Table of Contents

Advertisement

Quick Links

®

4097.16 ROP-1

DO NOT

HANDHELD

THIS TOOL

USE MANUAL and SPARE PARTS

IMPORTANT DO NOT DESTROY !

Via Foresto 42 - 31058 SUSEGANA TV ITALY

cod. 11530ROP-1

11530ROP-1_409716ROP-1_5 040520 IV

Tel.0438455318 Fax 0438455530

E-mail: omer@omer.it

INTRODUCTION:

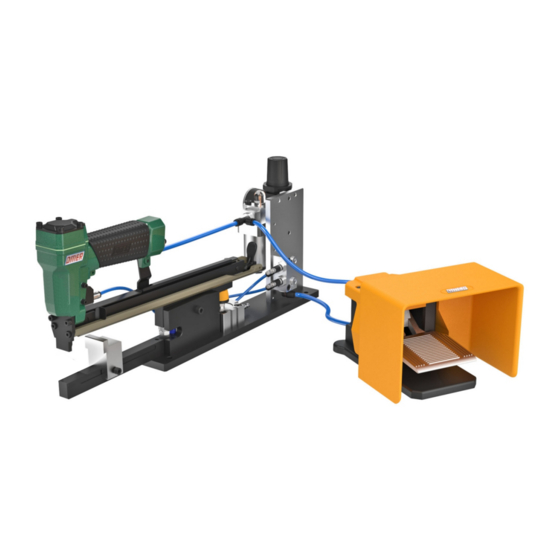

The bench-mounted stapler ROP is the optimal solution for fixing blisters, paper or

plastic bags, boxes, displaying cards, etc.

Features:

• Possibility to be easily fixed upon working surface

•Pneumatic system complete with FRL unit & manometer for a correct power

supply

• Pedal activated mode

•Working pressure: 5,5 ÷ 6,5 bar ( 80÷ 95 PSI )

• Top loading

• Magazine capacity: 2 strips

• Applicable sizes: 6 to 16mm

• Easy jam-clearing

• Easily replaceable pneumatic tool units (with units suitable for different fastener

series, i.e. 3G, 64, 80, 50, 65, 40, 4097)

• Possible adjustements:

MADE

IN

ITALY

www.omer.it

- Clinching depth

- Front side opening

- Clinching speed

- Fire delay

Advertisement

Table of Contents

Summary of Contents for Omer 4097.16 ROP-1

- Page 1 ® INTRODUCTION: The bench-mounted stapler ROP is the optimal solution for fixing blisters, paper or 4097.16 ROP-1 plastic bags, boxes, displaying cards, etc. Features: cod. 11530ROP-1 • Possibility to be easily fixed upon working surface •Pneumatic system complete with FRL unit & manometer for a correct power supply •...

- Page 2 Easy jam-clearing trigger Manometer Silenced rear exhaust Automated hold down Filter/reducer/lubricator unit opening mechanism Rapid rear airplug Clinching speed regulator 2 strips capacity magazine Distributor (opening) Fire delay regulator Pneumatic pedal Adjustable spacer Plate for bench-mounting Front side opening adjustment Adjustment of clinching depth Clinching speed regulator (closing)

-

Page 3: Table Of Contents

Loading ........................14 Jam-clearing ........................ 15 Spare parts ........................16 Spare parts for 4097.16 ROC-C stapler ..............17 Spare parts for 4097.16 ROP-1 ................... 18 Pneumatic diagram ..................... 19 Accessories – O-Rings ....................20 Spare parts list ......................21 Notes ........................... 22... -

Page 4: Introduction

INTRODUCTION In order to assure high reliability, OMER has made a careful choice of the materials and components to be used in the manufacturing process of the tool and has tested it before delivery. Proper performance of the tacker in time also depends on its correct use and on adequate servicing according to the instructions contained in this manual. - Page 5 OMER spa does not answer for damage to the gun due to the use of staples or nails of types not suitable for the model.

- Page 6 To do so, unscrew the head screws with the hex spanner supplied, open the gun and remove the different components. Check carefully the state of wear of the O-rings and of the rubber parts. Replace the worn parts with OMER original spare parts.

-

Page 7: Technical Data

Technical data Suitable staple series : 4097 0,65x0,95 0,65x0,95 5/32“ 5/32“ 5/8" 5/8“ Crown: .170” (3/16") Crown: .180” (3/16“) Thickness: .025“ Thickness: .025" Width: .037“ Width: .037" Gauge: Gauge: 6÷16 Usable lenghts mm 1/4"÷5/8" Usable lengths inch Magazine capacity No. of fasteners 5,5÷6,5 Working pressure bar Working pressure psi... - Page 8 Technical data *all sizes are shown in mm 152,5 160,5 - 9 -...

- Page 9 Azionamento - Actuation Before using the unit make sure all necessary adjustments for a correct and safe usage have been performed. Setting of staple position 1 - Loosen the screws. 2 - Slide the spacer along the guide until required position. 3 - Tighten the screws .

-

Page 10: Front Side Opening

Adjustment of front side opening A front side opening adjustment must be carried out to allow an easy insertion of the material to be fastened. max 18 mm 2 mm 1 - Press the stapler head and keep this position to gain access to the pneumatic cylinder and bumper. -

Page 11: Clinching Depth

Clinching depth adjustment To avoid flattening/damaging the material to be fastened it is possible to set the clinching depth by adjusting the end-run screw. Disconnect the air before proceeding with the adjustment. max 10 mm min 0,5 mm 1 - Loosen the nut which stops the end-run screw. 2 - Screw or unscrew the end-run screw to adjust the clinching depth. -

Page 12: Clinching Speed

Fire delay adjustment Fire delay adjustment is the more necessary the wider is the front opening on the tool, since you must give time to the stapler to block the material before firing. delays firing anticipates firing Clinching speed adjustment This adjustment allows you to set the most comfortable working speed. -

Page 13: Loading

Loading DO NOT press pedal while loading, to avoid activating the device 1 - Pull the pusher backwards and lock it at the stop position at the rear of the tool, this will open the movable hold down 2 - Load staples 3 - Release the slider - 14 -... -

Page 14: Jam-Clearing

Jam-clearing In case of jamming, proceed as follows: 1 - Pull the pusher all the way back and lock it. 2 - Remove the staples from the magazine. 3 - Open the slider closing trigger. 4 - Pull the slider all the way back by acting on the pusher and holding it in such a position. 5 - Pull the jammed staple out from the firing channel. -

Page 15: Spare Parts

Spare parts - 16 -... - Page 16 08.00.1Z 08.16.6Z 4097.16 ROC-C1 c o d . 2 1 5 3 0 R O C - C 1 4097.16 ROP-1 Upgrade c o d . 1 1 5 3 0 R O P - 1 Number - 17 -...

- Page 17 17.37.2 17.31.4 06.00.3 17.34.8 98.07.1 B(V) 18.02 05.30 17.38 05.12 Connetion tubes 98.01 98.05.2 05.20 ø 05.25 Ø 05.20 4097.16 ROP-1 Upgrade c o d . 1 1 5 3 0 R O P - 1 Number - 18 -...

-

Page 18: Pneumatic Diagram

Pneumatic diagram 5,5 ÷ 6,5 bar 5,5 ÷ 6,5 bar B(V) Ø4 Ø4 A(C) B(V) Ø6 Ø6 R P S 5,5 ÷ 6,5 bar Ø6 Ø6 17.39.6 - 19 -... -

Page 19: Spare Parts List

00.06 00.04 18.22.1 Filtro riduttore lubrificatore Reducer group 4097.16 ROP-1 Upgrade 4097.16 ROP-1 Upgrade c o d . 1 1 5 3 0 R O P - 1 c o d . 1 1 5 3 0 R O P - 1... -

Page 20: Notes

Notes - 22 -...

Need help?

Do you have a question about the 4097.16 ROP-1 and is the answer not in the manual?

Questions and answers