Table of Contents

Advertisement

Quick Links

MOUNTING AND

OPERATING INSTRUCTIONS

EB LTR 43

Translation of the original manual

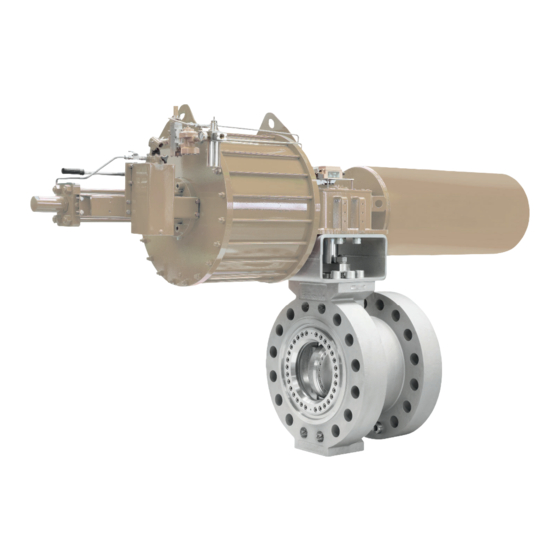

Control and shut-off valve type LTR 43 in the standard version

to combine with actuators

May 2023 edition

LEUSCH GmbH Industriearmaturen · Ziegeleistraße 10 · 41472 Neuss

Phone: +49 2131 7699-0 · Fax: +49 2131 7699-129

E-Mail: sales-leusch-de@samsongroup.com · Internet: www.leusch.de

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for Samson EB LTR 43

- Page 1 MOUNTING AND OPERATING INSTRUCTIONS EB LTR 43 Translation of the original manual Control and shut-off valve type LTR 43 in the standard version to combine with actuators May 2023 edition LEUSCH GmbH Industriearmaturen · Ziegeleistraße 10 · 41472 Neuss Phone: +49 2131 7699-0 · Fax: +49 2131 7699-129...

- Page 2 The notes and instructions in this EB are binding when handling SAMSON LEUSCH devices. The fi gures and illustrations in this EB are examples and must therefore be considered as such. For safe and correct use, read this EB carefully prior to use and keep it for later reference.

-

Page 3: Table Of Contents

Content Content Safety instructions and safety measures Notes regarding possible severe personnel injury Notes regarding possible personnel injury Notes regarding possible property damage Warning notes on the device Markings on the device Control and shut-off valve type plate Actuator type plate Material markings Design and principle of operation Variants... - Page 4 11.1 Removing the butterfl y valve with an assembled actuator from the pipe 11-1 11.2 Disassembling the actuator 11-2 12 Repairs 12-1 12.1 Sending devices to SAMSON LEUSCH 12-1 13 Disposal 13-1 14 Certifi cates 14-1 Annex 15-1 15.1 Tightening torques, lubricant and tools 15-1 15.1.1...

-

Page 5: Safety Instructions And Safety Measures

LEUSCH. Changes, conversions and other modifi cations to the valve are − SAMSON LEUSCH shall not be held liable for damage that not authorised by SAMSON LEUSCH. They are made at your result from non-compliance with the intended use, as well as own risk and can lead to safety risks, for example, that cause the for damage that results from external forces or external infl... -

Page 6: Notes Regarding Possible Severe Personnel Injury

VDI 2180, EN 61508, EN 61511) and in the applicable Danger due to falling of suspended loads! SAMSON Group Manual (Functional safety for control Do not stand under suspended loads. valves, rotary plug valves, ball valves and control butterfl y Secure the transport paths. -

Page 7: Notes Regarding Possible Personnel Injury

Do not allow the jamming of objects in the bracket to hinder butterfl y valve. the rotation of the shaft. In the case of a blocked shaft, contact SAMSON LEUSCH Danger due to escaping medium as a result of unsuitable through the nearest SAMSON offi ce. -

Page 8: Notes Regarding Possible Property Damage

Safety instructions and safety measures WARNING NOTE Danger of injury due to pressurised components and escaping Damage to the butterfl y valve due to unsuitable tools! medium! Unsuitable tools can damage the valve. Do not loosen pressurised components. Suitable commercially available tools are needed to work on the butterfl... -

Page 9: Markings On The Device

Markings on the device The preferable pressure force direction is marked by a direction Markings on the device arrow that is integrated in the butterfl y valve body or is fastened as a metal label on the body in a suitable position. Further infor- 2.1 Control and shut-off valve type plate mation can be provided on additional metal labels. - Page 10 Markings on the device EB LTR 43_EN May 2023 edition Subject to technical changes...

-

Page 11: Design And Principle Of Operation

Design and principle of operation Design and principle of operation Figure 3-1: Sectional view LTR 43 Table 3-1: Parts list Pos. Designation Pos. Designation Body Bracket Disc Coupling Seal ring Packing Seat Centre console actuator Shaft Spring cylinder actuator Cover Pneumatic cylinder actuator Gland The LTR 43 is a triple-eccentric control and shut-off butterfl... -

Page 12: Variants

Design and principle of operation The butterfl y valve reaches its maximum tightness when it is oper- Various variants and special designs, such as a heating jacket ated according to the preferable pressure force direction (FTC) body, sealing gas connections, exterior bearing points, oxygen when installed in the pipe system. -

Page 13: Control-Related Additional Equipment

DIN EN 60534-4 (Leakage class I-VI) − Others upon agreement Noise emissions SAMSON LEUSCH cannot make a general statement about noise emission. Noise emissions depend on the version of the butterfl y valve, the plant equipment as well as the utilised medium. - Page 14 Design and principle of operation EB LTR 43_EN May 2023 edition Subject to technical changes...

-

Page 15: Shipment And On-Site Transport

2. Check the supply for transport damage. Report transport Damage to the valve due to improper fastening of the sling! damage through the nearest SAMSON offi ce to SAMSON The lifting eye/eyebolts on the actuators are used only for actua- LEUSCH and the transport company, see the delivery note. -

Page 16: Storing The Valve

In the case of deviating storage conditions and long storage, contact SAMSON LEUSCH through the nearest SAMSON of- fi ce. Info SAMSON LEUSCH recommends checking the valve and the stor- age conditions regularly during a longer storage period. EB LTR 43_EN May 2023 edition... - Page 17 Example of elastomer: Actuator seals To maintain the shape and avoid the formation of cracks, do not suspend or bend elastomers. SAMSON LEUSCH recommends a storage temperature of 15 °C for elastomers. Store elastomers separately from lubricants, chemicals, solutions and fuels.

- Page 18 Shipment and on-site transport EB LTR 43_EN May 2023 edition Subject to technical changes...

-

Page 19: Installation

The work described in this chapter may only be performed by Table 5-1. specialist personnel qualifi ed to perform the corresponding task. If the lengths recommended by SAMSON LEUSCH are Observe chapter 4.3 for transport to the installation site. signifi cantly undershot, contact SAMSON LEUSCH. -

Page 20: Preparing For Assembly

-60 °C or above 350 °C only up to the maxi- actuator mum permissible height. The SAMSON LEUSCH actuators are delivered in working order. In the case of high temperature applications, insulate only the In individual cases, the actuator and butterfl y valve are delivered lowest third of the insulation part. -

Page 21: Installing The Actuator In The Pipe

“OPEN” and “CLOSED” end stops must be Any change to the “OPEN” and “CLOSED” end stops preset by adapted to the butterfl y valve. SAMSON LEUSCH is only permissible upon consultation and ap- proval. WARNING Danger and damage due to use of an electrical actuator! 5.3.2... -

Page 22: Checking The Assembled Actuator

Do not allow the jamming of objects in the bracket to hinder the rotation of the shaft. In the case of a blocked shaft, contact SAMSON LEUSCH through the nearest SAMSON offi ce. Danger of injury due to preloaded springs! -

Page 23: Pressure And Leak Test

torque, see Chapter “15.1.1 Tightening torques” or 10017, Annex 15.2. In the case of insuffi cient tightness, contact SAMSON LE- Upon request, the After Sales Service can provide you with sup- USCH through the nearest SAMSON offi ce. port for the planning and implementation of a leak test specifi c to your plant. -

Page 24: Checking The Rotary Movement

Installation 5.4.2 Checking the rotary movement The rotary movement of the actuator shaft must be even (smooth). 5.4.3 Checking the fail-safe position It must be checked if the actuator moves to the fail-safe position indicated on the actuator type plate, see Chapter “3 Design and principle of operation”. -

Page 25: Start-Up

(seat/seal ring) and require more frequent maintenance In the case of a blocked shaft, contact SAMSON LEUSCH intervals. through the nearest SAMSON offi ce. - Page 26 Start-up EB LTR 43_EN May 2023 edition Subject to technical changes...

-

Page 27: Operation

Do not allow the jamming of objects in the bracket to hinder the rotation of the shaft. In the case of a blocked shaft, contact SAMSON LEUSCH through the nearest SAMSON offi ce. Danger of injury due to escaping exhaust air! During operation, when regulating or when opening and closing the butterfl... - Page 28 Operation EB LTR 43_EN May 2023 edition Subject to technical changes...

-

Page 29: Malfunction

Contact SAMSON LEUSCH through the nearest SAMSON offi ce. In the case of faults that are not listed in the table, contact the After Sales Service at SAMSON LEUSCH. In this case, contact the nearest SAMSON offi ce. Recommissioning after faults 8.2 Carrying out emergency measures... - Page 30 Malfunction EB LTR 43_EN May 2023 edition Subject to technical changes...

-

Page 31: Servicing

Do not allow the jamming of objects in the bracket to hinder the rotation of the shaft. Info In the case of a blocked shaft, contact SAMSON LEUSCH The actuator was checked by SAMSON LEUSCH prior to through the nearest SAMSON offi ce. -

Page 32: Periodic Tests

Servicing − Certain test results certifi ed by SAMSON LEUSCH are no Measures in the case of a negative test Test longer valid when performing maintenance work on the result actuator. This includes the test for seat leakage and the leak... - Page 33 Servicing 9.3.3.1 Replacing the packing Figure 9-1: Packing replacement Table 9-1: Parts list Pos. Designation Pos. Designation Shaft Gland Screw Bracket Coupling Wedge-lock-washer Packing Stud bolt Screw Washer Support ring Actuator Spring washer EB LTR 43_EN May 2023 edition Subject to technical changes...

- Page 34 If there is still leakage, contact washers (59). When reassembling the spring washer set, ob- SAMSON LEUSCH through the nearest SAMSON offi ce. serve the correct sequence and alignment. Release the screws (108) until the stuffi ng box can be pulled off.

-

Page 35: Maintenance Work On The Butterfl Y Valve In A Removed Condition

Chapter “15.1.1 Tightening torques” or LW-10017 Annex 15.2. Check the butterfl y valve for any leaks in this area prior to commissioning. If there is still leakage, contact SAMSON LE- USCH through the nearest SAMSON offi ce. 9.3.4 Maintenance work on the butterfl y valve in a removed condition Observe Chapter 11 for actuator disassembly. -

Page 36: Butterfl Y Valve Ltr 43-4 And Ltr

Servicing 9.5.3 Butterfl y valve LTR 43-4 and LTR 43-9.4 Figure 9-6: LTR 43-4 and LTR 43-9.4 Table 9-5: Parts list for LTR 43-4 and LTR 43-9.4 Pos. Designation Body Wedge-lock-washer Clamping ring Seal ring 9.5.4 Butterfl y valve LTR 43-9.9 Figure 9-7: LTR 43-9.9 Table 9-6: Parts list for LTR 43-9.9... -

Page 37: Decommissioning

Do not allow the jamming of objects in the bracket to hinder the rotation of the shaft. If the shaft is blocked, contact SAMSON LEUSCH through the nearest SAMSON offi ce. Danger of injury due to escaping exhaust air! During operation, when regulating or when opening and closing the butterfl... - Page 38 Decommissioning EB LTR 43_EN 10-2 May 2023 edition Subject to technical changes...

-

Page 39: Removal

The After Sales Service of SAMSON is glad to provide on-site served. consultation and support. Contact the nearest SAMSON offi ce. -

Page 40: Disassembling The Actuator

Removal DANGER Danger of injury due to a spring-loaded opening actuator The uncontrolled swinging movement of the wedge-lock-washer can be dangerous. Do not stay in danger zone. Mark or document the installation position of the actuator. For the transport and storage of the actuator, observe Chapter “4 Shipment and on-site transport”. -

Page 41: Repairs

If required, SAMSON LEUSCH can be contacted through the nearest SAMSON offi ce. 12.1 Sending devices to SAMSON LEUSCH Defective actuators can be sent to SAMSON LEUSCH for repair. When returning devices to SAMSON LEUSCH, proceed as follows: Decommission the actuator, see chapter 10, and disassemble it, see Chapter 11. - Page 42 Repairs EB LTR 43_EN 12-2 M;ai 2023 edition Subject to technical changes...

-

Page 43: Disposal

Disposal 13 Disposal For disposal, observe the local, national and international regulations. Do not dispose of old components, lubricant and hazardous materials with domestic waste. EB LTR 43_EN 13-1 May 2023 edition Subject to technical changes... - Page 44 Disposal EB LTR 43_EN 13-2 May 2023 edition Subject to technical changes...

-

Page 45: Certifi Cates

Certifi cates 14 Certifi cates The declaration of conformity is available on the following pages: − Declaration of conformity according to Pressure Equipment Directive 2014/68/EU and according to AD 2000 regulations, see Page 14-2. − Declaration of conformity according to Pressure Equipment Directive 2014/68/EU and according to EN 16668 and EN 1349, see page 14-3. - Page 46 Certifi cates EB LTR 43_EN 14-2 May 2023 edition Subject to technical changes...

- Page 47 Certifi cates EB LTR 43_EN 14-3 May 2023 edition Subject to technical changes...

- Page 48 Certifi cates EB LTR 43_EN 14-4 May 2023 edition Subject to technical changes...

- Page 49 Certifi cates EB LTR 43_EN 14-5 May 2023 edition Subject to technical changes...

- Page 50 Certifi cates EB LTR 43_EN 14-6 May 2023 edition Subject to technical changes...

-

Page 51: Annex

Annex 15 Annex 15.1.1.2 Stuffi ng box nuts (standard) Values in the following table according to technical data sheet 15.1 Tightening torques, lubricant and tools LW-10006 Table 15-2: PN 10 / 16 / 25 and cl150 (max. 28 bar) 15.1.1 Tightening torques Nominal size Graphite... - Page 52 Annex Table 15-4: PN 63 (cl400) (max. 70 bar) 15.1.1.3 Stuffi ng box nuts (TA-Luft) Nominal size Graphite PTFE Max. per- Values in the following table according to technical data sheet Stuffi ng Ø shaft packing packing missible LW-10007 [Nm] [Nm] [Nm]...

-

Page 53: Lubricant

Stuffi ng Ø Shaft Addresses for SAMSON AG and LEUSCH GmbH The addresses for SAMSON AG and LEUSCH GmbH as well as their representatives and service locations are available online at www.samsongroup.com. Necessary data Provide the following information in the case of questions and for troubleshooting: −... -

Page 54: Series Ltr43-2, Ltr43-9.2

Annex 15.3.1 Series LTR43-2, LTR43-9.2 Figure 15-3: Exploded drawing of series LTR43-2, LTR43-9.2 Table 15-9: Parts list for series LTR43-2, LTR43-9.2 Pos. Designation Pos. Designation Body Packing Disc Screw Seal ring Wedge-lock-washer Seat Screw Retaining ring Screw Shaft Stud bolt Cover Washer Gland... -

Page 55: Series Ltr43-3

Annex 15.3.2 Series LTR43-3 Figure 15-4: Exploded drawing of series LTR43-32 Table 15-10: Parts list for series LTR43-3 Pos. Designation Pos. Designation Body Packing Disc Screw Seal ring Wedge-lock-washer Shaft Screw Cover Stud bolt Gland Washer Extension Stud bolt Extension spacer Wedge-lock-washer Bracket Coupling... -

Page 56: Series Ltr43-4, Ltr43-9.4

Annex 15.3.3 Series LTR43-4, LTR43-9.4 Figure 15-5: Exploded drawing of series LTR43-4, LTR43-9.4 Table 15-11: Parts list for series LTR43-4, LTR43-9.4 Pos. Designation Pos. Designation Body Packing Disc Screw Seal ring Wedge-lock-washer Retaining ring Screw Shaft Screw Cover Stud bolt Gland Washer Extension... -

Page 57: Series Ltr43-9

Annex 15.3.4 Series LTR43-9 Figure 15-6: Exploded drawing of series LTR43-9 Table 15-12: Parts list for series LTR43-9 Pos. Designation Pos. Designation Body Packing Disc Screw Seal ring Wedge-lock-washer Seat Screw Retaining ring Screw Shaft Stud bolt Cover Washer Gland Stud bolt Extension Wedge-lock-washer... - Page 58 Annex EB LTR 43_EN 15-8 May 2023 edition Subject to technical changes...

- Page 59 EB LTR 43_EN May 2023 edition Subject to technical changes...

- Page 60 SAMLooP LEUSCH GMBH Ziegeleistraße 10 · 41472 Neuss, Germany Phone: 02131 7699-0 E-Mail: info-leusch-de@samsongroup.com Internet: www.leusch.de EB LTR 43_EN May 2023 edition Subject to technical changes...

Need help?

Do you have a question about the EB LTR 43 and is the answer not in the manual?

Questions and answers