Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for Hyundai 20EPS

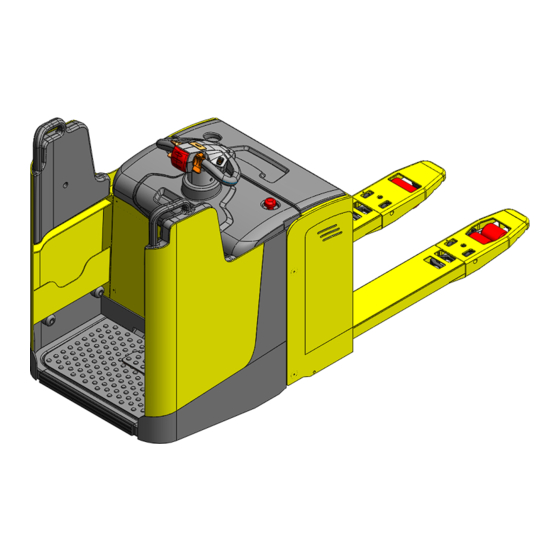

- Page 1 20EPS Electric Pallet Truck Operation Manual HYUNDAI CONSTRUCTION EQUIPMENT...

- Page 2 Welcome to choose “HYUNDAI” Electric pallet truck! We hope our electric trucks will bring great convenience to your work ! Please read the manual carefully before operation. This manual is a common manual. We reserve the right to modify technology of the electric pallet truck.

-

Page 3: Table Of Contents

......................1 Ⅱ.Forklift introduction ....................1 1. applications ......................1 2. service environment ....................1 3. technical parameters ....................1 3.1 structure ...................... 2 3.2 main technical parameters (20EPS Electric Pallet Truck) ........2 Operation ........................7 Ⅲ. 1Safety norms………………………………………………………………………………………………………..9 1.1 safety instructions ..................... -

Page 4: Ⅰ.specified Use

Ⅰ.Specified use The truck is introduced for a ground conveying equipment, suitable for lifting and transporting goods. Must be in strict accordance with the provisions of the operating instructions in use, operation and maintenance of forklift.it is used for any other purpose,which are not in conformity with the provisions operation behavior, can lead to injuries and fork lift truck or other property damage. -

Page 5: Ⅱ.forklift Introduction

Ⅱ.Forklift introduction 1. Applications 20EPS series electric pallet truck is powered by storage battery, and driven by motor. This kind of truck travels by means of gear transmission. The fork is lifted by means of DC motor and hydraulic actuation, which motivate hydraulic cylinder up and down to lift fork and goods together. - Page 6 Number 20EPS Name ● Frei Handle ● Electric lock ● Instrument ● Backrest、handrail ○ Built-in charger ● Pedal switch ● Standing platform ● Rubber stripe ● Drive power unit Steering power unit ● Hydraulic power unit ● Battery ● ○...

- Page 7 (1)Instrument: Electricity Quantity Indicator This instrument is a combination of battery capacity indicator and LCD hour meter, with the battery indicator of ten segments of colorful LED display (5 red segments, 3 yellow segments and 2 red LED).When battery discharges by 70% capacity, one red flicker lamp shows “energy storage”...

- Page 8 ①Lifting and lowering operation: Press the lowering button of the forks, the forks will lower. While the lifting button is pressed, the fork will lift. ②Accelerator knob: It is used to control the travel direction and speed of the electric truck. Before operation of the truck, firstly turn the operation handle to area B shown as above.

-

Page 9: Main Technical Parameters (20Eps Electric Pallet Truck)

3.2 Main technical parameters (20EPS Electric Pallet Truck) - Page 10 Manufacturer(abbreviated) HYUNDAI C. E. Model 20EPS Driving type Electric Operating type(Manual, Walking, Stand driving, Stand driving Seat driving ,Order picking) Rated load Q(kg) 2000 Load center distance (mm) Front overhang (mm) 815/865/835 Tread (mm) 1300/1350/1420 Service weight(with battery) Axle load, front/rear, laden...

-

Page 11: Ⅲ. Operation

Ⅲ. Operation Warning 1. Safety Norms Please pay attention to the following items first before operation of the truck: 1. This electric truck is only limited to utilization indoor with a hard flat floor. Operation in inflammable, explosive environment or corrosive environment such as acid or alkaline condition shall be strictly forbidden. 2. -

Page 12: Safety Instructions

1.1 Safety instructions ⑴Training of driver: Notice Even though each electric pallet truck may have the same technical parameters, there may be differences on features of braking and acceleration as well. Never drive the truck until you get familiar with all those operations. ⑵Wear of the driver during truck driving:... - Page 13 operation of the truck. Safety shall be taken into full consideration in preparation of the safety operation procedure.. (7)Operation of truck under unsafe condition is strictly forbidden: A Operation under unsafe condition is forbidden, such as under conditions with uneven floor, or impeded road.

- Page 14 other truck or vehicles. Avoid driving in places with bad view.. C Ensure to provide certain clearance between truck and entrance. (3) Never drive too close to roadside Ensure to provide enough distance between the truck and roadside or platform edge. (When running on narrow road or platform, keep a certain safety distance with the edge against falling of the truck).

-

Page 15: Inspection Before Operation

2. Drive and operation 2.1 Inspection before operation For the sake of safety operation and good situation of the electric truck, it is compulsory to check the truck completely before operation. Contact the sales department of our company when founding problems. -

Page 16: Driving

2.2 Driving: (1) Start-up Get on the standing pedal and open the guardrail to turn the switch of electric lock to ON position. When the operation handle is turned to area B and accelerator knob is rotated slowly, the truck will start gradually. -

Page 17: Important Notice After Operation

2.3 Important notice after operation (1) Parking: Park the truck at appointed place. Never park the truck on slope. Ensure the following points to be achieved before leaving away the truck: Lay down the fork to the lowest position naturally. Turn the steering wheel to the middle position. - Page 18 Ⅳ.Maintenance, charge and replacement of storage battery Standard configuration is external charger and the optional is built in charger. Charging operation method as follow: External charger Charging ways for external charger: Open the cover, the first step,pull out the charging socket from main circuit;step two,connect with charging plug of battery and charger;step three,put the battery socket into two-phase AC power supply;step four, open the power switch, it starts to charger in a few seconds.

-

Page 19: Initial Charge

Built-in charger Charging ways for built-in charger:open the cell box cover if the truck has car charger and then put one head of charger lead into charging socket hole.put the other head into two-phase AC power supply. It starts to charge in a few seconds. -

Page 20: Use And Maintenance

batteries with those of D.C. source (charger) respectively and then turn on the power. Charge with the current of 30A (the current of the first stage). After the charge voltage achieves 28.8V (12× 2.4V=28.8V), switch to the 15A current of the second stage for continuative charge. When charging, the temperature of electrolyte shall never exceed 45℃. -

Page 21: Storage

3、Storage The storage battery shall be kept in clean, dry and ventilated warehouse within the temperature range of 5 to 40℃. The valid storage period is 2 years. Safekeeping shall be made within storage period according to the following requirements: a. - Page 22 Note Handle the storage battery gently during hoisting and transportation of the battery. Otherwise it will cause damage to the battery or bring danger to human body.

-

Page 23: Ⅴ. Maintenance And Repair

Ⅴ. Maintenance and repair 1. Maintenance Comprehensive check for truck can avoid malfunction and ensure the service life. The hours listed in maintenance procedures is based on the cases that the truck works for 8 hours per day and 200 hours per month. -

Page 24: Routine Inspection

storage battery is filled, conduct initial charge to the storage battery timely according to the operation requirements of initial charge 4.1. 1.3 Routine inspection Inspection of hydraulic oil level: lower the fork to the lowest position, look over the oil level from the oil window. - Page 25 Connecting Function and check the cracks, bending, wheel carrier deformation and lubrication condition. Oil pipe Whether oil pipes leak or not. Hydraulic oil Proper quantity of oil. Lifting oil cylinder Whether there is any oil leakage or not. Liquid level,specific gravity and cleanness Electrolyte Plug Function, whether it is damaged or not...

-

Page 26: Recommended Working Medium

1.6 Recommended working medium: ⑴ Hydraulic oil: A. When it is normally loaded, we advise: Hydraulic oil: LHPISOVG46, in accordance with standard DIN51524T.2, the average sustained temperature should between 40 degrees to 60 degrees. B. When it is over loaded, we advise: Hydraulic oil: LHPISOVG68, in accordance with standard DIN51524T.2, the average sustained temperature is above 60 degrees. -

Page 27: Common Faults And Trouble Shooting

Strainer of hydraulic Cleaning 1000 hours reservoir Check for carbon brushes and Driving motor 1000 hours bearings Check for carbon brushes and Steering motor 1000 hours bearings Check for carbon brushes and Oil pump motor 1000 hours bearings 1. Common faults and trouble shooting: 1. - Page 28 and heavy. The bearings of steering device are Replace the bearings worn. Brake cannot The friction plates of the Replace work electromagnetic brake are damaged The electromagnetic brake is out of Check the circuit. Not release electricity. after braked The clearance of the Adjust the brake clearance to 0.2mm.

- Page 29 Hydraulic principle diagram...

- Page 30 (2) Adjustment of the brake clearance ①Hollow screw ②Fitting screw ④spline sleeve ③Coil ⑤Friction plate ⑧Mounting screw ⑥Spring ⑦Iron ⑨Mounting cover plate ⑩Clearance The brake structure is indicated as the Fig on the right. After being used for a while, the performance of the brake may decline with the wearing of the brake block or the brake plate can’t be released.

- Page 31 The disassembly of the brake is shown as the following picture, use tools to loose screw 8.

- Page 32 2. Electrical faults...

- Page 33 1311 DISPLAY EXPLANATION POSSIBLE CAUSE CODE 1 Incorrect or ineffective speed sensor The speed sensor signal motor speed encoder wiring. can’t be detected. 2 Controller defective. 1 Speed sensor malfunction. The motor speed is not in Motor Failsafe 2 The electromagnetic brake of motor is not the normal scope.

- Page 34 fault. 2 Brake driver fault. Service Total Disable Total KSI timer has expired. Expired total KSI timer. Total driving timer has 4,1 Service Driver Disable Total driving timer has expired. expired. Setted (KSI) service timer Service Total Expired Setted (KSI) service timer has expired. has expired.

-

Page 35: Ⅵ. Loading And Unloading, Transportation And Storage Of Truck

VI. Loading and unloading, transportation and storage of truck 1. Loading and unloading: Before loading the truck, check out the nameplate for the total weight of truck to choose appropriate hoisting handling equipment. The hoisting of truck shall be kept level, and landing shall be kept slow and stable. - Page 36 Technical documents, Accessory bag accessories and spare parts Note:1.The following documents are in the file bag ① 20EPS Electric Pallet Truck operating instruction 1 volume ② Packing list 1 copy ③ Certificate of quality 1 copy 2. Accessory and spare parts Q’ty...

- Page 37 Appendix II Maintenance and repairing recording card: Maintenance Maintenance Maintenance Items Material used Remarks time part personnel...

- Page 38 Appendix III Customer advisement feedback Time Items Trouble location Fault cause Trouble-shooting Remarks occurred...

Need help?

Do you have a question about the 20EPS and is the answer not in the manual?

Questions and answers