Summary of Contents for Gree GEH18AA-K3DNA1D

- Page 1 Change for Life Service Manual Models: GEH12AA-K3DNA1D GEH18AA-K3DNA1D (Refrigerant R410A) GREE ELECTRIC APPLIANCES,INC.OF ZHUHAI...

-

Page 2: Table Of Contents

6.1 Remote Controller Introduction ..................15 6.2 Operation of Smart Control (Smart Phone, Tablet PC) ..........19 6.3 Operation of Smart Control (Smart Phone, Tablet PC) For Gree ........30 6.4 Brief Description of Modes and Functions ..............41 Part Ⅱ : Installation and Maintenance ..........43... - Page 3 Service Manual 10. Exploded View and Parts List ..............63 10.1 Indoor Unit ........................63 10.2 Outdoor Unit .........................65 11. Removal Procedure ..................69 11.1 Removal Procedure of Indoor Unit ................69 11.2 Removal Procedure of Outdoor Unit ................73 Appendix: ........................85 Appendix 1: Reference Sheet of Celsius and Fahrenheit ............85 Appendix 2: Configuration of Connection Pipe ..............85 Appendix 3: Pipe Expanding Method ...................86 Appendix 4: List of Resistance for Temperature Sensor ............87...

-

Page 4: Part Ⅰ : Technical Information

Service Manual Part Ⅰ : Technical Information 1. Summary Indoor Unit GEH12AA-K3DNA1D/I GEH18AA-K3DNA1D/I Outdoor Unit GEH18AA-K3DNA1D/O(LCLH) GEH12AA-K3DNA1D/O(LCLH) Remote Controller YAA1FB8(WiFi) Technical Information... -

Page 5: Specifications

Service Manual 2. Specifications 2.1 Specification Sheet Parameter Unit Value Model GEH12AA-K3DNA1D GEH18AA-K3DNA1D Product Code CV010002600 CV010002400 Rated Voltage V ~ 220-240 220-240 Power Rated Frequency Supply Phases Power Supply Mode Outdoor Outdoor Cooling Capacity(Min~Max) 3500 5200 Heating Capacity(Min~Max) 3750... - Page 6 Service Manual Outdoor Unit Model GEH12AA-K3DNA1D/O GEH18AA-K3DNA1D/O Outdoor Unit Product Code CV010W02600 CV010W02400 ZHUHAI LANDA COMPRESSOR ZHUHAI LANDA COMPRESSOR Compressor Manufacturer CO.,LTD CO.,LTD Compressor Model QXA-B102zE190 QXA-B141zF030 Compressor Oil RB68EP 68EP Compressor Type Rotary Rotary Compressor LRA. Compressor RLA Compressor Power Input...

-

Page 7: Operation Characteristic Curve

Service Manual 2.2 Operation Characteristic Curve Heating Cooling 220V 220V • Conditions Indoor : DB27˚C/WB19˚C Outdoor : DB35˚C/WB24˚C Indoor air flow : High Pipe length : 5m 230V 230V 240V • Conditions 240V Indoor : DB20˚C/WB15˚C Outdoor : DB7˚C/WB6˚C Indoor air flow : High Pipe length : 5m Compressor frequency(Hz) -

Page 8: Capacity Variation Ratio According To Temperature

Service Manual 2.3 Capacity Variation Ratio According to Temperature Cooling Heating • Conditions • Conditions Indoor: DB27°C/WB19°C Indoor: DB20°C/WB15°C Outdoor: DB35°C/WB24°C Outdoor: DB7°C/WB6°C Indoor air flow: High Indoor air flow: High Pipe length: 5m Pipe length: 5m –15 –10 –5 Outdoor temp. -

Page 9: Cooling And Heating Data Sheet In Rated Frequency

Service Manual 2.4 Cooling and Heating Data Sheet in Rated Frequency Cooling: Rated cooling Pressure of gas pipe Inlet and outlet pipe Compressor condition(°C) connecting indoor and temperature of heat Fan speed of Fan speed of Model frequency (DB/WB) outdoor unit exchanger indoor unit outdoor unit... -

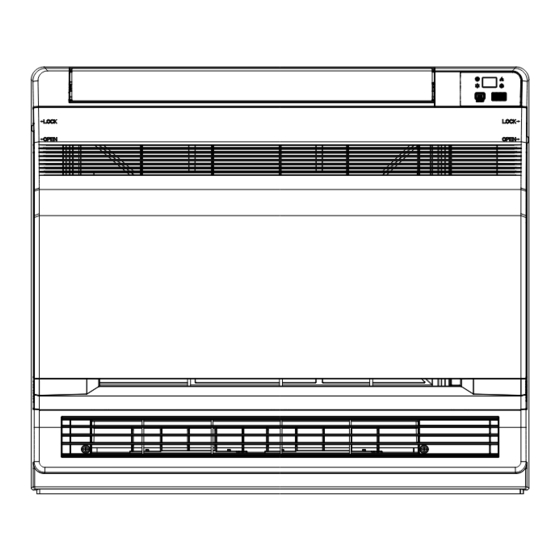

Page 10: Outline Dimension Diagram

Service Manual 3. Outline Dimension Diagram 3.1 Indoor Unit Unit:mm Technical Information... -

Page 11: Outdoor Unit

Service Manual 3.2 Outdoor Unit Unit:mm Unit:mm Technical Information... -

Page 12: Refrigerant System Diagram

Service Manual 4. Refrigerant System Diagram Indoor unit Outdoor unit Gas pipe side Valve 4-Way valve Di s charge Heat Suction exchanger (evaporator) Heat exchanger Liquid pipe (condenser) side Valve Electron Strainer Strainer expansion valve COOLING HEATING Connection pipe specification: Liquid pipe:1/4"... -

Page 13: Electrical Part

Service Manual 5. Electrical Part 5.1 Wiring Diagram ● Instruction Symbol Symbol Color Symbol Symbol Color Symbol Name White Green Jumper cap Yellow Brown COMP Compressor Blue Grounding wire YEGN Yellow/Green Black Violet Orange Note: Jumper cap is used to determine fan speed and the swing angle of horizontal lover for this model. ●... - Page 14 Service Manual ● Outdoor Unit 600007001181 6361000008302 These circuit diagrams are subject to change without notice, please refer to the one supplied with the unit. Technical Information...

-

Page 15: Pcb Printed Diagram

Service Manual 5.2 PCB Printed Diagram Indoor Unit ● Top view Name Interface of tube temperature sensor Interface of ambient temperature sensor Up swing interface Down swing interface Door control interface (this is only for the model with this function) Interface of EMC shielding wire DC motor interface Earthing wire of main board... - Page 16 Service Manual Outdoor Unit ● Top view Compressor UVW three phase input interface Interface of reactor Interface of fan 4-way valve Interface of earthing wire Interface of live wire Interface of netural wire Interface of communication Interface of electronic expansion valve Overload interface of compressor...

- Page 17 Service Manual ● Top view Name Terminal of compressor overload protection Terminal of temperature sensor Terminal of electronic expansion valve 4 Terminal of outdoor fan 5 Terminal of 4-way valve Terminal of compressorelectric heating Terminal of chassis electric heating Terminal of indoor unit and outdoor unit communication 9 Power supply live wire 10 Earthing wire...

-

Page 18: Function And Control

Service Manual 6. Function and Control 6.1 Remote Controller Introduction Buttons on Remote Controller ON/OFF button +/- button MODE button button SWING button I FEEL button button SLEEP button TEMP button QUIET button ClOCK button T-ON T-OFF button TURBO button WiFi WiFi button LIGHT button... - Page 19 Service Manual MODE button Each time you press this button , a mode is selected in a sequence that goes from AUTO,COOL, DRY, FAN, and HEAT * , as the following: *Note:Only for models with heating function. After energization, AUTO mode is defaulted. In AUTO mode, the set temperature will not be displayed on the LCD, and the unit will automatically select the suitable operation mode in accordance with the room temperature to make indoor room comfortable.(As for cooling only unit,it won’t have any action when it receives the signal of heating operation.) button...

- Page 20 Service Manual (1) Under Sleep 3 mode, press "Turbo" button for a long time, remote control enters into user individuation sleep setting status, at this time, the time of remote control will display "1hour ",the setting temperature "88" will display the corresponding temperature of last setting sleep curve and blink (The fi...

- Page 21 Service Manual WiFi button Press " WiF "i button to turn on or turn off WiFi function. When WiFi function is turned on, the " W i F i " icon will be displayed on remote controller; Under status of unit off, press "MODE" and "W i F i " " buttons simultaneously for 1s, WiFi module will restore to factory default setting.

-

Page 22: Operation Of Smart Control (Smart Phone, Tablet Pc)

8 numbers of the air condtioner mac address. Password is 12345678. Step 2: Open Gree APP and the screen will show the air conditioner that you just connected. Click this air conditioner to enter and realize short-distance control, as shown below. - Page 23 Service Manual If configuration succeeds, APP will notify user that configuration is successful and displays its homepage. If configuration failes, APP will notify user that configuation failes. In this case, please repeat the above steps until the APP shows that configuration is successful. Functions introduction 1.User registration Purpose: To realize long-distance control...

- Page 24 Service Manual 2.Personal setting Purpose: Set name (device name, preset name, etc.) and image (device image) for the convenience of user identification. (1) Set device name After quick configuration, a list of controllable smart devices will be generated. Step 1: Click and hold "a3" to enter the page "Edit device". Click "Image" to select the source of image. Select from "Default images" or "Take a picture"...

- Page 25 Service Manual (3) Set device image Please refer to the steps as instructed in 2(1) 3.Control functions (1) Common control functions: General control on the operation of smart devices(On/Off, temperature, fan speed, mode, etc.) and the setting of advanced functions(Air exchange, dry, heath, light, sleep, energy saving lower limit). Step 1: General control Enter the homepage "Home control"...

- Page 26 Service Manual Step 2: Advanced settings Click to enter advanced settings. You may select "Air", "Dry", "Health", "Light", "Sleep" or "Energy saving/ upper limit". (2) Advanced control functions: Set scene; Preset; Link; Infrared control (limited to the smart phone with infrared emitter) Set scene: Preset the operation of several devices by one click On the page "Home control", click the image of "Home control"...

- Page 27 Service Manual Save it and the scene "back home" will be executed. You may also view the execution condition of the scene. (3) Preset includes single-device preset and multi-device preset Single-device preset: This can preset a certain device to execute On/Off at a specific time.

- Page 28 Service Manual Multi-device preset: This can preset multiple devices to execute at a specified time Please refer to the instructions as how to set preset time, name, timer type and repeat days of a single device. On the page "Select device", select one or more devices to preset multiple devices.Then return to the page "Home control". (4) Link(This function is applicable to partial of models) set in the master device, slave devices will execute commands to realize devices Select a master device.

- Page 29 Service Manual Step 2: Set linkage time parameter. Click "Time parameter" to enter the page "Set time". Slide right to turn on the setting time. Click "Execution time" to select the start time and stop time. Then click "OK" to save the data. Click the days below "Repeat".

- Page 30 Service Manual Click "Save". Repeat the above steps to set linkage for several scenes. (5) Infrared control (limited to the smart phone with infrared emitter) Function: Smart phone can be used like a remote controller. Click at the top right corner of the homepage "Home control". Select "Infrared" and enter the page "Remote controller". Click and slide up to enter the page of advanced functions.

- Page 31 Service Manual 4.Menu functions Menu functions (Share, Set, History, Feedback) functions. (1) Share: To share quick configuration information and unit’s information, including local export and local import. For local import, you just need to select "Local import"and wait for the data download. Local export Step 1: Export local data to another smart phone.

- Page 32 Service Manual Select "Backup list on the cloud". Then backup records will appear. Click "Record"to download data and recover data to local unit. (3) Set User can set click vibration, message alerts, gesture password (usable only after registration), etc. (4) Feedback User may feedback suggestions to back-stage management for maintenance and development.

-

Page 33: Operation Of Smart Control (Smart Phone, Tablet Pc) For Gree

8 numbers of the air condtioner mac address. Password is 12345678. Step 2: Open Gree APP and the screen will show the air conditioner that you just connected. Click this air conditioner to enter and realize short-distance control, as shown below. - Page 34 Service Manual Please note: Please select the encrypt mode "empty" if your wifi has been set without password. Functions introduction 1.User registration Purpose: To realize long-distance control Operation instruction: For the first time login, you have to register a new username. If you already have a username, skip the registration step and enter email address and password on the "Login Page"...

- Page 35 Service Manual 2.Personal setting Purpose: Set name (device name, preset name, etc.) and images (device image) in order to identify a user easily. (1) Set device name After quick configuration, a list of controllable smart devices will be generated. Default name for air conditioner is "AC". Step 1: Tap and hold "babyroom"...

- Page 36 Service Manual (3) Set device image Please refer to step 1 in 2(1) 3.Control functions (1) Common control functions: General control on the operation of smart devices (On/Off, temperature, fan speed, mode, etc.) and the setting of advanced functions (air exchange, dry, health, light, sleep, energy saving upper limit). Step 1: General control Enter the homepage ""Device"...

- Page 37 Service Manual Step 2: Advanced settings Tap to enter advanced settings. You mayselect "Air", "Dry", "Health", "Light", "Sleep" or "Energy saving". (2) Advanced control functions: Set scene; Preset; Link: Infrared control (only applicable to smart phone with infrared emitter) Set scene: Preset the operation of several smart devices by one tap. On the page "Device", tap the image of "Device" to enter the page "Edit scene".

- Page 38 Service Manual Continue to select the next execution device as instructed above. Tap to set the interval. Tap "Save". Tap the scene picture displaye d in "Home control" home page to send the command. Then the scene "Back home" will be in execution.

- Page 39 Service Manual Tap "Name" to customize the preset name. Preset device can’t be selected and it will default to "babyroom". Select "On" for the timer type. Select repeating days to complete the preset. Multi-device preset: This can preset multiple devices to execute a command at a specific time. Please refer to the instructions as how to set preset time, name, timer type and repeating days for a single device.

- Page 40 Service Manual Tap "Temperature" to enter the page "Select temperature parameter". Slide up or down to adjust temperature. Tap "Upper limit" or "Lower limit". Tap "Mode" and "On/Off" to select the status of master device. Then tap "Save". Step 2: Set time parameter for linkage. Tap "Time parameter" to enter the page "Set time". Slide rightwards to turn on the setting time.

- Page 41 Service Manual Tap the name of device that you want to control. Tap "ON" or "OFF" and then tap "Save" to complete the linkage. Tap "Save" and then repeat the above steps to set linkage of several scenes. (5) Infrared control (only applicable to smart phone with infrared emitter). Function: Smart phone can be used as a r emote controller.

- Page 42 Service Manual to turn on the device. Tap to select mode. Tap to adjust fan speed . Tap "Health", "Energy saving", "Sleep" etc. to setadvanced functions. Tap "Sleep" to enter the page "Sleep". You can select "Traditional sleep", "Expert sleep" or "DIY sleep". Tap "DIY sleep" and then tap the left and right arrows to set sleep time.

- Page 43 Service Manual Tap "Backup to cloud" and then tap "Yes". Then wait for the data download. Select "Backup list on the cloud". Then backup records will appear. Tap "Record" to download data and recover data to local unit. (3) Settings User can set vibration, message alerts, gesture password (usable only after registration), etc.

-

Page 44: Brief Description Of Modes And Functions

Service Manual 6.4 Brief Description of Modes and Functions 1. Cooling mode (1) Under this mode, the fan and the up swing will operate at setting status. The temperature setting range is 16~30ºC. (2) The unit is stopped because of malfunction of outdoor unit or protection. The indoor unit keeps original operation status and the error code is displayed. - Page 45 Service Manual 7.4 I FEEL function When I FEEL command is received, the controller will operate according to the ambient temperature sent by the remote controller (For defrosting and cold blow prevention, the unit operates according to the ambient temperature sensed by the air conditioner). The remote controller will send ambient temperature data to the controller every 10min.

-

Page 46: Part Ⅱ : Installation And Maintenance

Service Manual Part Ⅱ : Installation and Maintenance 7. Notes for Installation and Maintenance Safety Precautions: 10. If the power cord or connection wire is not long enough, please get the specialized power cord or connection wire Important! from the manufacture or distributor. Prohibit prolong the wire by yourself. - Page 47 Service Manual Main Tools for Installation and Maintenance 1. Level meter, measuring tape 2. Screw driver 3. Impact drill, drill head, electric drill 4. Electroprobe 5. Universal meter 6. Torque wrench, open-end wrench, inner hexagon spanner 7. Electronic leakage detector 8.

-

Page 48: Installation

Service Manual 8. Installation 8.1 Requirements for Electric Connection 1. Safety Precaution (1) Must follow the electric safety regulations when installing the unit. (2) If the supply cord is damaged, it must be replaced by the manufacturer or its service agent or a similarly qualified person in order to (avoid a hazard. - Page 49 Service Manual Cautions for installation where air conditioner troubleis liable Schematic drawing of hooks: tooccur. Where there is toomuch of oil area. Where it is acid base area. Where there is irregular electrical supply. 2. Indoor Unit Installation Drawings The indoor unit may be mounted in any of the three styles shown here.

- Page 50 Service Manual CAUTION Min.allowable length ● The suggested shortest pipe length is 2.5m,in order to avoid noise from the outdoor unit and vibration. (Mechanical noise and vibration may occur depending on how the unit is installed and the environment in which it is used.) ●...

- Page 51 Service Manual 3 tabs 6. Installing Indoor Unit Preparation Casing ●Open the front panel, remove the 4 screws and dismount Front the front grille while pulling it forward. grille ●Follow the arrows to disengage the clasps on the front case to remove it. Front panel Remove ●Follow the procedure below when removing the slit portions.

- Page 52 Service Manual (3) Once refrigerant piping and drain piping connections are complete, fill in the gap of the through hole with putty. A gap can lead to condensation on the refrigerant pipe, and drain pipe, and the entry of insects into the pipes. (4) Attach the front panel and front grille in their original positions once all connections are complete.

- Page 53 Service Manual Selection of Copper and Heat Insulation Materials Inter-unit wiring When using commercial copper pipes and fittings, observe the Gas pipe following: Liquid pipe (1) Insulation material: Polyethylene foam Heat transfer rate:0.041 to 0.052W/mK(0.035 to 0.045kca/(mh Liquid pipe Refrigerant gas pipes surface temperature reaches 110 max. Gas pipe insulation insulstion...

-

Page 54: Outdoor Unit Installation

Service Manual Sensor securing plate Firmly fix the wires with the terminal screws Outdoor unit Terminal block Shape wires so N(1) When wire length exceeds 10m, that the front metal use 2.0mmdiameter wires Electrical plate cover will fit component securely. Wire retainer Firmly secure wire retainer so that... -

Page 55: Vacuum Pumping And Leak Detection

Service Manual 2. Install Drain Joint(Only for cooling and heating unit) Foot holes (1) Connect the outdoor drain joint into the hole on the chassis. (2) Connect the drain hose into the drain vent. 3. Fix Outdoor Unit (1) Place the outdoor unit on the support. (2) Fix the foot holes of outdoor unit with bolts. -

Page 56: Check After Installation And Test Operation

Service Manual 2. Leakage Detection (1) With leakage detector: Check if there is leakage with leakage detector. (2) With soap water: If leakage detector is not available, please use soap water for leakage detection. Apply soap water at the suspected position and keep the soap water for more than 3min. -

Page 57: Maintenance

Service Manual 9. Maintenance 9.1 Error Code List Malfunction and Mode Display Sheet Malfunction name Malfunction type Double 8 Zero-cross detection circuit malfunction Hardware malfunction Malfunction protection of jumper cap Hardware malfunction No feedback of indoor motor Hardware malfunction Indoor ambient temperature sensor is Hardware malfunction open/short- circuited Indoor evaporator temperature sensor is... - Page 58 Service Manual Refrigerant recovery mode Running mode Defrosting or oil return in heating mode Running mode Rating cooling or heating Running mode Max cooling or heating Running mode Middle cooling or heating Running mode Min cooling or heating Running mode Compressor losing of synchronism Compressor start failure High discharge temperature protection of...

-

Page 59: Troubleshooting For Main Malfunction

Service Manual 9.2 Troubleshooting for Main Malfunction (1) Troubleshooting for malfunction of temperature sensor main check point: ●Whether the temperature sensor is broken or damaged; ●Whether the temperature sensor terminal is loosened or not connected; ●Whether the mainboard is damged; Check flow chart: Start the troubleshooting for temperature sensor... - Page 60 Service Manual (2) Troubleshooting for communiction malfunction Main check point: ●Check whether the connection wire for indoor and outdoor units and the wires inside the indoor unit is connected well; ●Check whether the mainboards of indoor unit or outdoor unit are damaged; Check flow chart: Communication malfunction for some indoor unit...

- Page 61 Service Manual All indoor units alarms communication malfunction Disconnect the power, and check connection wire for indoor and outdoor units and wires inside electric box are connected correctly Connect wire Wires are connectly according connected correctly? Is malfunction eliminated? to wiring diagram Disconnect the power, and check whether theconnection wires between mainboard of outdoorunit and filter palte are connected...

- Page 62 Service Manual (3) Troubleshooting for C5 malfunction Display displays C5 Check whether the Insert the jumper mainbaord ofcontroller is inserted with thejumper cap? Is malfunction eliminated? Check Re-insert the jumper whether the jumper cap is poorly connected? Is malfunction eliminated? Replace the jumper Is malfunction eliminated?

- Page 63 Service Manual (4) Troubleshooting for H6 malfunction Start the troubleshooting for H6 malfunction Check whether the terminal of DC motor is connected tightly Insert the motor terminal tightly Is mafunction eliminated? Pull blade with hand to see whether it can rotate smoothly Re-assemble blade and motor correctly...

-

Page 64: Maintenance Method For Normal Malfunction

Service Manual 9.3 Maintenance Method for Normal Malfunction 1. Air Conditioner Can't be Started Up Possible Causes Discriminating Method (Air conditioner Status) Troubleshooting Confirm whether it's due to power failure. If yes, No power supply, or poor After energization, operation indicator isn’t bright wait for power recovery. - Page 65 Service Manual 4. ODU Fan Motor Can't Operate Possible causes Discriminating method (air conditioner status) Troubleshooting Connect wires according to wiring diagram to Wrong wire connection, or poor Check the wiring status according to circuit make sure all wiring terminals are connected connection diagram firmly...

-

Page 66: Exploded View And Parts List

Service Manual 10. Exploded View and Parts List 10.1 Indoor Unit The component is only for reference;please refer to the actual product. Installation and Maintenance... - Page 67 Service Manual Part Code Description GEH12AA-K3DNA1D/I GEH18AA-K3DNA1D/I Product Code CV010N02600 CV010N02400 Front Panel Assy 20012756 20012756 Filter Sub-Assy 11122139 11122139 Front Case Assy 20012601 20012601 Evaporator Assy 01100100160 01100100164 Cold Plasma Generator 1114001604 1114001604 Rear Case Assy 000001000051 22202462 Centrifugal Fan...

-

Page 68: Outdoor Unit

Service Manual 10.2 Outdoor Unit The component is only for reference;please refer to the actual product. Installation and Maintenance... - Page 69 Service Manual Part Code Description GEH12AA-K3DNA1D/O Product Code CV010W02600 Electric Box Assy 100002002950 Electric Box Sub-Assy 017007000476 Main Board 300027000469 Reactor 43130184 Terminal Board 42010313 Wire Clamp 71010103 Front Grill 22413049 Front Panel 01533034P Axial Flow Fan 10333004 Chassis Sub-assy 017000000126P Fan Motor 1501308506...

- Page 70 Service Manual The component is only for reference;please refer to the actual product. Installation and Maintenance...

- Page 71 Service Manual Part Code Description GEH18AA-K3DNA1D/O Product Code CV010W02400 Front Grill 22413045 Front Panel 01535013P Drainage Connecter 06123401 Chassis Sub-assy 02803270P Drainage hole Cap 06813401 Compressor and fittings 00105246G Magnet Coil 4300040045 4-Way Valve Assy 03015200069 Cut off Valve Assy 1/2...

-

Page 72: Removal Procedure

Service Manual 11. Removal Procedure Warning: Be sure to wait for a minimum of 20 minutes after turning off all power supplies and discharge the refrigerant completely before removal. 11.1 Removal Procedure of Indoor Unit Steps Procedure 1. Remove panel Pull sliding clasps at both sides of panel, pull out the panel outwards and then move the panel upwards to remove it. - Page 73 Service Manual 4. Remove swing parts swing parts screw Remove 2 screws fixing the swing parts, and then pull the swing parts outwards to remove it. 5. Remove water tray Remove 2 screws fixing water tray, and then pull the water tray outwards to remove it.

- Page 74 Service Manual 7. Remove fixer of piping Pry out the clasps connecting fixer of piping and bottom case, and then pull the fixer of piping outwards to remove it. clasps fixer of piping 8. Remove evaporator Pry out the clasps connecting evaporator clasps and bottom case, and then pull the evaporator...

- Page 75 Service Manual 10. Remove centrifugal blade Remove one nut fixing the centrifugal blade, and then pull the centrifugal blade outwards to remove it. centrifugal blade 11. Remove fixing bracket of motor Remove 3 nuts on fixing bracket of motor, and then pull the fixing bracket of motor fixing bracket outwards to remove it.

-

Page 76: Removal Procedure Of Outdoor Unit

Service Manual 11.2 Removal Procedure of Outdoor Unit Steps Procedure 1. Remove big handle Right side plate Remove the screw fixing big handle; slide out the big handle upwards to make the clasp of big handle separate from the groove of right side plate, and then remove the big handle. - Page 77 Service Manual Steps Procedure 4. Remove front panel Screws Remove the screws fixing front panel,and then remove the front panel. Screws Screws Panel Screws 5. Remove axial flow blade Remove the nut fixing axial flow blade and then remove the axial flow blade. Axial flow blade Installation and Maintenance...

- Page 78 Service Manual Steps Procedure 6. Remove protective grille and right side plate Remove the screws 1 fixing protective grille and then remove the protective Protective grille. grille Screws 2 Screws 1 Right side plate Right side plate Remove the screws 2 fixing right side plate and then remove the right side plate.

- Page 79 Service Manual Steps Procedure 8. Remove 4-way valve assy Unsolder the spot weld of 4-way valve assy, compressor and condenser, and then remove the 4-way valve assy . 4-way valve assy Note: When unsoldering the spot weld, wrap the 4-way valve with wet cloth completely to avoid damaging the valve due to high temperature.

- Page 80 Service Manual Steps Procedure 11. Remove gas valve and liquid valve Remove two screws fixing the gas valve, then remove the gas valve. Remove two screws fixing the liquid valve, then remove the liquid valve. Liquid valve Screws Gas valve Screws 12.

- Page 81 Service Manual Steps Procedure 14. Remove compressor Remove 3 foot nuts on compressor, and then remove the compressor. Note: Protect the ports of discharge pipe and suction pipe to avoid foreign objects to enter it. Compressor Foot nuts 15. Remove condenser Remove one screw fixing the condenser, then remove the condenser.

- Page 82 Service Manual Steps Procedure 1. Remove handle and valve cover Remove the screws used for fixing the handle and valve cover,pull the handle and valve Handle cover up ward to remove them. Screw Screw Valve cover 2. Remove top panel Screws Top panel Screws...

- Page 83 Service Manual Steps Procedure 4. Remove front panel Screws Front panel Remove the screws connecting the front panel with the chassis and the motor support, and then remove the front panel. Screws 5. Remove rear grill and right side plate Rear grill Remove the screws 1 connecing the left side Screws 2...

- Page 84 Service Manual Steps Procedure 6. Remove left side plate Left side plate Remove the screws connecting the left side plate and the chassis, and then remove the left side plate. Screws 7. Remove axial flow blade Remove the nut fixing the blade and then remove the axial flow blade.

- Page 85 Service Manual Steps Procedure 9. Remove electric box assy Screws Remove the screws fixing electric box Electric box assy assy ; pull out each wiring terminal; lift the electric box assy upwards to remove it. Note: When pulling out the wiring terminal, pay attention to loose the clasp and don’t pull it so hard.

- Page 86 Service Manual Steps Procedure 12. Remove clapboard Clapboard Remove the screws fixing clapboard and then remove the clapboard. Screws 13. Remove gas valve ,liquid valve and valve support Since the piping ports on the soundproof sponge are torn easily, remove the soundproof sponge carefully.

- Page 87 Service Manual Steps Procedure 15. Remove condenser Condenser Remove one screw fixing the condenser, then remove the condenser. Screw Installation and Maintenance...

-

Page 88: Appendix

Service Manual Appendix: Appendix 1: Reference Sheet of Celsius and Fahrenheit Conversion formula for Fahrenheit degree and Celsius degree: Tf=Tcx1.8+32 Set temperature Fahrenheit Fahrenheit Fahrenheit display Fahrenheit display Fahrenheit display Fahrenheit Celsius (℃) Celsius (℃) Celsius (℃) temperature temperature temperature (℉)... -

Page 89: Appendix 3: Pipe Expanding Method

Service Manual Appendix 3: Pipe Expanding Method Pipe Note: Pipe cutter Improper pipe expanding is the main cause of refrigerant leakage.Please expand the pipe according to the following steps: Leaning Uneven Burr A:Cut the pip ● Confirm the pipe length according to the distance of indoor unit and outdoor unit. ●... -

Page 90: Appendix 4: List Of Resistance For Temperature Sensor

Service Manual Appendix 4: List of Resistance for Temperature Sensor Resistance Table of Ambient Temperature Sensor for Indoor and Outdoor Units(15K) Temp( C) Resistance(kΩ) Temp( C) Resistance(kΩ) Temp( Resistance(kΩ) Temp( Resistance(kΩ) 138.1 18.75 3.848 1.071 128.6 17.93 3.711 1.039 121.6 17.14 3.579 1.009... - Page 91 Service Manual Resistance Table of Tube Temperature Sensors for Outdoor and Indoor(20K) Temp( C) Resistance(kΩ) Temp( C) Resistance(kΩ) Temp( Resistance(kΩ) Temp( Resistance(kΩ) 181.4 25.01 5.13 1.427 171.4 23.9 4.948 1.386 162.1 22.85 4.773 1.346 153.3 21.85 4.605 1.307 20.9 4.443 1.269 137.2 4.289...

- Page 92 Service Manual Resistance Table of Discharge Temperature Sensor for Outdoor(50K) Temp( C) Resistance(kΩ) Temp( Resistance(kΩ) Temp( C) Resistance(kΩ) Temp( Resistance(kΩ) 853.5 18.34 4.75 799.8 93.42 17.65 4.61 89.07 16.99 4.47 703.8 84.95 16.36 4.33 660.8 81.05 15.75 4.20 620.8 77.35 15.17 4.08 580.6...

- Page 93 GREE ELECTRIC APPLIANCES,INC.OF ZHUHAI Add: West Jinji Rd, Qianshan, Zhuhai, Guangdong, China 519070 Tel: (+86-756) 8522218 Fax: (+86-756) 8669426 Email: gree@gree.com.cn Http://www.gree.com HONG KONG GREE ELECTRIC APPLIANCES SALES LIMITED Add: Unit 2612,26/F.,Miramar Tower 132 Nathan Road,TST,Kowloon,HK Tel: (852) 31658898 Fax: (852) 31651029...

Need help?

Do you have a question about the GEH18AA-K3DNA1D and is the answer not in the manual?

Questions and answers