Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for AMCOL 3500-ETC

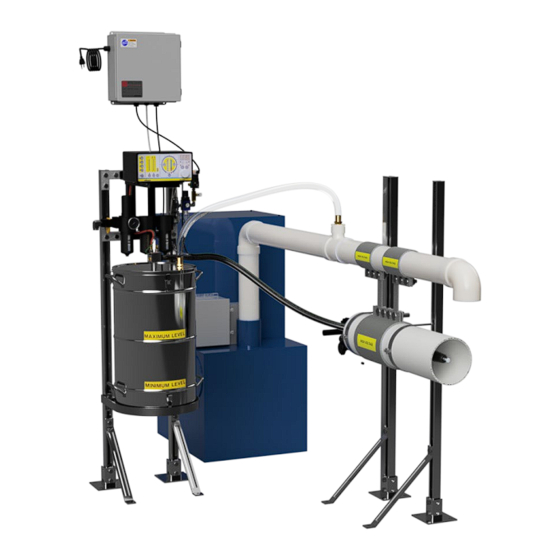

- Page 1 AMCOL CORPORATION 3500-ETC ELECTRONIC TIMING CONTROLLER Operator’s Manual...

-

Page 2: Table Of Contents

4 Recommended Settings ..................6 5 Operation ........................7 6 System Troubleshooting and Maintenance ............9 7 Schematics ......................10 AMCOL Corporation 21435 Dequindre, Hazel Park, MI 48030 248-414-5700 fax: 248-414-7489 www.amcolcorp.com P a g e | 1 3500-ETC Operator’s Manual... -

Page 3: Introduction

To solve this problem, AMCOL has created a simple package to effectively control a 3500E system with a single PLC output. If used properly, the 3500-ETC will allow for consistent, repeatable coatings with settings that can be easily seen and changed where necessary. -

Page 4: Included Components

2 Included Components Each 3500-ETC comes standard with the following components: 1. Preprogrammed Allen Bradley PLC 2. 6’ grounded power cord with plug 3. Open cable gland to insert the machine PLC control output 4. NEMA 12/13 sealed steel electrical enclosure 5. -

Page 5: Assembly And Installation

3 Assembly and Installation PRIOR TO GETTING STARTED WARNING! AMCOL 3500-ETC systems are only designed to function with correctly • installed and grounded 3500E Powder Coating Systems. For installation instructions for 3500E Systems, see the AMCOL 3500E Electrostatic Powder Dispensing System Operator’s Manual. - Page 6 Note that holding the manual button will cycle the system as long as it is held. 11. Adjust system settings where necessary. 12. Under careful observation, operate system in production environment. P a g e | 5 3500-ETC Operator’s Manual...

-

Page 7: Recommended Settings

Fluidizing Air Set to at least 1 second Valve Spray Time Set according to billet size (start at 0.5s, increase for larger billets) Collector Set to at least 1 second P a g e | 6 3500-ETC Operator’s Manual... -

Page 8: Operation

• Minimum timings are as follows: o Fluidizing Air – 0.5s (0.1s increments) o Spray On – 0.5s (0.1s increments) o Collector – 1.0s (1s increments) P a g e | 7 3500-ETC Operator’s Manual... - Page 9 Holding the button will perform multiple cycles until the button is released. Manual operation should be used to verify current settings, test spray coating, and troubleshoot errors. P a g e | 8 3500-ETC Operator’s Manual...

-

Page 10: System Troubleshooting And Maintenance

• Press any button on the PLC inside the ETC. • Turn the ETC off and on. Recommended Spares Description Part Number Quantity Lighted cap for solenoid 24VDC E-01013-61 110VAC E-01013-11 Cable gland 69915K54 P a g e | 9 3500-ETC Operator’s Manual... -

Page 11: Schematics

7 Schematics 3500-ETC-110 3500-ETC-24 P a g e | 10 3500-ETC Operator’s Manual... - Page 12 AMCOL Corporation 21435 Dequindre, Hazel Park, MI 48030 248-414-5700 fax: 248-414-7489 www.amcolcorp.com P a g e | 11 3500-ETC Operator’s Manual...

Need help?

Do you have a question about the 3500-ETC and is the answer not in the manual?

Questions and answers