Summary of Contents for SMC Networks VO317 Series

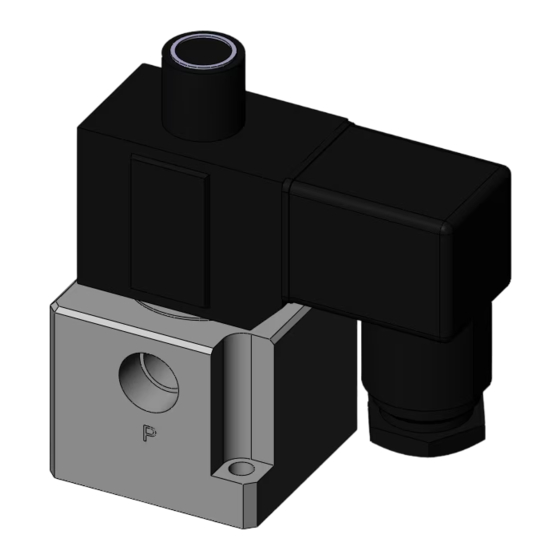

- Page 1 Doc. no. VT317∗∗-OMH0002-B PRODUCT NAME 3 Port Solenoid Valve MODEL / Series / Product Number VT/O317 Series...

-

Page 2: Table Of Contents

Contents Safety Instructions ----------------------------------------------------------------------------------- Design / Selection ----------------------------------------------------------------------------------- Mounting ----------------------------------------------------------------------------------------------- Piping --------------------------------------------------------------------------------------------------- Wiring --------------------------------------------------------------------------------------------------- Lubrication --------------------------------------------------------------------------------------------- Air Supply ---------------------------------------------------------------------------------------------- Operating Environment ----------------------------------------------------------------------------- Maintenance ------------------------------------------------------------------------------------------- Specific Product Precautions ---------------------------------------------------------------------- 7 to 9 Trouble shooting -------------------------------------------------------------------------------------- 10 ,11 VT317∗∗-OMH0002-B... -

Page 3: Safety Instructions

Safety Instructions These safety instructions are intended to prevent hazardous situations and/or equipment damage. These instructions indicate the level of potential hazard with the labels of “Caution,” “Warning” or “Danger.” They are all important notes for safety and must be followed in addition to International Standards (ISO/IEC) , and other safety regulations. - Page 4 Safety Instructions Caution 1. The product is provided for use in manufacturing industries. The product herein described is basically provided for peaceful use in manufacturing industries. If considering using the product in other industries, consult SMC beforehand and exchange specifications or a contract if necessary. If anything is unclear, contact your nearest sales branch.

-

Page 5: Design/Selection

VT317 Series 3 port solenoid valve/ Precautions (1) Be sure to read this before handling the products. Design/Selection equipment. If the total energizing time per day is expected to be longer than the total de-energizing time per day, use a Warning continuous duty type valve. -

Page 6: Mounting

VT317 Series 3 port solenoid valve/ Precautions (2) Be sure to read this before handling the products. 3. Connection of fittings Design/Selection For a fitting with sealant R or NPT, first, tighten it by hand, then use a suitable wrench to tighten the hexagonal portion Caution of the body an additional two or three turns. -

Page 7: Air Supply

VT317 Series 3 port solenoid valve/ Precautions (3) Be sure to read this before handling the products. 6. If it is used in an environment where there is Air Supply possible contact with oil, weld spatter, etc., exercise preventive measures. Warning 7. - Page 8 Specific Product Precautions (1) Be sure to read this before handling the products. Continuous duty type: VT317E Change of Electrical Entry Angle This product can be used for an extended period of time. Caution 1. The VT317 series can change Caution electrical entry angle.(4 directions 1.

- Page 9 Specific Product Precautions (2) Be sure to read this before handling the products. How to wire DIN terminal 1. Disassembly 1) After loosening the screw (1), then if the housing (4) is pulled in the direction of the screw (1), the connector will be Exploded view removed from the body of equipment (solenoid, etc.).

-

Page 10: Specific Product Precautions

Specific Product Precautions (3) Be sure to read this before handling the products. Manifold Mounting Changing from N.C. to N.O. Warning Caution 1. When mounting valves on the manifold Universal porting permits convertibility N.C./N.O. by a simple 180 degree rotation. base, mounting orientation... -

Page 11: Troubleshooting

Troubleshooting Perform troubleshooting with higher possibility based on the failure phenomenon. Failure phenomenon Possible causes Countermeasures (Refer to the next page) The valve does not perform the Operation failure Incorrect wiring switching operation. Fuse blown out and/or lead wire broken (2),(4) Incorrect contact at the contact and connection Broken wire in the coil... - Page 12 Countermeasures Countermeasures Connect wires correctly. Replace the parts. Replace the parts or connect wires correctly. Replace the valve. Adjust the pressure so that pilot pressure is within the specified range during operation. ・If incorrect oil has been used for lubrication, remove the oil with air blow, and replace the valve with a new one.

- Page 13 Revision history □ S afety Instructions □ R enewal 1st printing :MX 4-14-1, Sotokanda, Chiyoda-ku, Tokyo 101-0021 JAPAN Tel: + 81 3 5207 8249 Fax: +81 3 5298 5362 http://www.smcworld.com Note: Specifications are subject to change without prior notice and any obligation on the part of the manufacturer. ©...

Need help?

Do you have a question about the VO317 Series and is the answer not in the manual?

Questions and answers