAT THERMOSTAT ONLY LOW VOLTAGE SECTIO Yellow * DEHUMIDISTAT CLOSES ON RISE IN HUMIDITY Figure 13: Typical Field Power and Control Wiring Johnson Controls Unitary Products... -

Page 16: Electrical Data

25.5 38.4 15.9 38.2 54.3 21.2 51.0 70.2 None 11.6 13.5 460-3-60 6.2 41.0 10.1 12.1 18.4 13.6 16.4 23.7 19.5 23.5 32.6 None 10.6 10.2 15.2 575-3-60 4.8 33.0 15.9 15.3 21.6 21.2 20.4 28.0 Johnson Controls Unitary Products... - Page 17 32.6 28.8 34.6 46.6 None 10.2 10.6 10.2 15.2 575-3-60 5.7 38.9 15.9 15.3 21.6 21.2 20.4 28.0 30.4 29.3 39.1 1. Minimum Circuit Ampacity. 2. Dual Element, Time Delay Type. 3. HACR type per NEC. Johnson Controls Unitary Products...

- Page 18 25.5 38.4 15.9 38.2 54.3 21.2 51.0 70.2 None 11.6 13.5 460-3-60 6.2 41.0 10.1 12.1 18.4 13.6 16.4 23.7 19.5 23.5 32.6 None 10.6 10.2 15.2 575-3-60 4.8 33.0 15.9 15.3 21.6 21.2 20.4 28.0 Johnson Controls Unitary Products...

- Page 19 34.4 28.8 34.6 48.4 None 11.8 10.6 10.2 17.2 575-3-60 5.7 38.9 15.9 15.3 23.6 21.2 20.4 30.0 30.4 29.3 41.1 1. Minimum Circuit Ampacity. 2. Dual Element, Time Delay Type. 3. HACR type per NEC. Johnson Controls Unitary Products...

- Page 20 27.0 11.1 27.0 15.5 28.9 208-3-60 13.7 83.1 21.4 22.2 37.3 11.9 33.0 50.8 15.9 44.1 64.7 None 27.0 12.7 27.0 18.0 32.1 230-3-60 13.7 83.1 21.4 10.6 25.5 41.4 15.9 38.2 57.3 21.2 51.0 73.2 Johnson Controls Unitary Products...

- Page 21 29.8 12.7 29.8 18.0 32.1 230-3-60 15.9 110.0 24.9 10.6 25.5 41.4 15.9 38.2 57.3 21.2 51.0 73.2 29.6 71.2 98.5 1. Minimum Circuit Ampacity. 2. Dual Element, Time Delay Type. 3. HACR type per NEC. Johnson Controls Unitary Products...

- Page 22 50.9 15.9 38.2 66.8 21.2 51.0 82.7 None 16.6 19.7 460-3-60 6.2 41.0 10.1 12.1 24.7 13.6 16.4 29.9 19.5 23.5 38.8 None 13.0 10.6 10.2 20.2 575-3-60 4.8 33.0 15.9 15.3 26.6 21.2 20.4 33.0 Johnson Controls Unitary Products...

- Page 23 38.8 28.8 34.6 52.8 None 14.2 10.6 10.2 20.2 575-3-60 5.7 38.9 15.9 15.3 26.6 21.2 20.4 33.0 30.4 29.3 44.1 1. Minimum Circuit Ampacity. 2. Dual Element, Time Delay Type. 3. HACR type per NEC. Johnson Controls Unitary Products...

- Page 24 50.9 15.9 38.2 66.8 21.2 51.0 82.7 None 16.6 19.7 460-3-60 6.2 41.0 10.1 12.1 24.7 13.6 16.4 29.9 19.5 23.5 38.8 None 13.0 10.6 10.2 20.2 575-3-60 4.8 33.0 15.9 15.3 26.6 21.2 20.4 33.0 Johnson Controls Unitary Products...

- Page 25 40.7 28.8 34.6 54.7 None 15.8 10.6 10.2 22.2 575-3-60 5.7 38.9 15.9 15.3 28.6 21.2 20.4 35.0 30.4 29.3 46.1 1. Minimum Circuit Ampacity. 2. Dual Element, Time Delay Type. 3. HACR type per NEC. Johnson Controls Unitary Products...

- Page 26 37.0 15.5 41.4 208-3-60 13.7 83.1 21.4 10.0 22.2 49.8 11.9 33.0 63.3 15.9 44.1 77.2 None 37.0 12.7 37.9 18.0 44.6 230-3-60 13.7 83.1 21.4 10.0 10.6 25.5 53.9 15.9 38.2 69.8 21.2 51.0 85.7 Johnson Controls Unitary Products...

- Page 27 12.7 39.8 18.0 44.6 230-3-60 15.9 110.0 24.9 10.0 10.6 25.5 53.9 15.9 38.2 69.8 21.2 51.0 85.7 29.6 71.2 111.0 1. Minimum Circuit Ampacity. 2. Dual Element, Time Delay Type. 3. HACR type per NEC. Johnson Controls Unitary Products...

-

Page 28: J03 Thru 05 Zr Physical Data

Fins per inch Tube diameter (in.) Circuitry Type Split-face Split-face Split-face EVAPORATOR COIL DATA Face area (Sq. Ft.) 5.06 5.06 5.06 Rows Fins per inch Tube diameter 0.375 0.375 0.375 Circuitry Type Split-face Split-face Split-face Refrigerant control Johnson Controls Unitary Products... - Page 29 Centrifugal Motor HP each 1050 1050 1050 FILTERS 15” x 20” x 1” or 2” 14” x 25” x 1” or 2” NOTE: All 2 Stage Gas Heat, 60% Capacity 1 Stage, 40% Capacity 2 Stage. Johnson Controls Unitary Products...

-

Page 30: Optional Electric Heat

NOTE: Gas Heaters are shipped available for natural gas, but can be converted to L.P. with Kit Model No. 1NP0440 or 1NP0485 (2 Stage). All furnaces meet the latest California seasonal efficiency requirements. 1. Based on 1075 Btu/Ft. 2. The air flow must be adjusted to obtain a temperature rise within the range shown. Johnson Controls Unitary Products... -

Page 31: Gas Pipe Sizing - Capacity Of Pipe

After the gas connections have been completed, open the main shut-off valve admitting normal gas pressure to the mains. Check all joints for leaks with soap solution or other material suitable for the purpose. NEVER USE A FLAME. Johnson Controls Unitary Products... - Page 32 “wetted surface” area of the container(s). The products of combustion are discharged horizontally through The proper pressure regulation. (Two-stage regulation is this screened, hooded vent opening on the gas heat access panel. recommended). Johnson Controls Unitary Products...

-

Page 33: Options/Accessories

When there is no call for free cooling, the damper will be made. position is limited by the IAQ Max damper position setting. When the signal exceeds it's set point (Demand Control Johnson Controls Unitary Products... -

Page 34: Enthalpy Set Point Chart

Figure 17: Enthalpy Set Point Chart condenser fans, or compressor rotate correctly. Blower Rotation Check for proper supply air blower rotation. If the blower is rotating backwards, the line voltage at the unit point of power connection is misphased (See ‘PHASING’). Johnson Controls Unitary Products... -

Page 35: Altitude/Temperature Correction Factors

0.743 0.715 0.688 0.982 0.947 0.913 0.880 0.848 0.817 0.787 0.758 0.730 0.702 0.676 0.964 0.929 0.897 0.864 0.833 0.802 0.772 0.744 0.716 0.689 0.663 0.946 0.912 0.880 0.848 0.817 0.787 0.758 0.730 0.703 0.676 0.651 Johnson Controls Unitary Products... -

Page 36: Altitude/Temperature Correction Factors

This value must be corrected for elevation. Example 2: A system, located at 5,000 feet of elevation, is to deliver 1,400 CFM at a static pressure of 1.5". Use the unit BHP at 5,000 ft. = 0.7 x .832 = 0.58 Johnson Controls Unitary Products... - Page 37 5 Turns 4 Turns 3 Turns 2 Turns 1 Turn Fully Model (Tons) Sheave Sheave Open Open Open Open Open Closed 1.73 1VL44 AK56 1060 1130 1195 1260 1VP56 AK56 1325 1395 1460 1525 1590 1660 Johnson Controls Unitary Products...

-

Page 38: Zr Blower Performance Side Duct

1. Blower performance includes gas heat exchangers and 1” filters. See STATIC RESISTANCE table for additional applications. 2. See RPM SELECTION table to determine desired motor sheave setting and to determine the maximum continuous BHP. 3. kW = BHP x 0.932. Johnson Controls Unitary Products... -

Page 39: Zr Blower Performance Bottom Duct

1. Blower performance includes gas heat exchangers and 1” filters. See STATIC RESISTANCE table for additional applications. 2. See RPM SELECTION table to determine desired motor sheave setting and to determine the maximum continuous BHP. 3. kW = BHP x 0.932. Johnson Controls Unitary Products... -

Page 40: Belt Drive Rpm Selection

AK66 1-1/2 1725 1.15 2.8 - 3.8 1VL44 AK56 J04ZR (4.0) 1-1/2 1725 1.15 4.0 - 5.0 1VP56 AK61 J05ZR 1-1/2 1725 1.15 2.8 - 3.8 1VL44 AK56 (5.0) 1725 1.15 4.0 - 5.0 1VP56 AK56 Johnson Controls Unitary Products... -

Page 41: Checking Supply Air Cfm

1000 1500 2000 2500 3000 3500 Insert at least 8" of 1/4 inch tubing into each of these holes NOMINAL CFM for sufficient penetration into the air flow on both sides of the indoor coil. Figure 21: Pressure Drop Across Coil Johnson Controls Unitary Products... -

Page 42: Operation

(RHG) and will associated with the operation. energize both the liquid line and the hot gas solenoids which directs hot gas through part of the indoor coil and decreases the sensible capacity of the unit. Johnson Controls Unitary Products... -

Page 43: Cooling Operation Errors

10 minutes on, 5 minutes off. The indoor blower is operated by the thumbwheel on the damper motor. When the “R” to “G” circuit is opened, the damper spring returns fully closed. Johnson Controls Unitary Products... -

Page 44: Electric Heating Sequence Of Operations

Remove the call for cooling, by raising thermostat setting higher heater and energizing the blower. than the conditioned space temperature. This resets any pressure or freezestat flash codes. Johnson Controls Unitary Products... -

Page 45: Gas Heating Sequence Of Operations

ICB will immediately move to high 0.35 0.38 fire operation. If a W1 and W2 call for heat is present, then the 0.35 0.38 furnace will remain on high fire operation until the W2 call for heat is satisfied. Johnson Controls Unitary Products... -

Page 46: Gas Heat Operation Errors

ICB will lock out furnace operation for 5 minutes. If the primary limit opens three times within one hour, then the UCB will lock on the indoor blower and flash a fault code (Table 28). Johnson Controls Unitary Products... -

Page 47: Flash Codes

Set the room thermostat to the off position. Turn “off” electric power to unit. Turn unit electrical power on. Turn room thermostat to lowest setting. Set the room thermostat fan switch to on. Turn gas valve knob or switch to “on” position. Johnson Controls Unitary Products... -

Page 48: Typical Single Stage Gas Valves

(Under Screw) High Fire Adj. (Under Screw) 1/8” gap between carry-over tube and flame sensor bulb Honeywell VR8204M “ON” - “OFF” Control Carry-over tube Figure 25: Proper Flame Adjustment Figure 23: Typical Single Stage Gas Valves Johnson Controls Unitary Products... -

Page 49: Checking Gas Input

The result is 99,750 With the furnace turned on, measure the time needed for Btuh, which is close to the 100,000 Btuh rating of the furnace. one revolution of the hand on the smallest dial on the Johnson Controls Unitary Products... -

Page 50: Charging The Unit

Pressure Indoor Db/Wb Pressure Temp. Temp. Evap Db Evap Db Amps Pressure 300 Cfm/Ton 80/62 300 Cfm/Ton 80/67 300 Cfm/Ton 80/72 300 Cfm/Ton 75/63 400 Cfm/Ton 80/62 400 Cfm/Ton 80/67 400 Cfm/Ton 80/72 400 Cfm/Ton 75/63 Johnson Controls Unitary Products... -

Page 51: J04Zr Charging Table

300 Cfm/Ton 10.6 80/67 11.8 10.0 300 Cfm/Ton 10.9 80/72 12.1 300 Cfm/Ton 10.8 75/63 11.9 400 Cfm/Ton 10.7 80/62 11.9 400 Cfm/Ton 10.7 80/67 11.6 400 Cfm/Ton 10.9 80/72 12.0 400 Cfm/Ton 10.8 75/63 11.9 Johnson Controls Unitary Products... -

Page 52: Troubleshooting

If 24 volts are not present volts at the HPS1, LPS1, and FS1 terminals of the UCB. If from the room thermostat, check for the following: a switch has opened, there should be a voltage potential Johnson Controls Unitary Products... - Page 53 LAS set point is reached. flash code troubleshooting section. Refer to Table 29 for flash code identification and component causing fault. Johnson Controls Unitary Products...

- Page 54 If clean, then replace the visually inspect the draft motor blower wheel area for flame sensor and adjust pilot per the start up procedures. If debris. If debris is present, then clear debris and verify Johnson Controls Unitary Products...

- Page 55 Loose blower wheel on draft motor. Verify that the blower On calls for heating, the draft motor operates and the furnace wheel is securely fastened to the draft motor shaft. lights but the supply air blower motor does not energize after a Johnson Controls Unitary Products...

- Page 56 The draft motor has inherent protection. If the motor shell is hot to the touch, wait for the internal overload to reset. Make the same checks and adjustment as described in “PILOT CHECKOUT” on page 49. Johnson Controls Unitary Products...

-

Page 57: Fan On And Off Delays

Control Board one time within five seconds, any anti-short cycle delays (ASCD) is by-passed for one cycle. When this button is pressed twice within five seconds, any active lockouts are reset. Figure 27: Unit Control Board Johnson Controls Unitary Products... -

Page 58: Unit Control Board Flash Codes

No Power or Control Failure 1. These flash codes do not represent alarms. Subject to change without notice. Printed in U.S.A. 860273-JIM-A-1012 Copyright © 2012 by Johnson Controls, Inc. All rights reserved. Supersedes: 409130-JIM-H-0212 Johnson Controls Unitary Products 5005 York Drive Norman, OK 73069...

Need help?

Do you have a question about the 5 Series and is the answer not in the manual?

Questions and answers